2.9.4. Dissolution Test For Transdermal Patches

Diunggah oleh

Sandeep KumarDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

2.9.4. Dissolution Test For Transdermal Patches

Diunggah oleh

Sandeep KumarHak Cipta:

Format Tersedia

EUROPEAN PHARMACOPOEIA 5.

2.9.4. Dissolution test for transdermal patches

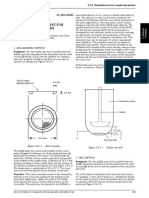

01/2005:20904 prescribed adhesive or by a strip of a double-sided adhesive tape. The adhesive or tape are previously tested for the absence of interference with the assay and of adsorption of the active ingredient(s). Press the patch, release surface facing up, onto the side of the SSDA made adhesive. The 2.9.4. DISSOLUTION TEST FOR applied patch must not overlap the borders of the SSDA. TRANSDERMAL PATCHES For this purpose and provided that the preparation is homogeneous and uniformly spread on the outer covering, an appropriate and exactly measured piece of the patch This test is used to determine the dissolution rate of the may be cut and used for testing the dissolution rate. This active ingredients of transdermal patches. procedure may also be necessary to achieve appropriate sink conditions. This procedure must not be applied to membrane-type patches. Place the patch mounted on the SSDA flat at the bottom of the vessel with the release surface 1. DISK ASSEMBLY METHOD facing upwards. Immediately rotate the paddle at 100 r/min, Equipment. Use the paddle and vessel assembly from the for example. At predetermined intervals, withdraw a sample paddle apparatus described in the dissolution test for solid from the zone midway between the surface of the dissolution oral dosage forms (2.9.3) with the addition of a stainless medium and the top of the blade, not less than 1 cm from steel disk assembly (SSDA) in the form of a net with an the vessel wall. aperture of 125 m (see Figure 2.9.4.-1). Perform the assay on each sample, correcting for any volume losses, as necessary. Repeat the test with additional patches.

Figure 2.9.4.-1. Disk assembly The SSDA holds the system at the bottom of the vessel and is designed to minimise any dead volume between the SSDA and the bottom of the vessel. The SSDA holds the patch flat, with the release surface uppermost and parallel to the bottom of the paddle blade. A distance of 25 2 mm between the bottom of the paddle blade and the surface of the SSDA is maintained during the test (see Figure 2.9.4.-2). The temperature is maintained at 32 0.5 C. The vessel may be covered during the test to minimise evaporation. Procedure. Place the prescribed volume of the dissolution medium in the vessel and equilibrate the medium to the prescribed temperature. Apply the patch to the SSDA, ensuring that the release surface of the patch is as flat as possible. The patch may be attached to the SSDA by a General Notices (1) apply to all monographs and other texts

Figure 2.9.4.-2. Paddle and disk

2. CELL METHOD Equipment. Use the paddle and vessel assembly from the paddle apparatus described in the dissolution test for solid oral dosage forms (2.9.3) with the addition of the extraction cell (cell). The cell is made of chemically inert materials and consists of a support, a cover and, if necessary, a membrane placed on the patch to isolate it from the medium that may modify or adversely affect the physico-chemical properties of the patch (see Figure 2.9.4.-3). 231

2.9.4. Dissolution test for transdermal patches

EUROPEAN PHARMACOPOEIA 5.0

predetermined intervals, withdraw a sample from the zone midway between the surface of the dissolution medium and the top of the paddle blade, not less than 1 cm from the vessel wall. Perform the assay on each sample, correcting for any volume losses, as necessary. Repeat the test with additional patches.

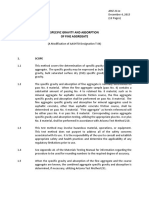

Figure 2.9.4.-4. Paddle over extraction cell 3. ROTATING CYLINDER METHOD Equipment. Use the assembly of the paddle apparatus described in the dissolution test for solid oral dosage forms (2.9.3). Replace the paddle and shaft with a stainless steel cylinder stirring element (cylinder) (see Figure 2.9.4.-5). The patch is placed on the cylinder at the beginning of each test. The distance between the inside bottom of the vessel Figure 2.9.4.-3. Extraction cell and the cylinder is maintained at 25 2 mm during the test. Support. The central part of the support forms a cavity The temperature is maintained at 32 0.5 C. The vessel is intended to hold the patch. The cavity has a depth of 2.6 mm covered during the test to minimise evaporation. and a diameter that is appropriate to the size of the patch to Procedure. Place the prescribed volume of the dissolution be examined. The following diameters can be used : 27 mm, medium in the vessel and equilibrate the medium to the 38 mm, 45 mm, 52 mm, corresponding to volumes of 1.48 ml, prescribed temperature. Remove the protective liner from 2.94 ml, 4.13 ml, 5.52 ml, respectively. the patch and place the adhesive side on a piece of suitable inert porous membrane that is at least 1 cm larger on all Cover. The cover has a central opening with a diameter sides than the patch. Place the patch on a clean surface with selected according to the size of the patch to be examined. the membrane in contact with this surface. Two systems for The patch can thus be precisely centred, and its releasing adhesion to the cylinder may be used : surface limited. The following diameters may be used : 20 mm, 32 mm, 40 mm, 50 mm corresponding to areas of apply a suitable adhesive to the exposed membrane 3.14 cm2, 8.03 cm2, 12.56 cm2, 19.63 cm2, respectively. The borders and, if necessary, to the back of the patch, cover is held in place by nuts screwed onto bolts projecting apply a double-sided adhesive tape to the external wall from the support. The cover is sealed to the support by a of the cylinder. rubber ring set on the reservoir. Using gentle pressure, carefully apply the non-adhesive side Extraction cell. The cell holds the patch flat, with the of the patch to the cylinder, so that the release surface is in release surface uppermost and parallel to the bottom of contact with the dissolution medium and the long axis of the the paddle blade. A distance of 25 2 mm is maintained patch fits around the circumference of the cylinder. between the paddle blade and the surface of the patch The system for adhesion used is previously tested for absence (see Figure 2.9.4.-4). The temperature is maintained at of interference with the assay and of adsorption of the active 32 0.5 C. The vessel may be covered during the test to ingredient(s). minimise evaporation. Place the cylinder in the apparatus, and immediately rotate Procedure. Place the prescribed volume of the dissolution the cylinder at 100 r/min, for example. At determined medium in the vessel and equilibrate the medium to the intervals, withdraw a sample of dissolution medium from a prescribed temperature. Precisely centre the patch in the zone midway between the surface of the dissolution medium cell with the releasing surface uppermost. Close the cell, if and the top of the rotating cylinder, and not less than 1 cm necessary applying a hydrophobic substance (for example, from the vessel wall. petrolatum) to the flat surfaces to ensure the seal, and Perform the assay on each sample as directed in the ensure that the patch stays in place. Introduce the cell flat into the bottom of the vessel with the cover facing upwards. individual monograph, correcting for any volume withdrawn, Immediately rotate the paddle, at 100 r/min for example. At as necessary. Repeat the test with additional patches. 232 See the information section on general monographs (cover pages)

EUROPEAN PHARMACOPOEIA 5.0

2.9.5. Uniformity of mass of single-dose preparations

Figure 2.9.4.-5. Cylinder stirring element Dimensions in centimetres Interpretation. The requirements are met if the quantity of active ingredient(s) released from the patch, expressed as the amount per surface area per time unit, is within the prescribed limits at the defined sampling times. Table 2.9.5.-1

Pharmaceutical Form Tablets (uncoated and film-coated) Average Mass 80 mg or less More than 80 mg and less than 250 mg 250 mg or more Capsules, granules (uncoated, single-dose) and powders (single-dose) Powders for parenteral use* (single-dose) Suppositories and pessaries Powders for eye-drops and powders for eye lotions (single-dose) Less than 300 mg 300 mg or more More than 40 mg All masses Less than 300 mg 300 mg or more Percentage deviation 10 7.5 5 10 7.5 10 5 10 7.5

01/2005:20905

2.9.5. UNIFORMITY OF MASS OF SINGLE-DOSE PREPARATIONS

Weigh individually 20 units taken at random or, for single-dose preparations presented in individual containers, the contents of 20 units, and determine the average mass. Not more than 2 of the individual masses deviate from the average mass by more than the percentage deviation shown in Table 2.9.5.-1 and none deviates by more than twice that percentage. For capsules and powders for parenteral use, proceed as described below. CAPSULES Weigh an intact capsule. Open the capsule without losing any part of the shell and remove the contents as completely as possible. For soft shell capsules, wash the shell with a suitable solvent and allow to stand until the odour of the solvent is no longer perceptible. Weigh the shell. The mass of the contents is the difference between the weighings. Repeat the procedure with another 19 capsules. General Notices (1) apply to all monographs and other texts

* When the average mass is equal to or below 40 mg, the preparation is not submitted to the test for uniformity of mass but to the test for uniformity of content of single-dose preparations (2.9.6).

POWDERS FOR PARENTERAL USE Remove any paper labels from a container and wash and dry the outside. Open the container and without delay weigh the container and its contents. Empty the container as completely as possible by gentle tapping, rinse it if necessary with water R and then with alcohol R and dry at 100-105 C for 1 h, or, if the nature of the container precludes heating at this temperature, dry at a lower temperature to constant mass. Allow to cool in a desiccator and weigh. The mass of the contents is the difference between the weighings. Repeat the procedure with another 19 containers. 233

Anda mungkin juga menyukai

- Muscle and Fitness Hers Features Elite Lifestyle Chef Carlo FilipponeDokumen4 halamanMuscle and Fitness Hers Features Elite Lifestyle Chef Carlo FilipponeCarlo FilipponeBelum ada peringkat

- What To Do Following A Workplace AccidentDokumen5 halamanWhat To Do Following A Workplace AccidentMona DeldarBelum ada peringkat

- Mud Lab Manual - NewDokumen32 halamanMud Lab Manual - Newfisco4ril67% (6)

- Disorders of The Reproductive SystemDokumen10 halamanDisorders of The Reproductive SystemRose Kathreen Quintans AuxteroBelum ada peringkat

- Payroll Solution in Single SheetDokumen818 halamanPayroll Solution in Single SheetTarique KhanBelum ada peringkat

- AAC - Chapter 3 Centrifugation English - 20100325Dokumen66 halamanAAC - Chapter 3 Centrifugation English - 20100325Sandeep Kumar100% (1)

- Drilling Fluid Test Procedure: Filtration TestsDokumen5 halamanDrilling Fluid Test Procedure: Filtration TestsInam Ali AwanBelum ada peringkat

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDari EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryBelum ada peringkat

- Inked CultureDokumen90 halamanInked Culturemar phisBelum ada peringkat

- Tablet EvaluationDokumen5 halamanTablet EvaluationsudhansupBelum ada peringkat

- Aluminium - Hull Structure in Naval ApplicationsDokumen6 halamanAluminium - Hull Structure in Naval ApplicationsStefano CostaBelum ada peringkat

- Particle Size AnalysisDokumen31 halamanParticle Size Analysisحبيبه بيبيBelum ada peringkat

- D 2041 - 00Dokumen4 halamanD 2041 - 00harisahamedBelum ada peringkat

- Waste Heat Recovery UnitDokumen15 halamanWaste Heat Recovery UnitEDUARDOBelum ada peringkat

- Biodegradable Plastic Bag Manufacturing Industry-800655 PDFDokumen68 halamanBiodegradable Plastic Bag Manufacturing Industry-800655 PDFAryanBelum ada peringkat

- Astm D 3078 PDFDokumen2 halamanAstm D 3078 PDFRisnanto Hadi50% (4)

- T 826Dokumen6 halamanT 826burucuBelum ada peringkat

- Triaxial Test: Consolidated UndrainedDokumen9 halamanTriaxial Test: Consolidated UndrainedNguyễn Hòa100% (1)

- TMH-6 - ST10Dokumen10 halamanTMH-6 - ST10ATHOLSCHWARZBelum ada peringkat

- 2 9 4 Dissolution Test For Transdermal PatchesDokumen3 halaman2 9 4 Dissolution Test For Transdermal Patchesapi-261124906Belum ada peringkat

- 2.9.4. Dissolution Test For Transdermal Patches PDFDokumen3 halaman2.9.4. Dissolution Test For Transdermal Patches PDFRani RubiyantiBelum ada peringkat

- Dissolution Test For Solid Oral Dosage FormsDokumen8 halamanDissolution Test For Solid Oral Dosage FormsPedro Marcelo Alva PlasenciaBelum ada peringkat

- LS-297 R26 123Dokumen6 halamanLS-297 R26 123Gourav GoelBelum ada peringkat

- L Disso SeminarDokumen11 halamanL Disso SeminarRavindra TupeBelum ada peringkat

- AASHTO T84 (Specific Gravity & Absorption of Fine Aggregate) PDFDokumen12 halamanAASHTO T84 (Specific Gravity & Absorption of Fine Aggregate) PDFKhant Linn AungBelum ada peringkat

- Wurster Coating-Process and Product VariablesDokumen6 halamanWurster Coating-Process and Product VariablesMaría Reynel TarazonaBelum ada peringkat

- Filtration Tests: Test ProcedureDokumen4 halamanFiltration Tests: Test ProcedureAbdulHameed H. AlalwanBelum ada peringkat

- Dissolution Test-2554700864Dokumen12 halamanDissolution Test-2554700864Aanchal DeviBelum ada peringkat

- Astm d2726Dokumen26 halamanAstm d2726mzaimBelum ada peringkat

- PosiTestAT-v4 0 PDFDokumen45 halamanPosiTestAT-v4 0 PDFcentaury2013Belum ada peringkat

- USP FriabilityDokumen2 halamanUSP Friabilityshdph100% (1)

- Houghton 1998Dokumen15 halamanHoughton 1998_meiantiBelum ada peringkat

- 2.9.40. Uniformity of Dosage Units 20940eDokumen4 halaman2.9.40. Uniformity of Dosage Units 20940ecupidvishu123Belum ada peringkat

- 2.9.1. Disintegration of Tablets and CapsulesDokumen3 halaman2.9.1. Disintegration of Tablets and CapsulesPikiy PutriBelum ada peringkat

- Experiment No: Dry Shrinkage Test For MortarDokumen13 halamanExperiment No: Dry Shrinkage Test For Mortarruba.qammarBelum ada peringkat

- Disintegration Test For Tablet Dosage FormDokumen3 halamanDisintegration Test For Tablet Dosage FormasrielisabetBelum ada peringkat

- Keur 00821-029 201906Dokumen5 halamanKeur 00821-029 201906erik0007Belum ada peringkat

- Patches, TransdermalDokumen1 halamanPatches, TransdermalRani RubiyantiBelum ada peringkat

- Absorbency Under PressureDokumen3 halamanAbsorbency Under PressureMOHAMED DawiBelum ada peringkat

- tempPDF1343570608102872227 PDFDokumen2 halamantempPDF1343570608102872227 PDFwisang geniBelum ada peringkat

- QCtabletDokumen9 halamanQCtabletapi-3742263100% (3)

- Mobile Phase (A Liquid or A Gas) - The Mobile Phase Flows Through The StationaryDokumen9 halamanMobile Phase (A Liquid or A Gas) - The Mobile Phase Flows Through The StationarySudip TikaitBelum ada peringkat

- Resistance of Nonporous Paper To Passage of Air: Standard Test Method ForDokumen3 halamanResistance of Nonporous Paper To Passage of Air: Standard Test Method Forjamaljamal20Belum ada peringkat

- Standard Practice For Reducing Samples of Aggregate To Testing SizeDokumen7 halamanStandard Practice For Reducing Samples of Aggregate To Testing Sizejun floresBelum ada peringkat

- Á701Ñ Disintegration: 584 Á699ñ Density of Solids / Physical Tests USP 40Dokumen3 halamanÁ701Ñ Disintegration: 584 Á699ñ Density of Solids / Physical Tests USP 40Long ManBelum ada peringkat

- Iso 2781 TraducidaDokumen5 halamanIso 2781 TraducidaRenato Moises Rosales SaraviaBelum ada peringkat

- 11111Dokumen3 halaman11111Praful N KBelum ada peringkat

- Dissolution TestingDokumen37 halamanDissolution Testingampay ayubBelum ada peringkat

- Western Blotting: Gel Casting PreparationDokumen5 halamanWestern Blotting: Gel Casting Preparationsrividya84Belum ada peringkat

- Ink Adhesion Test1Dokumen75 halamanInk Adhesion Test1Pradeep JhaBelum ada peringkat

- Geoinformatics (2) ..Dokumen12 halamanGeoinformatics (2) ..Dinesh SBelum ada peringkat

- Manual 2 Inch Adapter ENG 1Dokumen35 halamanManual 2 Inch Adapter ENG 1DimitrisPetsasODeuterosBelum ada peringkat

- Aggregate Test ProcetureDokumen34 halamanAggregate Test ProceturesubhaschandraBelum ada peringkat

- Northern HittingerDokumen3 halamanNorthern HittingerRD AntolinBelum ada peringkat

- AASHTO T 84 - Specific Gravity and Absorption of Fine AggregateDokumen4 halamanAASHTO T 84 - Specific Gravity and Absorption of Fine AggregateBambang DwihargonoBelum ada peringkat

- Successful PSA of Dry PowdersDokumen3 halamanSuccessful PSA of Dry PowderssiswantoBelum ada peringkat

- Quality Control of Tablets Lecture 2Dokumen24 halamanQuality Control of Tablets Lecture 2sakrishnagoud BingiBelum ada peringkat

- F 2250 - 03 RjiyntaDokumen3 halamanF 2250 - 03 RjiyntafrostestBelum ada peringkat

- ABAA T0002 Standard Test Method For Pull Off Strength of Adhered Air and Water Resistive Barriers Using An Adhesion TesterDokumen4 halamanABAA T0002 Standard Test Method For Pull Off Strength of Adhered Air and Water Resistive Barriers Using An Adhesion Testerzaheerahmed77Belum ada peringkat

- Densidad Especifica Del Agregado GruesoDokumen2 halamanDensidad Especifica Del Agregado GruesoAdolfo Elizondo FocilBelum ada peringkat

- Usp 28 DistgrDokumen6 halamanUsp 28 DistgrxaverBelum ada peringkat

- Triaxial Test: Xzdetermination of Shear Parameters by Triaxail TestDokumen8 halamanTriaxial Test: Xzdetermination of Shear Parameters by Triaxail TestTenzinKesangBelum ada peringkat

- Disclosure To Promote The Right To InformationDokumen8 halamanDisclosure To Promote The Right To InformationSantosh KumarBelum ada peringkat

- LS-297 - Rev 34 - May 2020Dokumen9 halamanLS-297 - Rev 34 - May 2020ming_zhu10Belum ada peringkat

- Flow charts of pharmaceutical quality control tests for different dosage formsDari EverandFlow charts of pharmaceutical quality control tests for different dosage formsBelum ada peringkat

- Section Cutting and Staining: A practical introduction to histological methods for students and practitionersDari EverandSection Cutting and Staining: A practical introduction to histological methods for students and practitionersBelum ada peringkat

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionDari EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionBelum ada peringkat

- Granulation: Preparation, Evaluation & Control: Chetan Pujara, Ph.D. 25 October, 2007Dokumen59 halamanGranulation: Preparation, Evaluation & Control: Chetan Pujara, Ph.D. 25 October, 2007Tasmih Rob MowBelum ada peringkat

- Nova Some S ChartDokumen1 halamanNova Some S ChartSandeep KumarBelum ada peringkat

- Metformin Hydrochloride Matrix TabletsDokumen14 halamanMetformin Hydrochloride Matrix TabletsSandeep KumarBelum ada peringkat

- ChronoDokumen3 halamanChronoSandeep KumarBelum ada peringkat

- Complement Fixation Test: Process Testing For Antigen Semi-Quantitative Testing References External LinksDokumen2 halamanComplement Fixation Test: Process Testing For Antigen Semi-Quantitative Testing References External LinksYASMINABelum ada peringkat

- ომარ ხაიამი - რობაიები (პარალელური ტექსტები)Dokumen31 halamanომარ ხაიამი - რობაიები (პარალელური ტექსტები)გენო მუმლაძეBelum ada peringkat

- (Cô Vũ Mai Phương) Tài liệu LIVESTREAM - Chuyên đề thi THPT - Câu hỏi giao tiếp xã hội (Buổi 1)Dokumen4 halaman(Cô Vũ Mai Phương) Tài liệu LIVESTREAM - Chuyên đề thi THPT - Câu hỏi giao tiếp xã hội (Buổi 1)nguyen duong trungBelum ada peringkat

- EB Research Report 2011Dokumen96 halamanEB Research Report 2011ferlacunaBelum ada peringkat

- WeaknessesDokumen4 halamanWeaknessesshyamiliBelum ada peringkat

- Gay Costa Del Sol - 2010Dokumen2 halamanGay Costa Del Sol - 2010gayinfospainBelum ada peringkat

- Variance AnalysisDokumen22 halamanVariance AnalysisFrederick GbliBelum ada peringkat

- Experiment Number 16 Formal ReportDokumen4 halamanExperiment Number 16 Formal Reportapi-524547303Belum ada peringkat

- Remote Control Unit Manual BookDokumen21 halamanRemote Control Unit Manual BookIgor Ungur100% (1)

- OM Hospital NEFTDokumen1 halamanOM Hospital NEFTMahendra DahiyaBelum ada peringkat

- Emission Estimation Technique Manual: For Mining and Processing of Non-Metallic MineralsDokumen84 halamanEmission Estimation Technique Manual: For Mining and Processing of Non-Metallic MineralsAbdelaziem mahmoud abdelaalBelum ada peringkat

- White Vaseline: Safety Data SheetDokumen9 halamanWhite Vaseline: Safety Data SheetHilmi FauziBelum ada peringkat

- Aakanksha ProjectDokumen32 halamanAakanksha ProjectAakash murarkaBelum ada peringkat

- What Has The Government and The Department of Health Done To Address To The Issues of Reproductive and Sexual Health?Dokumen5 halamanWhat Has The Government and The Department of Health Done To Address To The Issues of Reproductive and Sexual Health?Rica machells DaydaBelum ada peringkat

- Tri-Partite Agreement AssociationDokumen9 halamanTri-Partite Agreement AssociationThiyagarjanBelum ada peringkat

- BR Interlock Pallet Racking System 2009 enDokumen8 halamanBR Interlock Pallet Racking System 2009 enMalik Rehan SyedBelum ada peringkat

- f2607-#### f2607 20191203 111644Dokumen2 halamanf2607-#### f2607 20191203 111644คุณชายธวัชชัย เจริญสุขBelum ada peringkat

- Power Divider and Combiner: EE403-Microwave Engineering MTC, EE Dep., Electromagnetic Waves GroupDokumen52 halamanPower Divider and Combiner: EE403-Microwave Engineering MTC, EE Dep., Electromagnetic Waves GroupHabibat El Rahman AshrafBelum ada peringkat

- Overall Summary:: SAP MM Certified Associate & SAP Certification ID: 0019350978Dokumen6 halamanOverall Summary:: SAP MM Certified Associate & SAP Certification ID: 0019350978Ganapathi RajBelum ada peringkat

- 4EVC800802-LFEN DCwallbox 5 19Dokumen2 halaman4EVC800802-LFEN DCwallbox 5 19michael esoBelum ada peringkat

- Argumentative Essay Research PaperDokumen5 halamanArgumentative Essay Research PaperJadBelum ada peringkat

- ContinueDokumen2 halamanContinueNeal ReppBelum ada peringkat