Norsok L-004-CR Ror Og

Diunggah oleh

Wissam JarmakHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Norsok L-004-CR Ror Og

Diunggah oleh

Wissam JarmakHak Cipta:

Format Tersedia

NORSOK STANDARD

COMMON REQUIREMENTS

PIPING FABRICATION, INSTALLATION, FLUSHING AND TESTING

L-CR-004 Rev 1, January 1996

Please note that whilst every effort has been made to ensure the accuracy of the NORSOK standards neither OLF nor TBL or any of their members will assume liability for any use thereof.

Piping fabrication, installation, flushing and testing

L-CR-004 Rev 1, January 1996

CONTENTS 1 FOREWORD 2 SCOPE 3 NORMATIVE REFERENCES 4 DEFINITIONS AND ABBREVIATIONS 4.1 Definitions 4.2 Abbreviations 5 MATERIALS 5.1 Colour marking of materials 5.2 Material storage, handling, recieval and identification control 6 FABRICATION OF PIPEWORK 6.1 General requirements 6.2 Welding and NDE 6.3 Butt welds for orifice runs 6.4 Screwed pipework 6.5 Dimensional tolerances for pre-fabricated piping assemblies 6.6 Branch connections and outlets 6.7 Pipe coupling 7 INSTALLATION OF PIPING 7.1 Pipework erection 7.2 Flanged joints 7.3 Valve and equipment flange connections 7.4 Gaskets 7.5 Bolting 7.6 Pipe support 7.7 Global tolerances, installation 8 FLUSHING 8.1 General 8.2 Hydro flushing 8.3 Pressurised air shockblowing 8.4 Pneumatic flushing 9 PRESSURE TESTS 9.1 General 9.2 Test preparation 9.3 Test media 9.4 Hydrostatic testing 9.5 Pneumatic testing 9.6 After completion of test 9.7 Verification of cleanliness 10 CHEMICAL CLEANING 11 HOT OIL FLUSHING 11.1 General 11.2 Marking NORSOK standard 4 4 4 4 4 5 5 5 5 5 5 8 8 8 8 8 8 9 9 9 10 10 10 10 11 11 11 11 11 12 13 13 13 14 14 15 15 15 1 of 27 ERROR! BOOKMARK NOT DEFINED. 3 3 4

Piping fabrication, installation, flushing and testing 11.3 Documentation 12 SYSTEM COLOUR CODING OF PIPING 12.1 Purpose 12.2 Types of markers 12.3 Marker texts 12.4 Material of markers 12.5 Positioning of markers 12.6 Fluid description/colour code tabulation 12.7 Colour coding information. ANNEX A ALTERNATIVE TEST METHODS A.1 SCOPE A.2 GENERAL A.3 ALTERNATIVE TESTING METHOD A.4 DOCUMENTATION A.5 ALTERNATIVE TEST MATRIX

L-CR-004 Rev 1, January 1996 15 16 16 16 16 16 17 18 18 19 19 19 19 19 20 21

ANNEX B REQUIREMENTS FOR INTERNAL TREATMENT OF PIPING AFTER PREFAB AND INSTALLATION BEFORE COMMISSIONING (TABLE 1)

1 ERRATA: CORRECTED TYPING ERROR IN ANNEX A.3 (APRIL 1998)

NORSOK standard

2 of 27

Piping fabrication, installation, flushing and testing

L-CR-004 Rev 1, January 1996

FOREWORD

NORSOK (The competitive standing of the Norwegian offshore sector) is the industry initiative to add value, reduce cost and lead time and remove unnecessary activities in offshore field developments and operations. The NORSOK standards are developed by the Norwegian petroleum industry as a part of the NORSOK initiative and are jointly issued by OLF (The Norwegian Oil Industry Association) and TBL (The Federation of Norwegian Engineering Industries). NORSOK standards are administered by NTS (Norwegian Technology Standards Institution). The purpose of this industry standard is to replace the individual oil company specifications for use in existing and future petroleum industry developments, subject to the individual company's review and application. The NORSOK standards make extensive references to international standards. Where relevant, the contents of this standard will be used to provide input to the international standardisation process. Subject to implementation into international standards, this NORSOK standard will be withdrawn. All annexes are normative.

SCOPE

This standard covers the basis for fabrication, installation, flushing, pressure testing, chemical cleaning, hot oil flushing and system colour coding of process, drilling and utility piping for offshore oil and/or gas production facilities. This standard does not cover the following: All instrument control piping downstream of first piping block valve. Sub-sea pipework and risers. Flexible hoses. Sanitary piping systems within living quarters and other domestic areas (H-CR-002). GRP piping.

NORMATIVE REFERENCES

The fabrication, installation, flushing, pressure testing, chemical cleaning, hot oil flushing and system colour coding shall be in accordance with all applicable sections of the latest edition of the regulations, codes, standards listed below: ASME B31.3 ASME B2.1 DIN 2505 Norsok Z-DP-002 Norsok L-CR-001 Norsok M-CR-601 NS 813 NORSOK standard Chemical plant and petroleum refinery piping Pipe threads, general purpose Flanged joint calculation Coding system Piping and valves Welding and inspection of piping Piping systems. Identification colours for the content. 3 of 27

Piping fabrication, installation, flushing and testing NS 4054 ISO 4406 ISO 9095 Colour for identification.

L-CR-004 Rev 1, January 1996

Hydraulic fluid power-fluids-method for coding level of contamination by solid particles Steel tubes - Continuous character marking and colour coding for material identification

DEFINITIONS AND ABBREVIATIONS

Shall mean normative in the application of NORSOK standards. Shall mean informative in the application of NORSOK standards. Shall is an absolute requirement which shall be followed strictly in order to conform with the standard. Should is a recommendation. Alternative solutions having the same functionality and quality are acceptable. May indicates a course of action that is permissible within the limits of the standard (a permission). Can-requirements are conditional and indicates a possibility open to the user of the standard.

4.1 Definitions Normative references Informative references Shall Should May Can

4.2 Abbreviations ABS Absolute CTF Cut To Fit HVWF High Velocity Water Flushing NS Norwegian Standard ASME American Society of Mechanical Engineers PVC Polyester Vinyl Chlorid ID Inner Diameter PAS Pressurised Air Shock Blowing P&ID Piping and Instrument Diagram NDE Non Destructive Examination HVAC Heating, Ventilation and Air-Conditioning ISO International Organisation for Standardisation RAL bersichtkarte. bersicht ber die farben des farbregisters RAL 840 HR RTJ Ring Type Joint GRP Glassfiber Reinforced Plastic

MATERIALS

5.1 Colour marking of materials If colour marking shall be implemented, ISO 9095 shall be used. 5.2 Material storage, handling, recieval and identification control Procedures for off-loading, storage, recieval, control, traceability and inspection of piping material supplied for fabrication and installation shall be worked out.

NORSOK standard

4 of 27

Piping fabrication, installation, flushing and testing

L-CR-004 Rev 1, January 1996

FABRICATION OF PIPEWORK

6.1 General requirements Prefabricated pipe spools shall be cleaned, painted (if required) and preserved prior to installation. 6.2 Welding and NDE All welding and NDE shall be in accordance with M-CR-601. Internals of in-line valves and equipment that could be damaged due to heat transfer shall be removed prior to welding and/or heat treatment. 6.3 Butt welds for orifice runs When the design of an orifice run necessitates welds, these shall be ground smooth and flush with the inside of the pipe. Pipe-tap connections where required, shall be drilled through the pipe wall and be smooth inside. 6.4 Screwed pipework Unless otherwise stated on approved drawing or specifications, pipe threads shall conform to ASME B2.1. All threading shall be carried-out after bending, forging or heat treatment but where this is not possible, suitable thread protection must be provided. 6.5 Dimensional tolerances for pre-fabricated piping assemblies The tolerances on linear dimensions (intermediate or overall) is illustrated on figures 1 and 2. These tolerances are not accumulative. Angularity tolerances across the face of flanges, weld end preparation and rotation of flanges shall be as stated in figures 1 and 2. Closer tolerances on weld end preparations than stated in figures 1 and 2, may be specified in the relevant welding specification for the material in question, and shown on the fabrication isometric(s). When closer tolerances other than those given above are required, these shall be as specified on the isometric drawing in question.

NORSOK standard

5 of 27

Piping fabrication, installation, flushing and testing

L-CR-004 Rev 1, January 1996

3 mm per 1 m Max 6 mm

L T

L

L

L (m) 6 >6 L 5 10

Tolerances (mm) T 1.5 1.5

Figure 1. Tolerances for prefabricated piping assemblies

NORSOK standard

6 of 27

Piping fabrication, installation, flushing and testing

L2 d L1

L-CR-004 Rev 1, January 1996

L T

H d

L2 L1

L (m) 6 >6

Tolerances (mm) L A T 3 1.5 1.5 5 1.5 1.5

L1 L2 H T K

Tolerances (mm) 2" d 10" 12" d 20" 3 5 3 5 3 3 1.5 1.5 2 3 d=nominal diameter

d >20" 5 5 3 1.5 3

1.5 mm

X"

X"

Figure 2: Tolerances for prefabricated piping assemblies Notes: 1. Before reworking any spools contact engineering department in order to check complete isometric. 2. For spools CTF dimensions the overall length to be approximately 50mm overlength. 3. Bolt holes on flanges shall straddle the horizontal or vertical lines or plant north/south centre lines when orientation is not given on drawings.

NORSOK standard

7 of 27

Piping fabrication, installation, flushing and testing

L-CR-004 Rev 1, January 1996

6.6 Branch connections and outlets All welded branch connections shall be jointed to the header with full penetration welds. Stub-in connections shall be set-on type. Set-in type is not acceptable. Reinforcement pads or saddles required by specifications and drawings shall be of the same material as the main pipe (unless specified otherwise) and shall be formed and countered to provide a good fit to both main and branch pipe. Branch reinforcement pads or each segment thereof shall be provided with a minimum 3.0mm drilled and tapped hole prior to fitting to the pipe, so ensuring leak detection, venting and testing facilities. Whenever possible, pad should be made in one piece before fitting onto pipe. 6.7 Pipe coupling Seal faces of mechanical couplings/hubs and flanges shall be protected during fabrication and storage. Where possible couplings/hubs shall be protected by fitting and hand tightening the complete coupling assembly.

INSTALLATION OF PIPING

7.1 Pipework erection All pipes shall be inspected before erection to ensure that they are free from loose contamination. Pipework shall be erected on permanent supports designated for the line. Temporary supports shall be kept to an absolute minimum, but to an extent sufficient to protect nozzles and adjacent piping from excessive loads during the erection. Pipework shall be fitted in place without springing or forcing to avoid undue stressing of the line or strain being placed on a vessel or item of equipment, etc. All temporary pipe spools and supports that are an aid to erection, testing/flushing, sea fastening, etc. are to be specially marked for removal identification. 7.2 Flanged joints Before assembly flanges shall be clean and free from any detritus matter (e.g rust, dirt or other contamination). The joints shall be brought up flush and square without forcing so that the entire mating surfaces bear uniformly on the gasket and then mated-up with uniform bolt tension. 7.3 Valve and equipment flange connections Flange covers shall be retained on all flange connections to valve or equipment, until ready to connect the mating piping. All equipment shall be blanked, either by pressure test blanks, spades or blinds, to stop the ingress of internal pipe debris. Flanges connecting to strain sensitive mechanical equipment e.g. pumps, compressors, turbines, etc. shall be fitted-up in close parallel and lateral alignment prior to tightening the bolting.

NORSOK standard

8 of 27

Piping fabrication, installation, flushing and testing

L-CR-004 Rev 1, January 1996

In general, flange connections to equipment shall be the last connection made on completion of a line or interconnecting system of lines. With the piping flange fitted and prior to bolting-up the joint, the following tolerances shall be maintained: Bolting shall move freely through accompanying bolt-holes at right angle to the flange faces. There shall be a clear gap between two flange faces before gasket installation. There shall be sufficient flexibility to install and replace gaskets. 7.4 Gaskets Gaskets shall be treated in accordance with manufacturers instructions. Gaskets shall be replaced after opening or dismantling of flange connections. RTJ gaskets are to be lightly smeared on the mating surface with a propriety anti-friction lubricant prior to fitting between the flange grooves. Anti-friction lubricant, compatible with the flange material and process fluid shall be used. 7.5 Bolting Bolting shall be in accordance with the requirements in the Piping and valve material standard L-CR-001. Manually pulled flange bolts and studbolts shall extend fully through their nuts with minimum one, maximum five threads. All flanged stud bolts shall be progressively controlled to equalise bolt pressure on the gasket. A detailed procedure shall be developed prior to start. Hydraulic bolt thigthening shall be used on all bolts greater than 1" diameter. Calculation of the required bolt tension value shall be in accordance with the DIN 2505, with the following exeptions: Minimum required bolt tension value shall be multiplied with 1.5. Maximum bolt tension value shall not exeed 2/3 of the specified yield of the bolt or maximum allowable stress for the gasket. Nuts and bolts shall have their grade marks visible after installation. Studbolts cut from long lengths of studding shall have material grade stamped on end of each cut. Bolts larger than 1" shall be protected against mechanical damage and corrosion. 7.6 Pipe support Pipe supports shall be in accordance with the relevant pipe support detail drawings developed for the project. Piping shall not be forced to fit with support locations in such a manner that additional stress is introduced. Where spring support are installed the spring shall locked gagged until commissioning/start up.

NORSOK standard

9 of 27

Piping fabrication, installation, flushing and testing

L-CR-004 Rev 1, January 1996

All piping shall be arranged to facilitate supporting, and shall be planned for ease of removal of equipment for inspection and servicing. Pipes shall not normally be supported by other pipes, i.e. individual supporting is required. Vent holes in wear plates and trunnions are generally not required. However, when the wear plate or a trunnion covers a circumferential weld that has not been pressure tested, a vent hole is required for leak detection. 7.7 Global tolerances, installation Hook-up termination points shall be within 25mm in all directions. Overlength may be provided where required. Installation tolerances of piping components shall be as required by the individual service of the piping component including requirements for: Maintenance access. Position relative to surrounding steelwork, equipment, cable tray and HVAC duct routings. Positioning of pipe supports relative to the structural steel. Pipe stress.

FLUSHING

8.1 General The initial flushing shall be carried out prior to pressure testing. For austenitic steelwork flushing can be performed after pressure testing, upon agreement. General requirements for flushing for specific systems are listed in table 1, annex B. Procedures for flushing shall be developed prior to start. All pipework shall be free from dirt, grease and temporary protective coating upon completion of flushing. 8.2 Hydro flushing Items of equipment which would be sensitive to damage during hydro flushing shall be removed, blocked off or isolated. A list shall be prepared and be part of the flush & test procedure. Ball valves shall be flushed in fully open position. All piping systems shall be flushed using high pressure jetflushing equipment, such as rotating hose or rotating nozzle. Minimum pressure shall be 600 bar. Below 4, High Velocity Water Flushing (HVWF) may be used. Water velocity shall be a minimum of 10m/s. On systems where high pressure jet flushing cannot be used due to complicated shapes and/or long runs HVWF may be used. The flushing medium shall in general be fresh water. When flushing stainless steel lines, the chloride ion content shall be less than 200ppm.

NORSOK standard

10 of 27

Piping fabrication, installation, flushing and testing

L-CR-004 Rev 1, January 1996

After flushing, the piping systems shall be completely drained and protected against corrosion. Ball valves shall be flushed fully open. 8.3 Pressurised air shockblowing This method may be used as an initial cleaning method for instrument air, plant air and as an alternative method for initial cleaning of small bore pipe (less than 2 inch). This method may also be used when there are problems removing trapped liquid in the circuit, or to verify cleanliness of small bore pipe where video inspection is impossible or inadequate due to pipe dimension or configuration. When using PAS method for cleaning or verification the procedure shall be repeated until cleanliness is acceptable. The air shocking pressure shall never exceed the working pressure of the system and shall never be more than 8 bar. Safety precaution shall be taken when this method is used. 8.4 Pneumatic flushing In cases where water is not desirable in the piping system (e.g. instrument/utility air), flushing by pressurised air or PAS shall be carried out. When pressurised air is used, the minimum velocity shall be 35m/s. Procedure covering all safety aspects shall be established.

PRESSURE TESTS

9.1 General The test pressure shall, unless otherwise specified, be in accordance with ASME B31.3. Testing shall not take place with system temperatures 4C or less or where the ambient temperature during test falls by 5C or more, nor during rain or fog unless under suitable cover. Hydrostatic pressure test may however be performed under a lower temperature with a proper frost preventive added to the test water. The following are excluded from pressure tests: All small bore instrument control piping downstream of the first piping block valve. Open drains and vents to atmosphere (leak test only). For alternative testing of tie-in welds, see annex A. 9.2 Test preparation Pressure, temperature and time recorders shall be used for all hydrostatic tests. The pressure shall be shown in barg. Pressure gauges and recorders used to indicate and record test pressure shall be dead weight tested for accuracy according to a procedure, dependent of type of equipment. Minimum of one gauge shall be positioned at the highest point and one recorder to be positioned at the lowest point. Accuracy of pressure gauge shall be at least 1-2% at full scale and 1-2% for the recorder. The test pressure shall be within 60% of the gauge range (20% from top and 20% from bottom).

NORSOK standard

11 of 27

Piping fabrication, installation, flushing and testing

L-CR-004 Rev 1, January 1996

If there is a deviation of more than 2% between gauge and recorder during test, the test shall be stopped and the equipment recalibrated. Piping joints and welds shall not be insulated or physically covered until satisfactory completion of testing in accordance with this specification, except for painting of prefabricated welds. All piping shall be adequately supported before the pressure test. Spring or other variable type supports shall be blocked to prevent movement. Unless otherwise noted, all valves are to be through body tested. First block valve for pressure instruments shall be included in the test. Piping containing check valves shall have the source of test pressure on the upstream side. If this is not possible, the check valve disc shall be removed or jacked open. Ball valves shall be pressure tested in the half open position. Other valves shall be tested in the fully open position. Where the test pressure to be applied to the piping is greater than the maximum allowable test pressure for valves, the valves shall be blinded off on the side to be tested, or removed and replaced by dummy spools. Turbines, pumps, compressors and vessels shall be blinded off prior to pressure testing. A list shall be prepared for sensitive equipment that shall be removed, blocked off or isolated during testing, such as relief valves, inline instruments, turbines, pumps, compressors and vessels. This list shall be a part of the test procedure. 9.3 Test media For hydrostatic testing the test medium shall in general be fresh water, except that other suitable liquid may be used if: The piping or inline equipment would be adversely affected by water. If the liquid is flammable, it's flash point shall be at least 49C and consideration shall be given to the environment. The liquid is approved to be used. The chloride ion content of the water used for pressure testing stainless steel lines shall be less than 200ppm and the line shall be properly drained soon after testing. Ph value of the water shall be between 6.5 and 7.5. Carbon steel systems as defined in table 1, annex B shall be tested with an acceptable preservation fluid. The preservation fluid shall be water impellent and emulsifiable rust preventives lubricating oils that contain detergents and inhibitors that have been specially formulated to prevent rust. For pneumatic testing, the test media shall be oil free, dry air or any inert gas. The use of air for testing shall be limited to a maximum pressure of 7.0 barg. Above this pressure nitrogen shall be used. The extent of pneumatic testing shall be approved.

NORSOK standard

12 of 27

Piping fabrication, installation, flushing and testing

L-CR-004 Rev 1, January 1996

For instrument/utility air systems, where the introduction of water is undesirable, test media shall be air or inert gas. 9.4 Hydrostatic testing The test pressure shall be maintained for a sufficient length of time to permit visual examination to be made of all surfaces, welds and connections, but not less than thirty minutes. A one hour test duration shall apply for piping systems with pressure rating class 600# and above. Care shall be taken to ensure that overpressuring due to static head does not take place. The piping systems shall not show any sign of plastic deformation or leakage. 9.5 Pneumatic testing The sequence of test pressuring installed systems shall be as follows: A pressure of 0.5 barg shall be introduced in the system and a leak test performed. The pressure shall gradually be increased to 50% of the specified test pressure and kept for minimum 10 minutes to equalise strain. The pressure shall then be increased in steps of 10% of the specified test pressure, until the specified test pressure is reached. At each step, the pressure shall be kept for 10 minutes minimum to equalise strain. The specified test pressure shall be kept for one hour. The pressure shall than be reduced to the design pressure before examining for leakage. The piping systems shall not show any sign of plastic deformation or leakage. 9.6 After completion of test The tested systems shall be depressurised by opening the depressurising valve in the test rig. After depressurisation, all vents and low point drain valves shall be opened and the system shall be thoroughly drained where the test medium is water. Where required, blowing by dry air or Pressurised Air Shock Blowing to remove any trapped water to be performed. Systems with drying requirement as defined in table 1, annex B shall be dried out after hydrotesting with dry oil free air with a dew point of -10C. Drying can be terminated when the dew point at the outlet is equal to the dew point at the inlet. Other methods, such as vacuum drying or air shocking, may also be used if the same dryness can be documented. Requirement for drying as defined in table 2, annex C shall take in to consideration the time for start up of system. If more than 3 months to commissioning, drying shall be followed by preservation with nitrogen to keep the pipe system completely dry and to avoid condense. Other alternatives are subject to agreement. Reinstallation of the system shall be performed in accordance with the test procedure. Where permanent or temporary strainers have remained in place for the hydrostatic pressure test, they shall be removed following the test and thoroughly cleaned before reinstalling.

NORSOK standard

13 of 27

Piping fabrication, installation, flushing and testing

L-CR-004 Rev 1, January 1996

Ends of pipes and nozzles shall be fully protected against the ingress of foreign material by the use of caps, plugs or plate blinds sealed with gaskets. These shall not be removed until just prior to final assembly. Flange parallellity and alignment to equipment shall be checked prior to reinstatement. Vent holes in reinforcing pads shall be sealed upon completion of pressure test. 9.7 Verification of cleanliness All systems shall be internal visual inspected for acceptable cleanliness by spot check. Internal visual inspection includes the use of Boroscope, video etc. If pipe configuration in critical parts of systems as defined in table 1, annex B is too complicated for visual inspection, the PAS method or other suitable methods shall be used for verification of cleanliness.

10

CHEMICAL CLEANING

Lines to be chemical cleaned shall be identified on the P&ID's and Line Index. For system overview see table 1, annex B. A procedure shall describe in detail the steps for chemical cleaning. Chemical cleaning shall include: Degassing. Chemical cleaning/descaling. Neutralisation. Passivation. Water flushing. Drying. The end result shall be a clean smooth surface. Maximum temperatures used during these operations shall not exeed maximum design temperature for the systems as listed in the Line Index. For equipment such as turbines, generators, pumps and compressors, the piping to be cleaned shall have all sensitive items that can be damaged by the cleaning medium removed or blanked off. Generally, the following items shall not be chemically cleaned (items shall be identified on chemical cleaning iso): All instrument tubing downstream the first piping block valve. Piping systems with copper alloy materials. Flexible hoses. Vessels. Exchangers. Pumps. All bolted/screwed valves and instruments. NORSOK standard 14 of 27

Piping fabrication, installation, flushing and testing

L-CR-004 Rev 1, January 1996

Removed or blanked off items shall be cleaned separately prior to reinstallation. The systems to be cleaned shall have high and low point vents and drains installed. "Dead legs" shall be avoided. Cleaning shall be carried out after pressure testing unless otherwise specified. If more than 3 months to start up of commissioning activities, system shall be preserved with nitrogen. Overpressure shall be 0.5 bar.

11

HOT OIL FLUSHING

11.1 General Required cleanliness for systems subject to hot oil flushing shall be in accordance with table 1, annex B. A detailed procedure for hot oil flushing shall be developed out prior to start. Filters used for hot oil flushing shall be: 3m ABS for hydraulic systems. <= 10m ABS for lube and seal oil. Filling of lubricant oil shall take place through filters with 10m ABS. Flushing and sampling to verify cleanness shall take place at turbulent flow, upstream any filters. The Reynolds number shall be min. 4000. The level of cleanness shall be documented from an automatic particle counter or a membrane checked in a microscope before a flushing operation is considered finalised. A flowmeter shall be installed to verify flow used during flushing operation. Maximum water content in oil used for flushing shall be less than 500ppm. 11.2 Marking Piping spools or systems that have been chemical cleaned or hot oil flushed shall be marked in a unique manner. 11.3 Documentation The compliance to specified ISO 4406 requirements shall be documented by relevant laboratory analysis certificates or other acceptable methods.

NORSOK standard

15 of 27

Piping fabrication, installation, flushing and testing

L-CR-004 Rev 1, January 1996

12

SYSTEM COLOUR CODING OF PIPING

12.1 Purpose In addition to line-numbering, the purpose of having a system for colour coding of piping is to ensure quick recognition of medium and flow direction for any system. 12.2 Types of markers

12.2.1 All piping One out of two types of markers shall be used. Plastic tape glued to the pipe surface. The required text shall appear in an arrow shaped window. Laminated plastic signs, fastened to the pipes by plastic straps and locks. The required text shall appear in an arrow shaped window. 12.2.2 Insulated lines On insulated lines with hidden electrical tracing additional marking band to be according to I-CR-003. 12.2.3 Plastic/rubber lined piping In addition to the markings mentioned here each spool of all plastic or rubber lined piping shall be marked with the warning "Ikke sveis, innvendig belagt". The warning shall be with red letters on a white background. 12.2.4 Obstructions The warning tape shall be yellow with black diagonal stripes. This tape is used in conjunction with a standard marker to indicate special precaution requirements. 12.3 Marker texts The text shall be in letters and figures of minimum height of 7mm, but size may be adjusted to fit all required information within the arrow. Max. no. of letters in each line = 18; longer words to be abbreviated. Maximum 2 lines can be used. On laminated plastic signs, the size of the letters is to be adjusted to fit the size of the sign. The marking shall be with Norwegian text only. Exception is potable water, which shall have both Norwegian and English text, thus: "Drikkevann/Potable Water". 12.4 Material of markers Materials for tape adhesive, text strips or laminated signs with straps shall be polyethylene, polypropylene or PVC. These signs must be resistive for humidity, UV-radiation and temperature changes. 12.4.1 Tape The tape requirements are: The tape shall be 160mm wide and made from a suitable plastic film on which the colour is printed on the reverse (adhesive) side in such a way that the printing colour is protected against mechanical and chemical attacks by the plastic film. Adhesive tape must not be used on stainless steel and high alloyed materials. Laminated signs as specified in clause 12.4.2 shall be used for all sizes. NORSOK standard 16 of 27

Piping fabrication, installation, flushing and testing

L-CR-004 Rev 1, January 1996

Consideration must be given when determining the length of tape, e.g. "insulation thicknesses", reference shall be made to P&IDs, line index, isometrics and insulation specification. All types must have a 50mm overlap at joints. 12.4.2 Laminated signs Laminated plastic signs shall be used instead of tape markers in the following instances: On all pipes sizes 5" and above in exposed areas. On all pipe sizes 18" and above in sheltered areas. On all pipe sizes for stainless steel and high alloy materials. The sizes of the coloured area of signs shall be as follows: Small pipes below 3/4 Pipe size 1"-8" Pipe size 10"-16" Pipe size 18" and above : Size no. 0 : Size no. 1 : Size no. 2 : Size no. 3 (6x15.5cm) (10x15.5cm) (17x30.5cm) (26x44cm)

The signs shall be fastened to the bare pipe or over insulated pipe by means of non metallic strapping with a width proportionate to the size of the sign. The laminated tag shall be soft/elastic in -5C. Bending tests shall be documented. Minimum bending radius is 10-12 times the thickness of the tag (minimum thickness is 0.9mm). 12.5 Positioning of markers The length of tape shall extend all the way around the pipe and overlap min. 50mm on itself. On pipes with a surface temperature of more than 60C, suitable insulation must be used between the identification tape and the pipe surface. Markers are to be applied with the arrow pointing in the direction of flow. The following special application rules shall be followed: Markers shall be positioned specially considering operational aspects of the plant, and shall be easily readable from ground, platform or ordinary access road. Ladders, scaffolding or other temporary equipment shall not be needed for identification of markers. A marker is to be placed at each branching point. A marker is to be placed on each side of bulkheads, decks and other penetration points. A marker shall be positioned on the pipe close to major components of the actual system (vessel, pumps, etc.). (Markers are not required next to each and every valve or pump etc. of a system comprising several identical components adjacent to each other). Maximum spacing between markers shall not exceed 10m. Special locations as specified. Marker shall be positioned by inlet and outlet of process train. On elevated pipes, markers shall be positioned adjacent to stairways and platforms. Markers shall be positioned at end of piperack. To ensure no mistakes in marking, a separate inspection team to control the quality of the job shall be arranged.

NORSOK standard

17 of 27

Piping fabrication, installation, flushing and testing

L-CR-004 Rev 1, January 1996

12.6 Fluid description/colour code tabulation Colour coding shall be in accordance with NS 813 (Piping Systems. Identification colours for the content) and NS 4054 (Colour for identification). A detailed coding for systems within oil and gas production is given in NORSOK Z-DP-002, Coding system. 12.7 Colour coding information. The platform shall have a complete chart (size to be A2) of the colour coding used, signposted approximately 165cm above deck level on the right/left hand side when entering a door to an area, or in other strategically located positions.

NORSOK standard

18 of 27

Piping Fabrication, Installation, Flushing and Testing Annex A

L-CR-004 Rev. 1, January 1996

ANNEX A

A.1 SCOPE

ALTERNATIVE TEST METHODS

This annex defines the alternative test options and methods that may be applied to replace the pressure test requirement for closure welds in hookup spools, and for minor changes and addition in piping system which have already been hydrostatically tested.

A.2

GENERAL

All installed piping shall have been pressure tested at the test conditions and medium as specified in accordance with the requirements laid down in ASME B31.3 Chemical Plant and Petroleum Refinery Piping and this standard. All integral welds in a hook-up spool shall have been previously pressure tested. Prior to any alternative testing taking place, acceptance shall be obtained. If allowable stress exeeds 70% of yield, there are no alternative to hydrostatic test.

A.3

ALTERNATIVE TESTING METHOD

In all cases where pressure testing of hook-up spools welds and any minor changes or additions to the piping system will entail an extensive retest, the closure/minor welds may be alternatively tested to the stipulations of this document without being subjected to any leak test requirements. The qualification of a weld by alternative testing falls into two categories which are determined by service/pressure. These are as follows: Alternative I All hook-up spool closure welds and any minor change/additional welds shall be NDE tested in accordance with ASME-B31.3 Para 345.1(a) and visually inspected. Welding and Inspection standard.(M-CR-621). NDE shall not be less than specified in welding and inspection standard (M-CR-621). All hook-up spool closure welds and any minor change/additional welds shall be subject to 100% - radiography, and 100% MPI or dye penetrant as applicable to material. NDE shall not be less than specified in Welding and Inspection standard (M-CR-621).

Alternative II

The above alternatives are clearly depicted in clause A.5 which shall be used as a guideline to define the acceptable alternative testing method.

A.4

DOCUMENTATION

All alternative testing shall be documented with full traceability to the applicable welds.

NORSOK standard

19 of 27

Piping Fabrication, Installation, Flushing and Testing Annex A

L-CR-004 Rev. 1, January 1996

A.5

Fluids

ALTERNATIVE TEST MATRIX

Alternative Test Method Note (1) II

Normal fluid service (as defined in ASME B31.3). Category D fluid service (as defined in ASME B31.3). Note 1: See description clause A3.

NORSOK standard

20 of 27

Piping Fabrication, Installation, Flushing and Testing Annex B

L-CR-004 Rev. 1, January 1996

ANNEX B REQUIREMENTS FOR INTERNAL TREATMENT OF PIPING AFTER PREFAB AND INSTALLATION BEFORE COMMISSIONING (TABLE 1)

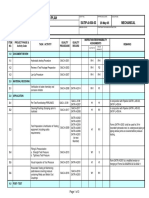

Table 1 Requirements for internal treatment of piping after prefab and installation before commissioning

PIPE FLUSH TEST W/ CHEM. DRYING PRESERMATR. WATER/ PRESERV. CLEAN. VATION AIR FLUID YES/NO C.S WATER WATER WATER WATER WATER WATER WATER WATER WATER YES YES YES NO YES NO YES NO NO NO NO NO NO NO NO NO NO NO NO NO NO NO NO NO NO NO NO NORMAL NORMAL NORMAL NORMAL NORMAL NORMAL NORMAL NORMAL NORMAL FINAL CLEANING/ REQUIRED CLEANLINESS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS REMARKS

SYSTEM SYSTEM DESCRIPTION

10 11 12

DRILLING SYSTEMS

DRILLING PROCESS SYSTEMS C.S DRILLING WELLCONTROL SYSTEMS C.S SSTL

13

RISER AND WELL SYSTEMTOPSIDE

C.S SSTL

15

WELL RELATED PRODUCTION C.S SYSTEMS TOPSIDE SSTL GAS AND WATER INJECTION WELL SYSTEM TOPSIDE SSTL

16

20

SEPARATION AND STABILIZATION

C.S SSTL

WATER WATER

YES NO

NO NO

NO NO

NORMAL NORMAL

NO FOREIGN MATERIALS NO FOREIGN MATERIALS

NORSOK Standard

Page 21 of 27

Piping Fabrication, Installation, Flushing and Testing Annex B

SYSTEM SYSTEM DESCRIPTION PIPE FLUSH TEST W/ CHEM. DRYING PRESERMATR. WATER/ PRESERV. CLEAN. VATION AIR FLUID YES/NO C.S SSTL 23 23-10 23-10 23-20 23-20 23-20 23-20 24 24-10 24-10 24-20/30 24-20/30 GAS RECOMPRESSION, COOLING AND SCRUBBING GAS COOLING AND SCRUBBING GAS COOLING AND SCRUBBING GAS RECOMPRESSION If no chem.cleaning req. GAS RECOMPRESSION If no chem.cleaning req. GAS TREATMENT GAS COOLING AND SCRUBBING GAS COOLING AND SCRUBBING GAS DEHYDRATION/ REGENERATION GAS DEHYDRATION/ REGENERATION GAS REINJECTION TO RESERVOIR C.S SSTL C.S SSTL WATER WATER WATER WATER YES NO NO NO NO NO NO NO NO NO NO NO NORMAL NORMAL NORMAL NORMAL NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS WATER WATER YES NO NO NO NO NO NORMAL NORMAL FINAL CLEANING/ REQUIRED CLEANLINESS NO FOREIGN MATERIALS NO FOREIGN MATERIALS REMARKS

L-CR-004 Rev. 1, January 1996

21

CRUDE HANDLING

C.S SSTL C.S C.S SSTL SSTL

WATER WATER WATER WATER WATER WATER

YES NO NO YES NO NO

NO NO

NO NO

NORMAL

ACC. TO YES P&ID NO YES ACC.TO P&ID NO YES YES

NO FOREIGN MATERIALS NORMAL NO FOREIGN MATERIALS SEE NOTE 4 ISO 4406,17/14 NO FOREIGN MATERIALS SEE NOTE 4 ISO 4406,17/14 NO FOREIGN MATERIALS

(100% visual insp. on suction side of compressor).

NORMAL

(100% visual insp. on suction side of compressor).

NORMAL

26

NORSOK Standard

Page 22 of 27

Piping Fabrication, Installation, Flushing and Testing Annex B

SYSTEM SYSTEM DESCRIPTION PIPE FLUSH TEST W/ CHEM. DRYING PRESERMATR. WATER/ PRESERV. CLEAN. VATION AIR FLUID YES/NO C.S WATER YES NO NO NORMAL FINAL CLEANING/ REQUIRED CLEANLINESS NO FOREIGN MATERIALS NO FOREIGN MATERIALS REMARKS

L-CR-004 Rev. 1, January 1996

26-10/30

26-10/30

26-20 26-20 26-20 26-20 27 27-10 27-10 27-20/30 27-20/30 27-20/30

REINJECTION GAS COOLING AND SCRUBBING / REINJECTION MANIFOLD REINJECTION GAS COOLING AND SCRUBBING / REINJECTION MANIFOLD REINJECTION GAS COMPRESSION If no chem.cleaning req. REINJECTION GAS COMPRESSION If no chem. cleaning req. GAS PIPELINE COMPRESSION, MEETERING AND TRANSFER GAS COOLING AND SCRUBBING GAS COOLING AND SCRUBBING GAS PIPELINE COMPRESSION / GAS METERING If no chem. cleaning req.

SSTL

WATER

NO

NO

NO

NORMAL

C.S C.S SSTL SSTL

WATER WATER WATER WATER

NO YES NO NO

ACC.TO P&ID NO ACC.TO P&ID NO

YES NO YES YES

SEE NOTE 4 ISO4406,17/14 NORMAL NO FOREIGN MATERIALS SEE NOTE 4 ISO4406,17/14 NO FOREIGN MATERIALS

(100% visual insp. on suction side of compressor)

(100% visual insp. on suction side of compressor)

NORMAL

C.S SSTL C.S C.S

WATER WATER WATER WATER WATER

YES NO NO YES NO

NO NO

NO NO

NORMAL

ACC. TO YES P&ID NO YES ACC.TO P&ID NO YES

NO FOREIGN MATERIALS NORMAL NO FOREIGN MATERIALS SEE NOTE 4 ISO 4406,17/14 FOREIGN MAT.

(100% visual insp. on suction side of compressor)

NORMAL

GAS PIPELINE COMPRESSION / SSTL GAS METERING If no chem. cleaning req. SSTL

SEE NOTE 4 ISO 4406,17/14

(100% visual insp. on suction side of compressor)

27-20/30

WATER

NO

YES

NORMAL

NO FOREIGN MATERIALS NO FOREIGN MATERIALS

28

GAS SWEETENING

SSTL

WATER

NO

NO

NO

NORMAL

NORSOK Standard

Page 23 of 27

Piping Fabrication, Installation, Flushing and Testing Annex B

SYSTEM SYSTEM DESCRIPTION PIPE FLUSH TEST W/ CHEM. DRYING PRESERMATR. WATER/ PRESERV. CLEAN. VATION AIR FLUID YES/NO C.S WATER YES NO NO NORMAL FINAL CLEANING/ REQUIRED CLEANLINESS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS REMARKS

L-CR-004 Rev. 1, January 1996

30

OIL PIPELINE,EXPORT STABILIZED OIL-Upstream of Piglauncher

SSTL 31 CONDENSATE EXPORT PIPELINE-Upstream of Piglauncher C.S

WATER WATER

NO YES

NO NO

NO NO

NORMAL NORMAL

SSTL 32 GAS EXPORT PIPELINEUpstream of Piglauncher C.S SSTL 34 WATER PIPELINE HIGH SSTL PRESSURE-Upstream of Piglauncher METHANOL PIPELINE-Upstream C.S of Piglauncher SSTL PIPELINE WELLSTREAM,MULTIPHASEUpstream of Piglauncher C.S

WATER WATER WATER WATER

NO YES NO NO

NO NO NO NO

NO NO NO NO

NORMAL NORMAL NORMAL NORMAL

35

WATER WATER WATER

YES NO YES

NO NO NO

NO NO NO

NORMAL NORMAL NORMAL

36

SSTL 40 COOLING MEDIUM AND REFRIGERATION SYSTEM C.S SSTL 41 HEATING MEDIUM SYSTEM C.S

WATER WATER WATER WATER

NO YES NO YES

NO NO NO NO

NO NO NO NO

NORMAL NORMAL NORMAL NORMAL

(See NORSOK Standard

Acceptable preserv, fluid to avoid blockage of heating unit.

Page 24 of 27

Piping Fabrication, Installation, Flushing and Testing Annex B

SYSTEM SYSTEM DESCRIPTION PIPE FLUSH TEST W/ CHEM. DRYING PRESERMATR. WATER/ PRESERV. CLEAN. VATION AIR FLUID YES/NO FINAL CLEANING/ REQUIRED CLEANLINESS REMARKS

L-CR-004 Rev. 1, January 1996

remarks)

SSTL 42 43 CHEMICAL INJECTION SYSTEM FLARE,VENT AND BLOWDOWN SYSTEMS SSTL C.S SSTL 44 45 OILY WATER TREATMENT FUEL GAS SSTL C.S SSTL 50 SEAWATER SYSTEMS (LOW TO MEDIUM PRESSURE) SEAWATER SYSTEMS (HIGH PRESSURE) BALLAST SYSTEMS SSTL WATER WATER AIR/N2 AIR/N2 WATER WATER WATER WATER NO NO N/A N/A NO NO NO NO NO NO NO NO NO ACC.TO P&ID ACC.TO P&ID NO NO NO N/A N/A NO YES YES NO NO FOREIGN MATERIALS NORMAL NO FOREIGN MATERIALS NORMAL NO FOREIGN MATERIALS NORMAL NO FOREIGN MATERIALS NORMAL NO FOREIGN MATERIALS SEE NOTE 4 ISO 4406,17/14 SEE NOTE 4 ISO 4406,17/14 NORMAL NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NORMAL

51 52

SSTL C.S SSTL

WATER WATER WATER

NO YES NO

NO NO NO

NO NO NO

NORMAL NORMAL NORMAL

53 55

FRESH WATER SYSTEM STEAM,CONDENSATE AND HOT WATER SYSTEM

SSTL C.S

WATER WATER

NO YES

NO NO

NO NO

NORMAL NORMAL

NORSOK Standard

Page 25 of 27

Piping Fabrication, Installation, Flushing and Testing Annex B

SYSTEM SYSTEM DESCRIPTION PIPE FLUSH TEST W/ CHEM. DRYING PRESERMATR. WATER/ PRESERV. CLEAN. VATION AIR FLUID YES/NO SSTL 56 57 60 OPEN DRAIN SYSTEM CLOSED DRAIN SYSTEM DRY AND WET BULK LOADING C.S C.S C.S SSTL 61 62 JET FUEL SYSTEM DIESEL OIL SYSTEM SSTL C.S SSTL 63 64 65 66 COMPRESSED AIR SYSTEM INERT PURGE SYSTEM SSTL SSTL WATER WATER WATER WATER WATER WATER WATER WATER AIR/N2 AIR/N2 WATER WATER WATER WATER WATER NO NO NO YES NO NO YES NO N/A N/A NO YES NO NO NO NO NO NO NO NO ACC.TO P&ID NO NO NO NO ACC.TO P&ID NO NO NO NO NO NO NO NO NO YES NO NO N/A N/A YES NO NO NO NO NORMAL NORMAL NORMAL NORMAL NORMAL LIQUID FILLED NORMAL NORMAL NORMAL NORMAL LIQUID FILLED NORMAL NORMAL NORMAL NORMAL FINAL CLEANING/ REQUIRED CLEANLINESS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS ISO 4406 17/14 NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS HOT OIL FLUSH ISO 4406 15/12 NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS NO FOREIGN MATERIALS REMARKS

L-CR-004 Rev. 1, January 1996

HYDRAULIC POWER SYSTEM SSTL SEWAGE TREATMENT C.S SSTL

70 71

FIRE AND GAS DETECTION FIRE WATER SYSTEM

SSTL SSTL

NORSOK Standard

Page 26 of 27

Piping Fabrication, Installation, Flushing and Testing Annex B

SYSTEM SYSTEM DESCRIPTION PIPE FLUSH TEST W/ CHEM. DRYING PRESERMATR. WATER/ PRESERV. CLEAN. VATION AIR FLUID YES/NO SSTL WATER NO NO NO NORMAL FINAL CLEANING/ REQUIRED CLEANLINESS NO FOREIGN MATERIALS NO FOREIGN MATERIALS HOT OIL FLUSH ISO 4406 17/14 HOT OIL FLUSH ISO 4406 16/13 ISO 4406 15/12 REMARKS

L-CR-004 Rev. 1, January 1996

72

MISCELLANEOUS FIRE FIGHTING SYSTEMS

77

HEATING AND VENTILATION SSTL LUBE OIL SYSTEM SEAL OIL SYSTEM SEAL GAS SYSTEM SSTL SSTL SSTL

WATER WATER WATER WATER

NO NO NO NO

NO ACC.TO P&ID ACC.TO P&ID ACC.TO P&ID

NO YES YES YES

NORMAL LIQUID FILLED LIQUID FILLED SEE NOTE 4

Notes: 1. SSTL means 316, 6MO, duplex etc. 2. Cleanliness to be verified by visual inspection. 3. If commissioning starts later than 3 months after internal treatment, drying, represervation with preservation fluid or other acceptable methods shall be considered. See also Note 4. 4. Where commissioning are later than 3 months after chemical cleaning, system shall be preserved with nitrogen, overpressure 0.5 bar. Other alternatives are subject to agreement.

NORSOK Standard

Page 27 of 27

Anda mungkin juga menyukai

- NORSOK Piping Details Standard for Instrument ConnectionsDokumen41 halamanNORSOK Piping Details Standard for Instrument ConnectionsAli BariBelum ada peringkat

- Pi Ups 1004Dokumen39 halamanPi Ups 1004JOEL ARNAO CORTEGANABelum ada peringkat

- Iit MumbaiDokumen243 halamanIit MumbaiYogesh JagdaleBelum ada peringkat

- Pressure Drop of Full Bore Vs Reduced Bore Ball ValvesDokumen1 halamanPressure Drop of Full Bore Vs Reduced Bore Ball ValvesArt G. EnziBelum ada peringkat

- UI 9253-06 Part 1 E (2009-11) - WeldingAndWeldExaminationOfMetallicPipingDokumen12 halamanUI 9253-06 Part 1 E (2009-11) - WeldingAndWeldExaminationOfMetallicPipingmahmoud_allam3100% (1)

- Piping Engineering Course OverviewDokumen2 halamanPiping Engineering Course Overviewmayur_lanjewar0% (1)

- Vacuum Piping Guide 02 09 08 - ENGDokumen30 halamanVacuum Piping Guide 02 09 08 - ENGChristopher BrownBelum ada peringkat

- Basics of Piping Engineering - Online Certificate CourseDokumen2 halamanBasics of Piping Engineering - Online Certificate CourseSharjeel Aslam FaizBelum ada peringkat

- Fluor Piping TraingTOCDokumen1 halamanFluor Piping TraingTOCSergio SmithBelum ada peringkat

- Piping Engineering NotesDokumen46 halamanPiping Engineering NoteslightsonsBelum ada peringkat

- Pressure Surges and Air Valve Specification PDFDokumen22 halamanPressure Surges and Air Valve Specification PDFTONBelum ada peringkat

- Piping Material Take Off-MTO, BOM, BOQ & MTO Stages (With PDFDokumen5 halamanPiping Material Take Off-MTO, BOM, BOQ & MTO Stages (With PDFDhiren PatelBelum ada peringkat

- Section IDokumen58 halamanSection IARAVINDRAJ V RBelum ada peringkat

- Steam Tracing StudyDokumen4 halamanSteam Tracing StudypalluraviBelum ada peringkat

- 312013145817piping Design Engineering With PDMS Training CourseDokumen4 halaman312013145817piping Design Engineering With PDMS Training CourseAsan IbrahimBelum ada peringkat

- Online Piping and Caesar Course SyllabusDokumen10 halamanOnline Piping and Caesar Course Syllabusm 418Belum ada peringkat

- Diaphragm ValveDokumen10 halamanDiaphragm Valveshganesh81Belum ada peringkat

- DGS 1300 160 Bolt TorquingDokumen12 halamanDGS 1300 160 Bolt TorquingMcmiltondmordom100% (1)

- PDS Tutorials: Basic Sketching CommandsDokumen133 halamanPDS Tutorials: Basic Sketching CommandsMahendran Kuppusamy100% (3)

- Pump & Pump Piping PresentationDokumen55 halamanPump & Pump Piping PresentationEduard Gonzalo Rojas Cervantes100% (1)

- Reviewed Design Input for QIPP Slop Tank FabricationDokumen2 halamanReviewed Design Input for QIPP Slop Tank FabricationMathivanan AnbazhaganBelum ada peringkat

- Steam Trap and Drain Trap FunctionsDokumen23 halamanSteam Trap and Drain Trap FunctionsMallela Sampath KumarBelum ada peringkat

- PIPENET SPRAY/SPRINKLER MODULE VERSION 1.6.0 RESULTSDokumen23 halamanPIPENET SPRAY/SPRINKLER MODULE VERSION 1.6.0 RESULTSLucious LightBelum ada peringkat

- Piping Engineering (Full Time)Dokumen2 halamanPiping Engineering (Full Time)vedangBelum ada peringkat

- 2009 Ashrae Handbook - Fundamentals (Si Edition)Dokumen16 halaman2009 Ashrae Handbook - Fundamentals (Si Edition)Christian Andrés Cortés Suárez100% (1)

- Zinq - AnalysisDokumen116 halamanZinq - AnalysisAimiBelum ada peringkat

- Avk Saudi National Price ListDokumen46 halamanAvk Saudi National Price Listjanpaul2481Belum ada peringkat

- Process EngineeringDokumen2 halamanProcess EngineeringSuvidya Institute of TechnologyBelum ada peringkat

- PDMS Basic CommandsDokumen2 halamanPDMS Basic CommandsSuhas MvBelum ada peringkat

- PDMS Shortcuts - The Piping Engineering WorldDokumen10 halamanPDMS Shortcuts - The Piping Engineering WorldsanmiteBelum ada peringkat

- Instrument Symbols GuideDokumen5 halamanInstrument Symbols GuideWahyuDimantaraBelum ada peringkat

- Bulk Modulus and Fluid ElasticityDokumen3 halamanBulk Modulus and Fluid ElasticitycookienutBelum ada peringkat

- Process Safeguarding - PSE02Dokumen2 halamanProcess Safeguarding - PSE02Sarfraz AliBelum ada peringkat

- List of Valve StandardsDokumen8 halamanList of Valve StandardsMuthu BalamuruganBelum ada peringkat

- Valve World Magazine PDFDokumen4 halamanValve World Magazine PDFshan07011984Belum ada peringkat

- Theoretical overview of surge analysesDokumen14 halamanTheoretical overview of surge analysesdBelum ada peringkat

- NEOPRSP001WI017 - Rev. 01 - Pages 07 - Cleaning in Place of RO System Work InstructionsDokumen7 halamanNEOPRSP001WI017 - Rev. 01 - Pages 07 - Cleaning in Place of RO System Work Instructionsalialharbi021Belum ada peringkat

- Piping and Valves - Fundamentals For The Water and Wastewater Maintenance Operator Series - Frank R. Spellman, Joanne Drinan (2001)Dokumen185 halamanPiping and Valves - Fundamentals For The Water and Wastewater Maintenance Operator Series - Frank R. Spellman, Joanne Drinan (2001)guillermoBelum ada peringkat

- Pipeline Design: PagesDokumen32 halamanPipeline Design: Pagesdennykvg100% (1)

- Catalogue of 3051SFCDokumen50 halamanCatalogue of 3051SFCKarthikeyan LakshminarayananBelum ada peringkat

- Piping Designers Vessel OrientationDokumen13 halamanPiping Designers Vessel OrientationkazishidotaBelum ada peringkat

- Automated Valves - GeneralDokumen19 halamanAutomated Valves - Generalhafizi07Belum ada peringkat

- 5060 Piping and ValvesDokumen9 halaman5060 Piping and Valvesnmosilva100% (1)

- KV CV Flow Coefficient - ValviasDokumen2 halamanKV CV Flow Coefficient - Valviasdevika11Belum ada peringkat

- Control Valve Products CatalogDokumen6 halamanControl Valve Products CataloghermanBelum ada peringkat

- Piping fabrication standardsDokumen10 halamanPiping fabrication standardsGabrielPantilicaBelum ada peringkat

- NORSOK Structural Steel Fabrication StandardDokumen0 halamanNORSOK Structural Steel Fabrication StandardmastorfaizalBelum ada peringkat

- ASI Steelwork Fabrication Erection Code of Practice V1.0-UnlockedDokumen168 halamanASI Steelwork Fabrication Erection Code of Practice V1.0-UnlockedZac Francis Daymond0% (1)

- Ductwork SystemsDokumen28 halamanDuctwork SystemsSurekanth ManikkavasagamBelum ada peringkat

- Fabrication ProcedureDokumen16 halamanFabrication ProcedureAryo WicaksonoBelum ada peringkat

- Norsok L-CR-003Dokumen41 halamanNorsok L-CR-003asoka.pwBelum ada peringkat

- Piping Design, Layout and Stress Analysis: Foreword 1 Scope 2 Normative References 3 Definitions and AbbreviationsDokumen15 halamanPiping Design, Layout and Stress Analysis: Foreword 1 Scope 2 Normative References 3 Definitions and AbbreviationsWalid LabidiBelum ada peringkat

- WSA 109-2011 Flange GasketsDokumen39 halamanWSA 109-2011 Flange GasketsTon Phichit100% (1)

- Norsok Materials GuideDokumen37 halamanNorsok Materials GuideYomara Samantha Hernandez LaureanoBelum ada peringkat

- NORSOK L-002 Edition 3, July 2009 PDFDokumen36 halamanNORSOK L-002 Edition 3, July 2009 PDFKarthick VenkatswamyBelum ada peringkat

- Project Standards and Specifications Piping Construction Standards Rev01Dokumen10 halamanProject Standards and Specifications Piping Construction Standards Rev01hiyeonBelum ada peringkat

- Cathodic Protection: Foreword 1 Scope 2 Normative References 3 Definitions 4 Cathodic Protection DesignDokumen11 halamanCathodic Protection: Foreword 1 Scope 2 Normative References 3 Definitions 4 Cathodic Protection Designvvraghu12Belum ada peringkat

- NORSOK STANDARD CATHODIC PROTECTIONDokumen14 halamanNORSOK STANDARD CATHODIC PROTECTIONbreeeeezzzzzeBelum ada peringkat

- Welding Specification for Carbon and Alloy Steel PipingDokumen82 halamanWelding Specification for Carbon and Alloy Steel PipingsendelkrBelum ada peringkat

- Design Guidelines for Surface Mount TechnologyDari EverandDesign Guidelines for Surface Mount TechnologyPenilaian: 5 dari 5 bintang5/5 (1)

- Fees For ChildbirthDokumen1 halamanFees For ChildbirthWissam JarmakBelum ada peringkat

- Aksa Master Pricelist 2014Dokumen1 halamanAksa Master Pricelist 2014Wissam JarmakBelum ada peringkat

- FEM 2012 Price List Effective 1 Oct 2012 Version 10 With Service LevelsDokumen21 halamanFEM 2012 Price List Effective 1 Oct 2012 Version 10 With Service LevelsWissam JarmakBelum ada peringkat

- Kito Crane: End Carriage, Geared Motor, Peripheral EquipmentDokumen40 halamanKito Crane: End Carriage, Geared Motor, Peripheral EquipmentVenu GopalBelum ada peringkat

- Sound AttenuatorsDokumen10 halamanSound AttenuatorsArumugam MurugesanBelum ada peringkat

- PricelistDokumen184 halamanPricelistWissam JarmakBelum ada peringkat

- 800291pricelist PDFDokumen48 halaman800291pricelist PDFWissam Jarmak100% (1)

- Under Running Single Girder PDFDokumen8 halamanUnder Running Single Girder PDFWissam JarmakBelum ada peringkat

- 2016 WiloUSA ListPricing BuildingServices 0216Dokumen52 halaman2016 WiloUSA ListPricing BuildingServices 0216Wissam JarmakBelum ada peringkat

- 800291pricelist PDFDokumen48 halaman800291pricelist PDFWissam Jarmak100% (1)

- Gorbel PDFDokumen42 halamanGorbel PDFWissam JarmakBelum ada peringkat

- Overhead Munck Cranes - Crane and Trolleys Own WeightDokumen8 halamanOverhead Munck Cranes - Crane and Trolleys Own WeightWissam JarmakBelum ada peringkat

- Crane Components: Technical CatalogueDokumen30 halamanCrane Components: Technical CatalogueWissam JarmakBelum ada peringkat

- Air Release Vacuum Breaker ValveDokumen16 halamanAir Release Vacuum Breaker ValveLao Zhu100% (1)

- Guidance Fuel Storage May08 PDFDokumen35 halamanGuidance Fuel Storage May08 PDFWissam JarmakBelum ada peringkat

- Goulds Pump Selection GuideDokumen24 halamanGoulds Pump Selection GuidecladonellBelum ada peringkat

- Regulators PDFDokumen2 halamanRegulators PDFWissam JarmakBelum ada peringkat

- 1500 GPMDokumen5 halaman1500 GPMWissam JarmakBelum ada peringkat

- Leila Delivery MenuDokumen5 halamanLeila Delivery MenuWissam JarmakBelum ada peringkat

- Crane Components: Technical CatalogueDokumen30 halamanCrane Components: Technical CatalogueWissam JarmakBelum ada peringkat

- ABUS Overhead Cranes Design GuideDokumen12 halamanABUS Overhead Cranes Design GuideCelestino LucioBelum ada peringkat

- BAC MaintenanceVL MVLv10EN PDFDokumen16 halamanBAC MaintenanceVL MVLv10EN PDFWissam JarmakBelum ada peringkat

- Sound AttenuatorsDokumen10 halamanSound AttenuatorsArumugam MurugesanBelum ada peringkat

- GUYER 2012 Introduction To Pumping Stations For Water Supply Systems PDFDokumen42 halamanGUYER 2012 Introduction To Pumping Stations For Water Supply Systems PDFKaniz PriyangkaBelum ada peringkat

- Water Air Valve Lynx 3F RFPDokumen4 halamanWater Air Valve Lynx 3F RFPWissam JarmakBelum ada peringkat

- FIRE KiddeHoseReelsandCabinets PDFDokumen48 halamanFIRE KiddeHoseReelsandCabinets PDFVaidya PanditBelum ada peringkat

- Nominal Capacity Data: M100 RangeDokumen1 halamanNominal Capacity Data: M100 RangeWissam JarmakBelum ada peringkat

- Forward Osmosis - Principles, Applications, and Recent DevelopmentsDokumen18 halamanForward Osmosis - Principles, Applications, and Recent DevelopmentsYuMdzaBelum ada peringkat

- 2 Session 1opening Speech by ITA COSUF Chairman Final2 CompatibiliteitsmodusDokumen20 halaman2 Session 1opening Speech by ITA COSUF Chairman Final2 CompatibiliteitsmodusWissam JarmakBelum ada peringkat

- Bermad Fire ProtectionDokumen48 halamanBermad Fire ProtectionJay JayBelum ada peringkat

- Pressure Vessel Fabrication InspectionDokumen82 halamanPressure Vessel Fabrication InspectionHrishikesan100% (3)

- JX Nippon Oil & Gas Exploration (Malaysia) Limited INSPECTION TEST RECORD (ITR) - A Piping Work CompletionDokumen21 halamanJX Nippon Oil & Gas Exploration (Malaysia) Limited INSPECTION TEST RECORD (ITR) - A Piping Work CompletionAmyBelum ada peringkat

- Astm 999Dokumen12 halamanAstm 999MohammedRafeeqBelum ada peringkat

- Precision Media Blaster: Operation and Maintenance ManualDokumen50 halamanPrecision Media Blaster: Operation and Maintenance ManualIvan Roco100% (1)

- Commissioning Procedure For A Boiler PDFDokumen24 halamanCommissioning Procedure For A Boiler PDFpothan83% (6)

- Anexo T - API 650Dokumen4 halamanAnexo T - API 650ChristiaanBelum ada peringkat

- Hydrant Shell Tank Calculation Dia.5.82mDokumen20 halamanHydrant Shell Tank Calculation Dia.5.82mmozpcreationBelum ada peringkat

- Pressure Testing Codes and Best PracticesDokumen26 halamanPressure Testing Codes and Best Practicesriysall100% (1)

- Hydrostatic Test Water Management - 1996 PDFDokumen175 halamanHydrostatic Test Water Management - 1996 PDFPaolo FarinelliBelum ada peringkat

- Fabrication Procedure DMW-4820M00250-000120-19Dokumen8 halamanFabrication Procedure DMW-4820M00250-000120-19mohd as shahiddin jafriBelum ada peringkat

- P3-PTP-001 R0 Piping Pressure Test ProceduresDokumen8 halamanP3-PTP-001 R0 Piping Pressure Test ProceduresHengBelum ada peringkat

- ASME B31.3-2016 Leak Test RequirementsDokumen5 halamanASME B31.3-2016 Leak Test RequirementsGulzar AliBelum ada peringkat

- Rehabilitation of Sawfar Water Transmission Pipe Construction SpecificationsDokumen34 halamanRehabilitation of Sawfar Water Transmission Pipe Construction Specificationsayaz hasanBelum ada peringkat

- Karam S.mansour 10 1Dokumen6 halamanKaram S.mansour 10 1KaramSobhyBelum ada peringkat

- Oisd RP 167Dokumen28 halamanOisd RP 167akhilendraa6221100% (4)

- RCC-M IntroDokumen16 halamanRCC-M Introeuric82100% (2)

- CV-MICHAEL (QA QC Quality Engineer Const & Procurement)Dokumen5 halamanCV-MICHAEL (QA QC Quality Engineer Const & Procurement)Mike PushBelum ada peringkat

- ISA 75.19.01 Hydrostatic Testing of Control Valves PDFDokumen34 halamanISA 75.19.01 Hydrostatic Testing of Control Valves PDFChristianGuerreroBelum ada peringkat

- 0031R 50 D PR 004 Hydrotest Pre Commissioning Procedure Rev. 0Dokumen45 halaman0031R 50 D PR 004 Hydrotest Pre Commissioning Procedure Rev. 0bonnico100% (1)

- P Qac Pro 240 39467 CDokumen24 halamanP Qac Pro 240 39467 Ccsc EXPERTISEBelum ada peringkat

- Pdvsa: Material Technical SpecificationDokumen14 halamanPdvsa: Material Technical SpecificationAryelys PadillaBelum ada peringkat

- Final Standard 6 InchDokumen8 halamanFinal Standard 6 InchRaman Kumar100% (1)

- ESR-Suctionpot AssemblyDokumen10 halamanESR-Suctionpot Assemblybmanojkumar16Belum ada peringkat

- Asme B31.8Dokumen8 halamanAsme B31.8deepndeepsi100% (1)

- Saudi Aramco Typical Inspection Plan: Mechanical Hydrostatic Testing of Pipelines SATIP-A-004-03Dokumen3 halamanSaudi Aramco Typical Inspection Plan: Mechanical Hydrostatic Testing of Pipelines SATIP-A-004-03Fortunato SegubanBelum ada peringkat

- 04 Samss 048Dokumen11 halaman04 Samss 048SamiBelum ada peringkat

- Test and Drain ValveDokumen4 halamanTest and Drain ValveAhrian BenaBelum ada peringkat

- Form 72-Fire Hydrant and Sprinkler System Periodic Testing and MaintenanceDokumen3 halamanForm 72-Fire Hydrant and Sprinkler System Periodic Testing and MaintenanceSatrio Budi Prakosa RachmanBelum ada peringkat

- 1117715-Tecpetrol Sa CDDokumen2.054 halaman1117715-Tecpetrol Sa CDJorge KarlisBelum ada peringkat