Cement Evaluation Tool: A New Approach To Cement Evaluation

Diunggah oleh

Mauro Costa0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

45 tayangan7 halamanA new generation of cement and casing evaluation tools is being introduced. The design described in this paper exploits the principle of casing thickness resonance. It provides a measurement of cement presence and strength, which is largely insensitive to microannulus.

Deskripsi Asli:

Judul Asli

00010207

Hak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniA new generation of cement and casing evaluation tools is being introduced. The design described in this paper exploits the principle of casing thickness resonance. It provides a measurement of cement presence and strength, which is largely insensitive to microannulus.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

45 tayangan7 halamanCement Evaluation Tool: A New Approach To Cement Evaluation

Diunggah oleh

Mauro CostaA new generation of cement and casing evaluation tools is being introduced. The design described in this paper exploits the principle of casing thickness resonance. It provides a measurement of cement presence and strength, which is largely insensitive to microannulus.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 7

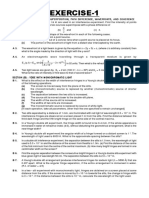

Cement Evaluation Tool:

A New Approach to Cement Evaluation

Benoit Froelich, Etudes et Production Schlumberger

A. Dumont, Etudes et Production Schlumberger

Dennis Pittman, Etudes et Production Schlumberger

Bruno Seeman, SPE, Etudes et Production Schlumberger

Summary

A new generation of cement and casing evaluation tools

is being introduced with construction permitting detailed

examination of cement behind casing. Classical cement

bond logging systems measure amplitude or attenuation

of plate waves propagating axially along the casing. The

design described in this paper exploits the principle of

casing thickness resonance to overcome previous tool

limitations. Applications and results from field tests il-

lustrate the advantages of this approach.

Cement bond logging achieves its greatest utility when

it provides the production engineer with precise indica-

tions of cement strength and distribution around the cas-

ing. Zone isolation is of critical importance in produc-

tion. Previous logging systems have yielded measures of

cement bond that were circumferential averages of ce-

ment quality. These were difficult to interpret. Addi-

tionally, they were sensitive to the degree of shear cou-

pling between pipe, cement, and formation and thus

were affected by microannulus. The cement evaluation

tool (CET) described here overcomes these difficulties.

It provides a measurement of cement presence and

strength, which is largely insensitive to microannulus.

Its log output is interpreted easily. Tool design allows

examination of the casing circumferentially at each

depth. Impedance behind casing is measured.

Laboratory calibration measurements allow this to be

presented in terms of cement compressive strength. Ce-

ment channels are distinguished easily, and a zone isola-

tion indicator can be presented. Additionally, casing in-

ternal diameter and distortion are displayed.

European and North American field tests have been

completed, and performance for a variety of well condi-

tions is discussed. The ability of the tool to identify

channels is confirmed. Sequential runs with and without

excess pressure demonstrate immunity to microannulus

in cases where CBL is affected but where microannulus

is small enough to prohibit hydraulic communication.

Geometrical measurements have been good indicators of

0149-2136/82/0081-0207$00.25

Copyright 1982 Society of Petroleum Engineers of AIME

AUGUST 1982

casing deformation and have identified casing corrosion

and wear.

Introduction

Conventional cement bond logs (CBL's) are run in cased

hole using a sonic logging tool in a single receiver mode

(or a simplified sonde specially designed for CBL). The

transmitter and receiver are more or less omnidirec-

tional, with an operating frequency around 20 kHz. The

most rapid wave path from transmitter to receiver is a

plate-type mode in the casing with a compressional wave

in the mud path from transmitter to casing and casing to

receiver. At this frequency, the casing is very thin with

respect to the wavelength, and the velocity is close to the

compressional velocity in steel. I Attenuation of this

wave depends mainly on loss of energy to the materials

on either side of the casing (mud, cement) and since the

particle movement at the surfaces of the casing is

predominantly parallel to the casing axis, 2 more loss oc-

curs through shear coupling to a solid medium (cement)

than to a liquid (mud).

Thus, the amplitude of the first ~ r r i v a l at the receiver is

indicative of the presence of cement around the casing:

low amplitude indicates cement, and high amplitude in-

dicates free pipe.

There are several drawbacks to this system.

1. The omnidirectional characteristics imply good cen-

tralization to ensure simultaneous first arrivals from all

azimuths.

2. The omnidirectional characteristics make it difficult

to distinguish high-strength cement with a channel

(hydraulic communication) from an even distribution of

low-strength cement (no communication) because the

amplitude may be the same in both cases.

3. The necessity for good shear coupling to the cement

implies practically free pipe amplitude in the case of a

microannulus.

4. In hard formations where the compressional veloci-

ty is higher than the plate mode velocity in steel, the first

arrival is no longer the casing wave, and the calibration

is no longer valid.

1835

A B

r---------

TRANSDUCER

Fig. 1-Ultrasonic wave propagation with an incident wave

normal to the steel wall.

The transit time measurement enables identification of

poor centralization or fast formations, and the addition of

a variable density log improves the interpretation of

channels, fast formations, and microannulus from a

qualitative point of view. Also, some newer, specialized

multitransducer CBL tools give a better quality attenua-

tion measurement, but the drawbacks resulting from the

type of wave propagation used are not eliminated.

The CET is an entirely new approach to cement quali-

ty evaluation, designed to overcome the drawbacks of

the CBL. It is a high-frequency ultrasonic device with

eight focused transducers examining different azimuths

of the casing with very fine vertical resolution, thus

enabling a channel to be identified clearly. The

transducers act as transmitters and receivers, each

transducer emitting a short pulse of acoustic energy and

then receiving the echo from the casing. The short, light,

rigid sonde is centralized easily. The type of wave prop-

agation used in a compressional wave normal to the cas-

ing surfaces thus is not affected by a microannulus that is

small with respect to the wavelength, and reflections

from the formation arrive later than from the cement and

thus can be distinguished.

The response of the tool is dependent on the acoustic .

impedance of the cement (product of density and

acoustic velocity), and an empirical relationship has

been established experimentally between this elastic

parameter and the compressive strength for oil well ce-

ment. Thus, the log can be calibrated directly in cement

compressive strength, and the azimuthal separation of

the transducers enables a pictorial representation of ce-

ment distribution around the casing. In addition, the time

between firing and reception of the first echo, associated

with a measurement of mud transit time, enables the

1836

. ~

..

..

'E

50

50

A

A

FREE PIPE

T sec

CEMENTED PIPE

100 T JI C

Fig. 2-lmpulse response for a free and a cemented pipe,

0.47 in. (12 mm) thick .

. distance of each transducer from the casing to be

calculated; therefore, four casing ID measurements can

be displayed, and the sonde position is known

accurately.

. Principle

The basic idea is to make the casing resonate in its

thickness mode. The presence of cement behind the cas-

ing is detected as a rapid damping of this resonance,

while a lack of cement gives a long resonance decay.

The geometric configuration is shown in Fig. I. The

. ultrasonic transducer, both emitter and receiver, is ap-

proximately 2 in. (5 cm) from the casing wall and sends

repeatedly a short ultrasonic pulse toward the casing; the

ultrasonic wave front can be considered as plane and

parallel to the steel interface.

Impulse Response

Let us first consider that this pulse is infinitely short.

After traveling through the fluid, the main part of this

pulse is reflected back to the transducer by the first inter-

face, A, but a small fraction of the energy enters the cas-

ing wall and is reflected back and forth inside it with part

of the energy transmitted outside at each reflection on A

or B.

The impulse response displayed on Fig. 2 is thus a

succession of impulses separated by twice the travel time

through the steel wall; each impulse amplitude is a func-

tion of the acoustic impedances in the three media (inside

fluid, steel, and outside medium). The first peak is ap-

proximately 10 times larger than the others. The follow-

ing impulses are of opposite sign, and their amplitudes

form an exponential decay. In the case of free pipe, with

water on both sides, the decay is slow. With cement the

JOURNAL OF PETROLEUM TECHNOLOGY

decay is fast because the acoustic coupling between steel

and the outside medium is better.

For typical casing thickness, the impulse response

lasts for approximately 50 /1-S, which corresponds to the

2-in. (5-cm) standoff for the transducer.

500-kHz Excitation

The impulse response would be obtained with a high-

frequency transducer and excitation. However, the tool

must operate in fluids, such as drilling muds, that are

very attenuative for high-frequency ultrasound, and most

of the energy would be lost. The transducers are better

operated at the lowest possible frequency, which is the

casing thickness resonance frequency with period LI.

The usual casing thickness range is from 0.2 to 0.6 in.

(5 to 15 mm). The thinnest casing corresponds to the

highest resonance frequency, 600 kHz. When the casing

wall thickness increases, this frequency decreases;

however, the casing also can vibrate on the harmonics or

multiples of the fundamental. This means that the

ultrasonic pulse emitted by the transducer must have a

frequency bandwidth extending from 600 kHz to half-

this value, 300 kHz, so that any casing encountered will

resonate on its fundamental or its harmonics.

Fig. 3a shows such a pulse as reflected from a single

interface; its length is approximately 6 /1-S, its 6-dB band-

width 270 to 630 kHz. The reflection from a casing is the

convolution of this pulse shape with the casing impulse

response (Fig. 3b and 3c).

Measurement and Calibration

To measure the properties of the material behind the cas- .

ing, the received waveform is rectified and integrated

within a gate that covers part of the resonance decay .. '

This gate is set so that the contrast between free and

cemented pipe is maximum. The output voltage, R, of

the gate is a function of the acoustic impedance of the

medium behind the casing. This function is represented

in Fig. 4 as calculated for a 0.35-in (9-mm) casing. R is

normalized to one when water is also outside the pipe. It

can be seen that the response is roughly 50% higher

when gas is behind the casing (very low acoustic im-

pedance). This is enough to allow gas detection. When

the acoustic impedance, z, increases above 70x 10

6

Ibm/ft-sec (lOx 10

6

kgm

2

/s), the slope of the curve

and the sensitivity become very small, but this is outside

the usual range of cement acoustic impedances.

The output can be transformed from acoustic im-

pedance into cement compressive strength, defined as

the maximum weight supported by a cubic sample before -

breaking. An empirical relationship (Fig. 5) has been

established for this with samples made of Class G ce-

ment mixed with various proportions of water and ad-'

ditives such as bentonite. The relation between acoustic

impedance and compressive strength is approximately

linear from 0 to 10,000 psi (0 to 69 MPa). Thus, it is

possible to convert the response, R, from acoustic im-

pedance to compressive strength of cement in front of the

transducer.

Samples with significantly different compositions also ~ .

were measured, such as pozzolan cement and

lightweight cement filled with glass microspheres. It was

found that these samples depart from the curve of Fig. 5,

AUGUST 1982

THIN PLATE

~ ~ a

1

R

..

1;

CEMENTED CASING 9 mm THICK

b

FREE CASING 9 mm THICK

Fig. 3-Typical ultrasonic waveform.

5 15 z

10' kg-m

2

/s

Fig. 4-Tool response vs. acoustic impedance of the medium

behind casing. Curve normalized to one for water

behind casing.

1837

5

o

COMPRESSIVE STRENGTH

10' PSI

5

+

ACOUSTIC IMPEDANCE

10 kg m'/s

10

Fig. 5-Experimental relation between acoustic impedance

and compressive strength of cement.

so different relationships should be used for unusual

slurry compositions.

Spurious Effects

In the discussion so far, it has been assumed that the

medium behind casing is infinite. In an actual well, finite

thickness layers must be considered.

The microannulus is a small water gap between pipe

and cement, which occurs when the pressure inside the

pipe is released after cement setting. From mechanical

data of casings and possible pressure changes, the

microannulus can be estimated to be less than 0.004 in.

(0.1 mm); such a thickness is thought to prevent any

communication. The theoretical and experimental effect

of this water gap is shown in Fig. 6. It is seen to be

negligible below 0.004 in. (0.1 mm), such a length being

only a small fraction of the ultrasonic wavelength

in water. This lack of sensitivity to water microannulus

is confirmed by actual logs run in wells where microan-

nulus is detected with conventional CBL as a large

amplitude change between logs recorded with and

without overpressure inside the casing. On the contrary,

this pressure has no effect on the CET response, which

thus requires only one pass in the well instead of two.

Typical thickness for the cement sheet is around 1 in.

(2.5 cm). As shown in Fig. 1, part of the acoustic energy

is transmitted through the steel wall to this cement sheet.

If the cement is nonattenuative and if the medium behind

provides an acoustic impedance contrast with the cement

and a smooth interface, part of the energy will be

reflected back to the transducer. Such a situation may oc-

cur in fast formations or double casing strings. For a

typical value of cement velocity, the time delay with

respect to the main echo is only about 20 J.ts. Thus, this

energy interferes with the normal resonance decay and

1838

R

2

1 FREE PIPE

II

'.t(

I

I

/

/

__ __ ________ __

o mm

Fig. 6-Experimental and computed effect of microannulus

on tool response.

the reading, R, is increased, leading to an apparent

decrease in cement quality.

This problem is not very common because cement is

usually attenuative. Laboratory results show that at-

tenuation is correlated with compressive strength-the

better the cement, the lower the attenuation. However, a

solution has been worked out to detect such formation

reflections: In addition to the regular Gate G 1, a second

gate, G2, is set with a short delay (Fig. 3) after the main

echo. The outputs from the two gates, R I and R

2

, are

compared and enable the detection of a nonexponential

decay, characteristic of formation reflections. Knowing

that formation reflections mean low attenuation cement,

it can be deduced that the cement quality is high, and a

default value of 1,000 psi (6.9 MPa) can be set for the

compressive strength at that point.

The effect of tool eccentering has been studied in the

laboratory with different casing diameters. When the

transducer is moved away from the center, the ultrasonic

beam is not normal to the casing wall and is reflected

away from the transducer. Fig. 7 shows the effect of

transducer eccentering on the gate output, R, in a typical

casing. The maximum eccentering not detrimental to log

quality ranges from 0.2 in (5 mm) in 5-in. (12.7-cm) cas-

ing to 0.4 in. (10 mm) in 9%-in. (24-cm) casing. This ac-

curacy is achieved easily with the new sonde design.

Tool and Log Description

Eight transducers are positioned on the sonde at 45

0

from one another in a helical path. These transducers are

about 1 in. (2.54 cm) in diameter; this size is also the

size of the illuminated spot on the casing because the

ultrasonic beam is almost cylindrical for the frequency of

interest. These transducers are fired in sequence and

multiplexed in reception; all data are put on depth by the

JOURNAL OF PETROLEUM TECHNOLOGY

TOOL RESPONSE R

FREE I CASING

,

I

I

I

I

,

I

CEMENTjED CASING

-10 -8 -6 -4 -2 0 2 4 6 8 10mm

TRANSDUCER EXCENTERING

Fig. 7-Effect of transducer eccentering on its response, R, in

7-in. (17.8-cm) casing, 20 Ibf (89 N).

surface equipment. A ninth transducer is in the axial

direction (Fig. 8), with a mirror fixed at a known

distance in front of it; its transit time measurement is

used to monitor continuously the velocity of sound in

the fluid.

Two different mandrels are available: a 3o/s-in

(8.6-cm) diameter for casings from 4V2 to 5Vz in. (11.4

to 14 cm) and a 4-in. (lO-cm) diameter for casings from

5

1

h to 9% in. (14 to 24 cm). On this last sonde, the posi-

tion of the transducers can be adjusted so that the stand-

off remains 2 in. (5 cm), even in large-diameter pipe;

this reduces the effect of ultrasonic attenuation in high-

density mud. The sonde body is supported at each end by

springs and roller centralizers, which provide efficient

centering up to 75 deviation without damage to the cas-

ing surface. The electronic signal processing and

telemetry cartridge is located above the sonde and is

mechanically decoupled from it by flex joints in the case

of deviated wells.

The log is divided into three tracks; the left track is

devoted to distance measurements from conversion of

transit times into distances with the mud velocity given

by the ninth transducer. One output is the mean diameter

as computed from the average of the eight transit times,

with a resolution close to 0.004 in. (0.1 mm). The casing

ovality is the difference between largest and smallest

AUGUST 1982

BULK

FIXED TRANSDUCER _--r::"'EtJ

-fiiiilt=l=t=---- MOVABLE TRANSDUCER

ADJUSTING SCREW

TRANSDUCER

['

NTRALIZER

003%/1

COMPENSATION

Fig.8-Tool.

diameters and gives a sensitive indication of casing cor-

rosion, wear, or collapse. The third output is the tool

centering inside the casing to check proper

centralization.

The right track can be viewed as a map of the cement

behind casing. At each depth the shading is proportional

to cement compressive strength from white (free pipe) to

black [good cement, with compressive strength typically

above 3,500 psi (24 MPa)]. The compressive strength is

interpolated linearly between two transducers that are

supposed to make point measurements on the cir-

cumference. At the far right, an optional display is used

to identify formation reflections or gas detection; eight

lines represent the eight transducers, and each line is nor-

mally narrow. Formation reflection is shown as a heavy

line and gas behind casing by two parallel narrow lines.

The middle track shows two compressive strength

curves, the best and the worst. These curves are com-

puted from the transducer outputs after vertical averag-

ing over 4 ft (1.2 m) and an azimuthal averaging over

45 or two transducers. The computation uses the em-

pirical relationship described earliet. When the

minimum compressive strength is above 0 psi (kPa) , a

shading can be added to flag good zone isolation. One

output is optional; the tool relative bearing with respect

to the deviation (when the well is deviated to show the

1839

Ir

r

-t

('

..

6"

"

..

t- MDIA

t

/ 1:

\

r

t

!

(

l

?

?' ... "

,}

I

t

700

0-:0 . __

( N

10000.

1---. _____ __ __

0.0

Fig. 9-CET log with acoustic caliper showing different cas-

ing weights.

orientation of cement defects, such as in a mud channel).

Another presentation can display four diameters as

computed by adding the transit times of opposite

transducers. These four calipers are useful in case of cas-

ing deformation or wear.

Log Examples

Fig. 9 shows a section of log with zones of good cement

with a minimum compressive strength in excess of 2,000

psi (13.7 MPa). In the left track, the acoustic caliper

demonstrates its resolution with three heavier casing

joints; one is apparently 26 Ibm/ft (38.7 kg/m), and two

others are 23 Ibm/ft (34.2 kg/m)-as opposed to 20

Ibm/ft (29.7 kg/m) for the rest of the well.

Casing ovality remains very low, as in the following

examples where casings are not damaged.

Fig. 10 shows a cement top with maximum com-

pressive strength gradually decreasing to zero. Below the

1840

I'

,.

-' --.

-

i

f

,-.-

M IA

t

f

t

l-

300

OVAL

V

i"

.:

"r

I.

1

t

r

pal

10000. 0.0

......... ........ .

10000. 0.0

...... 1'-' ... ......

Fig. 10-CET showing cement top and channel.

cement top, a vertical water channel is evident on the

right track; as a consequence, the minimum compressive

strength is zero most of the time, pointing out the lack of

zone isolation despite a good cement quality over most

of the pipe circumference.

Fig. II is an example of reflection from outside the ce-

ment sheath. In this particular case, reflection is provid-

ed by a 9%-in. (24-cm) casing outside the 7-in (17.8-cm)

pipe. The formation reflection flags are scarce below the

9%-in. (24-cm) shoe and are displayed suddenly above

for all transducers. A channel also is demonstrated below

the casing shoe, slowly rotating around the casing (con-

stant relative bearing reading means that the tool is not

rotating).

Fig. 12 shows an unusual channel. First, it can be seen

that the tool is rotating very slowly, with less than one

tum for 328 ft (100 m). The channel displayed not only

turns around the casing in approximately 33 ft (10 m),

JOURNAL OF PETROLEUM TECHNOLOGY

casing

shoe

MOIA

____ _ . .I:lyflJ .. sm .. ) ________ _

0.0 0.5000

10000. 0.0

\

- -'0-:0'

________ .I!'._.LC!'.a-, __

Fig. 11-CET with reflections from outer casing string.

but reverses its rotation in the central section. However,

this channel is not continuous, and the minimum com-

pressive strength curve shows zone isolation at several

spots, especially at the channel rotation reversal.

Conclusions

The CET measurement principle demonstrates clear ad-

vantages over a regular CBL in the case of channeling or

microannulus. Log interpretation is very simple, with

quantitative evaluation of cement quality and an easily

readable display of cement distribution around the pipe.

The casing internal geometry measurements are a

useful bonus, and their high resolution would make

repeated runs useful for evaluating progressive casing

damage, such as driUpipe wear of conductor pipe, before

running a liner.

AUGUST 1982

MOIA

II. ......

II

10000. 0.0

......... ... 1 ........ . ......... ) ........ .

0.0 D.SOOO 10000. 0.0

... PJl ... ...... .

Fig. 12-CET with channel.

References

1. Krautkramer, J.H.: Ultrasonic Testing of Materials, Springer-

Verlag New York Inc., New York City (1977), 618.

2. Viktorov, l.A.: Rayleigh and Lamb Waves, Plenum Publishing

Corp., New York City (1967), 76.

SI Metric Conversion Factors

in. x 2.54*

psi x 6.894 757

"Conversion factor is exact.

E+Ol

E+OO

mm

kPa

JPT

Original manuscript received in Society of Petroleum Engineers office July 20, 1981.

Paper accepted for publication Jan. 28, 1982. Revised manuscript received May 10,

1982. Paper (SPE 10207) first presented at the SPE 56th Annual Technical Con-

ference and EXhibition held in San Antonio Oct. 5-7,1981.

1841

Anda mungkin juga menyukai

- Isolation ScannerDokumen8 halamanIsolation ScannerAmr HegazyBelum ada peringkat

- Sound Engineers Survival GuideDokumen18 halamanSound Engineers Survival GuideBalbusBelum ada peringkat

- Cement Bond LogDokumen62 halamanCement Bond Logbinod_sunu100% (2)

- Observations On Magnetic WallDokumen10 halamanObservations On Magnetic WallMuhammad NozarBelum ada peringkat

- Second Periodical Examination Science Grade 10Dokumen6 halamanSecond Periodical Examination Science Grade 10Walter Orpilla100% (1)

- Evaluation of CBL, VDL, Usit, RFTDokumen13 halamanEvaluation of CBL, VDL, Usit, RFTvvmanoj100% (4)

- Cement Evaluation Tool PDFDokumen7 halamanCement Evaluation Tool PDFHamed SadeghiBelum ada peringkat

- Detection of Corrosion Under Insulation (CUI) by Pulse Eddy Current TechniqueDokumen8 halamanDetection of Corrosion Under Insulation (CUI) by Pulse Eddy Current Techniquedeepak912Belum ada peringkat

- A Practical, Low-Noise Coil System For MagnetotelluricsDokumen36 halamanA Practical, Low-Noise Coil System For MagnetotelluricsJuan RodríguezBelum ada peringkat

- OCTG Method InspectionDokumen24 halamanOCTG Method InspectionAdi Gunawan100% (2)

- Plasma Etching Processes for CMOS Devices RealizationDari EverandPlasma Etching Processes for CMOS Devices RealizationNicolas PossemeBelum ada peringkat

- CRA InspectionDokumen13 halamanCRA InspectionMajeed RumaniBelum ada peringkat

- LRUT - Guided Wave Inspection TechniqueDokumen40 halamanLRUT - Guided Wave Inspection TechniqueVijay Max100% (1)

- CBT - CetDokumen4 halamanCBT - CetWael FaragBelum ada peringkat

- Spe 157976 MSDokumen11 halamanSpe 157976 MSXiaomi Redmi Note 3Belum ada peringkat

- Ultrasonic Pulse Velocity TestDokumen4 halamanUltrasonic Pulse Velocity TestDeepak SahBelum ada peringkat

- A Practical Approach To The Interpretation of Cement Bond Logs @Dokumen10 halamanA Practical Approach To The Interpretation of Cement Bond Logs @Gilberto Garcia de la PazBelum ada peringkat

- 2011 XXDokumen15 halaman2011 XXMauro CostaBelum ada peringkat

- Sonic Logs: Figure 6 - 1Dokumen4 halamanSonic Logs: Figure 6 - 1Zaher Kammoun NaturalisteBelum ada peringkat

- Sound Review SheetsDokumen6 halamanSound Review SheetsEthan Medley100% (1)

- Curso CBL PDFDokumen30 halamanCurso CBL PDFriengoasBelum ada peringkat

- Cement Evaluation: Presented To: Dr. Adel SalemDokumen21 halamanCement Evaluation: Presented To: Dr. Adel SalemIbrahim elshamiBelum ada peringkat

- Understanding Acoustic Methods For Cement Bond Logging: Articles You May Be Interested inDokumen11 halamanUnderstanding Acoustic Methods For Cement Bond Logging: Articles You May Be Interested inheydaripostBelum ada peringkat

- Attenuation of Guided Wave Propagation by The Insulation PipeDokumen17 halamanAttenuation of Guided Wave Propagation by The Insulation PipeAbhijeet TawdeBelum ada peringkat

- Acoustic Logging Methods and ApplicationsDokumen36 halamanAcoustic Logging Methods and ApplicationsbijupiraBelum ada peringkat

- Wall Thickness Measurement Sensor For Pipeline Inspection Using EMAT Technology in Combination With Pulsed Eddy Current and MFLDokumen10 halamanWall Thickness Measurement Sensor For Pipeline Inspection Using EMAT Technology in Combination With Pulsed Eddy Current and MFLser_qc81Belum ada peringkat

- Ut Testing of Concrete StructuresDokumen6 halamanUt Testing of Concrete StructuresPDDELUCABelum ada peringkat

- Diaphragm WallDokumen14 halamanDiaphragm WallDwight AndersonBelum ada peringkat

- Wavelet Transform Analysis of Guided Waves TestingDokumen12 halamanWavelet Transform Analysis of Guided Waves Testingrotero_pujolBelum ada peringkat

- The Five-Point Bending Test Applied On Wearing Courses Laid On Orthotropic Steel DecksDokumen8 halamanThe Five-Point Bending Test Applied On Wearing Courses Laid On Orthotropic Steel DecksEmilioLimberArredondoOyolaBelum ada peringkat

- SPE-191675-MS Lectura Sobre Cemento Tipo UltrasonicoDokumen12 halamanSPE-191675-MS Lectura Sobre Cemento Tipo UltrasonicoPedroBelum ada peringkat

- Spie W Waveguide 2006Dokumen8 halamanSpie W Waveguide 2006SimplenBelum ada peringkat

- Foamed-Cement Evaluation With Conventional Cement Logs and Improved Interpretation MethodsDokumen2 halamanFoamed-Cement Evaluation With Conventional Cement Logs and Improved Interpretation MethodsHamed SadeghiBelum ada peringkat

- Recent Enhancements in Pulsed Eddy Current Analysis: Improving The Sizing of Small FlawsDokumen4 halamanRecent Enhancements in Pulsed Eddy Current Analysis: Improving The Sizing of Small Flawsafiqhashim89Belum ada peringkat

- Cummings 1978Dokumen19 halamanCummings 1978Carlos GuerraBelum ada peringkat

- Measurements of R Bouncing Off Flat Plate: Sondergaard K. Chancy C. E. RennenDokumen7 halamanMeasurements of R Bouncing Off Flat Plate: Sondergaard K. Chancy C. E. RennenDevinamacBelum ada peringkat

- Non-Destructive Test: Annex - ADokumen17 halamanNon-Destructive Test: Annex - AOfficial 074BCEGHBelum ada peringkat

- Jte10561j DL.1415051 1 PDFDokumen8 halamanJte10561j DL.1415051 1 PDFpaolaBelum ada peringkat

- Immersion Ultrasonic Testing On EUROFER Welded Joints For Determination of The Minimum Detectable Flaw SizeDokumen9 halamanImmersion Ultrasonic Testing On EUROFER Welded Joints For Determination of The Minimum Detectable Flaw SizeJanak LalBelum ada peringkat

- Determination of Formation Properties in Cased Boreholes Using Full Waveform Acoustic Logs - Massachusetts Institute of TechnologyDokumen18 halamanDetermination of Formation Properties in Cased Boreholes Using Full Waveform Acoustic Logs - Massachusetts Institute of TechnologyalizareiforoushBelum ada peringkat

- 50-Khz Capacitive Micromachined Ultrasonic Transducers For Generating Highly Directional Sound With Parametric ArraysDokumen4 halaman50-Khz Capacitive Micromachined Ultrasonic Transducers For Generating Highly Directional Sound With Parametric ArraysPoonam KaurBelum ada peringkat

- Determination of Quality of Concrete by Upv MachineDokumen5 halamanDetermination of Quality of Concrete by Upv Machinemohd waseemBelum ada peringkat

- Dr. Fadhil Luctures-6Dokumen12 halamanDr. Fadhil Luctures-6ﯧ٭ٴ٭ٴ٭ﯧ إيہۗزيہۗو ﯧ٭ٴ٭ٴ٭ﯧBelum ada peringkat

- Internal Inspection Report HopperDokumen10 halamanInternal Inspection Report HopperCepi Sindang KamulanBelum ada peringkat

- Materials: Ultra-Wideband Flexible Absorber in Microwave Frequency BandDokumen11 halamanMaterials: Ultra-Wideband Flexible Absorber in Microwave Frequency BandmeracarrBelum ada peringkat

- Embeded Length Anchor BoltDokumen19 halamanEmbeded Length Anchor BoltWai CYBelum ada peringkat

- Electromagnetic Induction of Ultrasonic Waves: Emat, Emus, EmarDokumen8 halamanElectromagnetic Induction of Ultrasonic Waves: Emat, Emus, EmarVuong Tran VanBelum ada peringkat

- CCR Xay CT SCANDokumen11 halamanCCR Xay CT SCANChau K.T.Belum ada peringkat

- FEM Acoustic Analysis - NDT Angle Beam ExampleDokumen28 halamanFEM Acoustic Analysis - NDT Angle Beam ExampleN DBelum ada peringkat

- Rebound Hammer Test: Type of ND TestsDokumen2 halamanRebound Hammer Test: Type of ND Testsrameshbabu_1979Belum ada peringkat

- Ref 43Dokumen10 halamanRef 43Tahir AbbasBelum ada peringkat

- NOE0415380416 ch045Dokumen7 halamanNOE0415380416 ch045Umed Abd-alsatarBelum ada peringkat

- Concrete DiagramDokumen6 halamanConcrete DiagramKaushal ModiBelum ada peringkat

- Testing of Buried Pipelines Using Guided Waves: A. Demma, D. Alleyne, B. PavlakovicDokumen7 halamanTesting of Buried Pipelines Using Guided Waves: A. Demma, D. Alleyne, B. PavlakovicNordin SuhadatBelum ada peringkat

- 2012 The Effect of Wall Vibrations On The Air Column Inside Trumpet Bells PDFDokumen6 halaman2012 The Effect of Wall Vibrations On The Air Column Inside Trumpet Bells PDFtitov33Belum ada peringkat

- Krylov NOVEM 2005Dokumen13 halamanKrylov NOVEM 2005Lokesh GorantlaBelum ada peringkat

- Cement Mapping ToolsDokumen7 halamanCement Mapping ToolsJosefa Maria Cardozo100% (1)

- MEXICO '13 NB4 Pre-Grouting and Rock Improvement 104 ScreensDokumen104 halamanMEXICO '13 NB4 Pre-Grouting and Rock Improvement 104 Screensalejandra castañedaBelum ada peringkat

- Ultrasonic Cement LoggingDokumen22 halamanUltrasonic Cement LoggingEzekiel AgberenBelum ada peringkat

- Unjamming A Granular Hopper by Vibration: EPLA, 2009Dokumen6 halamanUnjamming A Granular Hopper by Vibration: EPLA, 2009A94leo14hsetmaBelum ada peringkat

- Shyam Ac Performance of Nano ElectronicsDokumen30 halamanShyam Ac Performance of Nano Electronicsapi-3827000100% (1)

- Scientific American Supplement, No. 470, January 3, 1885Dari EverandScientific American Supplement, No. 470, January 3, 1885Belum ada peringkat

- HBX-6516DS-VTM Product SpecificationDokumen4 halamanHBX-6516DS-VTM Product SpecificationOscar Danilo Reyes ReyesBelum ada peringkat

- Modulation-Part 2-FMDokumen67 halamanModulation-Part 2-FMAzmilWahabBelum ada peringkat

- Hased Array Ultrasonic Testing, Sectorial ScanDokumen7 halamanHased Array Ultrasonic Testing, Sectorial Scanநந்த குமார் சம்பத் நாகராஜன்100% (1)

- The Basics of Patch AntennasDokumen9 halamanThe Basics of Patch Antennashamza1136Belum ada peringkat

- 10 EM Spectrum of Light Compiled Questions v2Dokumen4 halaman10 EM Spectrum of Light Compiled Questions v2Hafez MurtzaBelum ada peringkat

- Imp Qstions TLRFDokumen16 halamanImp Qstions TLRFSinan SinanBelum ada peringkat

- S S Tuto2Dokumen1 halamanS S Tuto2Sunny LeoneBelum ada peringkat

- ARI Standard 370-2001Dokumen17 halamanARI Standard 370-2001Niong DavidBelum ada peringkat

- Seismology Master2014Dokumen126 halamanSeismology Master2014AnjaneyBelum ada peringkat

- Comparison Table OM Vs SEMDokumen2 halamanComparison Table OM Vs SEMchevaneeBelum ada peringkat

- Physics Paper 1 Term 1 2015 - Y11Dokumen17 halamanPhysics Paper 1 Term 1 2015 - Y11Ezra Loganathan MuniandiBelum ada peringkat

- Tutorial 3Dokumen18 halamanTutorial 3PURUSHOTHAMBelum ada peringkat

- Black Body RadiationDokumen12 halamanBlack Body RadiationMahesh Lohith K.S100% (4)

- Barrie - Trower - SA 1 18 2Dokumen1 halamanBarrie - Trower - SA 1 18 2ALIN-MIHAI ȚENEABelum ada peringkat

- Microwave and Radar Engineering-Pcec 4101Dokumen2 halamanMicrowave and Radar Engineering-Pcec 4101Dr-Harish Chandra Mohanta0% (1)

- Personal Dosimetry Management: A Nuclear Industry Good Practice GuideDokumen26 halamanPersonal Dosimetry Management: A Nuclear Industry Good Practice GuideEm GerBelum ada peringkat

- Chapter 10 Exercise Short QuestionsDokumen2 halamanChapter 10 Exercise Short QuestionsSaif UllahBelum ada peringkat

- Lesson 11 - Seismic WavesDokumen10 halamanLesson 11 - Seismic WavesEugene Soriano-mangobaBelum ada peringkat

- Andrew Umwd 06516 2dhDokumen3 halamanAndrew Umwd 06516 2dhyevobimBelum ada peringkat

- Mont 1 STD 12Dokumen12 halamanMont 1 STD 12Avik DasBelum ada peringkat

- UHP-M 0.3m Dual Polarization Compact Class3 Antenna Datasheet (AXXD03MAC-3NX)Dokumen3 halamanUHP-M 0.3m Dual Polarization Compact Class3 Antenna Datasheet (AXXD03MAC-3NX)alejandratorres.ingenieriaBelum ada peringkat

- MCQ Ch16solDokumen4 halamanMCQ Ch16solandiswahlongwa870Belum ada peringkat

- UG Physics PH1101 - Lec-2-2Dokumen11 halamanUG Physics PH1101 - Lec-2-22023MEB023 RUPANJANBHATTACHARYYABelum ada peringkat

- PWT 10 PWT 17 PWT 18: Betriebsanleitung Mode D Emploi Modo de EmpleoDokumen24 halamanPWT 10 PWT 17 PWT 18: Betriebsanleitung Mode D Emploi Modo de EmpleoThanh LoiBelum ada peringkat

- Infrasound PDFDokumen72 halamanInfrasound PDFRahulBelum ada peringkat

- 9 AC Air - OutletsDokumen48 halaman9 AC Air - OutletsAhmed SherifBelum ada peringkat

- Signal AnalyzerDokumen22 halamanSignal AnalyzerVijayBhaskarReddyBelum ada peringkat