Axial Flux Permanent Magnet Generators For Pico-Hydropower

Diunggah oleh

Engineers Without Borders UKJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Axial Flux Permanent Magnet Generators For Pico-Hydropower

Diunggah oleh

Engineers Without Borders UKHak Cipta:

Format Tersedia

EWB-UK Research Conference 2009 Hosted by The Royal Academy of Engineering February 20

AXIAL FLUX PERMANENT MAGNET GENERATORS FOR PICO-HYDROPOWER

D.A. Howey

Electrical Engineering Department, Imperial College, Exhibition Road, South Kensington, London SW7 2AZ. Email: d.howey@imperial.ac.uk, Web: www.developingtechnologies.org

Abstract

This paper reviews research being undertaken to apply a novel electrical generator design, the axial flux permanent magnet (AFPM) machine, to pico-hydropower applications. Pico-hydropower is a well established and cost effective means of producing electricity in developing countries, but there is scope for improvement of cost and performance. AFPM machines have been explored in a variety of applications from electric vehicles to wind turbines but with little application to hydropower. Here it is shown that an AFPM machine of similar size and cost to the existing radial flux generators used for pico-hydropower could produce around double the power output (assuming the turbine power was available), with 90% rather than 75% efficiency. The aim of the research is to build & test such a design in the lab and then approach a manufacturer in Nepal with a view to mass production.

Introduction

About 1.6 billion people lack access to electricity and many of these are in rural areas with no hope of connection to the electrical grid [1]. Electricity is only one of various energy sources useful to the rural poor; other sources such as biomass are also important, and energy in itself cannot reduce poverty unless other enabling factors are present [2]. However, electricity provides many potential benefits, for example: better services at schools and clinics (through lighting, refrigeration and communications technology), better education opportunities (by access to lighting to study at night) and better income generation opportunities (by technical capacity building and being able to run electrically operated machinery and communications equipment) [1]. Electricity also enables communities to improve connections with their neighbours and friends and the world at large.

Pico-hydropower

Hydropower supplied 6.4% of the worlds primary energy in 2007, equating to almost a fifth of global electricity production [1, 3] . However, most large sites that can be exploited economically have already been developed. Smaller sites are now sought and much of the global undeveloped potential exists in the former Soviet Union and developing countries [4, 5]. Future focus will likely be on small and medium scale projects because environmental concerns are discouraging largescale projects. Johansson [4] notes that micro-hydropower (<100kW) is well positioned to make a contribution to future development, although one major disadvantage of smaller systems is, being mostly run-of-river, they often experience large seasonal variations in flow. This can be a serious challenge in parts of Africa for example where the river discharge during the wet season is significantly greater than that during the dry season, and this will be exacerbated by climate Community of Practice: Energy Author: D. A. Howey Institution: Imperial College London Previously published: N/A

EWB-UK Research Conference 2009 Hosted by The Royal Academy of Engineering February 20 change. However, in many areas micro-hydropower has proven to be reliable with usually continuous availability of power and low maintenance requirements [5]. Higher head sites (above 20m) are advantageous because power can be extracted with very compact and therefore cheaper machines such as Pelton turbines. However, the majority of pico-hydropower sites in use globally are low head sites (1-10m head) and the greatest scope for future small hydropower development is through low head sites [1, 6] for example with fixed geometry propeller turbines such as that shown in Figure 1. Definitions for pico-hydropower vary, but the term generally refers to systems below 5kW in size which can be shared between many households in a community, as per Williams et al [7]. At the very smallest sizes such systems are suitable for individual households or small clusters of households and are therefore also called family hydropower. One study [8] estimates potential for 4 million pico-hydropower systems globally. South East Asia leads the existing market, with hundreds of thousands of units deployed in the last 15 years in Vietnam and China. Other areas where pico-hydropower is Figure 1: Cast bronze propeller turbine being explored include the Philippines, India, Sri Lanka, Laos, designed at Kathmandu University, Nepal, for pico-hydropower use Ecuador, Bolivia, Peru and Columbia. Africa has not yet seen significant development [9]. The market for low head pico-hydropower developed in South China and the surrounding countries in the late 1980s and early 1990s, fuelled by cheap systems manufactured in Nanning City [7]. Turbines (typically 100-200W with AC permanent magnet generators) were illegally imported and sold for cash in North Vietnam, Southern China and Laos and the market developed primarily by word of mouth without significant government subsidies. Although very cheap (typically $20-$50 excluding balance of plant e.g. transmission cables and draft tube), the Chinese turbines were reportedly not of good quality or durability and had no after sales service and support. Taylor [10] estimates that less than 40% of the original turbines are still functioning. Figure 2: Commercially available picohydropower turbine and generator in- In response, a more durable design with better bearings and situ, generator exposed improved manufacturing quality and after-sales service was developed in Vietnam, costing $50-$100. This design is also being sold in the Philippines and trialled in Ecuador, and can be obtained for UK use through Powerpal Ltd. (www.powerpal.co.uk). Life cycle costs per year (in other words the total cost of a system over its entire lifetime, divided by the lifetime) of household-owned pico-hydropower systems range from $74 to $150/year per Community of Practice: Energy Author: D. A. Howey Institution: Imperial College London Previously published: N/A

EWB-UK Research Conference 2009 Hosted by The Royal Academy of Engineering February 20 household for a 200W sized unit [6]. This compares favourably with alternatives (such as solar PV, wind, hybrid and fossil fuel generators) which start at $140/year per household. If pico-hydropower systems can be shared between households, life cycle costs decrease. Taylor also notes that the market in South East Asia is demanding larger sizes of unit which can be shared between households, and 500-1000W units have been developed in Vietnam. This is a natural progression, because sites for hydropower are limited and where it is possible to share a single turbine amongst many this is a favoured option. However, this does rely on a community working closely together and also on there being sufficient population density to offset transmission distances and costs. Williams et al. [7] review a variety of technologies for low head pico-hydropower noting that many designs have cost and reliability problems, as already discussed. As a result, Williams undertook a programme of research at Nottingham Trent University in order to develop a low cost but more reliable and efficient propeller turbine [11]. In summary, pico-hydropower systems have enjoyed impressive unsubsidised sales in South East Asia, but there is certainly scope for improvement of the turbine and generator in terms of durability and quality, as long as any changes are cost effective. This paper is specifically focused on improving the electrical generator, so we now turn to an overview of the subject of electrical machines.

Electrical machines

Choosing a generator for a specific application is governed by a number of factors such as the prime mover speed, required output power, range of operation and end use (e.g. grid connection or battery charging). There are many different types of electrical machine available and roughly they can be divided into alternating current (AC) and direct current (DC) machines. Table 1 gives an overview (broadly sourced from [12]).

Table 1: Types of electrical machines

Generator type Synchronous AC machine

Induction AC machine

DC brushed machine1

Characteristics Rotor magnetic field produced by permanent magnets, or (for larger machines) an electromagnet fed via slip rings Output frequency locked to shaft frequency Small PM machines are efficient, quite simple and flexible Rotor magnetic field induced by stator field (like a transformer) Output frequency differs slightly from shaft frequency Cheap, robust, simple and reliable Some subtleties in getting them to operate as generators Usually less efficient than synchronous machines Requires slip rings or brushes, which wear out, cause voltage drops and various other problems at high speeds / loadings.

Note that the so-called brushless DC machine is really just an AC machine with electronic commutation

Community of Practice: Energy Author: D. A. Howey Institution: Imperial College London Previously published: N/A

EWB-UK Research Conference 2009 Hosted by The Royal Academy of Engineering February 20 Until the widespread adoption of power electronics, DC motors were the only solution for achieving a variable speed drive. AC motors obviously run on AC, but if it is a fixed frequency supply then the shaft speed is also fixed2. The opposite is also true: in generating mode, AC machines produce an AC electrical output which varies in frequency with shaft speed, and a DC brushed machine run as a generator produces a (choppy) DC output.

Electrical generators suitable for pico-hydropower

Let us now address the question of which electrical machines might be most suitable for picohydropower. Firstly, DC brushed machines can be ruled out because of the need for mechanical commutation. In a generator application, AC can easily be rectified to DC electronically if necessary and therefore there is no particular advantage in producing a direct DC output. Induction machines are a very attractive option for small hydropower greater than about 1kW in size [13] because they are cheap and reliable, despite lower efficiency than an equivalent permanent magnet synchronous machine and the need to run at a more or less fixed speed. When induction machines are used as generators rather than motors, capacitors are required for off-grid operation. For the smallest pico-hydropower systems (below 1kW), permanent magnet synchronous machines are more attractive than induction machines in terms of cost and performance, as demonstrated by Williams et al [13]. This is borne out in practice: the smallest pico-hydropower systems use radial flux permanent magnet (RFPM) generators. There is however scope for improvement of these in terms of both cost and efficiency. A significant advantage can be achieved by switching to a different geometry of PM synchronous machine, as follows: The vast majority of electrical machines are radial flux (RF), meaning they are cylindrically shaped and the magnetic field cuts the stator coils in a radial direction. However, another geometry called axial flux (AF) is also possible and this is particularly suitable for efficient, high power density machines. As the name suggests, in an AF machine the magnetic field cuts the stators in the axial direction. Whilst electrically similar, AF and RF machines differ significantly in terms of thermal management, mechanical design and assembly process [14]. The axial flux permanent magnet (AFPM) machine is well suited to pico-hydropower because it is easy to make (and therefore cheap), and can be made without iron in the stator (a further cost saving), yet it is very efficient if correctly designed. In fact, the successful application of small AFPM machines in appropriate technology is nothing new and can be seen in the wind turbines of Hugh Piggott and Practical Action [15]. In order to test this hypothesis that AFPM machines offer an advantage over RFPM machines for pico-hydropower, comparative experimental testing is being undertaken on both an existing radial flux generator used for pico-hydropower, imported directly from south east Asia (see Figure 3), and also on a new optimised axial flux design. A number of stator geometries are being investigated and the benefits of an optimised air-core design will be demonstrated.

2

There are some subtleties with AC induction machines but for clarity I have omitted a detailed discussion

Community of Practice: Energy Author: D. A. Howey Institution: Imperial College London Previously published: N/A

EWB-UK Research Conference 2009 Hosted by The Royal Academy of Engineering February 20

Permanent magnets on rotor

Stator coil

Figure 3: Inside an existing RFPM machine used for hydro in SE Asia

How an axial flux generator works

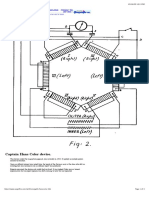

In an AFPM machine, the magnetic field in the generator is oriented axially at the point where it cuts the stator coils, see Figure 4. This configuration enables compact designs with high specific torque, and also allows the use of an ironless stator of simple construction. AFPMs have been the subject of intensive research since the introduction of high performance permanent magnets in the 1980s. Their geometry and high power density is beneficial in a variety of portable applications such as electric vehicles, aircraft and ships and also stationary applications such as wind turbines and high speed gas turbine generator sets. For an example of an AFPM applied to a small wind turbine, see Bumby et al [16]. To predict performance in an air-cored AFPM machine the process is reasonably straightforward because the magnetic field from the stator can be ignored. Figure 5 shows a flow chart of a Matlab mathematical model for air-cored AFPM performance prediction.

Figure 4: Side and end views of a simple 6-pole AFPM machine. The PMs are arranged to give alternating N-S magnetisation as shown, and the white arrow shows the axially oriented magnetic field.

Community of Practice: Energy Author: D. A. Howey Institution: Imperial College London Previously published: N/A

EWB-UK Research Conference 2009 Hosted by The Royal Academy of Engineering February 20

Figure 5: AFPM performance prediction model

Initial measurements

Some interesting preliminary measurements are available at this stage. Firstly, note that the nameplate on the RFPM machine shown in Figure 3 states the following: 220V, 500W at 1000rpm, using a EMF turbine suited to 8-35m head and about 5 litres/sec flow rate. How close is this to actual performance?

Rstator

Vload

Rload

Rough tests have shown that this machine produces Figure 6: Simple equivalent circuit for single phase generator an open circuit EMF of approximately 230VRMS (50Hz) at 1000rpm. It is a 6-pole single phase machine with all three stators connected in series. The total stator resistance was measured to be 38.7 at room temperature. Based on these two facts alone, it is possible to calculate approximately the maximum power point by constructing a simple equivalent circuit as shown in Figure 6, ignoring stator inductance and assuming the load is purely Community of Practice: Energy Author: D. A. Howey Institution: Imperial College London Previously published: N/A

EWB-UK Research Conference 2009 Hosted by The Royal Academy of Engineering February 20 resistive. As can be seen, maximum power is around 340W, short of the 500W quoted. After the machine has warmed up (a few hours of full load operation), the stator resistance will increase giving an even lower maximum point, about 275W. However in practice an electrical machine is never operated at maximum power point because the I2R losses and stator heating would be too high (the efficiency at maximum power point is 50%). So, assuming operation at perhaps 75% efficiency, the maximum power to the load is 200-250W. One problem is immediately apparent: the machines specification is not remotely credible! This is indicative of the wider quality control issues with this type of product in developing countries.

Figure 7: RFPM machine approximate predicted performance (power and efficiency vs. load)

Could an AFPM machine be built which improves on this? The outer diameter of the RFPM machine is about 200mm. If a 3-phase AFPM machine is built with a similar outer diameter, running at the same speed, calculations (using the model shown in Figure 5) show that at about 1.5A current drawn it could delivery 500W power to a resistive load (assuming this power was available from the turbine), with an efficiency at this point of 85-90%.

Concluding remarks

Pico-hydropower is already a proven electricity source for many people, particularly in SE Asia. The potential for further expansion of this technology is massive, but some improvements are needed to the turbines and generators. As an aside, there is also a huge need for more accurate cost prediction, and cost reduction of the civil works associated with micro hydropower generally. Electrical machines suitable for pico-hydropower include induction machines and permanent magnet machines. Regarding the latter, one particularly promising option is the axial flux PM machine, which has been the focus of this paper. An AFPM device could offer greater power output and greater efficiency than the incumbent technology, at a similar or lower cost. Research and comparison testing in this regard is ongoing. Once the benefits have been proven in the lab, and a Community of Practice: Energy Author: D. A. Howey Institution: Imperial College London Previously published: N/A

EWB-UK Research Conference 2009 Hosted by The Royal Academy of Engineering February 20 suitably simple, robust AFPM machine design is available, the intention is that prototype manufacturing and field testing would be carried out by a small hydropower manufacturer in Nepal. In addition, the design tools will also be applied to another AFPM machine already under development in Nepal, and possibly in other areas such as small wind turbines.

Acknowledgements

This project is financed by Developing Technologies through a grant from the Hadley Trust. The support of my PhD supervisor Dr Andrew Holmes and advisor Dr Keith Pullen is very gratefully acknowledged. Thanks also to Ron Dennis at Developing Technologies and Iain Wright, Jim Ford and Gary Austin at City University for technical support and being generally very accommodating. Finally, Andrew Hay in China kindly arranged the export of the RFPM machine.

References

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. OECD/IEA, World Energy Outlook 2006, ed. R. Priddle. 2007, Paris: International Energy Agency. DFID, Energy for the Poor - Underpinning the Millenium Development Goals. 2002, UK Department for International Development: London. BP, BP Statistical Review of World Energy June 2008. 2008, BP: London. Burnham, L. and T. Johansson, Renewable Energy: Sources for Fuels and Electricity . 1993, Washington D.C.: Island Press. Karekezi, S. and T. Ranja, Renewable energy technologies in Africa. 1997, London: Zed Books. Taylor, S.D.B., et al., Stimulating the Market for Pico-hydro in Ecuador. 2004, IT Power. Williams, A.A., et al. Low head pico hydropower: A review of available turbine technologies . in 6th World Renewable Energy Congress. 2000. Brighton: Pergamon. Mariyappan, J., et al., A guide to CDM and family hydro power. 2004, IT Power. Paish, O. and J. Green, The Pico Hydro Market in Vietnam. 2003, IT Power. Taylor, S., Conversation about pico-hydropower. 2006: IT Power offices, Basingstoke. Simpson, R. and A. Williams, The design of cost-effective pico-propeller turbines for developing countries. 2006, European Small Hydropower Association (ESHA). Hughes, A., Electric motors and drives. 3rd ed. 2006, Oxford: Elsevier/Newnes. Williams, A.A., et al., Technology options for low-head pico-hydropower. 2007, Nottingham Trent University: Nottingham. Gieras, J., R. Wang, and M. Kamper, Axial Flux Permanent Magnet Brushless Machines. 2004: Kluwer Academic Publishers. Dunnett, S., H. Piggott, and S. Electric. Axial airgap machines for small wind generators in developing countries. in IEE Seminar on Axial Airgap Machines. 2001. London: The Institution of Electrical Engineers (IEE). Bumby, J. and R. Martin, Axial-flux permanent-magnet air-cored generator for small-scale wind turbines. IEE Proceedings - Electric Power Applications, 2005. 152(5): p. 1065-1075.

16.

Community of Practice: Energy Author: D. A. Howey Institution: Imperial College London Previously published: N/A

Anda mungkin juga menyukai

- Matchett 140801073955 Phpapp01Dokumen8 halamanMatchett 140801073955 Phpapp01MamachelloBelum ada peringkat

- Homo Polar GeneratorDokumen7 halamanHomo Polar Generatorvinay kateBelum ada peringkat

- Muammer Yildiz - Over-Unity Homopolar Electrical Generator - Patent, ArticlesDokumen29 halamanMuammer Yildiz - Over-Unity Homopolar Electrical Generator - Patent, ArticlesMohd FakhriBelum ada peringkat

- Capacitor and Capacitance Marilag and Masicap KryztabelleDokumen3 halamanCapacitor and Capacitance Marilag and Masicap KryztabelleGenesis Austria100% (1)

- Power Generation by Foot Step Method - Rack and PinionDokumen13 halamanPower Generation by Foot Step Method - Rack and Pinionprem53100% (2)

- Practical Guide to Free-Energy Devices Chapter 16 Q&ADokumen44 halamanPractical Guide to Free-Energy Devices Chapter 16 Q&AAleksa Nataša RančićBelum ada peringkat

- Ijiset V6 I8 18Dokumen5 halamanIjiset V6 I8 18TeotiaBelum ada peringkat

- Bsse Knowledge How - The - Stan - Meyer - Tech - Works 2 July 2018Dokumen120 halamanBsse Knowledge How - The - Stan - Meyer - Tech - Works 2 July 2018Jumpman OutletBelum ada peringkat

- WWW - Lhup.edu Dsimanek Museum Themes SiphonDokumen6 halamanWWW - Lhup.edu Dsimanek Museum Themes SiphonRamesh Chandra100% (1)

- HPT (Ieee, 2005)Dokumen7 halamanHPT (Ieee, 2005)Muhammad Hadi MustajabBelum ada peringkat

- Design and Simulation of Free Energy Permanent Magnet MotorDokumen10 halamanDesign and Simulation of Free Energy Permanent Magnet MotorCristian IonescuBelum ada peringkat

- ML 073520098Dokumen55 halamanML 073520098Denise CarbonariBelum ada peringkat

- Les Banki Circuit Updated Version August 16Dokumen12 halamanLes Banki Circuit Updated Version August 16petar2009100% (2)

- Solid State Relay Backemf - Recoil Recovery Circuit - AlternativeWorld EnergyDokumen2 halamanSolid State Relay Backemf - Recoil Recovery Circuit - AlternativeWorld Energyfsilassie8012Belum ada peringkat

- 220V DC To 220V AC: DIY Inverter Part 2: InstructablesDokumen10 halaman220V DC To 220V AC: DIY Inverter Part 2: InstructablesTnT ElektricBelum ada peringkat

- Thermodynamics 2Dokumen7 halamanThermodynamics 2riez24Belum ada peringkat

- Bedini SG Intermediate HandbookDokumen8 halamanBedini SG Intermediate HandbookVlad Adrian0% (1)

- 0102 - Forever Flasher PDFDokumen3 halaman0102 - Forever Flasher PDFMuhammadAsifBelum ada peringkat

- The Inventions of CaptainDokumen3 halamanThe Inventions of CaptainAngela0220Belum ada peringkat

- Build A 3-Band Shortwave Converter For Your CarDokumen2 halamanBuild A 3-Band Shortwave Converter For Your CarbobbyunlockBelum ada peringkat

- Simple Free-Energy Devices: Chapter 33: The Simplified Perpetual LightDokumen4 halamanSimple Free-Energy Devices: Chapter 33: The Simplified Perpetual LightpranalarBelum ada peringkat

- Vacuum Energy An Electric SystemsDokumen3 halamanVacuum Energy An Electric SystemsMarcus ReidBelum ada peringkat

- Homopolar MotorDokumen3 halamanHomopolar MotorYashwanth SrinivasaBelum ada peringkat

- Dony WatssDokumen49 halamanDony WatssvbugaianBelum ada peringkat

- Hybrid Tech Eat On Fuel CellDokumen13 halamanHybrid Tech Eat On Fuel CellhhojonBelum ada peringkat

- Cosmic Energy Machines - Lawrence Tseung PDFDokumen41 halamanCosmic Energy Machines - Lawrence Tseung PDFhmarambio100% (1)

- On Nuclear MicrobatteriesDokumen20 halamanOn Nuclear MicrobatteriesVikasmatrey50% (2)

- Roto Verter - Rv-9Dokumen38 halamanRoto Verter - Rv-9chigoBelum ada peringkat

- Understanding Ferrite Beads and ApplicationsDokumen34 halamanUnderstanding Ferrite Beads and ApplicationsamittyadavBelum ada peringkat

- The High Voltage Homopolar GeneratorDokumen6 halamanThe High Voltage Homopolar Generatorapi-241035124Belum ada peringkat

- Antenna Add On 2 12 18 Pdfmate MergeDokumen946 halamanAntenna Add On 2 12 18 Pdfmate MergepowerinfiniteBelum ada peringkat

- (PANTONE STIRLING GEET SPAD) Thesis - Simple Gas Turbine Engine DesignDokumen130 halaman(PANTONE STIRLING GEET SPAD) Thesis - Simple Gas Turbine Engine DesignTri KurniawanBelum ada peringkat

- Nuclear BatteryDokumen22 halamanNuclear BatterySairajesh67% (3)

- Visible light and solar powerDokumen4 halamanVisible light and solar powerGilberto ManhattanBelum ada peringkat

- Top 10 OU Revised 3.1docxDokumen11 halamanTop 10 OU Revised 3.1docxBill ClarkeBelum ada peringkat

- High Voltage GenerationDokumen6 halamanHigh Voltage Generationdp500100% (1)

- 1 Modern Radiant Energy Circuit PDFDokumen3 halaman1 Modern Radiant Energy Circuit PDFavisenicBelum ada peringkat

- Homopolar Generator GuideDokumen5 halamanHomopolar Generator GuideYashwanth SrinivasaBelum ada peringkat

- Bedini Monopole 3 Group ExperimentDokumen5 halamanBedini Monopole 3 Group Experimentnadirma66Belum ada peringkat

- WWW Youtube Com Watch V HyTplvO4i9UDokumen2 halamanWWW Youtube Com Watch V HyTplvO4i9UJohnnyLarsonBelum ada peringkat

- Doubtful Devices GuideDokumen61 halamanDoubtful Devices GuideStevan FarkasBelum ada peringkat

- Experimenters Guide To The Joe Cell PDFDokumen2 halamanExperimenters Guide To The Joe Cell PDFJonathan0% (1)

- A New Unity Power Factor Quasi-Resonant Induction Heater PDFDokumen225 halamanA New Unity Power Factor Quasi-Resonant Induction Heater PDFŽarko Dačević100% (1)

- Nuclear BatteryDokumen20 halamanNuclear Batteryshefinbasheer100% (1)

- Don Smith Theory III-1 PDFDokumen1 halamanDon Smith Theory III-1 PDF77nicu100% (1)

- Bi Toroid Transformer DiscussionDokumen781 halamanBi Toroid Transformer DiscussionLuisLazoBelum ada peringkat

- Nuclear BatteryDokumen22 halamanNuclear BatteryPrayag P NairBelum ada peringkat

- Solar Refrigeration Using Peltier EffectDokumen15 halamanSolar Refrigeration Using Peltier EffectSyko GamingBelum ada peringkat

- Bill Williams Gas Splitter Dry CellDokumen4 halamanBill Williams Gas Splitter Dry CellCiprian ALBelum ada peringkat

- Geet Reactor RodDokumen11 halamanGeet Reactor RodthenjhomebuyerBelum ada peringkat

- Efficient 1.5V battery circuit produces over 50V and charges batteriesDokumen5 halamanEfficient 1.5V battery circuit produces over 50V and charges batteriesJohn WestfieldBelum ada peringkat

- Magnetic AmplifierDokumen2 halamanMagnetic Amplifierrintarejoy100% (1)

- Laser spectroscopy IXDari EverandLaser spectroscopy IXMichael FeldBelum ada peringkat

- Stanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinDari EverandStanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinBelum ada peringkat

- Applied Superconductivity: Volume IIDari EverandApplied Superconductivity: Volume IIVernon L. NewhouseBelum ada peringkat

- Binary Polar Liquids: Structural and Dynamic Characterization Using Spectroscopic MethodsDari EverandBinary Polar Liquids: Structural and Dynamic Characterization Using Spectroscopic MethodsPenilaian: 5 dari 5 bintang5/5 (1)

- Aluminum-Air Batteries The Ultimate Step-By-Step GuideDari EverandAluminum-Air Batteries The Ultimate Step-By-Step GuideBelum ada peringkat

- Study of a reluctance magnetic gearbox for energy storage system applicationDari EverandStudy of a reluctance magnetic gearbox for energy storage system applicationPenilaian: 1 dari 5 bintang1/5 (1)

- Application of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsDari EverandApplication of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsBelum ada peringkat

- 2011 EWB Challenge Introduction UK VersionDokumen23 halaman2011 EWB Challenge Introduction UK VersionEngineers Without Borders UKBelum ada peringkat

- Training 101 - Presentation From NVTW 2012Dokumen31 halamanTraining 101 - Presentation From NVTW 2012Engineers Without Borders UKBelum ada peringkat

- A Guide To Solving The Biggest Problems The Human Race Has Ever Known: Step 1: Be An Engineer. Step 2: Think Big. Step 3: Think Small. Step 4: RepeatDokumen60 halamanA Guide To Solving The Biggest Problems The Human Race Has Ever Known: Step 1: Be An Engineer. Step 2: Think Big. Step 3: Think Small. Step 4: RepeatEngineers Without Borders UKBelum ada peringkat

- The Design of A Rainwater Harvesting System For Pabal, IndiaDokumen105 halamanThe Design of A Rainwater Harvesting System For Pabal, IndiaEngineers Without Borders UKBelum ada peringkat

- Bamboo Housing in PabalDokumen21 halamanBamboo Housing in PabalEngineers Without Borders UKBelum ada peringkat

- Pre-Departure Course: Sacha Grodzinski Chairman of Engineers Without Borders UKDokumen32 halamanPre-Departure Course: Sacha Grodzinski Chairman of Engineers Without Borders UKEngineers Without Borders UKBelum ada peringkat

- Intro To International Development - Sacha Grodzinski (2010)Dokumen47 halamanIntro To International Development - Sacha Grodzinski (2010)Engineers Without Borders UKBelum ada peringkat

- Local Gumpole Timbers and Mud Bricks' An Example of The UK's Building Industry's International ContributionDokumen8 halamanLocal Gumpole Timbers and Mud Bricks' An Example of The UK's Building Industry's International ContributionEngineers Without Borders UKBelum ada peringkat

- Going Global - Proceedings 2013Dokumen112 halamanGoing Global - Proceedings 2013Engineers Without Borders UKBelum ada peringkat

- EWB Challenge OverviewDokumen2 halamanEWB Challenge OverviewEngineers Without Borders UK100% (1)

- EWB Challenge BrochureDokumen2 halamanEWB Challenge BrochureEngineers Without Borders UKBelum ada peringkat

- Extending The Collapse Time of Non-Engineered Masonry Buildings Under Seismic LoadingDokumen14 halamanExtending The Collapse Time of Non-Engineered Masonry Buildings Under Seismic LoadingEngineers Without Borders UKBelum ada peringkat

- Solar Powered Well PumpDokumen20 halamanSolar Powered Well PumpEngineers Without Borders UKBelum ada peringkat

- A Feasibility Study On The Implementation of A Micro-Hydro Scheme in Sioma, ZambiaDokumen17 halamanA Feasibility Study On The Implementation of A Micro-Hydro Scheme in Sioma, ZambiaEngineers Without Borders UKBelum ada peringkat

- An Experimental Study of The Combustion Characteristics of Low-Density Biomass BriquettesDokumen8 halamanAn Experimental Study of The Combustion Characteristics of Low-Density Biomass BriquettesEngineers Without Borders UKBelum ada peringkat

- Introduction To International DevelopmentDokumen45 halamanIntroduction To International DevelopmentEngineers Without Borders UKBelum ada peringkat

- Breeding A Better Stove: The Use of Genetic Algorithms and ComputationalFluid Dynamics To Improve Stove DesignDokumen10 halamanBreeding A Better Stove: The Use of Genetic Algorithms and ComputationalFluid Dynamics To Improve Stove DesignEngineers Without Borders UKBelum ada peringkat

- ICTs For Development: A Social Entrepreneur's PerspectiveDokumen8 halamanICTs For Development: A Social Entrepreneur's PerspectiveEngineers Without Borders UKBelum ada peringkat

- Passive Cooling Solutions For Residential Buildings in Pabal, Maharashtra, IndiaDokumen32 halamanPassive Cooling Solutions For Residential Buildings in Pabal, Maharashtra, IndiaEngineers Without Borders UK100% (1)

- Delivering On Sustainability Aspirations When Building Schools For The Future: Sharing Findings From Eco-Footprint ProgrammesDokumen14 halamanDelivering On Sustainability Aspirations When Building Schools For The Future: Sharing Findings From Eco-Footprint ProgrammesEngineers Without Borders UKBelum ada peringkat

- Maximizing The Benefits of Training Engineers About GenderDokumen8 halamanMaximizing The Benefits of Training Engineers About GenderEngineers Without Borders UKBelum ada peringkat

- EWB Bristol - NIGERIAN BOAT LIFT PROJECTDokumen9 halamanEWB Bristol - NIGERIAN BOAT LIFT PROJECTEngineers Without Borders UKBelum ada peringkat

- A Critical Review of Retrofitting Methods For Unreinforced Masonry StructuresDokumen19 halamanA Critical Review of Retrofitting Methods For Unreinforced Masonry StructuresEngineers Without Borders UK100% (1)

- The Role of The Foreign Engineer: Profiting From Poverty?Dokumen39 halamanThe Role of The Foreign Engineer: Profiting From Poverty?Engineers Without Borders UKBelum ada peringkat

- Bamboo Reinforced Concrete in Earthquake Resistant Housing Interim ReportDokumen37 halamanBamboo Reinforced Concrete in Earthquake Resistant Housing Interim ReportEngineers Without Borders UK100% (1)

- The Use of Rainwater Harvesting As A Poverty Reduction Strategy For Small-Scale Farmers in Developing Countries: The Need To Consider ContextDokumen7 halamanThe Use of Rainwater Harvesting As A Poverty Reduction Strategy For Small-Scale Farmers in Developing Countries: The Need To Consider ContextEngineers Without Borders UKBelum ada peringkat

- Innovative Water Scheme For Remote Nepalese Community: Raipali Village Clean Water High Lift Hand-Pump InstallationDokumen15 halamanInnovative Water Scheme For Remote Nepalese Community: Raipali Village Clean Water High Lift Hand-Pump InstallationEngineers Without Borders UKBelum ada peringkat

- The Application of Appropriate Well Drilling Technology in Sierra LeoneDokumen4 halamanThe Application of Appropriate Well Drilling Technology in Sierra LeoneEngineers Without Borders UKBelum ada peringkat

- Two Case Studies of Rural Water and Sanitation Development Projects in GhanaDokumen5 halamanTwo Case Studies of Rural Water and Sanitation Development Projects in GhanaEngineers Without Borders UK100% (1)

- Researching Temporary Sanitation: A Case Study of A UK MEng ThesisDokumen6 halamanResearching Temporary Sanitation: A Case Study of A UK MEng ThesisEngineers Without Borders UK100% (1)

- Single Point Loading Working Model Specifications and Parts OverviewDokumen4 halamanSingle Point Loading Working Model Specifications and Parts OverviewAnonymous CYdagI100% (1)

- Hydro Cyclone: Centripetal Force Fluid ResistanceDokumen10 halamanHydro Cyclone: Centripetal Force Fluid ResistanceMaxwell ToffahBelum ada peringkat

- Diagrama Montacargas AlmacenDokumen8 halamanDiagrama Montacargas AlmacenMiguel Gutierrez100% (1)

- Department Electrical Engineering Management IV Assignment 1 Semester 1, 2020Dokumen2 halamanDepartment Electrical Engineering Management IV Assignment 1 Semester 1, 2020samuelBelum ada peringkat

- SAP PPM 5.0 Certification Exam TopicsDokumen7 halamanSAP PPM 5.0 Certification Exam TopicsongkecanthoBelum ada peringkat

- Manual de Diagnostico D3E PDFDokumen72 halamanManual de Diagnostico D3E PDFJosé Luis Contreras Calderón100% (3)

- Fuji Noise Level Analyzer: For FUJI Digital Sound Detector FSB-8DDokumen2 halamanFuji Noise Level Analyzer: For FUJI Digital Sound Detector FSB-8DMar WilkBelum ada peringkat

- Mechanics of FlightDokumen1 halamanMechanics of FlightMoh Flit25% (4)

- Project Equipment Load AnalysisDokumen54 halamanProject Equipment Load Analysisrajeshmk2002100% (6)

- Public Dealing With UrduDokumen5 halamanPublic Dealing With UrduTariq Ghayyur86% (7)

- Katsina Polytechnic Lecture Notes on History and Philosophy of Science, Technology and MathematicsDokumen33 halamanKatsina Polytechnic Lecture Notes on History and Philosophy of Science, Technology and MathematicsHamisu TafashiyaBelum ada peringkat

- Chapter 6 THE SECOND LAW OF THERMODYNAMICS5704685Dokumen29 halamanChapter 6 THE SECOND LAW OF THERMODYNAMICS5704685bensonBelum ada peringkat

- Adss-Eke 150 (Mm12c) eDokumen7 halamanAdss-Eke 150 (Mm12c) eYuseidy Rguez PaezBelum ada peringkat

- Final Koni FinalDokumen124 halamanFinal Koni FinalBinod BoharaBelum ada peringkat

- ACP160DDokumen14 halamanACP160Dinbox934Belum ada peringkat

- ECOSYS FS-2100D Ecosys Fs-2100Dn Ecosys Fs-4100Dn Ecosys Fs-4200Dn Ecosys Fs-4300Dn Ecosys Ls-2100Dn Ecosys Ls-4200Dn Ecosys Ls-4300DnDokumen33 halamanECOSYS FS-2100D Ecosys Fs-2100Dn Ecosys Fs-4100Dn Ecosys Fs-4200Dn Ecosys Fs-4300Dn Ecosys Ls-2100Dn Ecosys Ls-4200Dn Ecosys Ls-4300DnJosé Bonifácio Marques de AmorimBelum ada peringkat

- Nordson EFD Ultimus I II Operating ManualDokumen32 halamanNordson EFD Ultimus I II Operating ManualFernando KrauchukBelum ada peringkat

- FlowTradersSOP PDFDokumen1 halamanFlowTradersSOP PDFAvinash IyerBelum ada peringkat

- The Importance of Understanding A CommunityDokumen23 halamanThe Importance of Understanding A Communityra sBelum ada peringkat

- Atuador Ip67Dokumen6 halamanAtuador Ip67Wellington SoaresBelum ada peringkat

- Zelenbabini Darovi Ivana N Esic - CompressDokumen167 halamanZelenbabini Darovi Ivana N Esic - CompressСања Р.0% (1)

- Generative NLP Robert DiltsDokumen11 halamanGenerative NLP Robert DiltsTyler Durden100% (22)

- Cop Y: Queueing TheoryDokumen7 halamanCop Y: Queueing TheoryDiego VásquezBelum ada peringkat

- PSP StompFilter Operation ManualDokumen26 halamanPSP StompFilter Operation ManualMoving BackwardsBelum ada peringkat

- How To Set Up Simulator Ard MMDokumen12 halamanHow To Set Up Simulator Ard MMJayakrishnaBelum ada peringkat

- SDS WD-40 Aerosol-AsiaDokumen4 halamanSDS WD-40 Aerosol-AsiazieyzzBelum ada peringkat

- Design TheoryDokumen2 halamanDesign Theoryhamidreza mohseniBelum ada peringkat

- Preview-9780429675119 A38620781Dokumen53 halamanPreview-9780429675119 A38620781Milton Alexandre ZiehlsdorffBelum ada peringkat

- Mockups Showeet (Standard)Dokumen46 halamanMockups Showeet (Standard)Palo Alto Turismo y EntretenimientoBelum ada peringkat

- Thandeka, Learning To Be White: Money, Race, and God in America (New York: Continuum International Publishing Group, 1999), 169 PPDokumen2 halamanThandeka, Learning To Be White: Money, Race, and God in America (New York: Continuum International Publishing Group, 1999), 169 PPFefa LinsBelum ada peringkat