WSHP

Diunggah oleh

hasan_6764896160 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

21 tayangan2 halamanWater SOURCE HEAT PUMP SYSTEMS consist of multiple heat pump units, a building piping loop, cooling tower, and boiler. WSHP units are available in many configerations including horizontal units for above the ceiling applications, small and large vertical units, rooftop units, and console units. R-22 is scheduled to be phased out of use by the year 2020 according to the Montreal protocol.

Deskripsi Asli:

Judul Asli

wshp

Hak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniWater SOURCE HEAT PUMP SYSTEMS consist of multiple heat pump units, a building piping loop, cooling tower, and boiler. WSHP units are available in many configerations including horizontal units for above the ceiling applications, small and large vertical units, rooftop units, and console units. R-22 is scheduled to be phased out of use by the year 2020 according to the Montreal protocol.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

21 tayangan2 halamanWSHP

Diunggah oleh

hasan_676489616Water SOURCE HEAT PUMP SYSTEMS consist of multiple heat pump units, a building piping loop, cooling tower, and boiler. WSHP units are available in many configerations including horizontal units for above the ceiling applications, small and large vertical units, rooftop units, and console units. R-22 is scheduled to be phased out of use by the year 2020 according to the Montreal protocol.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

Kohler and Lewis, Mechanical Engineers

WATER SOURCE HEAT PUMP SYSTEMS

by Daniel C. Lewis, M.S.M.E., P.E. Water Source Heat Pump Systems:

Water source heat pump systems consist of multiple water source heat pump (WSHP) units, a building piping loop, cooling tower, and boiler. The WSHP units themselves are water-to-air heat pumps comprised of a compressor, water/refrigerant heat exchanger, airside coil (refrigerant/air heat exchanger), reversing valve, fan section, filters, drain pan, and cabinet. WSHP units are available in many configerations including horizontal units for above the ceiling applications, small and large vertical units, rooftop units, and console units. All the unit configurations except the console units require a ductwork system for delivering conditioned air to the space. Console units are rarely ducted through the outside wall for ventilation air in this climate because air entering the WSHP units should be above 60 F.

Refrigerant:

These units currently use R-22 (HCFC-22) refrigerant. R-22 is scheduled to be phased out of use by the year 2020 according to the Montreal protocol. R-22 is the same refrigerant used in residential air conditioning systems. R-22 has a ozone depletion factor (ODF) of 0.05, and a global warming factor (GWF) of 0.37. Most people expect that R-410A will start to replace this refrigerant within the next few years. Therefore when units fail they would need to be replaced with units using the current refrigerant (probably not a problem since the units are inexpensive and to some extent throw-away). There is no problem mixing units with different refrigerants.

Building Water Loop:

Each zone or space will have one or more WSHP units which are connected to a two pipe water loop (one supply pipe and one return pipe). The heat pump units either reject heat to or extract heat from the piping loop depending on whether they are cooling or heating the space. This system will therefore recover and redistribute heat when some of the units are in the heating mode and other units are in the cooling mode. This is an advantage particularly where there is an interior building core which requires year around cooling, and a perimeter zone where heating is required in the winter. Rejected heat from daytime cooling requirements can also be used for nighttime heating requirements when thermal storage is provided. The piping loop is kept between 60 F and 90 F, which are the lower and higher limits for heat pump operation. The piping loop therefore does not need to be insulated which is a cost savings. If many or all of the building zones require heating then heat must be added to the piping loop to keep it from dropping below 60 F. Typically heat is added by a conventional boiler through a water-towater heat exchanger (because of the difference between normal boiler operating temperatures and the loop temperature). When all or most of the building zones require cooling then heat must be rejected from the loop using a closed cicuit evaporative cooler, a cooling tower and a water-to-water heat exchanger, or sometimes heat is rejected to a river or other heat sink.

Kohler and Lewis, Mechanical Engineers

Kohler and Lewis, Mechanical Engineers

Advantages of WSHP Systems:

WSHP systems provide good zoning capability, each unit can provide cooling or heating irregardless of what the other units are doing, or whether the rest of the building is in occupied mode or not. Small horizontal ceiling units can be relocated easily, or added as needed for changing building or tenant requirements. If a unit fails, the rest of the system remains operational (unless the boiler or cooling tower fails). Electrical energy use for the individual heat pump units can be metered for each tenant to recover at least a portion of heating and cooling costs (does not include the pumping, boiler and cooling tower operating costs). The installed cost of WSHP systems is lower than most competing systems, particularly two and four pipe fan coil systems because of savings in piping, pipe insulation, and control costs.

Disadvantages of WSHP Systems:

The primary disadvantage of WSHP systems is added maintenance. A typical system will have a large number of small heat pump units, all of which require maintenance, and repair or replacement as units fail. A WSHP unit is more complex and has more moving parts than a simple fan coil unit. In addition, the cooling tower is prone to freezing, and requires winterization. Cooling towers themselves are an added and often "strange" maintenance item.

Kohler and Lewis, Mechanical Engineers

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- OSHA - 29CFR - Construction StandardsDokumen22 halamanOSHA - 29CFR - Construction Standardshasan_676489616100% (1)

- ASME B16.47 Series B FlangeDokumen4 halamanASME B16.47 Series B Flange41h189Belum ada peringkat

- DIN2391 1EN10305 1 - 2003 02 - eDokumen27 halamanDIN2391 1EN10305 1 - 2003 02 - ehasan_676489616Belum ada peringkat

- ITP For Piping WorksDokumen91 halamanITP For Piping Workshasan_676489616100% (1)

- ITP For Piping WorksDokumen91 halamanITP For Piping Workshasan_676489616100% (1)

- Steel Grades ComparisonDokumen14 halamanSteel Grades Comparisonhasan_676489616Belum ada peringkat

- Din en Iso 4014Dokumen16 halamanDin en Iso 4014hasan_676489616100% (7)

- Method of Statement Piping Fab. ErectionDokumen22 halamanMethod of Statement Piping Fab. Erectionhasan_676489616Belum ada peringkat

- A Typical Design of Solar Water Pump SystemDokumen5 halamanA Typical Design of Solar Water Pump SystemJosephBelum ada peringkat

- LNG Tank Dismantling MS RevCDokumen14 halamanLNG Tank Dismantling MS RevChasan_676489616100% (1)

- Acid PipingDokumen1 halamanAcid Pipinghasan_676489616Belum ada peringkat

- New Haiti VillagesDokumen48 halamanNew Haiti Villagesclaudia beatoBelum ada peringkat

- Delayed PWHTDokumen4 halamanDelayed PWHThasan_676489616Belum ada peringkat

- MAK WATER - PDS Membrane Bioreactor (MBR) PDFDokumen2 halamanMAK WATER - PDS Membrane Bioreactor (MBR) PDFmeisam100% (1)

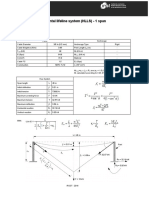

- Horizontal Life Line CalculationDokumen1 halamanHorizontal Life Line Calculationhasan_676489616100% (1)

- Plataformas PetrolerasDokumen61 halamanPlataformas PetrolerasNicky Love100% (1)

- Cross Cut TestDokumen1 halamanCross Cut Testhasan_676489616Belum ada peringkat

- Din 55928Dokumen16 halamanDin 55928hasan_676489616Belum ada peringkat

- E SN834Dokumen3 halamanE SN834hasan_676489616Belum ada peringkat

- E SN883Dokumen2 halamanE SN883hasan_676489616100% (1)

- Din 2614Dokumen11 halamanDin 2614hasan_676489616Belum ada peringkat

- Din 30678Dokumen6 halamanDin 30678hasan_676489616Belum ada peringkat

- Din 17240Dokumen24 halamanDin 17240hasan_676489616100% (1)

- E SN759Dokumen2 halamanE SN759hasan_676489616Belum ada peringkat

- Din 17221Dokumen9 halamanDin 17221hasan_676489616100% (1)

- Din 17155Dokumen16 halamanDin 17155hasan_676489616Belum ada peringkat

- E SN752Dokumen3 halamanE SN752hasan_676489616Belum ada peringkat

- Weld-On Pipe Coupling SN 789: Type ASDokumen1 halamanWeld-On Pipe Coupling SN 789: Type AShasan_676489616Belum ada peringkat

- E SN753Dokumen2 halamanE SN753hasan_676489616Belum ada peringkat

- Development and Climate Change in Bangladesh: Focus On Coastal Flooding and The SundarbansDokumen5 halamanDevelopment and Climate Change in Bangladesh: Focus On Coastal Flooding and The Sundarbanstrong anhBelum ada peringkat

- Mexico Workshop - Dam Break PresentationDokumen32 halamanMexico Workshop - Dam Break PresentationAdrian Luis Hernandez GarciaBelum ada peringkat

- Earth Subsystem-Earth ScienceDokumen29 halamanEarth Subsystem-Earth Sciencekenneth lo67% (3)

- Mineral Based Industry For Kerala by ThrivikramjiDokumen34 halamanMineral Based Industry For Kerala by ThrivikramjiDrThrivikramji KythBelum ada peringkat

- 10 Geography MapsDokumen45 halaman10 Geography MapsSiddharth KabirBelum ada peringkat

- Using HHO Gas To Reduce Fuel Consumption and Emissions in Internal Combustion Engines - En.esDokumen86 halamanUsing HHO Gas To Reduce Fuel Consumption and Emissions in Internal Combustion Engines - En.esSergio Ballestas100% (1)

- Environmental Studies Assignment-1 Topic: - Environmental Problems in Your LocalityDokumen11 halamanEnvironmental Studies Assignment-1 Topic: - Environmental Problems in Your LocalityLokesh Kumar GuptaBelum ada peringkat

- Prepsol SDSDokumen6 halamanPrepsol SDSelBelum ada peringkat

- Abattoir Waste Treatment in SivakasiDokumen8 halamanAbattoir Waste Treatment in SivakasivinothBelum ada peringkat

- Class VIII EnglishDokumen7 halamanClass VIII EnglishIT JPRBelum ada peringkat

- Etyl Mercaptan MSDSDokumen24 halamanEtyl Mercaptan MSDSmostafa_1000100% (1)

- Tunnel PPT Rakesh SehgalDokumen66 halamanTunnel PPT Rakesh SehgalS N satyanarayana100% (1)

- Origin of Eukaryotic Cell PDFDokumen8 halamanOrigin of Eukaryotic Cell PDFaco_golarBelum ada peringkat

- Ecosystem and The Components of Ecosystem: Jayesh N. IdateDokumen11 halamanEcosystem and The Components of Ecosystem: Jayesh N. IdatemkkamarajBelum ada peringkat

- Safety Data Sheet: 1. IdentificationDokumen8 halamanSafety Data Sheet: 1. IdentificationNurafindaBelum ada peringkat

- Ppe Midterm Project 1Dokumen14 halamanPpe Midterm Project 1Joanne EscolanoBelum ada peringkat

- Geomembranes For Canal LiningDokumen11 halamanGeomembranes For Canal Lininggalca_stefanBelum ada peringkat

- Case StudyDokumen15 halamanCase StudyAvinash YadavBelum ada peringkat

- Admixture Systems Brochure 2016Dokumen20 halamanAdmixture Systems Brochure 2016Gabriel HernandezBelum ada peringkat

- Md-89 Offshore Windwills 1Dokumen14 halamanMd-89 Offshore Windwills 1Roger Hazim100% (1)

- Mock Test 907Dokumen4 halamanMock Test 907KIMTHOABelum ada peringkat

- ShoppingmallDokumen102 halamanShoppingmallNiro ThakurBelum ada peringkat

- RET Problem SolvingDokumen13 halamanRET Problem SolvingJayanath Nuwan SameeraBelum ada peringkat

- 24 A - Review - On - The - Effect - of - Soil - Compaction - and - ItsDokumen23 halaman24 A - Review - On - The - Effect - of - Soil - Compaction - and - ItsLiv CBBelum ada peringkat

- Plumbing in ArchitectureDokumen8 halamanPlumbing in ArchitectureNethajiBelum ada peringkat