9.cummins. 2007

Diunggah oleh

Khaan SamiDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

9.cummins. 2007

Diunggah oleh

Khaan SamiHak Cipta:

Format Tersedia

Development and validation of a probabilistic second-order

exposure assessment model for Escherichia coli O157:H7

contamination of beef trimmings from Irish meat plants

E. Cummins

a,

*

, P. Nally

a

, F. Butler

a

, G. Duy

b

, S. OBrien

b

a

Biosystems Engineering, School of Agriculture, Food Science and Veterinary Medicine, University College Dublin, Earlsfort Terrace, Dublin 2, Ireland

b

The Ashtown Food Research Centre, Ashtown, Dublin 15, Ireland

Received 19 January 2007; received in revised form 20 August 2007; accepted 22 August 2007

Abstract

A second-order quantitative Monte Carlo simulation model was developed for Escherichia coli O157:H7 contamination of beef trim-

mings in Irish abattoirs. The assessment considers initial contamination levels, cross-contamination and decontamination events during

the cattle slaughter process. The mean simulated prevalence of E. coli O157:H7 on trimmings was 2.36% and the mean simulated counts

of E. coli O157:H7 on contaminated trimmings was 2.69log

10

CFU/g. A parallel validation survey provided some condence in the

model predictions. An uncertainty analysis indicated that microbial test sensitivity is a signicant factor contributing to model uncer-

tainty and requires further investigation while also indicating that risk reduction measures should be directed towards reducing the hide

to carcass transfer (correlation coecient 0.25) during dehiding and reducing the initial prevalence and counts on bovine hides (corre-

lation coecients 0.19 and 0.16, respectively). A characterisation of uncertainty and variability indicating that further research is

required to reduce parameter uncertainty and to achieve better understanding of microbial transfer in meat plants. The model developed

in this study highlights the need for further development of quantitative risk assessments in the food industry.

2007 Elsevier Ltd. All rights reserved.

Keywords: Exposure assessment; Simulation; Escherichia coli O157:H7; Beef

1. Introduction

Verocytotoxigenic Escherichia coli, in particular sero-

group O157, has emerged as a pathogen of major public

concern. High prole outbreaks have focused attention

on outbreaks connected to food products, in particular,

minced beef and beef burgers (CDC, 1993; Duy, Cum-

mins, Nally, OBrien, & Butler, 2006a). Preliminary gures

indicate that approximately 52 cases of E. coli O157:H7

poisoning occurred in Ireland during 2004 (HPSC, 2004),

while other suspected cases in 2005 are currently under

investigation. The current number of illnesses in Ireland

represents a worrying trend as the numbers remain at a rel-

atively high level with a peak of 88 occurring in 2003

(HPSC, 2004). Consequences of food borne poisoning

from the bacteria can vary from severe illness to kidney

failure, central nervous system damage and death.

The E. coli O157 bacterium is present in faeces and the

intestines of healthy bovines and can contaminate meat dur-

ing the slaughter process (Chapman, 2000). One of the most

signicant threats to food safety is the potential contamina-

tion of edible carcass tissues with the bacterium. The level of

this risk is related to the extent and nature of such contam-

ination and the stages which may distribute bacterial con-

tamination during the slaughter process (Gill, McGinnis,

& Badoni, 1996; McEvoy et al., 2001, 2003). Cross-contam-

ination can occur at multiple stages during the slaughter

process resulting in potential contamination of meat des-

tined for human consumption. Following removal of the

primal cuts of beef from the beef carcass the remaining cuts

0309-1740/$ - see front matter 2007 Elsevier Ltd. All rights reserved.

doi:10.1016/j.meatsci.2007.08.015

*

Corresponding author. Tel.: +353 1 7167476; fax: +353 1 4752119.

E-mail address: enda.cummins@ucd.ie (E. Cummins).

www.elsevier.com/locate/meatsci

Available online at www.sciencedirect.com

Meat Science 79 (2008) 139154

MEAT

SCIENCE

of meat, including ank and Jacobs ladder (part of the M.

serratus ventralis) are removed. These cuts are referred to

as beef trimmings and are later processed into saleable

products such as beef burgers. Given that beef trimmings

are processed into comminuted beef products for human

consumption, it stands to reason that beef trimmings should

be free from all sources of contamination, thus reducing

human exposure to potential hazards, including E. coli

O157:H7. Scientic evidence suggests that most E. coli

related food poisoning cases have been associated with

comminuted beef products (CDC, 1993), highlighting the

importance of investigating this source of contamination.

The objective of this work was to develop a quantitative

exposure assessment to model the contamination of beef

trimmings at Irish abattoirs in an eort to identify critical

points in the process and to assess the impact of process

stages on the prevalence and counts of E. coli O157:H7.

There exists previously published models of bacterial con-

tamination of beef trimmings in abattoirs (Cassin, Lam-

merding, Todd, Ross, & McColl, 1998; Jordan, McEwen,

Lammerding, McNab, & Wilson, 1999a; Roberts, Mal-

colm, & Narrod, 1999; Ebel et al., 2004; USDA, 2002).

However, few studies have conducted parallel validation

studies to ensure model predictions are an accurate repre-

sentation of reality. A unique element of this study was

the parallel microbial surveillance conducted at several

points in the abattoir, thus acting as a partial validation

for the model (OBrien et al., 2005; Carney et al., 2006;

Duy et al., 2005). We state partial validation as full vali-

dation would involve repeated comparisons between model

outputs and real data which would be unfeasible in a food

production situation due to limited time and resources.

However, the partial validation provides a snapshot of

how model outputs compare with real data and can pro-

vide an element of condence in model predictions. The

model used probability distributions to simulate both

uncertainty and variability in the construction of a sec-

ond-order model. The probability distributions of the com-

ponent variables were either derived from survey data or

estimated from the available literature. The output of the

model was a distribution of the prevalence of E. coli

O157:H7 on beef trimmings and a distribution for the num-

ber of organisms on contaminated beef trimmings. The

model used Monte Carlo simulation techniques (Vose,

2000) to create the output distributions. Monte Carlo

methods repeatedly select values randomly from distribu-

tions to create multiple scenarios of a problem. Together,

these scenarios give a range of possible solutions, some of

which are more probable and some less probable resulting

in a probability distribution for the solution parameter.

2. Materials and methods

2.1. Model development

The focus of the model was within the slaughterhouse.

The prevalence and counts of E. coli O157:H7 bacteria

were modelled at various stages along the slaughter line.

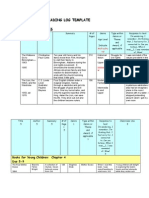

A ow diagram of the process is given in Fig. 1. The model

was created in Microsoft Excel 2000 with the add-on pack-

age @Risk (version 4.05, Palisade Corporation, New York,

USA).

Distributions can be used to represent the eect each

process stage has on microbial numbers by modelling inter-

mediary processing stages (e.g. dehiding, evisceration,

washing, chilling and boning out). As a result changes in

Decontamination

Stunning

Shackling/Hoisting

Neck Hide

opening

Removal of hooves

De-hiding

Head removal

Brisket sawing

Carcass splitting

Spinal Cord

removal

Trimming

Carcass grading,

weighing & stamping

Evisceration

Steam

Pasteurisation

Trimmings

Boxed Beef

trimmings (70VL)

Carcass

Washing

Chilling

Boning out

Fig. 1. Flow diagram of the stages involved in bovine slaughter and

subsequent production of beef trimmings. Ovals denote steps that may

either increase or decrease contamination. Rectangles denote steps with

little or no increase in contamination.

140 E. Cummins et al. / Meat Science 79 (2008) 139154

microbial counts on the carcass can be simulated as the car-

cass moves through the plant. Model inputs were derived

from Irish data where possible. A number of studies spe-

cic to Irish abattoir conditions (Carney et al., 2006; Duy

et al., 2005; McEvoy et al., 2000, 2001, 2003; OBrien et al.,

2005; Sheridan, Lynch, & Harrington, 1992) provided valu-

able input data; alternatively, international data and scien-

tic literature were consulted to improve the basis for the

model where Irish specic data were not available.

2.2. Uncertainty and variability

There is increasing emphasis being placed on quantify-

ing the impact of uncertainty and variability in risk assess-

ments (Bogen, 1995; Bogen & Spear, 1987; Borsuk, 2004;

Burmaster & Thompson, 1998; Cohen, Lampson, & Bow-

ers, 1996; Frey & Rhodes, 1996; Frey & Burmaster, 1999;

Kelly & Campbell, 2000; Nayak & Kundu, 2001; Pouillot,

Beaudeau, Denis, & Derouin, 2004). Variability refers to

the eect of chance and is a function of the system. It is

not reducible by further study. Variability represents a true

heterogeneity of the population. Uncertainty represents

our lack of knowledge about a particular parameter in

the model and can be reduced by further measurement or

study. Since ecological systems are highly variable and

our knowledge of model input parameters is uncertain, it

is important that models separate the eects of uncertainty

and variability (Regan et al., 2003). Separation of the two

will highlight the importance of uncertainty of the input

parameters by means of a sensitivity analysis and can pro-

vide greater accountability and transparency for key ele-

ments of the model. In a probabilistic risk assessment,

the term second-order is often used to describe the use

of probability distributions to represent variability and

uncertainty in the input parameters (Bogen & Spear,

1987; Frey, 1993; Price, Su, Harrington, & Keenan, 1996;

Vose, 2000). Variability and uncertainty in the input

parameters were incorporated in the construction of a sec-

ond-order model by means of probability distributions.

Previously published models of slaughterhouse contamina-

tion (Roberts et al., 1998; Cassin et al., 1998; Jordan et al.,

1999a, Jordan, McEwen, Lammerding, McNab, & Wilson,

1999b) were rst-order models and did not fully distinguish

between uncertainty and variability. Their separation in

this model allows us to understand the steps necessary to

reduce total uncertainty and allows us to gauge the value

of more information or some potential change to the sys-

tem. The second-order approach claries communication

of results to decision-makers, helping to identify sensitive

input parameters and future data collection requirements.

2.3. Model assumptions

Simulation models regularly require the use of unavoid-

able subjective assumptions. These assumptions can impact

on the results obtained in risk and exposure assessments,

hence models need to be viewed in the context of the

assumptions made. The following modelling assumptions

have been made in the development of this exposure

assessment:

The probability of one cow on the slaughter line being

infected is independent of the probability of another

cow on the slaughter line being infected. Random mix-

ing is assumed to occur.

Meat is normally sterile beneath exposed surfaces, but

some surface contamination with pathogens can occur

during the slaughter process.

The microbial prole of a production lot of beef trim-

mings is independent of previous lots processed at the

abattoir, i.e. that the plant environment is completely

sterilised between runs.

The model assumes homogenous distribution of feces on

bovine hides and carcass, assuming some clustering

may yield dierent results.

Contamination levels on a carcass following rupture of

the intestine were assumed to be the same as when a car-

cass is contaminated by the hide.

During storage and handling of meat, E. coli O157:H7

levels can increase.

An inability to obtain empirical data results in the appli-

cation of probability distributions to model process

stages; the model tries to err on the side of caution when

modelling inactivation and growth.

The model assumes no false positives for the partial val-

idation study used (i.e. specity equal to 100%).

Validation data points (Carney et al., 2006) are

assumed to be independent and identically (binomially)

distributed.

3. Model input parameters

For clarity, the model is compartmentalised into four

sections: (1) initiating parameters, (2) slaughter module,

(3) trimmings production module and (4) model run and

outputs. The model relies upon the generation of random

variables from input probability distributions and these

are represented in the model equations by the name of

the probability distribution (e.g. Poisson, triangular, etc.)

followed by the parameters in brackets. The input proba-

bilities for each of the sections, displayed in Figs. 2 and

3, were derived from the literature and expert opinion.

3.1. Initiating parameters (hide and gut prevalence)

The model starts with bovines entering the abattoir;

some initial parameters are needed at this stage. These

initiating parameters include the prevalence of E. coli

O157:H7 on bovine hides, in the bovine intestine and

on bovine carcasses. Table 1 summarises these input

distributions.

The prevalence of E. coli O157:H7 on the hides of live

cattle in Ireland was estimated from an extensive survey

carried out in conjunction with this research project (Duy

E. Cummins et al. / Meat Science 79 (2008) 139154 141

et al., 2006b), the details of which, including materials and

methods for detecting bacterial, are given in OBrien et al.

(2005). The survey was conducted at an Irish commercial

abattoir with a line speed of 4080 animals per hour. From

a sample of 1500 bovine hides, 109 hides were found to be

positive for the bacteria. If we have no prior information

about a prevalence, and do not wish to assume any prior

information, a uniform prior distribution is used (Vose,

2000), thus through Bayes theorem the posterior turns

out to be a beta distribution, which is a conjugate to the

Binomial distribution. A Beta distribution can be used to

model the condence one has about the probability of suc-

cess of a binomial trial p, where one has observed n inde-

pendent trials of which s were successes with the formula

p = beta (s + 1, n s + 1). A beta distribution with uni-

form prior is therefore used to model uncertainty about

prevalence estimates in this study. The prevalence (P

h

) on

animal hides was therefore modelled using a beta distribu-

tion (beta(109 + 1, 1500 109 + 1)) to represent parameter

uncertainty. The conrmatory test used during this survey

was the Immunomagnetic Separation test (IMS) (Duy

et al., 2005). Previous work has shown that test sensitivity

may be dependent on the condition of the animal hide (i.e.

wet or dry) as illustrated by OBrien et al. (2005). To

Tse: Test

sensitivity

P

h

: Prevalence on

hide

TR: Transfer

rate

P

ht

: True Prevalence

on Hide

I

h

: Counts on hide

(log CFU/100 cm

2

)

F

c

: Boolean Flag

CR: Growth during

chilling (log)

P

c

: Prevalence on

Carcass

Not

contaminated

I

ht

: True counts on

hide (log CFU/cm

2

)

Fi: Recovery

Factor

I

c

: Counts on Carcass

(log CFU/cm

2

)

R: Count

Reduction from

hide to carcass

B

ch,

B

cg

, B

cb

: Total

organisms on

contaminated surface

(log CFU)

A: Contaminated

surface area

(cm

2

)

N

d

, N

g

,N

b

: Total

organisms on

contaminated surface

following fabrication

(log CFU/carcass)

D1: Decontamination

(log)

G: Growth during

Fabrication (log)

n

d

, n

g

, n

b

: Total

organisms per unit

surface area (log

CFU/cm

2

)

A: Contaminated

surface area (cm

2

)

C

trim

: Total organisms

on a trimming (log

CFU)

Acontam:

Contaminated area

of a trimming (cm

2

)

C: Total Organisms on

a contaminated

trimming (Log CFU/g)

Mt: Mass of

trimming (g)

- Total Surface area (TSA)

- Trim per animal (Atrim)

- Contaminated surface area

I

t

: Infected

Trimmings

P: Prevalence of

contaminated

trimming

Nt: Total

trimmings

produced

D2: Decontamination

(log)

Input from Figure 2

I

n

i

t

i

a

t

i

n

g

P

a

r

a

m

e

t

e

r

s

S

l

a

u

g

h

t

e

r

M

o

d

u

l

e

T

r

i

m

m

i

n

g

s

P

r

o

d

u

c

t

i

o

n

C

c

: Number of

infected carcasses

As: Animals

Slaughtered

Fig. 2. Diagrammatic representation of the simulation model together with the input parameters.

142 E. Cummins et al. / Meat Science 79 (2008) 139154

account for this, a test sensitivity parameter (T

se

) was

derived using bayesian inference techniques (Cummins,

Nally, Butler, Duy, & O Brien, 2007). Bayesian inference

can be used to combine multiple data sets and expert opin-

ion to give a posterior distribution. The true (P

ht

) preva-

lence was calculated by dividing the detected prevalence

on bovine hide (P

h

) by the test sensitivity (T

se

). The nature

of the test is such that test specicity is assumed to be

100%, thus the model assumes that there are no false

positives.

The prevalence of E. coli O157:H7 in the intestine of

Irish bovine animals (P

g

) was determined from McEvoy

et al. (2001, 2003) where it was found that two animals

from a sample of 250 were positive for the bacteria. The

prevalence in the intestine was thus modelled using a beta

distribution (beta(2 + 1, 250 2 + 1)).

3.2. Slaughter module

3.2.1. Dehiding

The dehiding stage can contaminate the carcass in sev-

eral ways including direct contact between a carcass and

a contaminated hide or cross-contamination via worker

handling. Transfer of contamination from hide surface to

carcass is eectively unavoidable due to the nature of the

process (McEvoy et al., 2000). McEvoy et al. (2003)

reported the greatest carcass contamination occurs at sites

associated with the opening of the hide. McEvoy et al.

(2000, 2003) found E. coli O157:H7 on three carcasses from

a sample of 36 carcasses following hide removal. It is

unknown whether these animals were shedding the bacteria

or had contaminated hides. However, the results highlight

the likely transfer of bacteria to the carcasses at this process

point. Bell (1997) reported high contamination on sites

associated with opening cuts and/or subject to hide contact

during hide removal. Elder et al. (2000) performed a survey

in the USA to estimate the frequency of enterohemorrhagic

E. coli O157:H7 in faeces and on hides within groups of

cattle from single lots presented for slaughter at meat pro-

cessing plants and found that faecal and hide prevalence

were signicantly correlated with carcass contamination.

Previous models (Cassin et al., 1998; Ebel et al., 2004) cre-

ated a cross-contamination factor between prevalence of

E. coli O17:H7 in bovine feces and the prevalence on

bovine carcass. However, given the evidence for signicant

cross-contamination from bovine hides (Elder et al., 2000;

Gill, McGinnis, & Bryant, 1989; McEvoy et al., 2003), the

model developed in this study assumes that contaminated

animal hide is the main vehicle for cross-contamination

to bovine carcasses at the hide removal stage. Thus, a

cross-contamination factor (TR) from bovine hide to

carcass was created using Irish surveillance data. From a

E: Probability

of gut rupture

P

g

: Prevalence in gut

Ef: Boolean Flag

Not

contaminated

Output to Figure 1

B

cg

: Total organisms

on contaminated

surface (log CFU)

I

n

i

t

i

a

t

i

n

g

P

a

r

a

m

e

t

e

r

s

S

l

a

u

g

h

t

e

r

M

o

d

u

l

e

Fig. 3. Diagrammatic representation of the simulation of intestinal contamination of a bovine carcass.

Table 1

Initiating parameters, distributions and inputs used in the model

Parameter Symbol Distribution/model Category Units

Animals slaughtered in a day A

s

350 Fixed value Animals

Prevalence in the gut P

g

beta(3, 247) Uncertainty Prevalence

Prevalence on the hide P

h

beta(110, 1390) Uncertainty Prevalence

Test sensitivity T

se

derived by Bayesian inference (see text) Uncertainty Factor

True prevalence P

ht

P

h

/T

se

Prevalence

Transfer ratio between hide and carcass TR beta(4, 32)/beta(110, 1390) Uncertainty Prevalence

Prob. of infected carcass P

c

TR P

ht

/(1 P

h

+ TR P

ht

) Calculation Ratio

Number of contaminated carcasses C

c

Binomial(A

s

, P

c

) Variability Animals

Total surface area of animal TSA 32,000 Fixed value cm

2

Mass of a combi bin M 2700 Fixed g

E. Cummins et al. / Meat Science 79 (2008) 139154 143

sample of 1500 bovine hides, 109 hides tested positive for

E. coli on entering the slaughter plant (OBrien et al.,

2005). Following hide removal, three carcasses from a sam-

ple of 36 carcasses tested positive for E. coli O157:H7

(McEvoy et al., 2001, 2003). The two resulting beta distri-

butions were combined to create a cross-contamination

factor from animal hide to carcass, TR:

TR beta3 1; 36 3 1=beta109 1; 1500 109 1:

1

The probability of a carcass being contaminated (P

c

) is

thus given by the equation

P

c

TRP

ht

=1 P

ht

TR P

ht

: 2

The number of contaminated carcasses (C

c

) processed on a

particular day can therefore be simulated using a binomial

distribution (binomial(A

s

, P

c

), with the total number of ani-

mals slaughtered on a particular day represented by A

s

.

For this work, A

s

was set to 350, representing a typical days

slaughter in an Irish abattoir. A similar approach was

taken by Cassin et al. (1998) in modelling carcass contam-

ination, while Ebel et al. (2004) simply used the cross-

contamination factor as a multiplier for the number of

animals infected in a cattle lot.

3.2.2. Initial bacterial load on bovine hide and carcasses

Following the calculation of the prevalence of infected

carcasses, each carcass was simulated individually and a

Boolean (truefalse) ag generated as a Bernoulli random

variate with p (the probability of a carcass being contami-

nated) equal to the prevalence. Each Boolean ag used a

binomial distribution with the total number of events equal

to 1. Thus, the result of each Boolean ag will be 1 (con-

taminated) or 0 (uncontaminated). This was used to con-

rm contamination, or otherwise, of the carcass (F

c

) and

intestine (F

g

) of each individual animal (see Figs. 2 and 3,

respectively). Should the ag conrm the presence of con-

tamination, the model continues to model the counts of

bacteria from hide to carcass and the eect subsequent pro-

cessing treatments have on bacterial counts.

The initial number of bacteria on animal hides (I

h

) was

modelled by tting a second-order continuous non-para-

metric distribution to a data set. The methodology is

detailed in Vose (2000). This procedure thus gives a sec-

ond-order model of the initial counts of bacteria on animal

hides. The technique allows the construction of a non-para-

metric second-order distribution for a continuous variable

given a limited experimental data set.

The initial levels of bacteria on animal hides (I

h

) used in

this analysis were from a survey conducted at a large Irish

abattoir by OBrien et al. (2005) where they evaluated

microbial populations on bovine hides. The bacterial

counts were estimated using direct plate methods (OBrien

et al., 2005). Sponge swab samples yielded mean E. coli

O157:H7 counts on the exterior hide ranging from 0.13

to 4.24log

10

CFU/100 cm

2

. Of the 109 positive samples,

82 were detected by direct plate and enumerated, while

27 samples were detectable by enrichment only, indicating

that their count was below the detectable level for direct

plating (taken as 1 CFU/100 cm

2

) and, hence, counts for

these samples were not obtained. The frequency data for

the distribution of the counts are shown in Table 2. If

the counts on a carcass were deemed to be below 1 CFU/

100 cm

2

, the count was modelled using a uniform distribu-

tion ranging from 0 to 1 CFU/100 cm

2

. For carcasses with

counts above 1 CFU/100 cm

2

, a second-order non-para-

metric distribution was tted to the data set. Fig. 4 repre-

sents the resulting second-order non-parametric

distribution used to model the initial bacterial load on

bovine hides. The mean distribution is indicated by the

bold line. The 5th and 95th percentile values for the uncer-

tainty distribution are also included, represented by the

vertical grey lines.

Reduction in bacterial recovery from bovine hide and

meat has previously been noted (Byrne, Bolton, Sheridan,

McDowell, & Blair, 2000; Chapman et al., 1993; Firsten-

berd, 1981; McEvoy et al., 2003; Nortje & Naude, 1981)

but is a parameter which appears to have been omitted

from previous models of bacterial contamination in abatt-

oirs. The reduction may be due to the irreversible binding

of some of the bacteria deposited; it has been described

Table 2

Frequency distribution for E. coli O157:H7 counts on bovine hides

(adopted from OBrien et al. (2005))

CFU/100 cm

2

Frequency

<1 27

a

<10 37

<100 34

<1000 9

<10,000 1

<100,000 1

<1,000,000 0

Total 109

a

Undetectable by direct plate.

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

-1.5 -0.5 0.5 1.5 2.5 3.5

Log

10

CFU/100 cm

2

C

u

m

u

l

a

t

i

v

e

p

r

o

b

a

b

i

l

i

t

y

x<=-0.61

5.0%

x<=2.44

95.0%

Fig. 4. Cumulative distribution for E. coli O157:H7 counts on bovine

hides including separation of uncertainty (represented by the presence of

multiply lines) and variability (each line is a variability distribution).

144 E. Cummins et al. / Meat Science 79 (2008) 139154

as a two-stage process by McEvoy et al. (2003) whereby ini-

tial reversible absorption becomes irreversible over time.

Hence, the values estimated in the survey may themselves

be the subject of uncertainty due to this reduction in recov-

ery. Research was carried out by OBrien et al. (2004)

whereby a known number of E. coli O157:H7 bacteria were

inoculated onto an animal hide and recovery of the bacte-

ria from the hide was carried out using direct plate methods

(as used in the commercial survey). Successive tests

revealed that the recovered bacterial count could vary

between 0.50 and 1.50log

10

compared to the initial inocu-

lum level. To account for this, a recovery factor (F

i

) for

the initial counts of bacteria was incorporated into the

model with uniform uncertainty distribution ranging from

0.50 to 1.50log

10

. The true count (log

10

CFU/cm

2

) on ani-

mal hide (I

ht

) was modelled by taking account of the factor

increase due to the likely reduced bacterial recovery and is

represented by

I

ht

log10

I

h

F

i

=100: 3

Bacon, Belk, Sofos, & Smith (2000) evaluated microbial

populations on animal hides and changes in carcass micro-

bial population at various stages in the slaughtering pro-

cess in the USA. Sponge swab samples yielded mean

generic E. coli on the exterior hide of 5.507.50log

10

CFU/100 cm

2

with corresponding concentration levels on

the carcass (after hide removal but before any decontami-

nation intervention) of 2.605.30log

10

CFU/100 cm

2

. The

reduction in counts from animal hide to carcass (R) was

thus obtained by tting a continuous empirical cumulative

distribution to this data (Fig. 5). The initial counts

(log

10

CFU/cm

2

) on a carcass (I

c

) were therefore obtained

by subtracting the log reduction factor (R) from the true

initial counts on the animal hide (I

ht

) as given by

I

c

I

ht

R: 4

There are no scientic studies available to estimate the total

contaminated surface area (A) of a carcass. This model

used the same approach as suggested by Ebel et al.

(2004) as follows:

A 10

Triangularlog30;log300;log3000

: 5

This is based on the fact that initial runs of their model

indicated a maximum contamination area of 3000 cm

2

and the minimum contamination area arbitrarily set to

30 cm

2

. The total organisms (log

10

CFU/carcass) on a con-

taminated carcass after dehiding (B

c,h

) is therefore given as

B

c;h

log10

Ic

A: 6

3.2.3. Decontamination after dehiding

A number of decontamination steps are employed fol-

lowing dehiding, including knife trimming to remove visi-

ble spots of faecal contamination and/or a series of

washing treatments. The eectiveness of knife trimming is

highly variable (Prasai et al., 1995). In particular, work

by Smeltzer, Peel, and Collins (1998) and Sheridan et al.

(1992) have shown that equipment such as knives, gloves

and aprons can act as reservoirs for bacteria. Gill et al.

(1996) suggested that trimming can extensively decontami-

nate parts of the carcass. Scientic studies relating to car-

cass washing give conicting results. Typically animals

are washed with potable water at a temperature of 35

40 C. McEvoy et al. (2003) reported no signicant change

in generic E. coli counts following washing while Reagan

et al. (1996) concluded that carcass washing can have the

eect of reducing counts of bacteria. There is also evidence

that some washing procedures may redistribute bacteria to

other parts of the carcass (Bell, 1997; Castillo, Lucia,

Goodson, Savell, & Acu, 1998; McEvoy et al., 2003). Cas-

sin et al. (1998) modelled the reduction in counts due to

decontamination at this stage by using a uniform

distribution with minimum of 1 and a maximum of

2.50log

10

CFU/cm

2

reduction. In the present study, to cap-

ture the variability, reduction by decontamination (D1)

was modelled using a triangular distribution with a mini-

mum reduction of zero, a most likely of D1

mm

and maxi-

mum of D1

max

. A triangular density distribution is used

as a modelling tool where the range and most likely value

within a range can be estimated. The triangular distribu-

tion oers considerable exibility in its shape while

accounting for the uncertainty within the given range

(Vose, 2000). Gill (1999) reported a reduction in generic

E. coli counts of 0.32 log

10

CFU/cm

2

following rinsing

while (Dorsa, 1997) reported a 0.70log

10

CFU/cm

2

reduc-

tion of E. coli following rinsing. The uncertainty about

the most likely value (D1

mm

) was thus modelled using a

uniform distribution (uniform(0.30, 0.70)). The uncertain

maximum value was arbitrary set to vary between 0.80

and 1.20log

10

CFU/cm

2

(D1

max

= uniform(0.80, 1.20)).

3.2.4. Evisceration

Evisceration represents another opportunity for con-

tamination of the carcass to occur. If the intestine of an

animal is positive for E. coli O157:H7 and the intestine is

inadvertently ruptured during the evisceration process,

gross-contamination of the carcass may occur due to

X <= 3.91

95.0%

X <= 0.54

5.0%

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

log reduction in counts from animal hide to carcass (R)

C

u

m

u

l

a

t

i

v

e

p

r

o

b

a

b

i

l

i

t

y

-0.5 0 0.5 1 1.5 2 2.5 3 3.5 4 4.5

Fig. 5. Log reduction in counts from animal hide to carcass (R) (based on

Bacon et al., 2000).

E. Cummins et al. / Meat Science 79 (2008) 139154 145

spilling of the intestine contents. However, research by

McEvoy et al. (2003) reported that evisceration did not

appear to contribute to carcass contamination with

E. coli O157:H7, which is in agreement with other studies

(Nottingham & Harrison, 1974). Cassin et al. (1998) and

Roberts et al. (1999) neglected to consider the possible

impact of evisceration in their models. This is likely to be

due to the small number of occasions that an intestine is

ruptured at evisceration. In the present study, it was

decided to model the evisceration stage similarly to that

done by Ebel et al. (2004). The number of times eviscera-

tion resulted in a ruptured intestine was determined to be

relatively small (between 1 in 100 and 1 in 1000) as indi-

cated by the abattoir workers and plant manager (oral

communication). Thus, the probability of intestine con-

tents spilling (E) during evisceration was modelled as

E 10

uniform2;3

: 7

The model therefore uses another Boolean ag to simulate

the rupture of the intestine of an individual carcass (E

f

). If

the intestines of an animal are split and the animal does not

have an infected intestine it is assumed that the carcass is

not infected. Only when an intestine is positive for the bac-

teria and the intestine is ruptured will contamination of a

carcass occur through this route. The counts of bacteria

on a carcass after rupture (B

c,e

) were assumed to be the

same as when the carcass was contaminated from the ani-

mal hide (i.e. B

c,e

= B

c,h

). The model combines counts from

both sources in the unlikely event of a carcass being con-

taminated during dehiding and during evisceration.

3.2.5. Decontamination after evisceration

After carcass splitting and spinal cord removal, some

knife trimming is carried out to remove visible spots of fae-

cal contamination. Steam pasteurisers are installed in a

small number of meat plants in Ireland. Its eciency was

assessed by Phebus et al. (1997). Reductions of E. coli

O157:H7 were found to be approximately 3.53 (0.49)

log

10

CFU/cm

2

. Technical diculties have meant limited

use of these pasteurisers to date in Irish plants. In this anal-

ysis, the model considers production in a plant which does

not have steam pasteurisation in place, as it is more repre-

sentative of current abattoir practices in Ireland. After

splitting and spinal cord removal, animals are typically

washed with potable water at a temperature ranging from

35 to 40 C. A second decontamination step (D2) was con-

sidered in the model to take account of this. Similar eec-

tiveness of the rst decontamination step was assumed, as

the processes are similar (i.e. carcass washing). The process

was modelled, similarly to D1, using a triangular

distribution with uncertainty about the most likely value

[D2

mm

= uniform(0.30, 0.70)] and uncertainty about the

maximum reduction [D2

max

= uniform(0.80, 1.20)].

3.2.6. Chilling

It has been reported that chilling is not likely to have

any noticeable eect on E. coli prevalence or counts (Cassin

et al., 1998; McEvoy et al., 2003). McEvoy et al. (2003)

reported a reduction in prevalence on carcasses after chill-

ing for 24 h. McEvoy et al. (2003) hypothesised that chill-

ing may stress the bacterial cells due to the synergistic

eect of low water activity (a

w

) and temperature. Similarly,

Gill et al. (1996) reported a reduction in coliforms and

E. coli on carcasses following cooling processes of between

0.50log

10

and 2.00log

10

units. McEvoy et al. (2003) sug-

gested that cross-contamination between carcasses might

also occur during chilling, however, there was a lack of evi-

dence to support this claim. Sheridan (2000) noted that car-

cass contamination may increase, decrease or remain

unchanged following chilling and depended on parameters

such as temperature, air speed and relative humidity. In the

model, growth or decline is assumed to occur only on car-

casses that are contaminated on entering the chiller. Cassin

et al. (1998) modelled the potential growth using a triangu-

lar distribution with minimum growth of 2, a mode of 0

and a maximum of 5 generations. Similarly Roberts et al.

(1999) used a triangular distribution to model the chilling

stage with a minimum reduction of 0log

10

reduction and

a maximum and most likely reduction of 1.00log

10

. Similar

to Ebel et al. (2004), the change in counts on contaminated

carcasses during chilling (CR) was assumed to be normally

distributed and was modelled in this study using a normal

distribution with an uncertain mean (CR

m

) ranging from

0.50 to 0.50log

10

and a standard deviation (CR

stdev

) of

1, thus remaining within the bounds given in previous stud-

ies. Therefore, the most likely eect is that there is no eect

from chilling while allowing for some variability.

3.2.7. Growth in the boning hall

Growth of E. coli O157:H7 may occur at various stages

along the slaughter line. The boning hall in particular has

proven to be an area where signicant growth can occur.

Growth of generic E. coli has been shown to occur at this

stage (McEvoy et al., 2003) with a mean increase of

approximately 0.33log

10

. Sheridan et al. (1992) reported

that the level of contamination on the beef cuts as a result

of boning was related to the amount of trimming and

work-up the cuts received. The study also found that both

surfaces and personnel were sources of contamination of

the meat. While growth may occur during boning other

research has suggested that the prevalence does not

increase following the process (McEvoy et al., 2003). Bon-

ing halls are typically kept at 10 C, but there may be large

variations around this. Roberts et al. (1999) modelled the

growth during fabrication as a normal distribution with a

mean of 1 and a standard deviation of 0.5. Cassin et al.

(1998) modelled growth during processing in terms of gen-

erations, using a triangular distribution with a minimum of

2, most likely of 0 and a maximum of 5 generations of

growth. The latter represents a growth of approximately

1.50logs. A study of four abattoirs found an increase in

generic E. coli ranging from 0 to 2.00log

10

(Gill, 1999).

In the model developed in this study, growth (G) was mod-

elled using a triangular distribution with a minimum of

146 E. Cummins et al. / Meat Science 79 (2008) 139154

0logs of growth, most likely value of 0.33 and a maximum

growth of 2.00logs, in line with published literature from

Gill (1999) and Sheridan et al. (1992) and remaining within

the bounds indicated by other authors (Cassin et al., 1998;

McEvoy et al., 2003; Roberts et al., 1999).

3.2.8. Contamination of carcasses

The contamination level on a carcass can be calculated

following dehiding, washing, chilling and boning out oper-

ations by combining the eects of successive operations on

bacterial counts. The number of organisms will depend on

the source of contamination, for example the carcass may

have been contaminated during dehiding, evisceration or

both operations. The number of organisms (log

10

CFU/

carcass) following contamination after dehiding (N

d

) is

given as

N

d

B

c;h

D1 D2 CR G: 8

The number of organisms (log

10

CFU/carcass) following

contamination after evisceration (N

e

) is represented by

N

e

B

c;e

D1 D2 CR G: 9

If the carcass is contaminated from both sources (N

b

), the

number of organisms (log

10

CFU/carcass) is given as

N

b

log10

B

c;h

10

D1

10

Bc;e

D2 CR G: 10

The log number of bacteria per unit area (density) on con-

taminated carcasses can therefore be calculated, again

depending on the initial source of cross-contamination.

The density (log

10

CFU/cm

2

) on a carcass contaminated

from the hide (n

d

) is given as

n

d

log

10

N

d

A

_ _

: 11

The density (log

10

CFU/cm

2

) on a carcass contaminated

during evisceration (n

e

) is given as

n

e

log

10

N

e

A

_ _

12

while the density (log

10

CFU/cm

2

) on a carcass contami-

nated from both sources (n

b

) is given as

n

b

Log

10

N

b

A

_ _

: 13

These calculations and the distributions used are summa-

rised in Table 3.

3.3. Trimmings production module

3.3.1. Boxes of trimmings

In Irish abattoirs, beef trimmings are separated from

beef primals in the boning hall and boxed in cardboard

boxes at a xed mass (M) of 27.5 kg. As part of this study,

a survey was conducted to estimate a distribution for:

1. the number of 70% visually lean (70VL) trimmings

removed from a side of beef,

2. the number of trimmings it takes to ll a 27.5 kg box,

3. the weight of 70VL trimmings,

4. surface area of 70VL trimmings.

The number of 70VL trimmings removed per carcass

(N

c

) was modelled using a triangular distribution. Each

side of a carcass consistently produces three pieces of

70VL trimmings consisting of, what is referred to in the

industry as, the plate and the Jacobs ladder (part of the

M. serratus ventralis) from the fore-quarter and one piece

from the hind quarter. Slight variability was allowed

around this by including a minimum of ve trimmings,

most likely of six trimmings and a maximum number of

seven 70VL trimmings per carcass.

The number of trimmings a carcass contributes to a box

(N

tc

) can vary depending on such parameters as process

speed and trim weight. In order to account for this variabil-

ity, the number of trimmings a carcass contributes to a box

was modelled using a uniform distribution with a minimum

of four trimmings and maximum equal to N

c

. The mass of

trim a carcass (denoted a) contributes to a box (M

c,a

)

can therefore be calculated by Eq. (14).

M

c;a

Ntc

i1

M

trim;i

: 14

The cumulative mass in a box (C

m

), which should never ex-

ceed 27.5 kg, is thus given by Eq. (15).

C

m

x

a1

M

c;a

: 15

The number of trimmings placed in a box is, therefore,

determined by the mass of each trimming placed in the

box, i.e. in Eq. (15), the number of trimmings (x) is selected

such that C

m

= 27.5 kg.

The mass of a 70VL trimming i (M

trim,i

) was assumed to

be normally distributed and modelled using a normal

distribution with uncertainty about the mean (M

m

) and

uncertainty about the standard deviation (M

stdev

). Both

uncertainty parameters were obtained by bootstrapping a

survey data set (n = 50). Bootstrapping is a modelling

technique commonly used to characterise the uncertainty

in a distribution (Efron & Tibshirani, 1991, 1993; Frey &

Rhodes, 1996; Frey & Burmaster, 1999; Vose, 2000).

For this model, a sample of 50 trim weights was obtained

from survey data (Table 4), while 50 Bootstrap calculations

were made to yield a mean and standard deviation for the

new Bootstrap data sets. This data set forms a Bootstrap

estimate of the true distribution; a random point is taken

from the distribution with replacement to yield 50 Boot-

strap samples. The data (n = 50) are represented as a cumu-

lative probability graph (heavy line) as shown in Fig. 6; the

Bootstrap samples (representing uncertainty in the distribu-

tion) are represented by the light lines. The mean and stan-

dard deviation of the mass of a trim was calculated for this

Bootstrap sample. Running 1000 iterations of the model

produced the Bootstrap uncertainty distribution for both

the mean and standard deviation.

E. Cummins et al. / Meat Science 79 (2008) 139154 147

The surface area of the trimmings (S

trim,i

) was estimated

from a small trial (n = 6) where the mass of individual trim-

mings was noted and the area of individual trimmings was

traced out on aluminium foil and subsequently measured.

A table of measurements is given in Table 5. A uniform dis-

tribution with a minimum of 0.10 cm

2

/g and a maximum of

0.50 cm

2

/g was used in the model to reect the large uncer-

tainty due to the small sample size. The total surface area

placed in a box by an animal (A

trim,i

) could therefore be

calculated by

A

trim;i

M

trim;i

S

trim;i

; 16

Table 3

Model inputs and distributions for simulation of carcass contamination

Parameter Symbol Distribution/model Category Units

Flag for carcass infected F

c

Binomial(1, P

c

) Variability Boolean ag

Flag for infected gut F

g

Binomial(1, P

g

) Variability Boolean ag

Initial number on hide I

h

Second-order continuous non-parametric

distribution tted to data

Variability and

uncertainty (see text)

log

10

CFU/

100 cm

2

Factor increase for test se F

i

Uniform(0.5, 1.5) Uncertainty

True number on hide I

ht

log10

IhF i

=100 Calculation log

10

CFU/

cm

2

Log factor for decrease from hide to carcass R Cumulative distribution tted to data Variability Factor

Initial number introduced during dehiding (on carcass) I

c

I

ht

R Variability log

10

CFU/

cm

2

Total contaminated surface area A 10

Triangularlog30; log300; log3000 Variability cm

2

Total organisms on contam carcass at dehiding B

c,h

log10

Ic

A Variability log

10

CFU/

carcass

Most likely reduction due to decontam D1

mm

Uniform(0.3, 0.7) Uncertainty log

10

Maximum reduction due to decontam D1

max

Uniform(0.8, 1.2) Uncertainty log

10

Decontamination D1 Triangular(0, D1

mm

, D1

max

) Variability log

10

Probability of contam at evis E 10

Uniform2; 3

Uncertainty Probability

Cut at evis ag E

f

Binomial(1, E) Variability Boolean ag

Total organisms on contam carcass due to evis B

c,e

log10

Ic

A Calculation log

10

CFU/

carcass

Most likely decontamination D2

mm

Uniform(0.3, 0.7) Uncertainty log

10

Most likely max decontamination D2

max

Uniform(0.8, 1.2) Uncertainty log

10

Decontamination (pasteurise) D2 Triangular(0, D2

mm

, D2

max

) Variability log

10

Mean change in numbers during chilling CR

m

Uniform(0.5, 0.5) Uncertainty log

10

Chill, stdev CR

stdev

1 Fixed value log

10

Chill change in numbers CR Normal(CR

m

, CR

stdev

) Variability log

10

Change in numbers in boning hall (growth) G Triangular(0, 0.33, 2) Variability log

10

Number of organisms per carcass after boning out

(contam at dehiding only)

N

d

B

c,h

D

1

D

2

+ CR + G Calculation log

10

E. coli

organisms

Number of organisms per carcass after boning out

(contam at evis only)

N

e

B

c,e

D

1

D

2

+ GR + G Calculation log

10

E. coli

organisms

Number of organisms per carcass after boning out

(contam at eviseration and dehiding)

N

f

log10

Bc;h

10

D1

10

Bc;e

D2 CR G Calculation log

10

E. coli

organisms

Density on carcass (hide only) n

d

log10

Nd

=A Calculation log

10

/cm

2

Density on carcass (evis only) n

e

log10

Ne

=A Calculation log

10

/cm

2

Density on carcass (both) n

b

log10

Nf

=A Calculation log

10

/cm

2

Table 4

A frequency analysis for the mass of a piece of 70VL ank (n = 50)

Mass of trimming (g) Number of observations

<1000 0

10002000 5

20003000 9

30004000 4

40005000 1

50006000 0

60007000 4

70008000 8

80009000 9

900010,000 5

10,00011,000 2

11,00012,000 3

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0 2000 4000 6000 8000 10000 12000 14000

Trim mass (g)

C

u

m

u

l

a

t

i

v

e

p

r

o

b

a

b

i

l

i

t

y

Fig. 6. Cumulative probability distribution for trim mass with separation

of uncertainty and variability.

148 E. Cummins et al. / Meat Science 79 (2008) 139154

where i is a counter for the trimming in question, i.e.

1, 2, 3, . . .

The contaminated surface area per trim is likely to be

Poisson distributed, as the probability of a contaminated

unit area (cm

2

) is likely to be small over a large number

of observations. Hence, the expected contaminated area

per trimming (A

contam,i

) was calculated as

A

contam;i

Poisson A

trim;i

i

x0

A

contam;x

TSA

i

x0

A

trim;x

_ _ _ _

: 17

TSA is the total outside surface area of a carcass and is ta-

ken as a xed value of 32,000 cm

2

. The expected contami-

nated area (cm

2

) a carcass contributes to a box (Ac

a

) is the

sum of the contaminated trimmings that go into the box

and is given as

Ac

a

x

i0

A

contam;i

: 18

The count of E. coli O157:H7 on contaminated trimmings

will depend on the initial source of contamination (i.e. hide,

intestine or both) and is likely to be Poisson distributed, as

the number of bacteria is likely to be small in a xed spatial

area. The counts (CFU) resulting from contamination

from hide only is represented by

C

trim;i

Poisson10

n

d

A

contam;i

: 19

If contamination is only via perforation of the intestine at

evisceration the counts (CFU) on contaminated trimmings

are given as

C

trim;i

Poisson10

ne

A

contam;i

: 20

If both sources of contamination occur, the bacterial count

(CFU) is given as

C

trim;i

Poisson10

n

b

A

contam;i

: 21

The total bacterial load (TBL) in a box of trimmings can

also be calculated by summing the total bacterial load of

each trimming from each carcass that contributes to a

box and is given as

TBL

x

a1

Nt

i1

C

trim;a;i

: 22

A count of the number of infected trimmings (I

t

) can there-

fore be obtained from the simulation by counting the num-

ber of trimmings which have a count greater than zero. An

estimate of the prevalence of contaminated trimmings can

be calculated by dividing the number of infected trimmings

by the total trimmings produced (N

t

). The model makes use

of the central limit theorem to create an uncertainty distri-

bution around this prevalence. The central limit theorem

states that the mean of a set of n variables drawn indepen-

dently from the same distribution will be normally distrib-

uted. It follows from this that the sum of n variables drawn

independently from the same distribution has an uncer-

tainty distribution of the form Normalnl;

n

p

r.

The mean (TC

m

) and standard deviation (TC

stdev

) for

the number of trimmings per carcass can be calculated

from the distribution used for N

c

. The total trimmings pro-

duced (T

p

) can therefore be calculated using the central

limit theorem and is given as

T

p

normalA

s

TC

m

;

A

s

_

TC

stdev

: 23

The probability that a contaminated carcass will produce a

contaminated trimming (P

c

) is calculated from the model

by setting F

c

to a value of 1 and running the model for

10,000 iterations. Recall that F

c

is a Boolean ag indicating

whether a carcass is contaminated or not. By setting F

c

to a

value of 1, the model is eectively calculating the probabil-

ity that an infected carcass (i.e. F

c

= 1) will produce an in-

fected trimming (i.e. P

c

). The total contaminated trimmings

(T

ip

) can therefore be calculated as

T

ip

binomialnormalC

c

TC

m

;

C

c

_

TC

stdev

; P

c

:

24

The distributions and calculations used in this section of

the model are summarised in Table 6.

3.4. Model run and outputs

The input parameters were combined into a spreadsheet

(Microsoft Excel 2000) running the @Risk add-on package

(Palisade Software, Neweld, USA). The simulation was

run with 10,000 iterations of the model using Latin Hyper-

cube sampling and run initially without any separation of

uncertainty and variability. Outputs from the model are

distributions describing the prevalence and counts of

E. coli O157:H7 in beef trimmings destined for processing

into saleable products such as minced meat and beef bur-

gers. A table of the outputs recorded is given in Table 7.

In an attempt to identify the specic uncertainty param-

eters responsible for the wide spread of the probability

distributions for both prevalence and counts, a sensitivity

analysis was performed using the Spearmans rank order

correlation coecient. A sensitivity analysis is a systematic

evaluation of model inputs and assumptions. The parame-

ters are ranked in accordance with the magnitude of eect

the parameters are having on model predictions.

3.5. Partial validation

Validation is necessary to ensure model predictions are

realistic and also provides justication for model inputs.

Table 5

Surface area measurement of 70VL beef trimmings (n = 6)

Trimming Mass (g) Area (m

2

) Area/unit mass (cm

2

/g)

1 3925 0.10 0.25

2 2235 0.07 0.32

3 2350 0.09 0.38

4 1830 0.09 0.48

5 4418 0.22 0.50

6 4018 0.20 0.50

E. Cummins et al. / Meat Science 79 (2008) 139154 149

The validation stage for this model consisted of a survey of

the prevalence and counts of E. coli O157:H7 on beef

trimmings produced in an Irish abattoir and involved the

sampling of 1351 beef trimmings and testing for E. coli

O157:H7 contamination followed by enumeration where

possible. Ideally validation would involve multiple compar-

isons between model outputs and real data. However, this

is unlikely to be unfeasible in the food industry. Hence the

survey conducted by Carney et al. (2006) can be considered

a partial validation stage, providing snap shot comparison

between model predictions and real data. Survey results,

materials and methods for detecting bacterial are discussed

in Carney et al. (2006). The survey resulted in 32 positive

samples. Uncertainty around this data were modelled using

a beta distribution (beta(32 + 1, 1351 32 + 1)), thus,

allowing for comparison and partial validation with model

predictions.

3.6. Uncertainty

The inuence of uncertainty can be assessed by running

the model while xing on one random value from the

uncertainly distributions for each simulation and sampling

from the variability distributions for successive iterations

within that simulation (i.e. second-order modelling). To

interpret the outcomes, the resulting simulations can be

plotted alongside a cumulative plot of the output without

any separation of uncertainty and variability. The spread

in the distribution will indicate whether uncertainty or var-

iability is dominating the model. If uncertainty is the dom-

inant force, a cumulative plot of successive simulation

results will be almost perpendicular, intersecting the cumu-

lative graph where no separation has occurred. If variabil-

ity is the dominant force, a plot of successive simulations

will take a similar line to the graph where uncertainty has

not been separated. To simulate the role uncertainty was

playing in this model, a separate model run with 10,000

iterations (representing variability) and 1000 simulations

(representing uncertainty) was carried out.

4. Results

A plot of the simulated prevalence of E. coli O157:H7 in

Irish beef trimmings compared with survey results is given

in Fig. 7. The mean calculated prevalence of contaminated

trimmings was 2.36% with 90th percentile range between

Table 6

Summary of inputs used for simulating trimming contamination

Parameter Symbol Distribution/model Category Units

Mean mass of trimming (70VL) M

m

Bootstrap on data set (see text) Uncertainty g

Standard deviation for mass trimming M

stdev

Bootstrap on data set (see text) Uncertainty g

Mass of trimming (70VL) M

trim,i

Normal(M

m

, M

stdev

, Truncate(2000)) Variability g

Total scrap wt, Mass of trim a carcass contributes to a box M

c,a

Ntc

i1

M

trim;i

g

Cumulative mass in box C

m

a1

x M

c;a

g

Number of trimming per carcass (70VL) N

c

Triangular(5, 6, 7) Variability Trimmings

Number of trimmings a carcass contributes to a box N

tc

Uniform(4, N

c

) Variability Trimmings

Surface area of trim Sa

trim,i

Uniform(0.1, 0.5) Uncertainty cm

2

/g

Total cm

2

placed in a box by animal A

trim,i

M

trim,i

Sa

trim,i

cm

2

Expected number of contaminated cm

2

per trimming A

contam,i

Poisson A

trim;i

i

x0

Acontam;x

TSA

i

x0

Atrim;x

_ _ _ _

Variability cm

2

Expected number of contaminated cm

2

a carcass contributes

to a box

Ac

a

x

i0

A

contam;i

Calculation cm

2

E. coli numbers, hide only C

trim,i

Poisson(10

nd

A

contam,i

) Variability CFU

E. coli numbers, gut only C

trim,i

Poisson(10

ne

A

contam,i

) Variability CFU

E. coli numbers, both C

trim,i

Poisson(10

nf

A

contam,i

) Variability CFU

Infected trimmings I

t

Count if (C

trim

> 0) Calculation Trimmings

Total E. coli in combi

x

a1

Nt

i1

C

trim;a;i

Calculation CFU

Mean trimmings per carcass TC

m

From N

c

distribution Trimmings

Standard deviation of trimmings per carcass TC

stdev

From N

c

distribution Trimmings

Total trimmings produced T

p

Normal(A

s

TC

m

, SQRT(A

s

) TC

stdev

) Trimmings

Probability that a contaminated carcass will produce a

contaminated trim

P

c

Procedure in model, see text Probability

Total infected trimmings T

ip

Binomial(Normal(C

c

TC

m

,

SQRT(C

c

) TC

stdev

), P

c

)

Trimmings

Table 7

Summary of simulated model outputs

Parameter Symbol Distribution/model Category Units

Total number of trimmings produced N

t

i such that

Ntc

i1

M

trim;i

6 M Output Trimmings

Prevalence of infected trimmings P N

t

/I

t

Output Prevalence

Uncertainty distribution for contaminated trimmings P T

p

/T

ip

Output Prevalence

Counts of E. coli on contam trimmings C C

trim,i

/M

trim,i

Output CFU/g

150 E. Cummins et al. / Meat Science 79 (2008) 139154

1.00% and 5.00%. The parallel validation study also estab-

lished a prevalence of 2.37% (32/1351) which provides

some condence in the model predictions. However, as

can be seen in Fig. 7, the condence bounds for the simu-

lation are much wider due to parameter uncertainty.

Results from the second-order model are presented in

Fig. 8. Each light line represents an individual simulation,

while the heavy line represents the scenario with no separa-

tion of uncertainty or variability (i.e. cumulative distribu-

tion of Fig. 7). The spread of the distribution indicates

that the main driving parameters in the model are the

uncertainty parameters and better understanding of the

system dynamics may be achieved by reducing this uncer-

tainty of the model parameters. The wide spread and

almost vertical lines intersecting the cumulative plot

(Fig. 8) with no separation (heavy line) indicates that var-

iability is having very little impact on model predictions

and the model uncertainty is the main driving force and

is responsible for the wide distribution spread.

The calculated mean number of counts of E. coli

O157:H7 on contaminated trimmings was 2.69log

10

CFU/g, yet the model highlighted that much higher counts

are possible (Fig. 9). The contaminated trim samples which

were enumerated in the surveillance survey varied from

0.70 to 1.61log

10

CFU/g (Carney et al., 2006). The sensitiv-

ity of the prevalence and counts of E. coli O157:H7 on

contaminated trimmings to input values were measured

by Spearmans rank order correlation. The analysis

indicated the inputs having the greatest impact on contam-

inated trimmings prevalence were: test sensitivity (T

se

), hide

to carcass transfer rate (TR), initial hide prevalence (P

h

)

and the decontamination treatment (D

1max

), with Spear-

mans rank order correlation coecients of: 0.27, 0.26,

0.20 and 0.12, respectively. The parameters having the

greatest impact on hide counts were: initial count on

bovine hides (I

h

); the contaminated surface area (A); the

decrease from hide to carcass (R), with Spearmans rank

order correlations of: 016, 0.07, 0.07 and 0.05,

respectively.

5. Discussion

The observed prevalence of contaminated trimmings

(2.36%) is similar to the prevalence reported for minced

beef products, i.e. 2.80% (Cagney et al., 2004), which high-

lights the likely transfer of contaminated beef trimmings

into the food chain in the form of comminuted beef prod-

ucts. The mean values for the prevalence of contaminated

trimmings from the simulation and the survey (2.37%)

are similar, even though the simulated distribution is con-

siderably wider, highlighting the uncertainty of the input

parameters.

Simulated counts include situations where the simulated

value is less than the detection limit of the direct plate

method (i.e. <0.70log

10

units). Therefore, this has the eect

of pulling the graph in Fig. 9 to the left. The enumeration

technique of direct plating onto CT-SMAC as used by Car-

ney et al. (2006) is not sensitive at low concentrations. As a

Survey

Mean=0.0251

Simulation

Mean=0.024

X <=0.01

2.5%

X <=0.05

97.5%

0

10

20

30

40

50

60

70

80

0.00 0.02 0.05 0.07

Prevalence

P

r

o

b

a

b

i

l

i

t

y

D

e

n

s

i

t

y

Fig. 7. Simulation vs. survey results (including uncertainty analysis) for

the prevalence of E. coli O157:H7 on beef trimmings.

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0 0.01 0.02 0.03 0.04 0.05 0.06 0.07

Prevalence

C

u

m

u

l

a

t

i

v

e

P

r

o

b

a

b

i

l

i

t

y

Fig. 8. Second-order cumulative probability for the prevalence of E. coli

O157:H7 on beef trimmings. (Heavy line represents no separation of

uncertainty and variability; thin lines represent successive simulations with

separation of uncertainty and variability).

Mean = -2.69

X <=-0.55

95%

X <=-4.14

5%

0

0.1

0.2

0.3

0.4

0.5

0.6

-5 -4 -3 -2 -1 0 1 2

Counts (Log

10

CFU/g)

P

r

o

b

a

b

i

l

i

t

y

D

e

n

s

i

t

y

Fig. 9. Simulated counts of E. coli O157:H7 on contaminated beef

trimmings.

E. Cummins et al. / Meat Science 79 (2008) 139154 151

result, in most samples (25/32 of the beef trimming sam-

ples) the pathogen was detectable by enrichment only, sug-

gesting that the pathogen numbers are low i.e. <0.70log

10

units. This substantiates the models low estimate for bacte-

rial contamination on beef trimmings and provides some

condence in model results. However, given the estimated

small dose required to cause illness resulting from the

ingestion of E. coli O157:H7 (Cassin et al., 1998), these pre-

dictions may be a cause for concern. Cognisance needs to

be made of the impact of model assumptions as detailed

in Section 2.3, many of which tend to err on the side of cau-

tion, while also recognising that a change in these assump-

tions may yield dierent results.

The sensitivity analysis reveals the need for further

research; in particular, the analysis reveals the need for fur-

ther experimental work to reduce the uncertainty about the

microbial test sensitivity (T

se

). In addition, further research

should be directed at reducing cross-contamination at the

hide removal stage thus reducing TR. The fact that the ini-

tial microbial counts on animal hides (I

h

) and the initial

prevalence on animal hides (P

h

) are ranked highly in the

sensitivity analyses highlights the importance of minimising

microbial contamination of animals when presented for

slaughter. Possible interventions can be devised from con-

trollable variables which have a large impact on model pre-

dictions, for example reducing cross-contamination at the

hide removal stage, or reducing prevalence and counts on

bovine hides on entry into the plant. The analysis reveals

that additional eorts are also needed to understand the

processes involved in the initial transfer of E. coli to the

carcass and to reduce or limit such a transfer; this has also

been highlighted by McEvoy et al. (2001).

Hide prevalence was signicantly correlated with carcass

contamination, indicating a role for the control of E. coli

O157:H7 in live cattle; this is in agreement with previously

published surveillance studies (Elder et al., 2000). The anal-

ysis also reveals the impact successive decontamination

treatments may have on reducing bacterial contamination.

This supports the concept of using decontamination pro-

cesses in meat plants as a means of improving microbiolog-

ical quality of beef products. Measures used in the abattoir

may represent an important initial barrier in protecting

beef from contamination, and thus reducing human expo-

sure to E. coli O157:H7 through the food chain.

The initial count on the animal hide (I

h

) was the param-

eter having the greatest impact on count predictions in the

model, highlighting the need to investigate the uncertainty

about this parameter. The contaminated surface area (A)

and decrease from hide to carcass (R) were also having

an impact on model predictions, highlighting the increased

requirement to better understand microbial transfer

dynamics. Other input parameters in the model had a smal-

ler eect on model predictions.

The qualitative and quantitative validation data

obtained about E. coli O157:H7 on beef trimmings during

the parallel surveillance study and detailed in Carney et al.

(2006) provided a sound microbiological basis for the par-

tial validation of this risk assessment model, which is essen-

tial but currently rare in this area. The model ts well with

observed data suggesting that the mathematical approxi-

mations of all real life variables are justied while also

highlighting the impact of model assumptions and uncer-

tainty, as seem from the wide distribution for the simulated

data. The model validation provides sucient condence

that the model can be considered valid for estimating the

likely prevalence of contaminated trimmings in beef abatt-

oirs and estimating the likely bacterial counts on contami-

nated trimmings.

6. Conclusions

The model developed in this study predicted the preva-

lence and counts of E. coli O157:H7 in Irish beef trimmings

and provided partial validation of the results with reference

to an extensive parallel survey carried out at a commercial

abattoir in Ireland and conducted by Carney et al. (2006),

thus providing a degree of condence in model predictions.

The probability distributions used in the model allowed

quantication of inputs that are not well characterised

due to lack of knowledge (uncertainty) and model inputs

that are heterogeneous (variable). The model encompasses

available information about the processing, treatment and

production of beef trimmings and model results indicate

that there may be cause for concern if E. coli counts are

not reduced at a later stage during processing. The model

can play a vital role in the control and management of

food-borne hazards, such as E. coli O157:H7, and result

in an increased understanding of bacterial transmission

and exposure pathways.

Results need to be viewed in the context of uncertainties

and assumptions, which are implicit in the structure of

these models. Dierent model assumption can have an

eect on the results obtained in risk assessments, highlight-

ing the issue of model uncertainty. However, such assump-

tions tend to err on the side of caution, thus providing an

upper estimate of risk. Model complexity can be an issue

for those not familiar with the modelling process. This

highlights the need for clear, unambiguous descriptions

of model inputs, associated uncertainties and assumptions

to ensure transparency of the model and research process.

A sensitivity analysis provides a systematic and trans-