Indian Standard: Underground Fire Hydrant, Sluice Valve Type - Specification

Diunggah oleh

skilmagJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Indian Standard: Underground Fire Hydrant, Sluice Valve Type - Specification

Diunggah oleh

skilmagHak Cipta:

Format Tersedia

IS 909 f 1992

( Reaffirmed 1997 )

Indian Standard UNDERGROUND FIRE HYDRANT, SLUICE VALVE TYPE - SPECIFICATION ( Third Revision )

First Reprint JULY 1998

UDC

614.843~1

@ BIS 1992

BUREAU

MANAK

OF

BHAVAN,

INDIAN

STANDARDS

ZAFAR MARG

9 BAHADUR SHAH NEW DELHI 110002

Price croap 3

Fire Fighting Sectional

Committee,

CED 22

FOREWORD This Indian Standard ( Third Revision ) was adopted by the Bureau of Indian Standards, after the draft finaliied by the Fire Fighting Sectional Committee had been approved by the Civil Engineering Division -Council. Hydrants are invariably used for fire fighting purposes hydrants could be stand-post type or underground, covering underground fire hydrants, sluice-valve type 1965. The second revision has been prepared to bend besides making other contents up to date. to derive water from the water line. The that is, sluice-valve type. This standard was first published in 1958 and revised in incorporate complete details of duck-foot co-ordination to relating it major

In the formulation of this standard, due weightage has been given to international among the standards and practices prevailing in different countries in addition to the practices in the field in this country. In the present revision of the standard, changes have been introduced: in addition to general updating,

the following

a) A detailed figure of Underground Fire Hydrant ponents giving their details has been included. b) Valve seat tightness test has also been included

Valve including an under performance

item list of comrequirements.

of this standard is of deciding whether a particular requirment For the purpose or calculated, expressing the result of a test complied with, the final value, observed or analysis, shall be rounded off in accordance with IS 2 : 1960 Rules for rounding off numerical values ( revised). The number of significant places retained in the rounded off value should be the same as that of the specified value in this standard.

IS 909:1992,

Indian Standard

UNDERGROUND FIRE HYDRANT,SLUICE VALVE TYPE -SPECIFICATION

( Third Revision )

1 SCOPE

Ihis standard lays down the requirements regarding materials, shape, dimensions and tests of uderground hydrant, sluice-valve type.

NOTE - Generally the sluice-valve type hydrant shall have one sluice-valve. Where it is intended to introduce into this type of additional facilities for closing off mains for repairs, then an additional sluice-valve of a similar type may be introduced adjacent to the sluice-valve on the side of the mains,

4.3 Spindle shall be made of brass conforming to IS 320 : 1980 or IS 319 : 1974 or stainless steel Gr 04 Cr 18 Ni l(1 conforming to IS 6603 : 1972. 4.4 Gaskets shall be made of rubber conforming to IS 937 : 1981 or IS 638 : 1965 or leather conforming to IS 581 : 1976 or compressed asbestos fibre conforming to .IS 2712 : 1979. 4.5 Gland packing shall be of conforming to IS 4687 : 1980. asbestos thread

2 REFERENCES The Indian Standards listed in Annex necessary adjuncts to this standard. 3 GENERAL REQUIREMENTS A are

4.6 Bolts and nuts shall be made of carbon steel conforming to,IS 1367 ( Part 14 ) : 1984. 5 ROAD SURFACE BOX

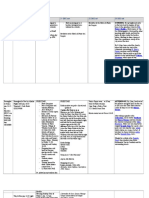

The hydrant shall consist of the following components ( see Fig. 1A and Fig. 1B ): a) b) c) d) e) f) g) h) j) Body Bonnet Spindle Gland Spindle cap Spindle nut Valve Screwed outlet Outlet cap and chain

The road surface box shall be made according to the details given in Fig. 2. The minimum weight of the surface box shall be 135 kg. When a second sluice-valve is provided surface box for this sluice-valve shall conform to IS 3950 : 1979. .6 CONSTRUCTION AND DIMENSIONS

4 MATERIAL 4.1 Body, .bonnet, gland, outlet cap and spindle cap shall be made of cast iron grade FG 200 of IS 210 : 1978. 4.2 Outlet, seat for valve, valve, spindle nut, check nut shall be made of copper alloys as stated below: a) Sand Casting - LTB-2 of IS 318 : 1981 or HTB 1 of IS 304 : 1981 b) Die castings - LCB 2 of IS 292 : 1983 c) Hot forging - Grade 1 of IS 291 : 1989 1

The outlet of the hydrant shall be of screwed type and provided with external round thread ( two threads per 2.54 cm ) as showi. in Fig. 3. It shall be attached to the flanged end of the pipe by means of bolts. The outlet cap shall completely cover the outlet thread and be attached to the outlet by means of a chain made from steel stock not less than 3 mm in diameter or from material having equivalent strength, with the chain length and its attachment arranged to permit removal of the cap without binding. Suitable anti-corrosive treatment should be given to the chain. 7 FINISH All parts shall be of good finish, clear of all burrs and sharp edges. All castings shall be clean and sound excluding of plugging, welding or repairs of any defects.

IS 909 : l992

DETAILS DETAILS OF

OF A REDUCER

FLANGED

8Omm VA

80 mm DUCKFOOT

~30 mm FLANGE

All dimensionsin millimetres. FIG. IA UNDERGROUNDFIRE HYDRANT, SLUICB-VALVE TYPE

I-=

100 min.

min.

9200 Nut and Bolt Chain 14 -------Cap 13 __~-----Outlet t 12 Drain Bolt 11 _p-e---__-Snindle Caa :li)_ : __.-9 , Grush Screw ( 12 mm ) Gland l_LI i *; l__.__ Suiudle -r ------or

rs

Snindle -,r .-_._ Nut - _-

I_._I_4

I Valve --~ Washer 3 __---Valve Seat 2 Body 1 ,___----No. Description

IS :210-1978 FG-200 ~-IS ! 319-1989 IS : 21055%%Gx m:318-1981 LBT-2 tG.M.-------I IS: 318-1981 LTB-2 -_---RUBBER --IS : 937-1981 IS : 318.1981 LTB-2 0. M. --p-pIS :210-1972 FG-200 c. I. Mat. Specification Mat.

MS. zii.MS.-------- c. I. --- G. M. M. S. c. L I. -_--- S. c. I. IBRASS -_. c. I. 1 G.M. I-

I -_ --I IS : 2110-1978 FG-2001 IS : 318-1981LTB-2 --

!M.

IS : 210-1978 --6094-I

FG-200

98 1

-__ .

TOLERANCES AS PER IS 2102 : 1962 All dimensions in millimetres.

Fla

ITJ

UNDBRGROUNDFIREHYDRA~,SLUICE-VALVB 3

GATE

Is909:1992

I_

165

--I

SECTtON

XX

______-_----------~-NOTE -The tolerance in dimensions shall be +2 mm for up to and includmg and above and up to arid incluling 50 mm, and f 5 mm for 51 mm and above. All dimensions FIG. 2

FEATHER EDGE TO BE REMOVED

15 mm, f 2 mm or 16 mm

in millimetres.

CI ROAD SURFACE Box

BE

THREAOEO

t-

k:.;;n

,-I?

2.85

SUIT REDUCER FLANGE

3A

OUTLET

AND

CAP

3B

DETAILS

OF THREAD

OF OUTLET

NOTES 1 Crest diameter

of Thread 82.2 Li:t

Root diameter of Thread 68-O Max

2 Thickness of Thread (t) 5.7 8:: All dimensions FIG. 3 in millimetres.

SCREWED OUTLETAND CAP ( ROUND THRBAD ) 4

IS 909 : 1992 8 COATING OF PARTS OTHER SLUICEVALVE THAN 10 PERFORMANCE 10.1 Hydrostatic REQUIREMENTS

8.1 Immediately after casting and before machining all cast iron parts shall be thoroughly cleaned, and before rusting commences, shall be coated by dipping in a bath containing a composition having a bituminous base ( see IS 158 :. 1981 ) and maintained at a temperature between 143 and 166C. The proportions of the ingredients of the composition shall be so regulated as to produce a coating having the properties specified in 8.3. 8.2 The casting shall be re-heated before dipping; either by immersion in hot water or by heating in an oven, or shall be held in the dipping bath sufficiently long to reach an equivalent temperature, the method used being at the makers option. Care shall be taken to see that the casting are perfectly dry immediately before dipping. On removal from the bath the castings shall be sufficiently drained and ensure that no portion is left uncoated. 8.3 The coating shall be such that it shall not impart any taste or smell to water. The coating shall be smooth, glossy and tenacious, sufficiently hard so as not to flow when exposed to a temperature of 77C and not so brittle at a temperature of 0C as to chip off when scribed lightly with the point of a penknife. 9 PAINTING Complete hydrant shall be painted externally with two coats of fire red paint conforming to .shade No. 536 of IS 5 : 1978. The cover of the road surface box shall be painted with two coats of canary yellow colour paint conforming to shade 309 of IS 5 : 1978.

Pressure Test

Each assembled unit shall be subjected to a hydrostatic pressure of 2.1 MN/ma with the valve open and outlet closed for a period of 2.5 minutes for the purpose of locating porosity in the casting. When so tested, it shall not fail or show any sign of leakage either through the valve body or through the gland of the spindle. 10.2 Valve Seat Tightness Test The stop valve shall be fully closed by screwing down the spindle. A hydrostatic pressure of 1.4 MN/me shall then be applied to each valve on its inlet side. There shall be no leakage through the valve and its seat. 11 CRITERIA FOR ACCEPTANCE require-

Each hydrant shall be tested for the ments prescribed in this standard. 12 MARKING

12.1 Each hydrant shall be clearly and permanently marked with the following information: a) Manufacturers name or trade-mark, b) Year of manufacture. and

12.2 The cover of the road surface box shall have the letters <FH embossed on it and painted in black colour. 12.2.1 The hydrant may also the Standard Mark. be marked with

IS 909: 1992

ANNEX

( Clause 2 )

IS No. 5 : 1978 158 : 1981 Title Specification for grey iron castings ( second revision ) Specification for ready mixed brushing bituminous, !:laa$ leadfree acid alkali waterand hea; resisting fo; general purposes ( second revision ) Grey iron revision ) castings ( third IS No. 320 : 1980 581 . 1976

l

Title High tensile brass rods and section ( other than forging stock ) ( second revision ) Vegetable tanned hydraulic leather ( second revision ) %;;kr rubber jomting and msertion jointing ( second revision ) Washer for water fittings for fire fighting purposes ( second revision ) Technical supply condition for steel threaded fasteners : Part 14 Stainless steel threaded fasteners ( second revision ) Compressed asbestos fibre joint ( second revision ) Surface boxes for sluice valves ( $rst revision ) Gland packing asbestos (first revision ) Hexagon socket set screws (first revision ) Stainless steel bars and flats

638 : i979

210 : 1978 291 : 1989

937 : 1981

Naval brass rods and sections ( suitable for machining and forging ) ( second revision ) Leaded brass ingots and0 castings ( second revision ) High tensile brass ingots and castings ( second revision ) Leaded tin bronze ingots and castings ( second revision ) Free-cutting and sections brass bars, rods ( third revision )

1367 $Ptit 14) : 2712 : 1979 3950 : 1979 4687 : 1980 6094 : 1981 6603 : 1972

292 : 1983 304 : 1981 318 : 1981 319 : 1989

Bureau of Indian Standards BIS is a statutory institution established under the Bureau of Indian Standards Act, 1986 to promote harmonious development of the activities of standardization, marking and quality certification of goods and attending to connected matters in the country. Copyright BIS has the copyright of all its publications. No part of these publications may be reproduced in any form without the prior permission in writing of BIS. This does not preclude the free use, in the course of implementing the standard, of necessary details, such as symbols and sizes, type or grade designations. Enquiries relating to copyright be addressed to the Director (Publications), BIS. Review of Indian Standards Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed periodically; a standard along with amendments is reaffirmed when such review indicates that no changes are needed; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standards should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue of BIS Handbook and Standards: Monthly Additions. This Indian Standard has been developed from Dot : No. CED 32 ( 46 IO )

Amendments Amend No.

Issued Since Publication Text Affected

Date of Issue

BUREAU Headquarters:

OF INDIAN

STANDARDS

Manak Bhavan, 9 Bahadyr Shah Zafar Marg, New Delhi 110 002 Telephones : 323 01 3 1, ~323 33 75, 323 94 02 Regional Central Offices : Shah Zafar Marg

Telegrams : Manaksanstha (Common to all offices) Telephone { 323 76 38 41 17

: Manak Bhavan, 9 Bahadur NEW DELHI 110 002

Eastern

: l/14 C. I.T. Scheme VII M, V. I. P. Road, Maniktola CALCUTTA 700 054 : SC0 335-336, Sector 34-A, CHANDIGARH 160 022

{ 337 84 86 99,337 26,337

91 85 61 20

Northern

1 Southern : C. I. T. Campus, IV Cross Road, CHENNAI 600 113

60 38 20 43 25

{ 235 02 15 16,235 19,235 04 23 42 15 Western : Manakalaya, E9 MIDC, MUMBAI 400 093 Marol, Andheri (East) 832 92 95,832 832 78 91,832 78 58 78 92

Branches

: AHMADABAD. BANGALORE. BHOPAL. BHUBANESHWAR. COIMBATORE. FARIDABAD. GHAZIABAD. GUWAHATI. HYDERABAD. JAIPUR. KANPUR. LUCKNOW. NAGPUR. PATNA. PUNE. THIRUVANANTHAPURAM. Printed at Printogmph, New Delhi, Ph : 5726847

Anda mungkin juga menyukai

- 16 Prinsip PencegahanDokumen49 halaman16 Prinsip PencegahanMiss DarknessBelum ada peringkat

- Energy ManagementDokumen254 halamanEnergy ManagementNguyễn Thanh HòaBelum ada peringkat

- New Trends in TechnologiesDokumen252 halamanNew Trends in TechnologiesskilmagBelum ada peringkat

- Handbook On Building Fire CodesDokumen287 halamanHandbook On Building Fire Codesmz1234567100% (1)

- A Brief Guide To Understand EverythingDokumen149 halamanA Brief Guide To Understand EverythingskilmagBelum ada peringkat

- Development and Implementation of RFID Technology PDFDokumen564 halamanDevelopment and Implementation of RFID Technology PDFskilmagBelum ada peringkat

- Modeling FlightDokumen202 halamanModeling Flightaeroprince100% (3)

- NotesDokumen382 halamanNotesskilmagBelum ada peringkat

- New Trends in TechnologiesDokumen252 halamanNew Trends in TechnologiesskilmagBelum ada peringkat

- Human Dignity and Bioethics PDFDokumen577 halamanHuman Dignity and Bioethics PDFskilmag100% (1)

- Tissue Engineering PDFDokumen534 halamanTissue Engineering PDFskilmag0% (1)

- Thermal Power Plants - Advanced ApplicationsDokumen186 halamanThermal Power Plants - Advanced ApplicationsskilmagBelum ada peringkat

- How To Be Happy: by Cara SteinDokumen41 halamanHow To Be Happy: by Cara SteinskilmagBelum ada peringkat

- Self SufficiencyDokumen147 halamanSelf SufficiencyskilmagBelum ada peringkat

- Introduction in Ship Hydromechanics: Lecture MT519 Draft EditionDokumen107 halamanIntroduction in Ship Hydromechanics: Lecture MT519 Draft EditionflouzanBelum ada peringkat

- Magic Squares and Cubes by WS Andrews (1917)Dokumen428 halamanMagic Squares and Cubes by WS Andrews (1917)morefaya2006100% (1)

- DOE Assessment of ITER Project Cost EstimateDokumen114 halamanDOE Assessment of ITER Project Cost EstimateskilmagBelum ada peringkat

- Cost PlanningDokumen39 halamanCost PlanningMwesigwa DanielBelum ada peringkat

- Estimating GuidelinesDokumen44 halamanEstimating GuidelinesKrm ChariBelum ada peringkat

- Advances in Landscape Architecture PDFDokumen938 halamanAdvances in Landscape Architecture PDFskilmag100% (4)

- Heart BookDokumen96 halamanHeart BookskilmagBelum ada peringkat

- ECEADokumen52 halamanECEAPercy SuarezBelum ada peringkat

- Expert SystemsDokumen246 halamanExpert Systemsgkgj2000100% (1)

- Fidic Conditions of ContractDokumen18 halamanFidic Conditions of ContractHasan Fakhimi100% (1)

- Calculusforengin 00 PerrrichDokumen404 halamanCalculusforengin 00 Perrrichgentooing100% (1)

- Stable Ang PDFDokumen468 halamanStable Ang PDFskilmagBelum ada peringkat

- Advances in Modeling of Fluid DynamicsDokumen316 halamanAdvances in Modeling of Fluid DynamicsskilmagBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- What Is PID - TutorialDokumen5 halamanWhat Is PID - Tutorialsocrates19582405Belum ada peringkat

- CEMEX Global Strategy CaseDokumen4 halamanCEMEX Global Strategy CaseSaif Ul Islam100% (1)

- Accor vs Airbnb: Business Models in Digital EconomyDokumen4 halamanAccor vs Airbnb: Business Models in Digital EconomyAkash PayunBelum ada peringkat

- Crypto Is New CurrencyDokumen1 halamanCrypto Is New CurrencyCM-A-12-Aditya BhopalbadeBelum ada peringkat

- AGCC Response of Performance Completed Projects Letter of recommendAGCC SS PDFDokumen54 halamanAGCC Response of Performance Completed Projects Letter of recommendAGCC SS PDFAnonymous rIKejWPuS100% (1)

- Cryptography Seminar - Types, Algorithms & AttacksDokumen18 halamanCryptography Seminar - Types, Algorithms & AttacksHari HaranBelum ada peringkat

- Fayol's Principles in McDonald's ManagementDokumen21 halamanFayol's Principles in McDonald's Managementpoo lolBelum ada peringkat

- Request For Information (Rfi) : Luxury Villa at Isola Dana-09 Island - Pearl QatarDokumen1 halamanRequest For Information (Rfi) : Luxury Villa at Isola Dana-09 Island - Pearl QatarRahmat KhanBelum ada peringkat

- RAMA - 54201 - 05011381320003 - 0025065101 - 0040225403 - 01 - Front - RefDokumen26 halamanRAMA - 54201 - 05011381320003 - 0025065101 - 0040225403 - 01 - Front - RefMardiana MardianaBelum ada peringkat

- Sierra Wireless firmware versions for cellular modulesDokumen20 halamanSierra Wireless firmware versions for cellular modulesjacobbowserBelum ada peringkat

- Dse Placement Report PDFDokumen78 halamanDse Placement Report PDFAbhijithKríshñàBelum ada peringkat

- Example Italy ItenararyDokumen35 halamanExample Italy ItenararyHafshary D. ThanialBelum ada peringkat

- Newcomb Theodore MDokumen20 halamanNewcomb Theodore MBang Ahmad UstuhriBelum ada peringkat

- Brochure of H1 Series Compact InverterDokumen10 halamanBrochure of H1 Series Compact InverterEnzo LizziBelum ada peringkat

- Igbt Irg 4p254sDokumen9 halamanIgbt Irg 4p254sMilagros Mendieta VegaBelum ada peringkat

- HR PlanningDokumen47 halamanHR PlanningPriyanka Joshi0% (1)

- CXS 310-2013 - PomegranateDokumen5 halamanCXS 310-2013 - PomegranateFranz DiazBelum ada peringkat

- Yamaha Stagepas 300Dokumen54 halamanYamaha Stagepas 300Ammar MataradzijaBelum ada peringkat

- Household Budget Worksheet - Track Income & ExpensesDokumen1 halamanHousehold Budget Worksheet - Track Income & ExpensesJohn GoodenBelum ada peringkat

- Ganbare Douki Chan MALDokumen5 halamanGanbare Douki Chan MALShivam AgnihotriBelum ada peringkat

- RIE 2013 Dumping and AD DutiesDokumen21 halamanRIE 2013 Dumping and AD Dutiessm jahedBelum ada peringkat

- CP Exit Srategy Plan TemplateDokumen4 halamanCP Exit Srategy Plan TemplateKristia Stephanie BejeranoBelum ada peringkat

- LK BMHS 30 September 2021Dokumen71 halamanLK BMHS 30 September 2021samudraBelum ada peringkat

- Soil Nailing and Rock Anchors ExplainedDokumen21 halamanSoil Nailing and Rock Anchors ExplainedMark Anthony Agnes AmoresBelum ada peringkat

- PTCL History, Services, Subsidiaries & SWOT AnalysisDokumen18 halamanPTCL History, Services, Subsidiaries & SWOT AnalysiswaqarrnBelum ada peringkat

- Keys and Couplings: Definitions and Useful InformationDokumen10 halamanKeys and Couplings: Definitions and Useful InformationRobert Michael CorpusBelum ada peringkat

- Infor Mashup SDK Developers Guide Mashup SDKDokumen51 halamanInfor Mashup SDK Developers Guide Mashup SDKGiovanni LeonardiBelum ada peringkat

- G.R. No. L-54171 October 28, 1980 JEWEL VILLACORTA, Assisted by Her Husband, GUERRERO VILLACORTA, COMPANY, Respondents. TEEHANKEE, Acting C.J.Dokumen6 halamanG.R. No. L-54171 October 28, 1980 JEWEL VILLACORTA, Assisted by Her Husband, GUERRERO VILLACORTA, COMPANY, Respondents. TEEHANKEE, Acting C.J.Lyra Cecille Vertudes AllasBelum ada peringkat

- 028 Ptrs Modul Matematik t4 Sel-96-99Dokumen4 halaman028 Ptrs Modul Matematik t4 Sel-96-99mardhiah88Belum ada peringkat

- Examples 5 PDFDokumen2 halamanExamples 5 PDFskaderbe1Belum ada peringkat