ACE Burn-Off Oven Spec.

Diunggah oleh

stuart3962Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

ACE Burn-Off Oven Spec.

Diunggah oleh

stuart3962Hak Cipta:

Format Tersedia

FORM OTC

ULTIMATE IN ENERGY SAVINGS

The new ACE (RT) Radiant Tube Heat Cleaning Ovens are big on performance and have the ultimate in energy savings, about 20% over convection-only Burn-Off ovens. ACE introduces the radiant tube heater, which for the first time utilizes radiant plus convection heat. Heat from the radiant tube results in a consequent heat extraction efficiency of 90%. Heats even in the harshest environment.

Illustrates Model 3600-RT

OVEN DESIGN

The ACE Heat Cleaning Oven System is designed to remove varnish, epoxy, paint, grease, oil, rubber or other combustible materials from metals. Heat clean motor stators, paint hooks, automotive engine parts, rubberto-metal bonded parts, virtually any metal part. The ACE system will also debond brake shoes and clutch plates. Parts are loaded on a wheel-in cart and heated to 650 - 800 F (340 - 427 C), in an oxygen deficient atmosphere, where the combustible hydrocarbons decompose. Parts leave the oven completely dry and ash residue is easily removed.

The integral high fire afterburner chamber is designed to provide excess air for complete combustion of the smoke. Discharges to atmosphere are harmless by-products of combustion, conforming to tough EPA air emission standards.

HEAT CLEAN WITHOUT POLLUTION

CONSTRUCTION

The ACE Oven is fabricated from 11 gauge steel and coated with a high temperature, rust resistant paint. 4 inches of high temperature insulation rated at 2,300o F (1,260o C) lines the oven and self-supporting exhaust stack to offer maximum energy efficiency. The thick door is securely sealed by husky cam type latching mechanisms located on the top and bottom of the door. For reasons of safety, the latch is designed to accept a lock, as the door should not be opened during the heating cycle.

ACE HYBRID HEATING DESIGN

The (RT) system consists of a radiant tube, which directs the radiant energy upward. The radiant tube is located under the oven cart. It is positioned in the center of the oven and extends from the back wall to oven door. A gas burner fires directly into the length of the Radiant Tube. Convection heat evenly comes out the numerous holes on the left and right side along the entire length of the Radiant Tube. Radiant energy is also evenly emitted along the entirelength of the Radiant Tube. The radiant tube is then mountedto the adapter tube.

Closeup of Radiant Tube heating oven chamber

ONE TOUCH CONTROL (OTC)

OTC is a new automatic self-adjusting control system. It monitors the combustible vapor in the oven and controls them at a safe level. Requires no program selection by the operator, thus removes the possibility of operator error. An accurate, simple, yet highly effective system to automatically provide the shortest possible safe heat cleaning cycle times. The OTC system automatically self adjusts the cycle time to the weight of the non-combustible and combustible load. Naturally, lighter combustible loads automatically take less processing cycle time than heavier combustible loads.

PATENTED

BURN OFF OVEN with ONE TOUCH CONTROL (OTC)

The automatic self-adjusting system permits no margin-oferror for over or under processing. It does not require an experienced operator to select a menu or estimate the amount of combustible material in the load. One touch of the start button, then let the OTC do the work for any size load. 1. Ramp & Soak Control Requires the operator to select the proper ramp and soak profile program for the size load to be processed. OTC is not a Ramp & Soak control system. OTC completely eliminates ramp & soak profile programs in the controller for various size HOW IT WORKS loads. OTC requires only one touch of the start A digital temperature control is programmed at the factory button, then lets the OTC do the work for any size to heat your load on high fire in the shortest possible time. load. OTC does not require the operator to make The primary and secondary water systems activate and or any decisions. It helps prevent operator error. the main burner goes to low fire to control the heat cycle at OTC automatically adjusts to safely run any size a safe rate. If the primary and back up secondary water load in the safest and shortest possible time. spray systems cannot control a rapid increase in OTC continuously monitors the heat-up rate in the temperature, the main burner will go to low fire. The oven chamber during the entire cycle. afterburner stays on, and both primary and secondary OTC automatically turns off the oven when the water spray systems continue to operate until the load is done. temperature is under control. 2. Rate-Of-Change Control OTC is not a rate-of-change control system that Rest assured, the OTC will not turn off the burners until continuously monitors the heat-up rate of both the there are no combustible materials remaining on the oven oven chamber and the afterburner. OTC only has load. When the load is done, the oven is automatically one digital control. Our automatic self adjusting turned off by the OTC. control systems sixth sense anticipates and OTC continuously monitors the heat-up rate of the oven prevents excessive combustion vapor in the oven chamber. If it heats up too rapidly, indicating excessive and controls it at a safe level. Vapors are combustible vapor, the load is cooled by the water spray generated in the oven and should rigidly be system or oven burner goes to low-fire until the heat-up controlled by one sensor in the oven and not rate is acceptable. The system starts working shuttled off to yet another interfaced sensor in the immediately after the process starts. Thus, controls are afterburner. automatically set for much faster processing time. Rate-of-change control requires two digital temperature controllers, one to monitor oven OTC is a successful system, because it has a sixth temperature and the other to monitor afterburner sense, a fast heat sensitive response time, which temperature. The rate-of-change control system is anticipates and prevents excessive combustion vapor in a factory programmed system that continuously the oven at a safe level. It works on a principle called monitors heat-up rate of both the oven chamber thermoelectricity, in which extremely small heat variations and the afterburner. If either heats up too rapidly, creates instant current flow to the OTC system. indicating excessive combustible vapor, the load is cooled until the heat-up rate is acceptable. OPTION Rate-of-change control requires two digital As an option, should there be a power failure, the water controls, which are hard wire interfaced to shuttle spray system is activated to cool down the load. Thus, data back and forth to monitor the temperature helping to prevent smoke, fumes and odor emissions rate-of-change of both the oven and afterburner. from the exhaust stack. The water system is 3. Batch Cycle Timer Control automatically turned off when oven temperature drops OTC is not a batch cycle timer control system. A below 300F. (149C) to prevent flooding the oven. batch cycle timer is not installed in the OTC system. In the batch cycle timer system, an experienced operator is required to select an estimated length of time the oven will run to do the job. The operator could very easily under or over estimate the required processing time for the COMPARISON OF (3) CONTROL SYSTEMS load. This could result in the oven prematurely OTC has many important improvements over the other shutting off during processing, resulting in partially three commonly used control systems: cleaned loads, and emissions of smoke, fumes and (1) Ramp & Soak control, (2) Rate-Of-Change control and odors out the exhaust stack. Extra time (3) Batch Cycle Timer control. inadvertently added to the cycle will result in wasted fuel and cycle time.

PATENT PENDING

Anda mungkin juga menyukai

- ManualDokumen31 halamanManualHarriJunaediBelum ada peringkat

- Metals Introduction Furnace BrazingDokumen48 halamanMetals Introduction Furnace BrazingMarlon OrdoñezBelum ada peringkat

- Air Flow Unit Conversion ChartDokumen1 halamanAir Flow Unit Conversion Chartghophal0% (1)

- MCFC Chapter OverviewDokumen4 halamanMCFC Chapter Overviewagam YuliantoBelum ada peringkat

- Teoria y Principios Eyectores TermocompresoresDokumen4 halamanTeoria y Principios Eyectores TermocompresoresJohn Kennedy FernandesBelum ada peringkat

- Metal Forming-Cold WorkingDokumen79 halamanMetal Forming-Cold Workinganjaiah_19945Belum ada peringkat

- Bombas Api VS Bombas Ansi PDFDokumen2 halamanBombas Api VS Bombas Ansi PDFABRAHAM ESTRADABelum ada peringkat

- Air Heat BurnerDokumen8 halamanAir Heat BurnerSinggih KurniawanBelum ada peringkat

- Calibration TablesDokumen32 halamanCalibration TablesDanielle BarkerBelum ada peringkat

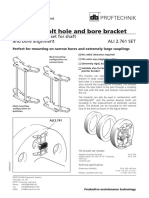

- Magnetic Bolt Hole & Bore Bracket - Magnetic Bracket Set For Shaft & Bore AlignmentDokumen1 halamanMagnetic Bolt Hole & Bore Bracket - Magnetic Bracket Set For Shaft & Bore AlignmentAlireza TakrimiBelum ada peringkat

- Catalogo Analitica Mettler Toledo PDFDokumen242 halamanCatalogo Analitica Mettler Toledo PDFMario Rivera AlonsoBelum ada peringkat

- Boiler Manual Updated 20131Dokumen50 halamanBoiler Manual Updated 20131api-251989125Belum ada peringkat

- Gates CatalogDokumen170 halamanGates CatalogIasm1neBelum ada peringkat

- K 7 PartsDokumen21 halamanK 7 PartsstrashnickBelum ada peringkat

- Limpieza de Catdos 03H07200-4-VEN-7813-13-R1 Trans1Dokumen173 halamanLimpieza de Catdos 03H07200-4-VEN-7813-13-R1 Trans1Piero SánchezBelum ada peringkat

- Owner & Operator's Manual: ModelsDokumen16 halamanOwner & Operator's Manual: ModelskmpoulosBelum ada peringkat

- Lincoln Transfer Pumps Model 82230Dokumen1 halamanLincoln Transfer Pumps Model 82230raisiflyBelum ada peringkat

- NAFA Guide To Air FiltrationDokumen20 halamanNAFA Guide To Air Filtrationkesavaganesan58Belum ada peringkat

- Chromalox - Process Heater Systems PresentationDokumen30 halamanChromalox - Process Heater Systems PresentationNicolae Visan100% (1)

- Operator Manual Buck ScientificDokumen103 halamanOperator Manual Buck ScientificRuben Martinez Reyna100% (1)

- Breaking From Tradition - Model Based Control vs. PIDDokumen7 halamanBreaking From Tradition - Model Based Control vs. PIDshivnairBelum ada peringkat

- Proyecto Final de Mini CNC PDFDokumen78 halamanProyecto Final de Mini CNC PDFAlberto ParedesBelum ada peringkat

- SCHOTT Ptr70 Receiver BrochureDokumen12 halamanSCHOTT Ptr70 Receiver Brochureiresa_nuratBelum ada peringkat

- Autoflame Emissions CalculatorDokumen9 halamanAutoflame Emissions CalculatorLuilio Esparza100% (1)

- Marcotullio DissertationDokumen156 halamanMarcotullio Dissertationn.hartonoBelum ada peringkat

- RT One Touch AltDokumen2 halamanRT One Touch AltsobheysaidBelum ada peringkat

- Parameters for Selecting Highly Efficient and Reliable BoilersDokumen7 halamanParameters for Selecting Highly Efficient and Reliable BoilersvanmurthyBelum ada peringkat

- Boiler Tuning BasicsDokumen18 halamanBoiler Tuning BasicsLester Pino100% (1)

- Boiler-Tuning Basics, Part I: What Constitutes Good Control?Dokumen11 halamanBoiler-Tuning Basics, Part I: What Constitutes Good Control?Udhayakumar VenkataramanBelum ada peringkat

- Why Automation Is RequiredDokumen2 halamanWhy Automation Is RequiredSagar PatilBelum ada peringkat

- Boiler Tuning BasicDokumen25 halamanBoiler Tuning Basictrung2iBelum ada peringkat

- Starting boiler procedure from cold conditionDokumen3 halamanStarting boiler procedure from cold conditionAbigail EscribaBelum ada peringkat

- Indirect Natural Gas Flow MeasurementDokumen3 halamanIndirect Natural Gas Flow MeasurementRago Ramirez GzzBelum ada peringkat

- Generator Aer Cald Pe Ulei Uzat Functionare Prin Vaporizare MTM 17 33 KW 1000 m3 H Fisa TehnicaDokumen11 halamanGenerator Aer Cald Pe Ulei Uzat Functionare Prin Vaporizare MTM 17 33 KW 1000 m3 H Fisa TehnicaGabriel DrideanuBelum ada peringkat

- Instrumentation and Process Control: Dr. Iftikhar A. SalarzaiDokumen81 halamanInstrumentation and Process Control: Dr. Iftikhar A. Salarzaimuhammad shahadat awanBelum ada peringkat

- Cru09en31 07 2014Dokumen4 halamanCru09en31 07 2014Abdessamad YOUSFIBelum ada peringkat

- Electronic Expansion ValveDokumen4 halamanElectronic Expansion ValvebassouadBelum ada peringkat

- High Pressure Natural Circulation Steam BoilerDokumen6 halamanHigh Pressure Natural Circulation Steam BoilerDevendra Kumar SethiBelum ada peringkat

- 0-System PhilosopyDokumen4 halaman0-System PhilosopydazcornishBelum ada peringkat

- Testing of Transformer Oil and Winding Temperature IndicatorsDokumen6 halamanTesting of Transformer Oil and Winding Temperature IndicatorsK Vijay Bhaskar ReddyBelum ada peringkat

- 2d Your Home Central Heating GuideDokumen4 halaman2d Your Home Central Heating Guidebendeni199632Belum ada peringkat

- MR TR v23 en Data SheetDokumen18 halamanMR TR v23 en Data SheetRenata TatićBelum ada peringkat

- Different Types of PH Control SystemsDokumen3 halamanDifferent Types of PH Control SystemsDerek Lua YongweiBelum ada peringkat

- EcoBurn Manual TextDokumen31 halamanEcoBurn Manual TextIoa SeuleanBelum ada peringkat

- User Manual For Danesmoor System Discontinued Dec 07Dokumen16 halamanUser Manual For Danesmoor System Discontinued Dec 07paul3384Belum ada peringkat

- Ekoster 2Dokumen4 halamanEkoster 2Adrian PopaBelum ada peringkat

- Furnace TempDokumen13 halamanFurnace TempRajasekhartg100% (1)

- Pyromat Eco-Soar HeatingDokumen8 halamanPyromat Eco-Soar HeatingSuren ShanBelum ada peringkat

- Slimpel Uputstvo Za UoptrebuDokumen25 halamanSlimpel Uputstvo Za UoptrebuBrksaBelum ada peringkat

- FASTflo WHC56 Service ManualDokumen40 halamanFASTflo WHC56 Service Manualn67250Belum ada peringkat

- Curing Oven Operation ManualDokumen16 halamanCuring Oven Operation ManualWONG TS0% (1)

- Thermostats: Wahler - Solutions in PartnershipDokumen12 halamanThermostats: Wahler - Solutions in PartnershipNitesh Kumar SenBelum ada peringkat

- Catalogue Temperatura 2018 PDFDokumen68 halamanCatalogue Temperatura 2018 PDFWagner Santos100% (1)

- Boiler Purge & Burner Management SystemDokumen7 halamanBoiler Purge & Burner Management SystemS V NAGESHBelum ada peringkat

- Baxi Luna3 Comfort Troubleshooting GuideDokumen16 halamanBaxi Luna3 Comfort Troubleshooting GuideGastón LlamasBelum ada peringkat

- Tuning BoilerDokumen6 halamanTuning BoilerGibby VonpoochcoughBelum ada peringkat

- Types of Burners and Combustion Systems - HEATER TREATER IMPORTANTDokumen5 halamanTypes of Burners and Combustion Systems - HEATER TREATER IMPORTANTadewunmi olufemiBelum ada peringkat

- Encon MVC Brochure 2015Dokumen4 halamanEncon MVC Brochure 2015Pragathees Waran100% (1)

- Automatic Process Control: Principles, Fundamentals and Advanced ConceptsDokumen29 halamanAutomatic Process Control: Principles, Fundamentals and Advanced ConceptsCleto TundumulaBelum ada peringkat

- LG Split, unit Commissioning ProcedureDokumen4 halamanLG Split, unit Commissioning ProcedureFerdie FernandezBelum ada peringkat

- Taper Lock Bush Sizes PDFDokumen4 halamanTaper Lock Bush Sizes PDFstuart3962Belum ada peringkat

- Catalogo RHPDokumen83 halamanCatalogo RHPLuisNovoaRivera100% (1)

- Inventor - (Handling Large Assemblies) .Dokumen36 halamanInventor - (Handling Large Assemblies) .Stuart GoodswenBelum ada peringkat

- Machine Safety Risk Assessment SafetyIIDokumen67 halamanMachine Safety Risk Assessment SafetyIIMarian Ion100% (3)

- Cam Followers - 148111032Dokumen2 halamanCam Followers - 148111032stuart3962Belum ada peringkat

- CleanSafe 787C - (Tech Data Sheet) .Dokumen2 halamanCleanSafe 787C - (Tech Data Sheet) .Stuart GoodswenBelum ada peringkat

- RGS c1518Dokumen2 halamanRGS c1518Amila AbeywickramaBelum ada peringkat

- Specification Output Torque: 440 LBF Ins/50 NM at 100 Psi/7 BarDokumen1 halamanSpecification Output Torque: 440 LBF Ins/50 NM at 100 Psi/7 Barstuart3962Belum ada peringkat

- Conversion Factors.Dokumen2 halamanConversion Factors.Stuart GoodswenBelum ada peringkat

- Cable Tray Selection GuideDokumen18 halamanCable Tray Selection Guidestuart3962Belum ada peringkat

- Tubeclamps Tech Manual.Dokumen16 halamanTubeclamps Tech Manual.stuart3962Belum ada peringkat

- HP Series Rotary Actuator DatasheetDokumen8 halamanHP Series Rotary Actuator Datasheetstuart3962Belum ada peringkat

- El 16Dokumen4 halamanEl 16nedduc20Belum ada peringkat

- Press Brake Metric Tonnage Chart For Air BendingDokumen1 halamanPress Brake Metric Tonnage Chart For Air BendingkokyawzawBelum ada peringkat

- CEILCOTE 505 Coroline.Dokumen2 halamanCEILCOTE 505 Coroline.stuart3962Belum ada peringkat

- Basic Wood Properties PDFDokumen12 halamanBasic Wood Properties PDFsorix2005Belum ada peringkat

- Blower Fans-Fiberglass ReinforcedDokumen4 halamanBlower Fans-Fiberglass ReinforcedthespalBelum ada peringkat

- Ardrox 2320A - (MSDS) .Dokumen6 halamanArdrox 2320A - (MSDS) .Stuart GoodswenBelum ada peringkat

- Fan LawsDokumen8 halamanFan Lawsstuart3962Belum ada peringkat

- BS 5345 P1 PDFDokumen48 halamanBS 5345 P1 PDFAnamulKabir100% (3)

- BS 5000 IndexDokumen2 halamanBS 5000 Indexstuart3962Belum ada peringkat

- Universal Switch Box Details.Dokumen2 halamanUniversal Switch Box Details.stuart3962Belum ada peringkat

- BS 5000-17Dokumen8 halamanBS 5000-17stuart3962Belum ada peringkat

- Wire RopeDokumen16 halamanWire Ropesori1386Belum ada peringkat

- Fastener Grades A1, A2, A3 & A4, A5 To BS en ISO 3506Dokumen3 halamanFastener Grades A1, A2, A3 & A4, A5 To BS en ISO 3506Paul OnionsBelum ada peringkat

- Timber Guide (Build Centre) .Dokumen82 halamanTimber Guide (Build Centre) .stuart3962Belum ada peringkat

- Mild Steel Flat Strip Sizes.Dokumen1 halamanMild Steel Flat Strip Sizes.Stuart GoodswenBelum ada peringkat

- Introduction to Stainless Steel Grades 304 and 316LDokumen2 halamanIntroduction to Stainless Steel Grades 304 and 316Lstuart3962100% (1)

- Durbar Floor Plate (Corus) .Dokumen12 halamanDurbar Floor Plate (Corus) .Stuart GoodswenBelum ada peringkat

- Chemflo PP PVDF FittingsDokumen68 halamanChemflo PP PVDF Fittingsstuart3962Belum ada peringkat

- Control Lights with SOU-1 Twilight SwitchDokumen1 halamanControl Lights with SOU-1 Twilight SwitchjsblBelum ada peringkat

- Blowfish Encryption AlgorithmDokumen3 halamanBlowfish Encryption AlgorithmParkerAllisonBelum ada peringkat

- 11+ Entrance Examination: Specimen PaperDokumen8 halaman11+ Entrance Examination: Specimen PaperNayem Hossain HemuBelum ada peringkat

- Introduction to Continuous Optimization for Machine LearningDokumen10 halamanIntroduction to Continuous Optimization for Machine LearningMarcos OliveiraBelum ada peringkat

- Lab Manual MCSE 101Dokumen35 halamanLab Manual MCSE 101Juan JacksonBelum ada peringkat

- Geotehnical Engg. - AEE - CRPQsDokumen48 halamanGeotehnical Engg. - AEE - CRPQsSureshKonamBelum ada peringkat

- ABC-S Plus Web Info '08Dokumen4 halamanABC-S Plus Web Info '08anon-331232Belum ada peringkat

- Serial Port InterfacingDokumen5 halamanSerial Port Interfacingyampire100% (1)

- ISCOM HT803 DatasheetDokumen2 halamanISCOM HT803 Datasheetnmc79Belum ada peringkat

- Camshaft Test SheetDokumen4 halamanCamshaft Test SheetsughieantoBelum ada peringkat

- 2017 Yr 9 Linear Relations Test A SolutionsDokumen13 halaman2017 Yr 9 Linear Relations Test A SolutionsSam JeffreyBelum ada peringkat

- User Mode I. System Support Processes: de Leon - Dolliente - Gayeta - Rondilla It201 - Platform Technology - TPDokumen6 halamanUser Mode I. System Support Processes: de Leon - Dolliente - Gayeta - Rondilla It201 - Platform Technology - TPCariza DollienteBelum ada peringkat

- Lesson 1Dokumen24 halamanLesson 1Jayzelle100% (1)

- RelativedensityipgDokumen2 halamanRelativedensityipgapi-310625232Belum ada peringkat

- Visualizing Interstellar WormholesDokumen14 halamanVisualizing Interstellar WormholesFranciscoBelum ada peringkat

- Algebra Translating Algebraic Phrases 001Dokumen2 halamanAlgebra Translating Algebraic Phrases 001crazyomnislash25% (4)

- Network Layer: Computer Networking: A Top Down ApproachDokumen83 halamanNetwork Layer: Computer Networking: A Top Down ApproachMuhammad Bin ShehzadBelum ada peringkat

- FTP FUNCTION MODULE in ABAPDokumen8 halamanFTP FUNCTION MODULE in ABAPAdriano PermanaBelum ada peringkat

- THKDokumen1.901 halamanTHKapi-26356646Belum ada peringkat

- Matlab programs to fit common curves using least squares methodDokumen5 halamanMatlab programs to fit common curves using least squares methodRavi ParkheBelum ada peringkat

- Winegard Sensar AntennasDokumen8 halamanWinegard Sensar AntennasMichael ColeBelum ada peringkat

- Java10 PDFDokumen137 halamanJava10 PDFswarup sarkarBelum ada peringkat

- CI SetDokumen18 halamanCI Setতন্ময় ঢালি Tanmay DhaliBelum ada peringkat

- CobolDokumen224 halamanCobolrahulravi007Belum ada peringkat

- VRV A 12 PDFDokumen1 halamanVRV A 12 PDFMoe Thiri ZunBelum ada peringkat

- Midterm Exam Result Ce199-1l 2Q1920Dokumen3 halamanMidterm Exam Result Ce199-1l 2Q1920RA CarpioBelum ada peringkat

- VLSI Design: Introduction & Motivation Introduction & MotivationDokumen33 halamanVLSI Design: Introduction & Motivation Introduction & MotivationPriyanka SharmaBelum ada peringkat

- Handout 06 - Geothermometry PDFDokumen7 halamanHandout 06 - Geothermometry PDFOg LocabaBelum ada peringkat

- Bash 101 Hacks PDFDokumen5 halamanBash 101 Hacks PDFAmira A MarreiBelum ada peringkat

- Operational Guidelines For VlsfoDokumen2 halamanOperational Guidelines For VlsfoИгорьBelum ada peringkat

- Well Control for Completions and InterventionsDari EverandWell Control for Completions and InterventionsPenilaian: 4 dari 5 bintang4/5 (10)

- Asset Integrity Management for Offshore and Onshore StructuresDari EverandAsset Integrity Management for Offshore and Onshore StructuresBelum ada peringkat

- Industrial Piping and Equipment Estimating ManualDari EverandIndustrial Piping and Equipment Estimating ManualPenilaian: 5 dari 5 bintang5/5 (7)

- Oil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsDari EverandOil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsBelum ada peringkat

- Black Gold Stranglehold: The Myth of Scarcity and the Politics of OilDari EverandBlack Gold Stranglehold: The Myth of Scarcity and the Politics of OilBelum ada peringkat

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisDari EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisBelum ada peringkat

- Pipeline Integrity: Management and Risk EvaluationDari EverandPipeline Integrity: Management and Risk EvaluationPenilaian: 4.5 dari 5 bintang4.5/5 (6)

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesDari EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesBelum ada peringkat

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsDari EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsPenilaian: 5 dari 5 bintang5/5 (1)

- Fire in the Night: The Piper Alpha DisasterDari EverandFire in the Night: The Piper Alpha DisasterPenilaian: 4.5 dari 5 bintang4.5/5 (5)

- Subsea Valves and Actuators for the Oil and Gas IndustryDari EverandSubsea Valves and Actuators for the Oil and Gas IndustryPenilaian: 5 dari 5 bintang5/5 (1)

- Petroleum Rock Mechanics: Drilling Operations and Well DesignDari EverandPetroleum Rock Mechanics: Drilling Operations and Well DesignPenilaian: 5 dari 5 bintang5/5 (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDari EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryBelum ada peringkat

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationDari EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisDari EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisPenilaian: 5 dari 5 bintang5/5 (1)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionDari EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionPenilaian: 4.5 dari 5 bintang4.5/5 (16)

- Corrosion Control in the Oil and Gas IndustryDari EverandCorrosion Control in the Oil and Gas IndustryPenilaian: 4 dari 5 bintang4/5 (12)

- Pocket Guide to Flanges, Fittings, and Piping DataDari EverandPocket Guide to Flanges, Fittings, and Piping DataPenilaian: 3.5 dari 5 bintang3.5/5 (22)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesDari EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertPenilaian: 3 dari 5 bintang3/5 (2)