Twin Screw Extruder Machine

Diunggah oleh

Poran SinghHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Twin Screw Extruder Machine

Diunggah oleh

Poran SinghHak Cipta:

Format Tersedia

Twin Screw Extruder Machine

Book buy online Twin extruders tools suppliers are best screw to use industries given manufacturer machine screw wide range of product Twin Screw Extruder driver Suppliers adding Twin Screw Extruder Supplier, best power capacity items more detail contact us meta-tech big company Twin Screw Extruder Suppliers

Top power Coating require, twin screw and machine. Extruder is the machine for producing more or less continuous powder coating of twin sections out of a selected type of twin recycle. There are a more number of twin extrusion techniques available such as co- twin extrusion, offset much more Powder Coating Machines. The essential part of industries utilized elements for a twin extruder are a tubular barrel, usually electrically heated avoide ; a revolving screw, good product of within the twin manufacturer ; a hopper at one end from which the material to be extruded is fed to the screw, ram or plunger; a die at the opposite end for shaping the extruded mass.

Extruders may be divided into three general types:

* twin Single Screw Extruder

* Twin or Multiples Screw Extruder Twin Single screw extruders and twin screw extuders are the most widely used extruders for organization. The twin screw that is used to push the resin out of the die is the important component of a screw extruder. In the earlier days rubber screw were used industries but the rubber screw was not able to give enough amount of shear into the polymer. Therefore, screws were designed that would start deeper in the feed and gradually taper shallower in the metering section to apply more work on the twin screw as it was going from the feed to the discharge.

Twin Screw Equipments

The Twin Screw Extruder Manufacturers is usually contained inside a tight fitting driven by a variable speed motor quality. It is a highly efficient device capable of processing several tons of per hour, even in modestly sized twin extruders. The screw is divided into three division the feed section, the compressor and the metering section.

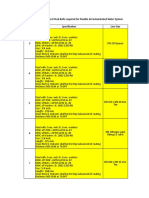

The feed section of the screw mechanism stores and delivers model MT-35,MT-45,MT-60,MT-65 Twin Screw Extruder Machine from a gravity fed hopper into the best made screw to begin the plastic longitudinal movement. Screw threads move the twin using axial rotation. Within the barrel, heaters help the twin develop a tack to

increase its friction against the strong wall. Without this friction the extruder could not be conveyed forward and would merely rotate inside the twin screw.

Anda mungkin juga menyukai

- Types of Plastic ExtrudersDokumen7 halamanTypes of Plastic ExtrudershvadnalaBelum ada peringkat

- Extrusion BasicsDokumen3 halamanExtrusion BasicsSaad AliBelum ada peringkat

- Unity Pwoer Point-2Dokumen61 halamanUnity Pwoer Point-2Jai SankerBelum ada peringkat

- Explain 10 Inch Extruder Process With DiagramDokumen14 halamanExplain 10 Inch Extruder Process With Diagramisuru jayalathBelum ada peringkat

- Mini Belt Grinder Project Jounal 4Dokumen3 halamanMini Belt Grinder Project Jounal 41DS19ME136-Shivam KumarBelum ada peringkat

- Design Hammer MillsDokumen12 halamanDesign Hammer MillsSaqib ChandBelum ada peringkat

- Ms 304 / Fall 2007 / The Project Manufacturing An Industrial Machine: Telling The Untold Story Version 1.0 AlphaDokumen107 halamanMs 304 / Fall 2007 / The Project Manufacturing An Industrial Machine: Telling The Untold Story Version 1.0 AlphaHAKAN100% (2)

- Injection MouldingDokumen7 halamanInjection MouldingAzizol WahabBelum ada peringkat

- Hydraulic Press Brake MachineDokumen7 halamanHydraulic Press Brake MachineWahyu SiwastanaBelum ada peringkat

- 2 1 ExtrusionDokumen69 halaman2 1 ExtrusionSingh Anuj0% (1)

- Proto Copy Finale DraeteDokumen60 halamanProto Copy Finale DraeteAjinkya MoreBelum ada peringkat

- Lathe Helping SidesDokumen27 halamanLathe Helping Sidest75zswxgwfBelum ada peringkat

- Classification o F ExtruderDokumen25 halamanClassification o F ExtruderSaman Waheed100% (1)

- Hydrolic Pipe Bending MachineDokumen54 halamanHydrolic Pipe Bending MachineSanketDhande0% (1)

- Advanced Drilling Using A Dual Bit SystemDokumen7 halamanAdvanced Drilling Using A Dual Bit Systemtarang_tusharBelum ada peringkat

- The Design of A Small-Scale Plastic Extruder MachiDokumen4 halamanThe Design of A Small-Scale Plastic Extruder MachiKARUPPUCHAMY GBelum ada peringkat

- Pneumatic Rod Bending Machine Project ReportDokumen3 halamanPneumatic Rod Bending Machine Project ReportJeyakumar NBelum ada peringkat

- Absorbent Cotton Manufacturing Machine CatalagueDokumen27 halamanAbsorbent Cotton Manufacturing Machine Catalaguesnsurgicare100% (3)

- ForgingDokumen7 halamanForgingBOOM BOYSBelum ada peringkat

- Literature Review Exp 2Dokumen7 halamanLiterature Review Exp 2Lris TanBelum ada peringkat

- Designing of Multi-Cavity Extrusion Die To Increase Productivity: A Survey and PerspectiveDokumen6 halamanDesigning of Multi-Cavity Extrusion Die To Increase Productivity: A Survey and PerspectiveIJRASETPublicationsBelum ada peringkat

- Injection Molding BasicsDokumen26 halamanInjection Molding BasicsVIGNESH100% (1)

- Basics of Milling Machine and Its RigidityDokumen9 halamanBasics of Milling Machine and Its RigidityshubhamBelum ada peringkat

- Hydrolic Pipe Bending MachineDokumen59 halamanHydrolic Pipe Bending MachineNilesh Maheshwari67% (3)

- Design and Development of Pneumatic Metal Sheet Cutting Machine Ijariie7954Dokumen6 halamanDesign and Development of Pneumatic Metal Sheet Cutting Machine Ijariie7954siddharth thoratBelum ada peringkat

- Fully Automatic Can Crusher 1280-6-1 With Cover Page v2Dokumen6 halamanFully Automatic Can Crusher 1280-6-1 With Cover Page v2Prakhar SinghBelum ada peringkat

- Can Crusher MechanismDokumen4 halamanCan Crusher MechanismaqmbaldiwalaBelum ada peringkat

- Presented by Geetha.R M.Pharm II - SemisterDokumen47 halamanPresented by Geetha.R M.Pharm II - SemisterjaiminBelum ada peringkat

- Mark Andrew Cabale, BSME-3ADokumen5 halamanMark Andrew Cabale, BSME-3AMark Andrew CabaleBelum ada peringkat

- Size Reduction by VDRDokumen43 halamanSize Reduction by VDRVinod D RamaniBelum ada peringkat

- Six Weeks Industrial Training ReportDokumen27 halamanSix Weeks Industrial Training ReportGagan Deep100% (2)

- Designing and Fabrication of Multipurpose Tool Post For Lathe MachineDokumen3 halamanDesigning and Fabrication of Multipurpose Tool Post For Lathe MachineRahul ShrivastavaBelum ada peringkat

- Colegio de San Juan de Letran School of Engineering S.Y. 2020Dokumen14 halamanColegio de San Juan de Letran School of Engineering S.Y. 2020Jonathan AysonBelum ada peringkat

- Meca ProjectDokumen29 halamanMeca ProjectSahilye Geha100% (1)

- Polymer Extrusion Experimental Report: April 2018Dokumen9 halamanPolymer Extrusion Experimental Report: April 2018Mehmet Sarı100% (1)

- Injection Molding FinalDokumen49 halamanInjection Molding FinalShoaib RathoreBelum ada peringkat

- My Side (11)Dokumen57 halamanMy Side (11)Rayyan TayyabBelum ada peringkat

- Chapter 1-2Dokumen70 halamanChapter 1-2Shivpoojan SinghBelum ada peringkat

- Fully Automatic Can Crusher-1280Dokumen5 halamanFully Automatic Can Crusher-1280fadya100% (1)

- A Review On Design and Analysis of Oil Expeller SparesDokumen7 halamanA Review On Design and Analysis of Oil Expeller SparesTANKO BAKOBelum ada peringkat

- Injection MoldingDokumen33 halamanInjection MoldingDineshkumar RathinavelBelum ada peringkat

- 69 Icriet-200Dokumen6 halaman69 Icriet-200Ragos SegundoBelum ada peringkat

- Hammer MillsDokumen56 halamanHammer MillskokiskoBelum ada peringkat

- Punch and DieDokumen16 halamanPunch and DieNani DatrikaBelum ada peringkat

- Problem StatementDokumen33 halamanProblem StatementKevin Jesus Tadeo Reyes MendezBelum ada peringkat

- Developmentand Performance Evaluationof Improved Hammer MillDokumen7 halamanDevelopmentand Performance Evaluationof Improved Hammer MillDaniella SabacBelum ada peringkat

- Particle Technology: Size Reduction EquipmentsDokumen7 halamanParticle Technology: Size Reduction EquipmentsMubarak AhmadBelum ada peringkat

- Extrusion PressDokumen17 halamanExtrusion PresssydengBelum ada peringkat

- 70D Manual BookDokumen43 halaman70D Manual BookgeorgioBelum ada peringkat

- Report Literture ReviewDokumen11 halamanReport Literture Reviewosama hasanBelum ada peringkat

- Multi Nut Tightner-ReportDokumen26 halamanMulti Nut Tightner-ReportBrightchip Technologies100% (1)

- Zones of ScrewDokumen111 halamanZones of Screwzubi0585100% (2)

- Industrial Visit Report of Kiran Machine Tool LTD Jalgaon Yogesh MandlikDokumen11 halamanIndustrial Visit Report of Kiran Machine Tool LTD Jalgaon Yogesh MandlikYogesh R MandlikBelum ada peringkat

- Double Roll CrusherDokumen9 halamanDouble Roll CrusherVăn Quang Ngô100% (2)

- Generation Ii Series Condenser Tube Expanders: FeaturesDokumen15 halamanGeneration Ii Series Condenser Tube Expanders: FeaturesSheikh ZakirBelum ada peringkat

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Dari EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Belum ada peringkat

- Weld Like a Pro: Beginning to Advanced TechniquesDari EverandWeld Like a Pro: Beginning to Advanced TechniquesPenilaian: 4.5 dari 5 bintang4.5/5 (6)

- Rigid InclusionsDokumen3 halamanRigid InclusionsFelicia LingBelum ada peringkat

- Laboratory Autoclaves IcanclaveDokumen8 halamanLaboratory Autoclaves IcanclaveХачатрян ГеворгBelum ada peringkat

- MCQDokumen5 halamanMCQAnonymous uTC8baBelum ada peringkat

- CyanideDokumen52 halamanCyanideWilliamEliezerClBelum ada peringkat

- Canada SCC Mexico Nyce or Nom United States NRTLDokumen5 halamanCanada SCC Mexico Nyce or Nom United States NRTLHamza saeedBelum ada peringkat

- WaterSaver Faucet CTBT Lab Service Fittings OnlineDokumen146 halamanWaterSaver Faucet CTBT Lab Service Fittings OnlineXavierBelum ada peringkat

- Experiments 3,4,5Dokumen13 halamanExperiments 3,4,5Athirah JamalludinBelum ada peringkat

- GCC - Plastic IndustryDokumen44 halamanGCC - Plastic IndustrySeshagiri KalyanasundaramBelum ada peringkat

- STP of Etratab BolusDokumen5 halamanSTP of Etratab BolusBejoy KarimBelum ada peringkat

- Lecture 22 Thinfilm Deposition-Sputteringr 9 PDFDokumen6 halamanLecture 22 Thinfilm Deposition-Sputteringr 9 PDFu11ee079Belum ada peringkat

- Ebook Membranes 2013Dokumen577 halamanEbook Membranes 2013sergiogonzalez371375% (4)

- PQR Amp WPQ Standard Testing Parameter WorksheetDokumen4 halamanPQR Amp WPQ Standard Testing Parameter WorksheetvinodBelum ada peringkat

- Assignment-7question and SolutionDokumen3 halamanAssignment-7question and SolutionTusharBelum ada peringkat

- MCAT - Past - PaperS - PDF Version 1Dokumen185 halamanMCAT - Past - PaperS - PDF Version 1Muddassar ZafarBelum ada peringkat

- Instrumental Presentation, Esma, 27.8.16Dokumen14 halamanInstrumental Presentation, Esma, 27.8.16John Paul DenajibaBelum ada peringkat

- Zoznam NoriemDokumen4 halamanZoznam NoriemPeter TvardzíkBelum ada peringkat

- METAL FORMING AND THE Fenite Element Method PDFDokumen9 halamanMETAL FORMING AND THE Fenite Element Method PDFThiran Boy Lingam0% (1)

- Sirafan SpeedDokumen5 halamanSirafan SpeedProsenjit76Belum ada peringkat

- EPF3701 - Lec8 ClosuresDokumen57 halamanEPF3701 - Lec8 ClosuresMuhd Khairul AmriBelum ada peringkat

- A. Reading Assignment: Analysis of Members With Axial Loads and MomentsDokumen19 halamanA. Reading Assignment: Analysis of Members With Axial Loads and MomentsIhab El AghouryBelum ada peringkat

- Regenerative Cooling of Liquid Rocket Engine Thrust ChambersDokumen100 halamanRegenerative Cooling of Liquid Rocket Engine Thrust ChambersRaol Martínez SantiagoBelum ada peringkat

- Design Analysis and Comparison Between The Conventional Materialswith Composite Material of The Leaf Springs Fmoa 1000127Dokumen20 halamanDesign Analysis and Comparison Between The Conventional Materialswith Composite Material of The Leaf Springs Fmoa 1000127Anonymous oTrMzaBelum ada peringkat

- Bom of Studs & Nuts For Balance SystemDokumen4 halamanBom of Studs & Nuts For Balance SystemmishtinilBelum ada peringkat

- WO2008033224A1 Polycaprolactone PolyurethaneDokumen31 halamanWO2008033224A1 Polycaprolactone PolyurethaneGİZEM DEMİRBelum ada peringkat

- BOQ SSB Part 1 PDFDokumen358 halamanBOQ SSB Part 1 PDFakshanshrail100% (1)

- Lab Report - Heat of CombustionDokumen3 halamanLab Report - Heat of CombustionDexter ClamohoyBelum ada peringkat

- Journal of Constructional Steel Research: Dongxu Li, Brian Uy, Farhad Aslani, Chao HouDokumen17 halamanJournal of Constructional Steel Research: Dongxu Li, Brian Uy, Farhad Aslani, Chao HouMahmoudAlyBelum ada peringkat

- Ess II - Water IDokumen16 halamanEss II - Water IDevang ParekhBelum ada peringkat

- Megafil 240M enDokumen1 halamanMegafil 240M endddassddBelum ada peringkat

- Acoustic Emission - Standards and Technology UpdateDokumen257 halamanAcoustic Emission - Standards and Technology Updatetobby65100% (1)