Regulations - 2009 M.E. Cad / Cam

Diunggah oleh

RajueswarJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Regulations - 2009 M.E. Cad / Cam

Diunggah oleh

RajueswarHak Cipta:

Format Tersedia

AFFILIATED INSTITUTIONS ANNA UNIVERSITY, CHENNAI

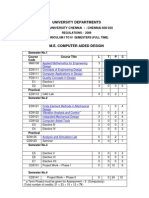

REGULATIONS - 2009 M.E. CAD / CAM

II TO IV SEMESTERS (FULL TIME) CURRICULUM AND SYLLABUS SEMESTER II Code No. THEORY CC 9221 CC 9222 CI 9211 PD 9221 Course Title Design for Manufacture, Assembl y and Envi ronments Integrated Manufacturing Systems A pplied Material s Engineering Integrated Product Design and Processes Dev el opment Elective-II Elective-III L 3 3 3 3 3 3 0 18 T 0 0 0 1 0 0 0 1 P 0 0 0 0 0 0 3 3 C 3 3 3 4 3 3 3 22

E2 E3 PRACTICAL CC 9225 CAM LAB

Total SEMESTER III Code No. THEORY E4 E5 E6 PRACTICAL CC 9231 Course Title Elective IV Elective V Elective VI Project Work (Phase I) Total

L 3 3 3 0 9

T 0 0 0 0 0

P 0 0 0 12 12

C 3 3 3 6 15

SEMESTER IV Code Course Title No. PRACTICAL CC 9241 Project Wok (Phase II ) Total Total Credits: 24+22+15+ 12 = 73 L 0 0 T 0 0 P 24 24 C 12 12

LIST OF ELECTIVES M.E. CAD / CAM Course Code CC9250 CC9251 CC9252 CC9253 CC9254 CC9255 CC9256 CC9257 CC9258 CC9259 CI9259 ED9222 ED9223 ED9250 ED9252 ED9253 ED9256 ED9258 ED9259 ED9264 IC9262 Course Title Mechatronics in Manufacturi ng Systems Computer Ai ded Process P lanning Dat a Communi cation in CAD/CAM Industrial Safety Management Performance Modelli ng and Analysi s of Manufact uri ng System Metrology and Non Destructive Testi ng Design f or Cel lul ar Manuf acturing Systems Total Quality Management Rel iability Engineeri ng Models Maintenance Engineering and Management Rapid Prototyping ** Vibration Analysi s and Control ** Mechani sms Design and Si mulation Optimization Techni ques in Design Tri bology in Desi gn Advanced Mechani cs of Materials Advanced Tool Design Industrial Robotics and Expert Systems Design of Material Handling Equipments Design of Hydraulic and Pneumatic Systems Computational Fluid Dynamics L 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 T 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 P 0 0 0 0 0 0 0 0 0 0 0 2 2 0 0 0 0 0 0 0 0 C 3 3 3 3 3 3 3 3 3 3 3 4 4 3 3 3 3 3 3 3 3

CC 9221

DESIGN FOR MANUFACTURE, ASSEMBLY AND ENVIRONMENTS

LPTC 30 03

UNIT I INTRODUCTION 5 General design principles for manufacturability - strength and mechanical factors, mechanisms selection, evaluation method, Process capability - Feature tolerances Geometric tolerances - Assembly limits -Datum features - Tolerance stacks. UNIT II FACTORS INFLUENCING FORM DESIGN 13 Working principle, Material, Manufacture, Design- Possible solutions - Materials choice - Influence of materials on form design - form design of welded members, forgings and castings. UNIT III COMPONENT DESIGN - MACHINING CONSIDERATION 8 Design features to facilitate machining - drills - milling cutters - keyways Doweling procedures, counter sunk screws - Reduction of machined areasimplification by separation - simplification by amalgamation - Design for machinability - Design for economy - Design for clampability - Design for accessibility Design for assembly. UNIT IV COMPONENT DESIGN - CASTING CONSIDERATION 10 Redesign of castings based on Parting line considerations - Minimizing core requirements, machined holes, redesign of cast members to obviate cores. Identification of uneconomical design - Modifying the design - group technology - Computer Applications for DFMA UNIT V DESIGN FOR THE ENVIRONMENT 9 Introduction Environmental objectives Global issues Regional and local issues Basic DFE methods Design guide lines Example application Lifecycle assessment Basic method AT&Ts environmentally responsible product assessment - Weighted sum assessment method Lifecycle assessment method Techniques to reduce environmental impact Design to minimize material usage Design for disassembly Design for recyclability Design for remanufacture Design for energy efficiency Design to regulations and standards. TOTAL: 45 PERIODS REFERENCES: 1. Boothroyd, G, 1980 Design for Assembly Automation and Product Design. New York, Marcel Dekker. 2. Bralla, Design for Manufacture handbook, McGraw hill, 1999. 3. Boothroyd, G, Heartz and Nike, Product Design for Manufacture, Marcel Dekker, 1994. 4. Dickson, John. R, and Corroda Poly, Engineering Design and Design for Manufacture and Structural Approach, Field Stone Publisher, USA, 1995. 5. Fixel, J. Design for the Environment McGraw hill., 1996. 6. Graedel T. Allen By. B, Design for the Environment Angle Wood Cliff, Prentice Hall. Reason Pub., 1996. 7. Kevien Otto and Kristin Wood, Product Design. Pearson Publication, 2004.

CC 9222 UNIT I

INTERGRATED MANUFACTURING SYSTEM INTRODUCTION

L T P C 3 0 0 3 5

Objectives of a manufacturing system-identifying business opportunities and problems classification production systems-linking manufacturing strategy and systems analysis of manufacturing operations.

UNIT II

GROUP TECHNOLOGY AND COMPUTER AIDED PROCESS PLANNING 10 Introduction-part families-parts classification and cooling - group technology machine cells-benefits of group technology. Process planning function CAPP Computer generated time standards. UNIT III COMPUTER AIDED PLANNING AND CONTROL 10 Production planning and control-cost planning and control-inventory management- Material requirements planning (MRP)-shop floor control-Factory data collection system- Automatic identification system-barcode technology- automated data collection system. UNIT IV COMPUTER MONITORING 10 Types of production monitoring systems-structure model of manufacturing processprocess control & strategies- direct digital control-supervisory computer controlcomputer in QC - contact inspection methods non-contact inspection method computer-aided testing - integration of CAQC with CAD/CAM. UNIT V INTEGRATED MANUFACTURING SYSTEM 10 Definition - application - features - types of manufacturing systems-machine toolsmaterials handling system- computer control system - DNC systems manufacturing cell. Flexible manufacturing systems (FMS) - the FMS concept-transfer systems - head changing FMS - variable mission manufacturing system - CAD/CAM system - human labor in the manufacturing system-computer integrated manufacturing system benefits. Rapid prototyping - Artificial Intelligence and Expert system in CIM. TOTAL: 45 PERIODS TEXT BOOKS: 1. Groover, M.P., "Automation, Production System and CIM", Prentice-Hall of India, 1998. REFERENCES: 1. David Bedworth, "Computer Integrated Design and Manufacturing", TMH, New Delhi, 1998. 2. Yorem Koren, "Computer Integrated Manufacturing Systems", McGraw Hill, 1983. 3. Ranky, Paul G., "Computer Integrated Manufacturing", Prentice Hall International 1986. 4. R.W. Yeomamas, A. Choudry and P.J.W. Ten Hagen, "Design rules for a CIM ystem", North Holland Amsterdam, 1985.

CI 9211

APPLIED MATERIALS ENGINEERING at an advanced level in applied materials

LTPC 300 3

AIM: To impart knowledge Engineering.

OBJECTIVE: This course provides knowledge in the areas Of Industrial Metallurgy, chemical Properties, heat treatment, advanced materials and selection of materials for important applications. UNIT I PLASTIC BEHAVIOUR & STRENGTHENING 8 Mechanism of Plastic deformation, role of dislocations, yield stress, shear strength of perfect and real crystals Strengthening mechanism, work, hardening, solid solutioning, grain boundary strengthening, Poly phase mixture, precipitation, particle fibre and dispersion strengthening. Effect of temperature, strain and strain rate on plastic behaviour Super plasticity. UNIT II FRACTURE BEHAVIOUR 8 Griffiths theory stress intensity factor and fracture toughness-Toughening mechanisms Ductile, brittle transition in steel-High temperature fracture, creep Larson-Miller, Parameter Deformation and fracture mechanism maps Fatigue. Low and high cycle fatigue test, crack initiation and propagation mechanisms and Paris law Effect of surface and metallurgical parameters on fatigue fracture of non metallic materials Failure analysis, sources of failure, procedure of failure analysis. UNIT III SELECTION OF MATERIALS 8 Motivation for selection, cost basis and service requirements selection for Mechanical properties, strength, toughness, fatigue and creep Selection for surface durability corrosion and wear resistance Relationship between materials selection and processing Case studies in materials selection with Relevance to aero, auto, marine, machinery and nuclear applications. UNIT IV UNITMATERIAL PROCESSING 9 Processing of engineering materials Primary and Secondary processes astability, Weldability, forgeability and malleability Criteria Process induced defects Monitoring and control. UNIT V MODERN MATERIALS AND TREATMENT: 12 Dual phase steels, high strength low alloy (HSLA) Steel transformation included plasticity (TRIP), Steel, maraging steel, shape memory alloys, properties applications of engineering plastics and composites materials advanced structural ceramics WC, Tic, Tac, Al2o3, Sic, Si3N4, CBN diamond, heat treatment alloy and tool steels, vapour deposition Plasma, PVD- thick and thin film deposition Nano materialsproduction of Nano sized materials. TOTAL: 45 PERIODS TEXT BOOKS: 1. George E.Dieter, Mechanical Metallurgy, McGraw Hill, 1988. 2. Charles, J.A., Crane, F.A.A and Furness, J.A.G., Selection and use of Engineering Materials, (3 rd Edition, Butterworth Heiremann, 1977. REFERENCES: 1. The Hand book of Advance Materials, James k.Wessel, Wiley, Intersam,john, Wilson Publishers., 2004. 2. Surface Engg of Meterials- Principles of Equipment, Techniques, TadensZ Burakonsa &T.Wierzchan nd 3. Thoas h.Courtney , Mechanical Behaviour of Meterials ,(2 edition),

McGraw Hill, 2000. 4. Flinn,R.A.and Trojan ,P.K.., Engg Meterials and their th Applications (4 Edition), Jaico, 1999.

PD 9221

INTEGRATED PRODUCT DESIGN AND PROCESS DEVELOPMENT

LTPC 31 04

UNIT I INTRODUCTION 12 Need for IPPD-Strategic importance of Product development - integration of customer, designer, material supplier and process planner, Competitor and customer - behavior analysis. Understanding customer-promoting customer understanding-involve customer in development and managing requirements - Organization process management and improvement UNIT II CONCEPT GENERATION, SELECTION AND TESTING 12 Plan and establish product specifications. Task - Structured approaches - clarification search-externally and internally-Explore systematically - reflect on the solutions and processes - concept selection - methodology - benefits. Implications - Product change - variety - component standardization - product performance - manufacturability Concept Testing Methodologies. UNIT III PRODUCT ARCHITECTURE 12 Product development management - establishing the architecture - creation - clustering geometric layout development - Fundamental and incidental interactions - related system level design issues - secondary systems -architecture of the chunks - creating detailed interface specifications-Portfolio Architecture. UNIT IV INDUSTRIAL DESIGN 12 Integrate process design - Managing costs - Robust design - Integrating CAE, CAD, CAM tools Simulating product performance and manufacturing processes electronically Need for industrial design-impact design process - investigation of customer needs conceptualization - refinement - management of the industrial design process - technology driven products - user - driven products - assessing the quality of industrial design. UNIT V DESIGN FOR MANUFACTURING AND PRODUCT DEVELOPMENT 12 Definition - Estimation of Manufacturing cost-reducing the component costs and assembly costs Minimize system complexity - Prototype basics - Principles of prototyping Planning for prototypes - Economic Analysis - Understanding and representing tasksbaseline project planning - accelerating the project-project execution. TOTAL: 60 PERIODS A Term Project/Presentation must be given for Assessment 3 (Compulsory) TEXT BOOK: 1. Product Design and Development, Karl T.Ulrich and Steven D.Eppinger, McGraw Hill International Edns.1999 REFERENCES: 1. Concurrent Engg./Integrated Product Development. Kemnneth Crow, DRM Associates, 6/3,Via Olivera, Palos Verdes, CA 90274(310) 377-569,Workshop Book 2. Effective Product Design and Development, Stephen Rosenthal, Business One Orwin, Homewood, 1992,ISBN, 1-55623-603-4 3. Tool Design Integrated Methods for successful Product Engineering, Stuart Pugh, Addison Wesley Publishing,Neyourk,NY,1991, ISBN 0-202-41639-5 4. www.me.mit/2.7444.

CC9251

COMPUTER AIDED PROCESS PLANNING

LT P C 3 0 03

UNIT I INTRODUCTION 9 The Place of Process Planning in the Manufacturing cycle - Process Planning and Production Planning Process Planning and Concurrent Engineering, CAPP, Group Technology. UNIT II PART DESIGN REPRESENTATION 9 Design Drafting - Dimensioning - Conventional tolerance - Geometric tolerance - CAD - input / output devices - topology - Geometric transformation - Perspective transformation - Data structure - Geometric modelling for process planning - GT coding - The optiz system - The MICLASS system. UNIT III PROCESS ENGINEERING AND PROCESS PLANNING 9 Experienced, based planning - Decision table and decision trees - Process capability analysis - Process Planning - Variant process planning - Generative approach - Forward and Backward planning, Input format, Al. UNIT IV COMPUTER AIDED PROCESS PLANNING SYSTEMS 9 Logical Design of a Process Planning - Implementation considerations -manufacturing system components, production Volume, No. of production families - CAM-I, CAPP, MIPLAN, APPAS, AUTOPLAN and PRO, CPPP. UNIT V AN INTERGRADED PROCESS PLANNING SYSTEMS 9 Totally integrated process planning systems - An Overview - Modulus structure Data Structure, operation - Report Generation, Expert process planning. TOTAL: 45 PERIODS REFERENCES: 1. Gideon Halevi and Roland D. Weill, " Principles of Process Planning ", A logical approach, Chapman & Hall, 1995. 2. Tien-Chien Chang, Richard A.Wysk, "An Introduction to automated process planning systems ", Prentice Hall, 1985. 3. Chang, T.C., " An Expert Process Planning System ", Prentice Hall, 1985. 4. Nanua Singh, " Systems Approach to Computer Integrated Design and Manufacturing ", John Wiley & Sons, 1996. 5. Rao, Computer Aided Manufacturing ", Tata McGraw Hill Publishing Co., 2000. WEB REFERENCES: 1. http://claymore.engineer.gusu.edu/jackh/eod/automate/capp/capp.htm 2. http://Estraj.ute.sk/journal/engl/027/027.htm

CC9257

LTPC 3 00 3 UNIT I INTRODUCTION 9 Need for TQM, evolution of quality, Definition of quality, TQM philosophy CONTRIBUTIONS OF Deming Juran, Crosby and Ishikawa, TQM models. UNIT II PLANNING 9 Vision, Mission, Quality policy and objective Planning and Organization for quality, Quality policy Deployment, Quality function deployment, introduction to BPR and analysis of Quality Costs. UNIT III TQM PRINCIPLES 9 Customer focus, Leadership and Top management commitment, Employee involvement Empowerment and Team work, Supplier Quality Management, Continuous process improvement, Training, performance Measurement and customer satisfaction. UNIT IV TQM TOOLS AND TECHNIQUES 9 PDSA, The Seven Tools of Quality, New Seven management tools, Concept of six sigma, FMEA, Bench Marking, JIT, POKA YOKE, 5S, KAIZEN, Quality circles. UNIT V QUALITY SYSTEMS 9 Need for ISO 9000 Systems, clauses Documentation, Implementation, Introduction to ISO14000 and OSHAS18000, Implementation of TQM, Case Studies. TOTAL: 45 PERIODS TEXT BOOK: 1. Dale H.Besterfiled, Total Quality Management, Pearson Education Asia, (Indian reprint 2002) REFERENCES: 1. Oakland.J.S. Total Quality Management, ButterworthHcinemann Ltd., Oxford, 1989. 2. Narayana V. and Sreenivasan, N.S., Quality Management Concepts and Tasks, New Age International 1996. 3. Zeiri. Total Quality Management for Engineers, Wood Head Publishers, 1991. 4. Juran J.M and Frank M.Gryna Jr., Quality Planning and Analysis, TMH, India, 1982. 5. Brain Rethery, ISO 9000, Productivity and Quality Publishing Pvt.Ltd., 1993. 6. D.Mills, Quality Auditing, Chapman and Hall, 1993.

TOTAL QUALITY MANAGEMENT

10

Anda mungkin juga menyukai

- Engineering Applications: A Project Resource BookDari EverandEngineering Applications: A Project Resource BookPenilaian: 2.5 dari 5 bintang2.5/5 (1)

- University Departments: Anna University Chennai:: Chennai 600 025Dokumen42 halamanUniversity Departments: Anna University Chennai:: Chennai 600 025Jeyaram KumarBelum ada peringkat

- Puter Integrated Manufacturing SyllabusDokumen41 halamanPuter Integrated Manufacturing SyllabusJoswa CaxtonBelum ada peringkat

- ManfDokumen34 halamanManfAnantha NarayananBelum ada peringkat

- M.E. CimDokumen40 halamanM.E. CimvenkatkrishnaBelum ada peringkat

- PDD Syllabus Anna UniversityDokumen41 halamanPDD Syllabus Anna UniversityVenkatakrishnan NatchiappanBelum ada peringkat

- Manufacturing and AssemblingDokumen6 halamanManufacturing and AssemblingMariappan ArumugamBelum ada peringkat

- Production Engineering: Jig and Tool DesignDari EverandProduction Engineering: Jig and Tool DesignPenilaian: 4 dari 5 bintang4/5 (9)

- Advanced ManufacturingDokumen13 halamanAdvanced ManufacturingnagBelum ada peringkat

- Manufact Engg FDokumen31 halamanManufact Engg FtskcbeBelum ada peringkat

- Methods for Petroleum Well Optimization: Automation and Data SolutionsDari EverandMethods for Petroleum Well Optimization: Automation and Data SolutionsBelum ada peringkat

- Anna University, Chennai: Affiliated InstitutionsDokumen36 halamanAnna University, Chennai: Affiliated InstitutionsAnonymous RCbfTbBelum ada peringkat

- CIM – Mechanical Aspects: State of the Art ReportDari EverandCIM – Mechanical Aspects: State of the Art ReportGareth EvansBelum ada peringkat

- Me Manufacturing Curriculum-2Dokumen11 halamanMe Manufacturing Curriculum-2Arun KumarBelum ada peringkat

- M.E. Mech (Prod Des & Devp)Dokumen41 halamanM.E. Mech (Prod Des & Devp)Peter PushpanathanBelum ada peringkat

- Mechanical Engineers' Handbook, Volume 3: Manufacturing and ManagementDari EverandMechanical Engineers' Handbook, Volume 3: Manufacturing and ManagementBelum ada peringkat

- Engineering DesignDokumen34 halamanEngineering DesignEmmanuel NicholasBelum ada peringkat

- Anna University ME Manufacturing EngineeringDokumen56 halamanAnna University ME Manufacturing EngineeringSreelal SreeBelum ada peringkat

- M.tech (Mech) Advanced Manufacturing SystemsDokumen12 halamanM.tech (Mech) Advanced Manufacturing SystemsSudeesh Babu100% (1)

- Me Manufacturing EngineeringDokumen33 halamanMe Manufacturing EngineeringsumikannuBelum ada peringkat

- ManufacturingDokumen35 halamanManufacturingMichael EnglishBelum ada peringkat

- Project Proposals For: Manufacturing Engineering Projects (IM-416) Batch: 2009-2010Dokumen2 halamanProject Proposals For: Manufacturing Engineering Projects (IM-416) Batch: 2009-2010Timothy FieldsBelum ada peringkat

- CV JuriDokumen10 halamanCV JuriHamka HidayahBelum ada peringkat

- ME1001 Unconventional Machining Process 3 0 0 100: (Common To Mechanical and Production)Dokumen22 halamanME1001 Unconventional Machining Process 3 0 0 100: (Common To Mechanical and Production)PatBelum ada peringkat

- Advanced Manufacturing SystemsDokumen23 halamanAdvanced Manufacturing SystemsDhanish KumarBelum ada peringkat

- Me Manufacturing CurriculumDokumen37 halamanMe Manufacturing CurriculumJeyaram kumarBelum ada peringkat

- 2.design For SustainabilityDokumen3 halaman2.design For SustainabilitySenthil KumarBelum ada peringkat

- Additive MFG SyllabusDokumen2 halamanAdditive MFG SyllabusDr.V.Sivakumar /KIOT-SALEM KIOTBelum ada peringkat

- M.E. Engineering DesignDokumen47 halamanM.E. Engineering DesignSms RajaBelum ada peringkat

- M.e.,cim SyllabusDokumen44 halamanM.e.,cim SyllabusSiva PrakashBelum ada peringkat

- TA202A: Introduction To Manufacturing Processes Manufacturing ProcessesDokumen51 halamanTA202A: Introduction To Manufacturing Processes Manufacturing ProcessesLalla DasBelum ada peringkat

- Anna University EDDokumen48 halamanAnna University EDSivaji SivaBelum ada peringkat

- Mee6015 Additive-Manufacturing-Technology Eth 1.0 40 Mee6015Dokumen3 halamanMee6015 Additive-Manufacturing-Technology Eth 1.0 40 Mee6015manoj smBelum ada peringkat

- A Review On Additive ManufacturingDokumen10 halamanA Review On Additive ManufacturingKamlesh RanaBelum ada peringkat

- M.E. MANUFACTURING ENGINEERING AU SyllabusDokumen35 halamanM.E. MANUFACTURING ENGINEERING AU SyllabusJoswa CaxtonBelum ada peringkat

- Syllabus MTech AdvMnfgDokumen35 halamanSyllabus MTech AdvMnfgKrishna AdityaBelum ada peringkat

- Engineering Design SyllabusDokumen49 halamanEngineering Design SyllabusanandandmeenaBelum ada peringkat

- Wa0000.Dokumen6 halamanWa0000.Quality DynamicBelum ada peringkat

- Sem 2Dokumen11 halamanSem 2jtsrinivasdownBelum ada peringkat

- DFM SyllabusDokumen2 halamanDFM SyllabusSantosh SBelum ada peringkat

- New Microsoft Office Word DocumentDokumen6 halamanNew Microsoft Office Word DocumentBala NarayanasamyBelum ada peringkat

- Manufacturing TechnologyDokumen34 halamanManufacturing TechnologyGeorge OliverBelum ada peringkat

- CC 9221 Design For ManufactureDokumen2 halamanCC 9221 Design For ManufactureM.Saravana Kumar..M.EBelum ada peringkat

- Article 1Dokumen8 halamanArticle 1Kay WhiteBelum ada peringkat

- 7th SemDokumen17 halaman7th SemShankar MukalBelum ada peringkat

- Tarp Final Report NewDokumen43 halamanTarp Final Report NewSahil Kumar DasBelum ada peringkat

- ME CAD SyllabusDokumen50 halamanME CAD Syllabussubha_aeroBelum ada peringkat

- M.E. Computer Aided Design SyllabusDokumen50 halamanM.E. Computer Aided Design SyllabusJoswa CaxtonBelum ada peringkat

- General Design Principles For ManufacturabilityDokumen2 halamanGeneral Design Principles For ManufacturabilityBala Mech SBBelum ada peringkat

- Machine Design Lec - 1Dokumen22 halamanMachine Design Lec - 1Sasthi HensBelum ada peringkat

- B.Tech. (Mechanical Engineering) Semester VIDokumen9 halamanB.Tech. (Mechanical Engineering) Semester VIRana SinghBelum ada peringkat

- The Use of CAD Applications in The Design of ShredDokumen8 halamanThe Use of CAD Applications in The Design of ShredLOUKILBelum ada peringkat

- Project PPT by GhananandDokumen19 halamanProject PPT by GhananandJK COTTONBelum ada peringkat

- ICE Lecture NotesDokumen12 halamanICE Lecture NotesRajueswar100% (1)

- Gnanamani College of TechnologyDokumen15 halamanGnanamani College of TechnologyRajueswarBelum ada peringkat

- Important Questions For Nov Dec 2016 ME6008 Welding TechnologyDokumen1 halamanImportant Questions For Nov Dec 2016 ME6008 Welding TechnologyRajueswarBelum ada peringkat

- EM QuestionsDokumen2 halamanEM QuestionsRajueswar100% (1)

- Me6611 - Cadcam Manual - RecordDokumen82 halamanMe6611 - Cadcam Manual - RecordRajueswarBelum ada peringkat

- Computer: Manufacturing SystemsDokumen39 halamanComputer: Manufacturing SystemsRajueswarBelum ada peringkat

- Lecture #02: Moments, Couples, and Force Couple SystemsDokumen71 halamanLecture #02: Moments, Couples, and Force Couple SystemsRajueswarBelum ada peringkat

- Presentation 1Dokumen14 halamanPresentation 1RajueswarBelum ada peringkat

- CIM Lecture Notes 1Dokumen16 halamanCIM Lecture Notes 1Kannan Sreenivasan100% (1)

- Hydraulics & Fluid Mechanics - Modi-SethDokumen528 halamanHydraulics & Fluid Mechanics - Modi-SethRajueswar75% (4)

- Title Block: Name: Roll No: Class: Plate No: Date: Title:Projection of Solids Scale 1:1 All Dim - Are in MMDokumen6 halamanTitle Block: Name: Roll No: Class: Plate No: Date: Title:Projection of Solids Scale 1:1 All Dim - Are in MMRajueswarBelum ada peringkat

- Sl. No Date Name of The Experiment Page No. Marks Awarded SignatureDokumen1 halamanSl. No Date Name of The Experiment Page No. Marks Awarded SignatureRajueswarBelum ada peringkat

- W W W - B I o L Y T I C - C O M: Enhance Chemical Reactions That Require Heat, Pressure or CoolingDokumen4 halamanW W W - B I o L Y T I C - C O M: Enhance Chemical Reactions That Require Heat, Pressure or CoolingRajueswarBelum ada peringkat

- Competitive Manufacturing Systems I 002Dokumen58 halamanCompetitive Manufacturing Systems I 002Rajueswar100% (1)

- M.E. Thermal Engineering Text BooksDokumen2 halamanM.E. Thermal Engineering Text BooksRajueswar100% (1)

- CAD&CAMDokumen26 halamanCAD&CAMnvasirajaBelum ada peringkat

- E.Physics-Assignments - Unit 3,4,5Dokumen3 halamanE.Physics-Assignments - Unit 3,4,5Naresh SinghBelum ada peringkat

- Pete 311 Lab 11 MemoDokumen3 halamanPete 311 Lab 11 MemoTyler MroskoBelum ada peringkat

- Drying & Curing of Paint FilmsDokumen5 halamanDrying & Curing of Paint FilmsOmar DhiebBelum ada peringkat

- Bridge Abutment Design ExampleDokumen10 halamanBridge Abutment Design Exampleloyalmate100% (3)

- Damage Tolerance Assessment BookDokumen174 halamanDamage Tolerance Assessment BooksemipurBelum ada peringkat

- DesignAirSystems (Part 2)Dokumen3 halamanDesignAirSystems (Part 2)marcoo8Belum ada peringkat

- Colligative Properties: Cryoscopy & EbulliosDokumen30 halamanColligative Properties: Cryoscopy & EbulliosRSL100% (1)

- Discovery X3 DSCDokumen16 halamanDiscovery X3 DSCDoloritasBelum ada peringkat

- DC-Lab Report 03Dokumen8 halamanDC-Lab Report 03Shahriar Ahsan JohaBelum ada peringkat

- Controversial Electro ProblemDokumen16 halamanControversial Electro ProblemJorge AlcarazBelum ada peringkat

- Roll List 20EL-Batch 5TH Sem IDokumen1 halamanRoll List 20EL-Batch 5TH Sem IAisha ShaikhBelum ada peringkat

- Apex SteelDokumen64 halamanApex SteelSteve Jsob100% (1)

- Assignment 2: Determine The Bending Stress at Points A, B, C and D and DRW (CLO-2, P2, C3)Dokumen3 halamanAssignment 2: Determine The Bending Stress at Points A, B, C and D and DRW (CLO-2, P2, C3)Ali ZubairBelum ada peringkat

- Chapter Viii: The Nano WorldDokumen2 halamanChapter Viii: The Nano WorldCherry Ann OlasimanBelum ada peringkat

- Chapter 3 Permeability Part 1Dokumen22 halamanChapter 3 Permeability Part 1PugalBelum ada peringkat

- Comparison Between Unit Cell and Plane Strain Models of Stone Column Ground ImprovementDokumen7 halamanComparison Between Unit Cell and Plane Strain Models of Stone Column Ground Improvementseif17Belum ada peringkat

- 51CDokumen6 halaman51Cjhacademyhyd100% (5)

- ASTM A710 Engineering Report Grade 50 Sheet Steel Formability Material For ClampsDokumen54 halamanASTM A710 Engineering Report Grade 50 Sheet Steel Formability Material For ClampsTony KrolikowskiBelum ada peringkat

- Department of Mining, Metallurgical and Materials EngineeringDokumen24 halamanDepartment of Mining, Metallurgical and Materials EngineeringDrakeBelum ada peringkat

- Aluminum Permanent-Mold Casting AlloyDokumen2 halamanAluminum Permanent-Mold Casting Alloymanjunath k sBelum ada peringkat

- UPS Neuttral EarthingDokumen11 halamanUPS Neuttral Earthingarun kumarBelum ada peringkat

- FEA Pressure VesselDokumen48 halamanFEA Pressure VesselnaimBelum ada peringkat

- Nanomaterials 08 00676Dokumen10 halamanNanomaterials 08 00676CatalinBelum ada peringkat

- Design of FRP-Profiles and All-FRP-StructuresDokumen67 halamanDesign of FRP-Profiles and All-FRP-StructuresjavierBelum ada peringkat

- EB CablesDokumen1 halamanEB CablesVijay KarthikeyanBelum ada peringkat

- UB UC Steel SectionsDokumen10 halamanUB UC Steel SectionsMuhammad HasanBelum ada peringkat

- Module-2b Fatigue Strength (Bhaskar)Dokumen35 halamanModule-2b Fatigue Strength (Bhaskar)AckshayaBelum ada peringkat

- Base Plate Design - BS CodeDokumen3 halamanBase Plate Design - BS Codemicheleling669667% (3)

- BICE-011 Drawing Sheet B. Tech. Civil Engineering (Btclevi) Term-End Examination December, 2013 Bice-011: Structural Analysis - IiDokumen3 halamanBICE-011 Drawing Sheet B. Tech. Civil Engineering (Btclevi) Term-End Examination December, 2013 Bice-011: Structural Analysis - IiSri DBelum ada peringkat

- Metals: Optimization of PWHT of Simulated HAZ Subzones in P91 Steel With Respect To Hardness and Impact ToughnessDokumen21 halamanMetals: Optimization of PWHT of Simulated HAZ Subzones in P91 Steel With Respect To Hardness and Impact ToughnessPEMCO InspectionBelum ada peringkat

- Beginning AutoCAD® 2022 Exercise Workbook: For Windows®Dari EverandBeginning AutoCAD® 2022 Exercise Workbook: For Windows®Belum ada peringkat

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Dari EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Penilaian: 5 dari 5 bintang5/5 (2)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchDari EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchPenilaian: 4 dari 5 bintang4/5 (10)

- From Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsDari EverandFrom Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsBelum ada peringkat

- AutoCAD 2010 Tutorial Series: Drawing Dimensions, Elevations and SectionsDari EverandAutoCAD 2010 Tutorial Series: Drawing Dimensions, Elevations and SectionsBelum ada peringkat

- SolidWorks 2015 Learn by doing-Part 1Dari EverandSolidWorks 2015 Learn by doing-Part 1Penilaian: 4.5 dari 5 bintang4.5/5 (11)