Control Valve Sizing

Diunggah oleh

kaveh-bahiraeeHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Control Valve Sizing

Diunggah oleh

kaveh-bahiraeeHak Cipta:

Format Tersedia

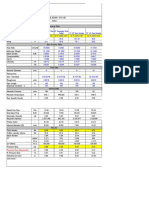

CONTROL VALVE SIZING

Cv - is a dimensionless coeficient that relates to a valve's flow capacity. Cv =

Q Dp

where Q = flowrate

Dp

pressure drop across the valve

XXX XXX

Prepared by : XXXX-XXXX Doc. No. XXXX-XXXX

Checked by : XXX Approved by: XXX

Internal Rev : X

Client Rev : 00

Page :

of

Date (Internal Rev): Date (Client Rev) :

xx.xx.xx xx.xx.xx

DB DP FF FK FL FLRE FLRA FP FR Gf Gg k Kc M P1 P2 Pc Pv Q T V2 W x xT Y Z l

= = = = = = = =

Inside diameter of Valve Body Outlet - Inches - see table 4 Inside diameter of Outlet Pipe - Inches Liquid Critical Pressure Ratio Factor Ratio specific Heats Factor Liquid Pressure Ratio Factor The FL factor to avoid Choked Flow The FL factor rated for individual trim styles - Table 3 Piping geometry factor, if the pipe size and valve size are equal, then FP=1, if not, refer to ISA S75.01 section 4.3 Reynolds Number Factor, Normally =1 but varies with very slow fluid velocities or very viscous fluids. Refer to ISA S75.01 section 4.4

0

= = = = = = = = = = = = = = = = = =

Specific gravity of a liquid relative to water at 60 0F (15.55 0C) Specific gravity of vapour realtive to air at 60 F and 14.7 PSIA (1atm) Ratio of specific Heats - see table 2 Cavitation index, see table 3 Molecular Weight, see table 2 Valve inlet pressure (psia) Valve outlet Pressure Fluid critical pressure (psia) - See Table2 Fluid Vapour pressure (psia) Volumetric Flow Rate Liquids - GPM; Vapour (SCFM)

0

R=0F+460 Secific Volume of vapour, either gas or steam = Ft3/Lb Fluid Temperature in Degreees Rankine Mass Flowrate = Lb./Hr. Pressure drop ratio Maximum pressure drop ratio - see table 3 Fluid expansion factor for vapour flow

Compressibillity Factor for vapour flow. Usually = 1. Refer to ISA Handbook of Control Valv

Specific Weight = Lb./Ft3 The ISA noise prediction formula for vapour flow loses accuracy at Mach numbers larger than 33

XXX XXX

Prepared by : XXXX-XXXX Doc. No. XXXX-XXXX

Checked by : XXX Approved by: XXX

Internal Rev : X

Client Rev : 00

Page :

of

Date (Internal Rev): Date (Client Rev) :

xx.xx.xx xx.xx.xx

CONTROL VALVE SIZING

Cv - is a dimensionless coeficient that relates to a valve's flow capacity. Cv =

Q Dp

where Q = flowrate

Dp

pressure drop across the valve

FL Liquid Pressure Recovery Coefficient, is a dimensionlesss constant used to calculate the pressure drop when the valve's liquid flow is choked. Rated FL varies with with the valve and trim style, it may vary from 0.99 for a special multiple stage trim to 0,30 for ball valve. Required FL : The required FL is the FL calculated for special condition. It indicates the required needed to avoid choked flow. If the rated FL is less than Required FL, the liquid flow will be choked with cavitation. Choked Flow : Liquid flow will become choked when the trim's vena contracta is filled with vapor from cavitation or flashing. Vapor flow also will become choked when the flow velocity at vena contracta reaches sonic. A choked flow rate is limited; a further decrease of the outlet pressure do not increase the flow. Choked Flow is is also called critical flow. Cavitation : Cavitation is a two stage phenomena with liquid flow. The first stage is the formation of vapor bubbles in the liquid as the fluid passes through the trim and the pressure is reduced below the fluid vapour pressure. The second stage is the collapse of the vapour bubbles as the fluid passes the vena contracta and the pressure recovers and increases above the vapor pressure. The collapasing bubbles are very destructive when they contact metal parts and the bubble colapse may produce hugh noise level. Flashing : Is similar to cavitation except the vapor bubbles do not colapse as the downstream pressure remains less then downstram pressure. The flow will remain a mixture of vapour and liquid.

XXX XXX

Prepared by : XXXX-XXXX Doc. No. XXXX-XXXX

Checked by : XXX Approved by: XXX

Internal Rev : X

Client Rev : 00

Page :

of

Date (Internal Rev): Date (Client Rev) :

xx.xx.xx xx.xx.xx

Anda mungkin juga menyukai

- Spreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2Dokumen33 halamanSpreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2MaheshBelum ada peringkat

- Valve CV Sizing Liquids GasesDokumen24 halamanValve CV Sizing Liquids Gasesmath62210Belum ada peringkat

- FGCP Line Sizing CalculationsDokumen86 halamanFGCP Line Sizing CalculationsToyinBelum ada peringkat

- Pump CalcDokumen1 halamanPump CalcMoch WildanBelum ada peringkat

- Control Valve Sizing - LiquidDokumen4 halamanControl Valve Sizing - Liquidcharro1623Belum ada peringkat

- Gas Line Sizing - Api 14E Input Description Unit: General DataDokumen13 halamanGas Line Sizing - Api 14E Input Description Unit: General DataSamuel Onyewuenyi100% (1)

- Cakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DataDokumen6 halamanCakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DatasterlingBelum ada peringkat

- Restriction Orifice Final CalculationDokumen1 halamanRestriction Orifice Final CalculationJasperTanBelum ada peringkat

- Gas Line Pressure LossesDokumen4 halamanGas Line Pressure Lossesyash saragiyaBelum ada peringkat

- Gas Line Capacity CalcDokumen2 halamanGas Line Capacity CalcMario Mendoza100% (1)

- Line Sizing - 2PHASEDokumen11 halamanLine Sizing - 2PHASEEbby Onyekwe100% (1)

- Liquid Valve CV CalcDokumen4 halamanLiquid Valve CV Calcamit_kt1973Belum ada peringkat

- Control Valve SizingDokumen5 halamanControl Valve SizingOwen HennessyBelum ada peringkat

- CCC1Dokumen5 halamanCCC1Uok RitchieBelum ada peringkat

- Control Valve CalculationDokumen18 halamanControl Valve CalculationLeonardo Ramirez Guzman100% (1)

- PSVDokumen8 halamanPSVMohamed Sayed AbdoBelum ada peringkat

- CVCALCSDokumen10 halamanCVCALCSmishtinilBelum ada peringkat

- Total Length Calcs For Pipes Valves and FittingsDokumen6 halamanTotal Length Calcs For Pipes Valves and FittingsImtinan MohsinBelum ada peringkat

- Condensate Line SizingDokumen2 halamanCondensate Line SizingAnonymous oVRvsdWzfBBelum ada peringkat

- Line Sizing With Api RP 14E Sizing For Liquid LinesDokumen5 halamanLine Sizing With Api RP 14E Sizing For Liquid LinesArief Rahman DhuhriBelum ada peringkat

- Calculation of Orifice CoefficientDokumen18 halamanCalculation of Orifice Coefficientvinayjoshi270586Belum ada peringkat

- PSV Blocked Fire Relief Valve CasesDokumen21 halamanPSV Blocked Fire Relief Valve CasesTun Naing WinBelum ada peringkat

- Line Sizing LiqDokumen12 halamanLine Sizing LiqDana GuerreroBelum ada peringkat

- Control Valve Sizing - Steam or Vapor Rev 2Dokumen2 halamanControl Valve Sizing - Steam or Vapor Rev 2dilip matalBelum ada peringkat

- Blowdown OrificeDokumen2 halamanBlowdown OrificeOmprakaash MokideBelum ada peringkat

- Process Group Spreadsheet-Based SoftwareDokumen10 halamanProcess Group Spreadsheet-Based SoftwareHendy ArmantoBelum ada peringkat

- Line Sizing For Liquid, (DO IT OWN)Dokumen11 halamanLine Sizing For Liquid, (DO IT OWN)sumitBelum ada peringkat

- Valve Sizing Calculation8Dokumen2 halamanValve Sizing Calculation8PIDBelum ada peringkat

- Hitungan PPDokumen30 halamanHitungan PPHamdan ShdBelum ada peringkat

- Line Losses (Fittings) ΔP (ft) ΔP (ft)Dokumen3 halamanLine Losses (Fittings) ΔP (ft) ΔP (ft)ahmadlieBelum ada peringkat

- Pipeline Hydraulics Modification ReqdDokumen6 halamanPipeline Hydraulics Modification ReqdchemtahirBelum ada peringkat

- Gas Pipeline Blowdown TimeDokumen7 halamanGas Pipeline Blowdown TimeBui Khoi NguyenBelum ada peringkat

- Cvts - Tag No. Mpt-tv-4161Dokumen2 halamanCvts - Tag No. Mpt-tv-4161biswasdipankar05Belum ada peringkat

- 01 - Fluid FlowDokumen76 halaman01 - Fluid FlowMubarak AhmadBelum ada peringkat

- Line Sizing File (No Password)Dokumen18 halamanLine Sizing File (No Password)Montian LuangsakultongBelum ada peringkat

- Restriction Orifice RO Flow Control InstrumentDokumen3 halamanRestriction Orifice RO Flow Control Instrumentmsr22Belum ada peringkat

- Gas Line SizingDokumen7 halamanGas Line SizingTun Naing WinBelum ada peringkat

- Compressor Settle Out PressureDokumen1 halamanCompressor Settle Out PressureAhmed GattoufiBelum ada peringkat

- Gas Line Sizing by API 14E Method Revision #: ??: Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, TeesDokumen4 halamanGas Line Sizing by API 14E Method Revision #: ??: Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, Teesusaid saifullahBelum ada peringkat

- Control Valve Sizing - EXXON Calculation MethodDokumen14 halamanControl Valve Sizing - EXXON Calculation Methodm0% (1)

- PSV Sizing (Liquid)Dokumen2 halamanPSV Sizing (Liquid)Saeid Rahimi Mofrad50% (2)

- Rosemount 1495 Orifice Plate, 1496 Flange Union, 1497 Meter SectionDokumen24 halamanRosemount 1495 Orifice Plate, 1496 Flange Union, 1497 Meter SectionJames ThomasBelum ada peringkat

- 1117 Ed 00 PL SP 013 A1 PDFDokumen5 halaman1117 Ed 00 PL SP 013 A1 PDFamini_mohiBelum ada peringkat

- Orifice Plate Calculator Pressure Drop CalculationDokumen6 halamanOrifice Plate Calculator Pressure Drop Calculationlutfi awnBelum ada peringkat

- Fire Relief Dynamic StudyDokumen2 halamanFire Relief Dynamic StudyImtinan MohsinBelum ada peringkat

- Line Sizing ReportDokumen7 halamanLine Sizing Reportmichael chiwuezeBelum ada peringkat

- Excel HYSYS Link Manipulate Oil ManagerDokumen19 halamanExcel HYSYS Link Manipulate Oil ManagerEbby OnyekweBelum ada peringkat

- 3.2.G.2.3.D Two Phase Sep Sizing API 521 SI Units1Dokumen1 halaman3.2.G.2.3.D Two Phase Sep Sizing API 521 SI Units1Mike DukasBelum ada peringkat

- Distillation Column: Major Equipment DesignDokumen45 halamanDistillation Column: Major Equipment Designrubesh_rajaBelum ada peringkat

- Gas-Liquid Line SizingDokumen1 halamanGas-Liquid Line Sizingagusnnn100% (2)

- Centrifugal Pump Calculation Summary Sheet: ConfidentialDokumen3 halamanCentrifugal Pump Calculation Summary Sheet: ConfidentialPrafitri KurniawanBelum ada peringkat

- Filter Vessel Shell VelocityDokumen12 halamanFilter Vessel Shell VelocityAye KyweBelum ada peringkat

- PSV Sizing TableDokumen14 halamanPSV Sizing TablebadelitamariusBelum ada peringkat

- Control Valve SizingDokumen21 halamanControl Valve Sizingamarnath982520% (1)

- Valtek Sizing ValvesDokumen17 halamanValtek Sizing ValvesederBelum ada peringkat

- IVPL Control Valve Sizing ManualDokumen20 halamanIVPL Control Valve Sizing ManualGanesh YadavBelum ada peringkat

- Liquid Flow in Control Valves - Choked Flow, Cavitation and FlashingDokumen14 halamanLiquid Flow in Control Valves - Choked Flow, Cavitation and FlashingSwapnilBelum ada peringkat

- Control Valve SizingDokumen16 halamanControl Valve SizingmsBelum ada peringkat

- VALTEK Valve Size PDFDokumen16 halamanVALTEK Valve Size PDFalbahbahaneeBelum ada peringkat

- Control ValvesDokumen50 halamanControl ValvesReaderRRGHT93% (15)

- P003en PDFDokumen18 halamanP003en PDFFalokid RaboBelum ada peringkat

- APIDokumen1 halamanAPIkaveh-bahiraeeBelum ada peringkat

- OCTG Running and Pulling TpsDokumen11 halamanOCTG Running and Pulling Tpskaveh-bahiraeeBelum ada peringkat

- Continuum PlasticityDokumen44 halamanContinuum PlasticityPrantik Adhar SamantaBelum ada peringkat

- Written Practice (Sample)Dokumen21 halamanWritten Practice (Sample)Patrick Dominguez89% (9)

- List of Corrosion TestsDokumen1 halamanList of Corrosion Testskaveh-bahiraeeBelum ada peringkat

- A Guide To Air Quality and Your HealthDokumen12 halamanA Guide To Air Quality and Your HealthNguyen Huu DanhBelum ada peringkat

- Earthquake TehranDokumen4 halamanEarthquake Tehrankaveh-bahiraeeBelum ada peringkat

- PNNL 14116Dokumen78 halamanPNNL 14116mapasabcBelum ada peringkat

- CentralizersDokumen4 halamanCentralizersDanielBelum ada peringkat

- Tuffy HP High Performance Round SlingsDokumen4 halamanTuffy HP High Performance Round Slingskaveh-bahiraeeBelum ada peringkat

- MSS SP44Dokumen26 halamanMSS SP44kaveh-bahiraeeBelum ada peringkat

- Tubular Products From Special MetalsDokumen26 halamanTubular Products From Special Metalskaveh-bahiraeeBelum ada peringkat

- Incoloy Alloy 028 SpecificationDokumen2 halamanIncoloy Alloy 028 SpecificationHeidarianBelum ada peringkat

- Aerospace Standards NewsletterDokumen9 halamanAerospace Standards Newsletterkaveh-bahiraeeBelum ada peringkat

- A Review About The Anisotropic Material PropertiesDokumen14 halamanA Review About The Anisotropic Material Propertieskaveh-bahiraeeBelum ada peringkat

- WSP HoldingsDokumen164 halamanWSP Holdingskaveh-bahiraeeBelum ada peringkat

- High Chromium AlloyDokumen3 halamanHigh Chromium Alloykaveh-bahiraeeBelum ada peringkat

- Circulating SwagesDokumen1 halamanCirculating Swageskaveh-bahiraeeBelum ada peringkat

- Flange Calculation Results: CloseDokumen2 halamanFlange Calculation Results: Closekaveh-bahiraeeBelum ada peringkat

- Indonesian EmbassyDokumen1 halamanIndonesian Embassykaveh-bahiraeeBelum ada peringkat

- Attachment 1-Business LicenseDokumen1 halamanAttachment 1-Business Licensekaveh-bahiraeeBelum ada peringkat

- Effect of Cold Work On Hardness - 1Dokumen1 halamanEffect of Cold Work On Hardness - 1kaveh-bahiraeeBelum ada peringkat

- AIAA2002-4349 Astrolink PresDokumen13 halamanAIAA2002-4349 Astrolink Preskaveh-bahiraeeBelum ada peringkat

- Factory Audit Sample ReportDokumen20 halamanFactory Audit Sample Reportkaveh-bahiraee100% (1)

- FMC 20K Wellhead SystemsDokumen4 halamanFMC 20K Wellhead Systemskaveh-bahiraeeBelum ada peringkat

- Preliminary Design of A Stainless Steel Helium Tank and Its Associated Cold Tuning System For 700 MHZ SCRF Cavities For ProtonDokumen5 halamanPreliminary Design of A Stainless Steel Helium Tank and Its Associated Cold Tuning System For 700 MHZ SCRF Cavities For Protonkaveh-bahiraeeBelum ada peringkat

- The Effect of Helium On Welding Irradiated MaterialsDokumen8 halamanThe Effect of Helium On Welding Irradiated Materialskaveh-bahiraeeBelum ada peringkat

- Floating EquipmentDokumen9 halamanFloating Equipmentkaveh-bahiraeeBelum ada peringkat

- Bridge PlugsDokumen9 halamanBridge Plugskaveh-bahiraeeBelum ada peringkat

- Unit 1 Fluid Power Priniciples and Hydraulic PumpsDokumen2 halamanUnit 1 Fluid Power Priniciples and Hydraulic PumpsSubramaniyan ChandrasekaranBelum ada peringkat

- PRV SizingDokumen28 halamanPRV Sizingjithin.rjn4055Belum ada peringkat

- MKE3B21 Solutions of Homework Given in Week 2 Dimensional Analysis of TurbomachinesDokumen11 halamanMKE3B21 Solutions of Homework Given in Week 2 Dimensional Analysis of TurbomachinesAli GhBelum ada peringkat

- PPSC Past Paper MCQs of Civil EngineeringDokumen101 halamanPPSC Past Paper MCQs of Civil Engineeringsalman khattak80% (5)

- TEC NPSH Calculation PUMP SelectionDokumen1 halamanTEC NPSH Calculation PUMP SelectionphibetBelum ada peringkat

- 1965013440Dokumen188 halaman1965013440ernestozagBelum ada peringkat

- Condensador Con 3 ZonasDokumen17 halamanCondensador Con 3 ZonasJohanita CoraLi Velasque OroscoBelum ada peringkat

- GAPS Guidelines: Fire Protection HydraulicsDokumen15 halamanGAPS Guidelines: Fire Protection HydraulicsLasandu WanniarachchiBelum ada peringkat

- Installation and Start-Up Information PV Series: Variable Displacement Axial Piston PumpDokumen14 halamanInstallation and Start-Up Information PV Series: Variable Displacement Axial Piston PumpAPURV GOYALBelum ada peringkat

- Topic - 7 - Permeability & SeepageDokumen32 halamanTopic - 7 - Permeability & Seepagejimmys45Belum ada peringkat

- 1 The World's Tallest Building Is The Burj Khalifa in Dubai, UAEDokumen14 halaman1 The World's Tallest Building Is The Burj Khalifa in Dubai, UAEPaing Khant KyawBelum ada peringkat

- Tips For VOF Modelling Using FluentDokumen2 halamanTips For VOF Modelling Using Fluentsurefooted1100% (1)

- On Bottom Stability of PipelinesDokumen62 halamanOn Bottom Stability of PipelinesVictor DaggersBelum ada peringkat

- Hot Wire AnemometerDokumen10 halamanHot Wire AnemometerLikhitha DBelum ada peringkat

- ADP000536Dokumen106 halamanADP000536Balaji HimakarBelum ada peringkat

- Application of Computers To Automobile AerodynamicsDokumen10 halamanApplication of Computers To Automobile AerodynamicsRodrigo BobBelum ada peringkat

- 12-Inch Parshall Flume Discharge TableDokumen6 halaman12-Inch Parshall Flume Discharge TablejcbobedaBelum ada peringkat

- Lecture Notes Mixing PFFL101 For 2020 MCDokumen20 halamanLecture Notes Mixing PFFL101 For 2020 MCAnele HadebeBelum ada peringkat

- (控制阀) Chaos in a Hydraulic Control ValveDokumen24 halaman(控制阀) Chaos in a Hydraulic Control ValveEric CBelum ada peringkat

- 0 - Mains Water Pipe SizingDokumen4 halaman0 - Mains Water Pipe SizingstarykltBelum ada peringkat

- Pumps and TurbinesDokumen20 halamanPumps and TurbinesEICQ/00154/2020 SAMUEL MWANGI RUKWAROBelum ada peringkat

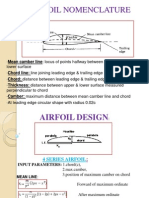

- Airfoil NomenclatureDokumen12 halamanAirfoil NomenclatureSagar MoreBelum ada peringkat

- 10 May 2020 Before 5 PM at Author - Uthm.edu - My (I Will Create The Folder To Submit)Dokumen2 halaman10 May 2020 Before 5 PM at Author - Uthm.edu - My (I Will Create The Folder To Submit)Sky FireBelum ada peringkat

- Calculus-Based Physics 2 PHYS 002 (TIP Reviewer)Dokumen28 halamanCalculus-Based Physics 2 PHYS 002 (TIP Reviewer)James LindoBelum ada peringkat

- Liquid Pipeline HydraulicsDokumen74 halamanLiquid Pipeline HydraulicsSimon Kapoma100% (1)

- 1 SY BTech Civil Engg Syllabuswef 21 22Dokumen58 halaman1 SY BTech Civil Engg Syllabuswef 21 22Sadam PathanBelum ada peringkat

- Lectures 5 Design RegulatorDokumen22 halamanLectures 5 Design RegulatorJai Singh RathorBelum ada peringkat

- Hypersonic AerodynamicsDokumen10 halamanHypersonic AerodynamicsBarbara SchlottBelum ada peringkat

- Steady State FlowDokumen12 halamanSteady State FlowNH SyzlnBelum ada peringkat