Hybrid Approach To Supplier Selection

Diunggah oleh

Kanagaraj GanesanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Hybrid Approach To Supplier Selection

Diunggah oleh

Kanagaraj GanesanHak Cipta:

Format Tersedia

International Journal of Innovative Computing, Information and Control Volume 6, Number 9, September 2010

ICIC International c 2010 ISSN 1349-4198

pp. 40934111

A TWO-PHASE HYBRID APPROACH TO SUPPLIER SELECTION THROUGH CLUSTER ANALYSIS WITH MULTIPLE DIMENSIONS Zhen-Hua Che

Department of Industrial Engineering and Management National Taipei University of Technology 1, Sec. 3, Chung-Hsiao E. Rd., Taipei 106, Taiwan zhche@ntut.edu.tw

Received April 2009; revised October 2009

Abstract. To eectively segment and select suppliers, a two-phase hybrid model was developed in this study for that purpose. Phase 1 developed a genetic simulated annealing k-means algorithm (GSKA) integrating genetic algorithm (GA), simulated annealing algorithm (SA) and k-means algorithm, and suppliers were clustered using this algorithm according to the characteristics for customer needs including multiple dimensions product cost, product quality and manufacturing time. In phase 2, a multi-criterion optimization mathematical model on supply partnership characterizing quality, cost and time was constructed based on the clusters from phase 1, and then the proposed Genetic Simulated Annealing Algorithm (GSA) was used to solve the optimization model to nd the optimum supplier combinations. To prove the eciency of the proposed model, a case study concerned with notebook computers was introduced in this study. According to the analysis results, the GSKA produced in phase 1 proved to be superior to k-means model and genetic k-means algorithm (GKA) model, while the multi-objective optimization model GSA proposed in phase 2 still proved better than GA. Moreover, by selecting suppliers after cluster analysis, unwanted candidate suppliers could be eectively eliminated, and the resulting supplier combination could still meet customer needs. Keywords: Supplier selection, Cluster analysis, K-means algorithm, Genetic algorithm, Simulated annealing algorithm

1. Introduction. Supply chain management refers to the integration methodology dealing with the planning and control of materials from suppliers down to end-users. It is based on the interests of all members making up the path, and resources and capacity can be utilized to their fullest potential while satisfying customer service standards on the path through collaborative management and planning among the members on the path [1]. Vrijhoel and Koskeia [2], Tominaga et al. [3], Zhao et al. [4] and Flint [5] also stated every member in the supply chain system played both the role of a customer and a supplier, and the major purpose of supply chain management was to integrate upstream and downstream suppliers to enhance the overall eciency of the supply chain and meet customer needs. For the products to meet various congurations of customer needs, suppliers must be segmented according to product characteristics before making preliminary planning for supplier management. Dillon et al. [6] referred to cluster analysis as an ecient and commonly used method among the segmentation methods. Li et al. [7] proposed a localclustered network model for cluster analysis, which is based on the evolving phenomenon. Anil et al. [8] considered k-means a commonly used method for cluster analysis, which could rapidly segment a large body of data. According to Bandyopadhyay and Mauliks [9] study, k-means are commonly used in cluster analysis, but k-means is largely aected

4093

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- FMEADokumen12 halamanFMEAboyetBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- A Brief History of Communications PDFDokumen166 halamanA Brief History of Communications PDFIbrahim G. GordilsBelum ada peringkat

- Press Working OperationsDokumen23 halamanPress Working OperationsKanagaraj Ganesan100% (1)

- 1990 Volvo 740 Wiring DiagramsDokumen14 halaman1990 Volvo 740 Wiring DiagramsDavid Cooley67% (3)

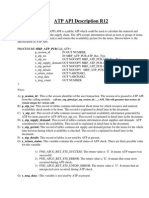

- Atp Api R12Dokumen16 halamanAtp Api R12prasad_jampanaBelum ada peringkat

- 590 Safety ManualDokumen54 halaman590 Safety ManualTaz Juan G100% (2)

- Principles of Clinical Chemistry AutomationDokumen25 halamanPrinciples of Clinical Chemistry AutomationChristine Rodriguez-Guerrero50% (2)

- False Ceiling: MMBC 7Th SemDokumen54 halamanFalse Ceiling: MMBC 7Th SemBmssa 2017BBelum ada peringkat

- Online Recruitment SystemDokumen42 halamanOnline Recruitment SystemTanmay Abhijeet74% (19)

- Electric Machines and Drives - Ned MohanDokumen3 halamanElectric Machines and Drives - Ned MohanNaveed Iqbal0% (4)

- Development of Robotic Driven Waste Segregation System-2Dokumen10 halamanDevelopment of Robotic Driven Waste Segregation System-2Kanagaraj GanesanBelum ada peringkat

- Customer Feedback FormDokumen3 halamanCustomer Feedback FormKanagaraj GanesanBelum ada peringkat

- Weight Optimization of Truss Structures Using Water Cycle AlgorithmDokumen15 halamanWeight Optimization of Truss Structures Using Water Cycle AlgorithmKanagaraj GanesanBelum ada peringkat

- Fatigue Testing PDFDokumen76 halamanFatigue Testing PDFtoru101Belum ada peringkat

- Pumper March 2011 IssueDokumen108 halamanPumper March 2011 IssuePumper MagazineBelum ada peringkat

- LO 2. Use FOS Tools, Equipment, and ParaphernaliaDokumen5 halamanLO 2. Use FOS Tools, Equipment, and ParaphernaliaReymond SumayloBelum ada peringkat

- Multimedia: Hardware & SoftwareDokumen18 halamanMultimedia: Hardware & SoftwareKalix JimenezBelum ada peringkat

- ZXG10 B8018 (V1.00) In-Door Base Transceiver Station Technical ManualDokumen128 halamanZXG10 B8018 (V1.00) In-Door Base Transceiver Station Technical ManualPrashant MaraBelum ada peringkat

- Hilux ANCAP PDFDokumen3 halamanHilux ANCAP PDFcarbasemyBelum ada peringkat

- Warning Chime System: SectionDokumen63 halamanWarning Chime System: SectionChang ChangBelum ada peringkat

- Huawei SE1000 Series Enterprise SBC Data SheetDokumen4 halamanHuawei SE1000 Series Enterprise SBC Data Sheetarranguezjr5991Belum ada peringkat

- Paragon Hard Disk Manager Pro 2009 Portable Rar PDFDokumen4 halamanParagon Hard Disk Manager Pro 2009 Portable Rar PDFDanBelum ada peringkat

- Leser at A GlanceDokumen12 halamanLeser at A Glanceธวัชชัย ขวัญเรียนBelum ada peringkat

- Event Management System1Dokumen24 halamanEvent Management System1Suchi UshaBelum ada peringkat

- CC1 - AssignmentDokumen1 halamanCC1 - AssignmentAssiah AndreaBelum ada peringkat

- Byjusbusinesscanvasmodel 190201155441Dokumen5 halamanByjusbusinesscanvasmodel 190201155441Aarsh SoniBelum ada peringkat

- BR4144A.8 英 (conector)Dokumen1 halamanBR4144A.8 英 (conector)Victor GuzmanBelum ada peringkat

- Samsung Ue40f5500 TrainingDokumen49 halamanSamsung Ue40f5500 TrainingLuizBelum ada peringkat

- CTXM-M FTXM-M 3PEN393186-10J Operation Manuals EnglishDokumen48 halamanCTXM-M FTXM-M 3PEN393186-10J Operation Manuals EnglishAllf AllfBelum ada peringkat

- Eurocode 3 Part 6 PDFDokumen2 halamanEurocode 3 Part 6 PDFDominic100% (1)

- LG Ht303su Ht353sd SM (ET)Dokumen81 halamanLG Ht303su Ht353sd SM (ET)domi56Belum ada peringkat

- Digital Hydraulic Valves Gaining Momentum: Newton, Ma-The Trend Toward De-Centralized Control On The Factory FloorDokumen2 halamanDigital Hydraulic Valves Gaining Momentum: Newton, Ma-The Trend Toward De-Centralized Control On The Factory Floorback1949100% (1)

- Agnes CVDokumen3 halamanAgnes CVMaziwa ProBelum ada peringkat

- Lenovo Yoga Book With Windows SWSG en FR Es-Us v1.1 201608Dokumen48 halamanLenovo Yoga Book With Windows SWSG en FR Es-Us v1.1 201608Jose David Sierra LugoBelum ada peringkat

- Internet & Web Basics Key Concepts Terry Ann Morris, Ed.DDokumen31 halamanInternet & Web Basics Key Concepts Terry Ann Morris, Ed.DDoris EsperanzaBelum ada peringkat