Basics of Drawing For Engineers

Diunggah oleh

muthu06101987Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Basics of Drawing For Engineers

Diunggah oleh

muthu06101987Hak Cipta:

Format Tersedia

Kirloskar Pneumatic Co.

Ltd

BASICS OF DRAWING FOR ENGINEERS- PART 2

Kirloskar Pneumatic Co. Ltd

Guide to types of ISO limits & fits

General Tolerancing

Limits & Fits for Shafts & Holes Basic Size & Shaft/ Hole Tolerancing System

Basic Size & Shaft/ Hole Tolerancing System

Fits

Fits

Limits & Fits Determining Working Limits

Surface Finish

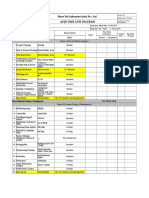

ENGINEERING CHANGE NOTICE Changes made in engineering documents, viz Drawings SBM BOM & STANDARDS, released for production/development, are communicated to all concerned, through a document called as Engineering change notice. Kpcl stand. Gives guidelines for procedure to be followed. ( the subject procedure is not applicable to drawings sent to customer for approval.) Enclosed is a format of the ECN . The ECN format, after filling the information, bears a specific number. & date. Configuration of the number can be decided by respective design offices This is recorded in a separate register with additional information as, - product reference. Brief record of the change, reason for change, & signature of authority. ECN number & brief record of change is also written on the drawing. Every change on drawing is indicated by a symbolic letter, A to H. This symbol is also written near area where the change is carried out. In addition to that a circle is marked around the symbol, to know the change at a glance Guidelines are also given for entering the data,- reason, effect on stock, , action by other depts. Effect on processes.

Codes R1 TO R7 are given for various reasons of ECN, e.g. drawing. update, drawing. error, improvement etc. Codes S1 TO S7 are provided for actions on stock ,e.g.-use as it is , rework, scrap, etc. Accordingly instructions are required to be given for Stock at various positions viz.in process , in assembly ,with dealers / branches etc. Effect on manufacturing departments, -m shop, assembly, materials, imports , stores etc. and effect on manufacturing process- tooling , pattern, heat treatment. material, machining manual Information is also given for effect on interchangeability & requirement of service bulletin. Different depts. To whom drg./ only ECN copy is to be circulated , are listed in a column . These are to be marked accordingly. Engineering changes in drawings. submitted for customers approval. -Different drawings. eg. GA drg, P I Diagram Electrical drawing. are submitted to customer / consultant, for approval as per contract. As per comments / suggestions drawing is changed. The changes are recorded on drg, & are identified by a REVISION NUMBER 1, 2, 3, ETC. written in a triangle. After final approval of drawing changes are incorporated on tracings & drg copies are released for production, through Release sheet Approved drawing prints are stored with R&D / MKTG. DEPT.

Present Format

Proposed Format

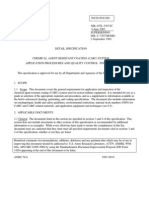

DRAWING RELEASE Before drg is released for manufacturing or customer as authentic document which may bear commercial as well as legal aspect, it should be signed by an authorized person. On Drg. sheet Three blocks are provided for signature. DRAWN , CHECKED & APPROVE. Computer signature/ initials of the draftsman or engineer is required in the column DRAWN. Checked signature is to be done by an engineer. He is supposed to be a responsible person for technical contents the in drawing. Approval should be given by other person. This is supposed to be an approval for expenditure for manufacturing the depicted component If a Draftsman, has drawn the drawing, & an engineer has checked the drawing & approval can be done by the same engineer, if authorized so. If an engineer himself has made the drawing he can sign for drawn & checked , but approval has to be given by the other authorized person RELEASE SHEET-. It is a Separate format made, which is to be filled in, & issued along with drawing prints. A separate number is allotted to each release sheet, through which DRAWINGS. SBM & BOM are released for a OA or Shop order. All documents need not be released at a time, but can be released in groups. Each group is called release number. .List of departments is printed on the sheet . Concerned departments are marked to whom drawing is released . This release sheet is to be used for first release of the document. If some drg or bom used in a product is common to some other product it need not be released again. In case of any specific requirement from the user document reference can be given, on release sheet with a special mention about it.

DRAWING STANDARDS . I] IS STANDARDS -IS 696- - CODE OF PRACTICE FOR - GENERAL ENGINEERING DRAWINGS (withdrawn ) IS 9609 PART (1) -1983 LETTERING OF TECHNICAL DRAWINGS. IS 10164 - 1985 REQUIREMENT TO EXECUTE TECHNICAL DRAWINGS FOR MICRO COPING IS 10714-1983 GENERAL PRINCIPLES OF PRESENTATION OF TECH DRAWING. IS 107181983 METHOD OF DIMENSIONING & TOLERANCING OF CONES ON TECH DRAWINGS IS 8000 PART (1) - 1985 GEOMETRICAL TOLERANCES ON TECHNICAL DRAWINGS FORMS , LOCATION , RUN OUT & GEOMETRICAL DEFINITION IS 8000 PART (2) -1992 MAXIMUM MATERIAL PRINCIPLE. IS 8000 PART (3) -1992 DIMENSIONING & TOLERANCING OF PROFILE IS 8000 PART (4) 1976 PRACTICAL EXAMPLES OF INDICATIONS ON DRAWINGS . IS 11664 -1986 FOLDING OF DRAWING PRINTS IS 11665 1985 TITLE BLOCK .IS 11666 -1985. TECHNICAL DRAWINGS ITEM LIST

IS 11667 1985 INDICATION OF LINEAR & ANGULAR TOLERANCES ON TECHNICAL DRAWINGS IS 11668 1985 TECHNICAL DRAWINGS SPECIFIED REPRESENTATION OF CENTER HOLES IS 11669 1986 GENERAL PRINCIPLES OF PRESENTATION OF TECH DRAWINGS IS 11670 - 1993 TECHNICAL DRAWINGS ABBREVIATION SYMBOLS FOR USE IN TECHNICAL DRAWINGS. IS 3073 - 1967 ASSESSMENT OF SURFACE ROUGHNESS. 2] KPC STANDARDS CODE & PRACTICE FOR DRAWING KPCL STD. NO- 999 700. It consists ofGuidelines for lay out drawings, sectional views , spacing Mat. Spec, alternative mat, heat treatment & special notes Guidelines for dimensioning & tolerancing Guidelines for checking & drawing details Guidelines for writing BOM & SBM Guidelines for ECN writing Guidelines for metrication of drawings. Guidelines for drawing sheet sizes for SBM , BOM & folding of prints. Abbreviations & conventions to be used in drafting work

3] ANSI Y-14 5 M GEOMETRIC DIMENSIONING & TOLERANCING

Anda mungkin juga menyukai

- Introduction to Civil EngineeringDokumen157 halamanIntroduction to Civil EngineeringXaviorOuseph100% (4)

- Solved Problems in Industrial Quality Control 20131 PDF Reliability Engineering Computer Aided DesignDokumen45 halamanSolved Problems in Industrial Quality Control 20131 PDF Reliability Engineering Computer Aided DesignKaye Domingo100% (1)

- Reply - API 610 TestingDokumen2 halamanReply - API 610 TestingMuhammad ImranBelum ada peringkat

- 10 - Drafting Manual - Revisions and RetracingDokumen20 halaman10 - Drafting Manual - Revisions and RetracingJOHNBelum ada peringkat

- EML2322L-Engineering Change NoticeDokumen5 halamanEML2322L-Engineering Change NoticeJohn MelvinBelum ada peringkat

- Supplier Controlled - Safe Launch PlanDokumen6 halamanSupplier Controlled - Safe Launch PlanMario RojasBelum ada peringkat

- Concrete Simplified Flat Slabs Tables BS 8110 EngineeringSoftwareGuideComDokumen24 halamanConcrete Simplified Flat Slabs Tables BS 8110 EngineeringSoftwareGuideComManuel SueroBelum ada peringkat

- SPECS Engineering Change Procedure 07-11-05Dokumen3 halamanSPECS Engineering Change Procedure 07-11-05backup hmnthBelum ada peringkat

- Supplier Manual 16-11 Bosch Thermotechniek B.V 1Dokumen20 halamanSupplier Manual 16-11 Bosch Thermotechniek B.V 1LOGANATHAN VBelum ada peringkat

- SP 2154Dokumen26 halamanSP 2154Anoop gokhaleBelum ada peringkat

- Jakarta Plant Engineering Standard: B. General Rules of PFMEA B.1. ScopeDokumen24 halamanJakarta Plant Engineering Standard: B. General Rules of PFMEA B.1. ScopeLeonardoViannaBelum ada peringkat

- Region of Waterloo Material Specifications for Municipal ServicesDokumen19 halamanRegion of Waterloo Material Specifications for Municipal ServicesNima ArvinBelum ada peringkat

- SafetyDokumen45 halamanSafetyDimitri KustrinBelum ada peringkat

- AAMI Quality Systems White Paper: Comparison of 21 CFR Part 820 To ISO 13485:2016Dokumen28 halamanAAMI Quality Systems White Paper: Comparison of 21 CFR Part 820 To ISO 13485:2016Hong XuyenBelum ada peringkat

- S 000 1378 001 - 1 - 0001Dokumen53 halamanS 000 1378 001 - 1 - 0001sifoouBelum ada peringkat

- DevOps Culture Q&ADokumen3 halamanDevOps Culture Q&APriti Sharma50% (2)

- Drawing StandardsDokumen12 halamanDrawing StandardsAgung Bayu100% (1)

- 175 010300 PDFDokumen2 halaman175 010300 PDFAbu Anas M.SalaheldinBelum ada peringkat

- NASA guide for heat treating aluminum alloysDokumen8 halamanNASA guide for heat treating aluminum alloysmarcoswanBelum ada peringkat

- AASHTO M 264 ASTD D 2680 ABS and Pol y Pomposite Sewer PipingDokumen7 halamanAASHTO M 264 ASTD D 2680 ABS and Pol y Pomposite Sewer PipingMuhammad Masood AbbasBelum ada peringkat

- Grade 5 Vs Grade 8 Fasteners - TineLokDokumen5 halamanGrade 5 Vs Grade 8 Fasteners - TineLokTodd AlexanderBelum ada peringkat

- Pipelines and Buried PipesDokumen22 halamanPipelines and Buried PipesjwochBelum ada peringkat

- Ped 6Dokumen16 halamanPed 6Everton ArrudaBelum ada peringkat

- Sleeve Bearing Load LimitsDokumen2 halamanSleeve Bearing Load Limitssperthawin2787630Belum ada peringkat

- Sub-Tier Control GuideDokumen10 halamanSub-Tier Control GuideJHBernardoBelum ada peringkat

- Work Pack - Guide For Reviewing Mechanical Engineering Work Packs - Rev1Dokumen8 halamanWork Pack - Guide For Reviewing Mechanical Engineering Work Packs - Rev1mkash028100% (4)

- Inspection & Testing Requirements Scope:: Test and Inspection PerDokumen2 halamanInspection & Testing Requirements Scope:: Test and Inspection PeraneeshjokayBelum ada peringkat

- Bcsa Circular For Pressure Piping Registration - Revised July 02-2015Dokumen3 halamanBcsa Circular For Pressure Piping Registration - Revised July 02-2015MamacintBelum ada peringkat

- Shree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramDokumen2 halamanShree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramS. R. OvhalBelum ada peringkat

- Bosch - Supplier-Quality-RequirementsDokumen55 halamanBosch - Supplier-Quality-RequirementsumtBelum ada peringkat

- FracasDokumen4 halamanFracasGerardo Cruz Espinosa100% (2)

- Sheet Pile Design SampleDokumen4 halamanSheet Pile Design SampleMarvin SabadoBelum ada peringkat

- Volkswagen Group CSR IATF 16949 Sept 2017Dokumen6 halamanVolkswagen Group CSR IATF 16949 Sept 2017Selvaraj SBelum ada peringkat

- Is 4326 2013Dokumen35 halamanIs 4326 2013Harsh Machchhar100% (2)

- Control of Crack WidthsDokumen55 halamanControl of Crack WidthsMahmood Mufti100% (1)

- 5 DCN - Design Change NoticeDokumen10 halaman5 DCN - Design Change NoticeZoebairBelum ada peringkat

- Siemens Ihm Pxm50.e A6v11211557 enDokumen71 halamanSiemens Ihm Pxm50.e A6v11211557 enMatheus PraseresBelum ada peringkat

- ECSS-Q-ST-70C-Rev.1 - Materials, Mechanical Parts and Processes (15 October 2014)Dokumen75 halamanECSS-Q-ST-70C-Rev.1 - Materials, Mechanical Parts and Processes (15 October 2014)Alberto RomeroBelum ada peringkat

- Sae Air81d PDFDokumen12 halamanSae Air81d PDFfarhad pashaei mehrBelum ada peringkat

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDokumen7 halamanSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanBelum ada peringkat

- NADCAP AC7114 Rev FDokumen23 halamanNADCAP AC7114 Rev Famirkhakzad498Belum ada peringkat

- Roots B Centrifugal BrochureDokumen24 halamanRoots B Centrifugal BrochureStephenson ViegasBelum ada peringkat

- AluminiumDokumen16 halamanAluminiumVigneswaranBelum ada peringkat

- OP1111Dokumen5 halamanOP1111Umit AytarBelum ada peringkat

- EXXON EPpressurevesselsDokumen14 halamanEXXON EPpressurevesselsharrinsonfBelum ada peringkat

- Fastenal - Mechanical Properties of Inch FastenersDokumen4 halamanFastenal - Mechanical Properties of Inch FastenersbclarkeoobBelum ada peringkat

- Mil STD 276Dokumen9 halamanMil STD 276D_D_76Belum ada peringkat

- CAC/GL 50-2004 General Guidelines on SamplingDokumen69 halamanCAC/GL 50-2004 General Guidelines on SamplingJanelle100% (1)

- Packaging and Distribution Environments: Standard Terminology ofDokumen13 halamanPackaging and Distribution Environments: Standard Terminology ofShaker QaidiBelum ada peringkat

- 03 Ppap-3 PDFDokumen91 halaman03 Ppap-3 PDFMalla Reddy AVBelum ada peringkat

- Saudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldDokumen4 halamanSaudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldRijwan MohammadBelum ada peringkat

- Nickel Lap Welding ProcedureDokumen5 halamanNickel Lap Welding ProcedureAnonymous 4IpmN7OnBelum ada peringkat

- Air Leak TestingDokumen6 halamanAir Leak TestingSubbarayan SaravanakumarBelum ada peringkat

- LS030 1oxDokumen6 halamanLS030 1oxANILBelum ada peringkat

- Labyrinth Type Seals FMEADokumen1 halamanLabyrinth Type Seals FMEAShukor AzBelum ada peringkat

- Specification and Requisition For Ball Valve: GTF-3-XXXX-XXX-XX-X-0Dokumen13 halamanSpecification and Requisition For Ball Valve: GTF-3-XXXX-XXX-XX-X-0shyamBelum ada peringkat

- First Article Inspection Report FormsDokumen5 halamanFirst Article Inspection Report FormsSivananthaa MurtheeBelum ada peringkat

- DFM and DFA Approach On Designing Pressure Vessel PDFDokumen6 halamanDFM and DFA Approach On Designing Pressure Vessel PDFOmkar MohiteBelum ada peringkat

- Mil C 53072Dokumen43 halamanMil C 53072Valerie Schmid BurnsBelum ada peringkat

- Good Manufacturing Practices-1Dokumen28 halamanGood Manufacturing Practices-1ramprasad battalaBelum ada peringkat

- Saudi Aramco Hardness Testing Procedure ReviewDokumen3 halamanSaudi Aramco Hardness Testing Procedure ReviewphilipyapBelum ada peringkat

- SAT Grammar Lesson - Subject-Verb AgreementDokumen17 halamanSAT Grammar Lesson - Subject-Verb AgreementBelinda Filippelli Whittaker100% (1)

- PDF Sat Practice Test 3 EssayDokumen4 halamanPDF Sat Practice Test 3 EssayMenekşe MenekBelum ada peringkat

- System-Based, Customer-Centered Quality Plan For ManufacturersDokumen9 halamanSystem-Based, Customer-Centered Quality Plan For ManufacturersmsbarretosBelum ada peringkat

- Supplier Quality Management A Complete Guide - 2021 EditionDari EverandSupplier Quality Management A Complete Guide - 2021 EditionBelum ada peringkat

- Interface control document The Ultimate Step-By-Step GuideDari EverandInterface control document The Ultimate Step-By-Step GuideBelum ada peringkat

- Wrawing Numbering ProcedureDokumen3 halamanWrawing Numbering ProcedureanilpkBelum ada peringkat

- Ags019 02Dokumen22 halamanAgs019 02Forbes KambaBelum ada peringkat

- Cussons Technology Brochure Highlights Marine Research EquipmentDokumen20 halamanCussons Technology Brochure Highlights Marine Research EquipmentArfah MpBelum ada peringkat

- I V T ' T M P T T: Electronic Devices and Circuits (MCT-122)Dokumen6 halamanI V T ' T M P T T: Electronic Devices and Circuits (MCT-122)Ahmed ChBelum ada peringkat

- Excel JobDokumen3 halamanExcel JobRithvika RamjiBelum ada peringkat

- Binu George CVDokumen5 halamanBinu George CVUmed UnnikrishnanBelum ada peringkat

- Power Factor & Star DeltaDokumen20 halamanPower Factor & Star DeltaSyahmi FadziBelum ada peringkat

- IEEE IAS Petroleum and Chemical Industry Committee 2017 Awards LuncheonDokumen2 halamanIEEE IAS Petroleum and Chemical Industry Committee 2017 Awards LuncheonBenBelum ada peringkat

- BEng EEDokumen12 halamanBEng EEJimmy NeoBelum ada peringkat

- National Electric CodeDokumen10 halamanNational Electric CodeRen MariBelum ada peringkat

- Coordination Protection of Low-Voltage AC Distribution Network in Vessel DC Zonal Electrical Distribution SystemDokumen5 halamanCoordination Protection of Low-Voltage AC Distribution Network in Vessel DC Zonal Electrical Distribution SystemFreddy Roberto PerugachiBelum ada peringkat

- CW 50 Building Connections Architect Catalogue EN PDFDokumen62 halamanCW 50 Building Connections Architect Catalogue EN PDFJaimasaBelum ada peringkat

- Team Design Notebooks and Team JournalsDokumen1 halamanTeam Design Notebooks and Team JournalsedwinmazoBelum ada peringkat

- 175-026600 10312016Dokumen2 halaman175-026600 10312016Prasanna UmapathyBelum ada peringkat

- PLC Program IntroductionDokumen3 halamanPLC Program IntroductionPravin BeheraBelum ada peringkat

- 3D Concrete Printing - From Material Design To Extrusion (ACE Workshop, 2017)Dokumen15 halaman3D Concrete Printing - From Material Design To Extrusion (ACE Workshop, 2017)Mirza BasitBelum ada peringkat

- Rahul Lohar: Aeronautical EngineerDokumen6 halamanRahul Lohar: Aeronautical EngineerRahul LoharBelum ada peringkat

- Bulletin 2018 19Dokumen404 halamanBulletin 2018 19AppleBelum ada peringkat

- Civilstructural Permit (For Building Permit)Dokumen2 halamanCivilstructural Permit (For Building Permit)Josef Kheraymuel VillalunaBelum ada peringkat

- Assignemt2 IT8029Dokumen11 halamanAssignemt2 IT8029AlexBelum ada peringkat

- Tutorial 2 (Basic) : Pin/Lug Assembly: 5Dplq5LdklDokumen11 halamanTutorial 2 (Basic) : Pin/Lug Assembly: 5Dplq5LdklIbnu RiswanBelum ada peringkat

- B Eng Hons Mcha 40064 S2 2017-18Dokumen3 halamanB Eng Hons Mcha 40064 S2 2017-18Thắng NguyễnBelum ada peringkat

- Eurocode 1 1 PDFDokumen2 halamanEurocode 1 1 PDFLaura0% (1)

- (Common To AUTO/MECH/CIVIL/CSE/IT) 3 0 0 3Dokumen2 halaman(Common To AUTO/MECH/CIVIL/CSE/IT) 3 0 0 3porseenaBelum ada peringkat