Factory Line Systems

Diunggah oleh

Sabrina DuongHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Factory Line Systems

Diunggah oleh

Sabrina DuongHak Cipta:

Format Tersedia

Fanasonic

K#wmw ffww $$#w

Factory Line Systems

. . Certilied to ISO 9001

ffiffi

001

Ouality Management System

Factory Line - a flexible wiring system for stationary loads. Branching of the line and power take-off can be accomplished from any location.

o-

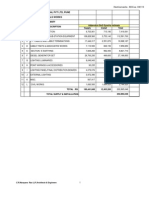

There are four duci models in the Factory Line system, classified according to the type and capacity of the power supply.

(D Factory Line lOO: For both main lines and branch

lines,

providing both a 3-phase power supply (maximum 100 A) and a single-phase power supply (maximum 20 A). (al Factory Line 60: For both main lines and branch lines, providing both a 3-phase power supply (maximum 60 A) and a single-phase power supply (maximum 20 A). ls) Factory Line 30: For branch lines. 30 A capacity. Provides either one 3-phase power supply circuit or iwo single-phase power supply circuits. G) Factory Line 20: For small branch lines. Provides a single-phase power supply of up to 20 A. Combine these Factory Line systems to create a completely flexible wiring system perfectly suited to the needs of your production line.

ln all Factory Line systems the plugs that supply electrical power from the ducts to the load or the branch lines

can be freely connected and removed at any location.Varying supply needs, quantity of production line equipment,

such as changes in the layout or

can be quickly and easily

satisfied

simply by moving or connecting more

plugs. Unlike conventional electrical

wiring systems, the Factory Line system does not need to be rewired. This significantly reduces both the e{fort and cost of making such changes.

t;

;T 6 I

i 7:l fffFtr" ia i I I ll

Lt

Factory Line 30

-r

e

lJ tJ

I ll

ls

!3

By replacing conventional powe

With the Factory Line 100 or Faclory

supply conduit wiring with lhe Factory

Line, all of the wiring that previously cluttered the floor and other areas can be neatly eliminated, thus preventing accidents or injury. In addition, i't

situations such as metalwork lactories, if the wiring is on the floor, metal chips can enter and cause shorting, but with the Factory Line all danger of problems such as these occurring is eliminated. Furthermore, because the Factory Line system is equipped with various types of breaker-equipped plugs, it provides inc reased saJety in the event of unforeseen emergencies.

Line 60, both a three-phase power supply and a single-phase power

supply can be obtained simultaneously.

power and the eleclrical outlet power supply can be handled from a single wiring line, the wiring is simplified. ln addition, with the Factory Line 30, two

single-phase power supply circuits can

Because, for example, both drive

the lighting power supply and the electrical power supply can be

combined in a single line.

be obtained simultaneously, so both

.::.:_:: :::,):::,::,'.:t'1'.-

.'.:,

... :t..)

Ground lerm nar(coppet

Factory Line

33

power supply circuit.

The Factory Line 20 is a duct for small-scare branchin

For the display of work standards sheets, process charts, parls lists, self-guided tour route indications, etc.

20

The Factory Line 20 is a duct for small-scale branching, and it contains a conductor fo.r o,ne single-phase 250-V circuit. tt is ideel for provjding the power supply for task lamps and electrical outlets, and fliorescenl line lighting can also be installed.

0{,

t-

1)t

I

I

{tJ

Hpable of providing one single-phase

P pe suspens on

llanger>

<Lockino electrcalTerm

fa

puq

Bee type p ugsocket>

Product guide

Factory tine

lFactory

20

lDuct

cover (cream-gray finish)

For Factory Line 20 system. Closing the main unit opening to protect from entering forejgn bodies or dusts into main unit. Length 1m. Made of PVC.

Line 20 main unit (cream-gray linish: Munsell 5Y7,211,4)

2P 20A 250V with ground. Conductor equipped ducts for a sinqle phase circuit. Galvanized steel core PVC resin housing and copper

conduclors.

I T, : E:a::::::::::: =a =

::a)

Ll-9!

-h--,|-q zal

lFeed-in cap (cream-gray finish)

For Factory Line 20 system. 2P 20A 250V with ground. Supplying power at an end ol the main unit. lriernal quick connect terminals for single core wrre. Galvanized steel and resin housing.

For Factory Line 20 system. 2P 20A 250V with ground. Supplying power between main units and connecting them. lnrernal quick connect terminals tor sinqle core wire. Galvanized steel and resin housing.

lCenter leed-in ioiner (cream-gray linish)

75 .-'-t,

'. Ll

100

rl

f--i75

lEnd

cap (cream-gray linish)

For Factory Line 20 system. Closing an end of the main unit. Besin molding.

lJoiner (cream-gray linish)

For Factory Line 20 system. 2P 20A 250V with ground. Connecting main units both physically and electrically. Resin molding. lCautionl Cannot supply power with ihis part.

*:

w3

r= tffitrt

,l

Product guide

L joiners (cream-gray finish) I ::'Factory

l,.sernb ing L, T and or X conf gurations.

Line 20 systern. 2P 20A 250V with ground.

ITerminal plug (cream-gray finish)

For Faciory Line 30 system. 2P 15A 250V wjth ground Power outlet for lhe main un tUrea res n molding.

::cording to the polarity, the right and the left types are avaitabte

:aS

JOrners.

resin housing

fgr

ffi;l

,50

.:a_r-. : il, i

r- r

4-ll L

cl4llD --v-

lJ

lPlug sockets (with ground) (cream-gray finish)

s c 8366of9 3round 2P 154'125V. ise for extracting single-phase 100V socket power.

Jrs c 8366

Gro!nd 2P 15A 125V.

ILocking plug socket ol,i

(cream-gray finish)

Use 10r extracting single-phase 100V socket power.

1{,

I

i

ff H_

Lt

::

f,r

lLocking plug socket (with ground)

JSC8366OCt

(cream-gray finish)

lReel-type plug socket

Jrs c 8366

(Plug: Cream-gray finish. Socket: Oft-white finish)

Ground 2P 15A 125V Locking. Use ior extracting slngie phase 100V socket power.

t*

,fc

rql

dr-=tT triT\ tEEti I

I

Twln 2P 15A 125V Can be owered 10 hand evel (max. 1.8rn lrom the duct). Lower ng up to 3m U from the duct availab e to order. ICaut on] ilTo rewirid the reel section press and hold the b!lion, , and s ow y raise the sockei Failure io do so rnay cause damage. Overa lenglh 4.. .2 Use with n lhe indicated 800 l800nrrn ioad carryjng capacity (up

to 1500W).

Tw n

2Pr5A125V

lReel-type plug socket (with ground)

(Plug:Cream-gray finish. Socket: Off-white finish)

"

IFluorescent lighting fixture plug

For Factory Line 20 system. 2P 6A 250V with ground. Mounting a fluorescent lighting fixture dlrectly to the main unit and suppiy power from upper or lower 2P conductors. Consists of clarnpJeeder and cramp. Galvanized steel lrarne. lCaulionl Weighl must be below 1okq c,amp

For lwin ground 2P 15A 125V, tw n ground 2P 15A 125V ocking. Can be lowered to hand leve (n'tax. 1.8m lrom the duct). Lowering up 1o 3m U from the duct availab e to order.

I01. -o o\

10 -.e t. r | . .. ttor. p,.\. and hold the bLrlton andsowly faise th-o socket. Failure to do sc Tn ay cause damage Use wth n lhe ndicated load .arry nq capac ty (up to 1500W)

A-

ffioouo'"'

0

v.

| : r:

-: aPprox "./ ' ._ aob rSoomm

overarrensrh

lffi |

,*" ."'o *,""r

Product guide

IPipe suspension hanger (cream-gray finish)

For Factory Line 20 system. Suspending main unit. The pipe can be cut at the llange side.

lHanger (with bolt)

For Factory Line 20 system. Suspending main unit from the building structure. Stainless steel hanger and galvanized bolt (200mm). ICautionl Suspending weight must be below 1Okg on each hanger.

Melamine coated steel pipe and ABS resin flange. lCautionl (1)Suspending weight musl be below 1okg on each hanger. Q)l\,4aximum suspension lntervai is 1.5m.

Note:The hangerfixlure alone ls a specalorder item.

lHanger (wilhout bolt)

For Factory Line 20 system. Suspending main unit with supplied bolts. Stainless steel hanger. lCautionl Suspending weight must be below 1okq on each hanqer.

.@-..

lHanging hook (cream-gray finish)

For Factory Line 20 system.

Hooking something on the Factory Line 20 main unil. lCautionl Hooking weight must be below 5kg.

z*.

3'%

IPoster clip (cream-gray tinish)

For Factory Line 20 system. Suspending document or sheet to the Factory Line 20 main unit. lCautionl Suspending weight must be below 5kg.

25

Factory Line 20 Installation Procedure

lnstallation of the ducts

Use the tapping screws inc uded with the ducts to mor-rnt the ducts directly to the ce ling(or wall).

A Caution

. Fix the duct to building structure firmly. T !,J freaoanp a aa rsp af ia if ll aaes foi sa

l[,,1o!nlna ]roer

Use

ol the mountinq ho es.

Screw one screw paTtway n, lit the elongated hole of lhe dllct onto that sar-aw and ihen screw lh-o olh-or screw n through the round hole in the duct. This allows the nsta lation to be cornp eted by one person.

E Mounting the pipe-suspended hangers

.Useths procedure lihe Faclory Lne

20 ducls

arelo be sLrspendedjrom pipes fnecessary,lhe

ppes can be shoirenedt0lhe required ength by

cufl

ig lhem

at llre

lange end.

66.7

. The standard interval for mounting ol the hangers is I m. and the n'rax mum interval is 1.5 m. Be sure 1o mount securelv io a struct!ra m-Amher

ls==l

\..1,-/

F

,'-'.]\

Slandard

Gaution

t.

drD!

1m raxmuml5m

ange mo!nuno d mens ons

the strength 0i building structures enough to suppott the hanging weight (a max mlm oi lOkg per sLtpport)

l',loi dalng sa mily aaLrse the hargEf

se two or more pieces of hanger ior one duct. t ,J'/ili becorne a calse oi fa if 1 does llot so

To prevent the ducts ir0m meandering, align the hanger centers.

No: dllnE

s:

r.r8\' caLrse

tle

hEneers ta

1 Tum the fange coverto the eftto rernove 1. 2 Use lhe wood screw ortapp ng screw.1hen mounl the f ange to a structuraimember. 3 A gn the p pe mouiting hole oflhe pipe suspenson harger\\]lh llre posilon oilhe pan head rnach ne screwto putlhe ppe n the f aige tioure 1 lou@ 2 and lhen iasten lhe pan head machine screw and the selscrew pipasLrspended hangers atter mountei (Fasten the pan head rnachine screwlhrough the ppe mcunling ho e.) aAdjustlhe lenglh lhe n order to adjustthe ength after the p pe-suspended 4Tum the Jange coverto the rghl to m0Ln1 lback in its hangers have been mo!nted to a slruclura member, org na postiof. loosen the securng screw. remove lhe plpe, and cLrl the p pe at lhe lange end.

'

A Caution

aAfter cutling, drill

a hole (05.5 mm), mount the

aSecure y fasten the wood screw oT tapping screw, pan head machine screw, and setscrew.

flange, and then mouni a p ipe 1o lhe flange.

Factorv Line 20 lnstalation Procedure

Mounting the pip+suspended hangers 2

and turn the cap to lhe lelt to

Hangers (with bolt)(without bolt) instalation

1. Loosen the cap secur ng screw

remove t lrom lhe hanger.

. The standard interua for mounting of the hangers is 1 ra, and the maxinrun-r nterval is 1.5 m. . Be sure to mount the hanger bo ts secure y to a structura member. . DH2652 hangers (w thoLrt bo t) come witho!i hanger bolts. . To mount the DH2652 hanqers, Use l\,48 bo ts.

2.Spread aparl lhe hanger and malch lhe po arty indicalion

on the duct

wth the polarty

ind cation on lhe hanger.

A Caution

aEnsure the strength of building structuTes enough to support the hanging weight (a maximum of i O kg per

support).

3. Fil

the duct into the hanger,

alo use long hanger

No1 dc ng so

ma! caLrle the hanger ro droc

and then turn the cap to the right and t ghten the securing screw n order to secure lhe ducl

boLts, mount these bo ts using sway braces. ause two or more pieces of hanger for one duct.

t !\' beco-e a aaLse -.:'a i t lo9: fra_r sa aTo prevent the ducts from meandering, align the hangeT centers. ll.t do ng:i rrat' aa-rse i_e l:a3ers :a Cro!

A Caution

aTurn the cap until it is fully locked. lrot doifg so may cluse the dlct to dro!

1.

Loosen the cap securing screw and turn the cap to lhe left to remove t from the hanger.

4 Mounting the pipesuspended

1. Supplying power

hangers 3

va the

pe'suspended hangers(method ior

bring ng n the power supply) Boute the cable Jrom the ceiling into the pipe- When doing thls,

it

s eas er if the cab e is passed through the pipe before

securinq the Factory Line 20 dLrct in the hanqer. 2. Fo ow ng the san're procedure for Step B, f t the dlrcl in the hanqer, al'rd then fix il with the cap.

- Use s nge.ondlctor cabLes ot

Hanger

l6or20mmnslze.

A Gaution

aMake wire connections with

the hanger and then turn the cap to the rlght and tighten the securlng screw in order to secure the dLrct.

['J,[#5''

careful attention so that cables wilL not be bitten or

damaged.

N!: aa'g:a __:.

I| -. ea:'a a-:: r:

fire

raa.] I :_

A caution

aTurn the cap until it is fully locked.

Not dolng so mrv cause lhe dLrct to dro0.

45

Factory L ne 20 lnsta lation

Procedurel

ElConnecting the ducts

. Use a joiner lo connect two ducts together. . Be sure to match the polarities of the ducts and the joiner drd secL'e oy rigl on 'lg lhe \er sc ews.

Zlnstalling the feed-in cap

IConnecting the ducts aFit the feed-in cap lnto the

the set screw to secure it.

Grolnd ternr

cluct and tighten

Ho d.E parl oi 3 lastnins band

na

IProcedure for providing knock-out part

.r-rFor cab

s ze u/ith three cores or

es not arger than VVF of 2 firi in less remolc the

shaded area

rl

O oO

5i2c

!x,

th three cores

8'

ot

!s

ol 'nj ess rerno\re the

nEt a Cb

3r"r,..-l@-l

shaded area aDebLrrr ttre .Lrt sLrface

e Kn fc.

?:::,4@

IConnection of power supply, remove about electric wire

asirio ire

sir corrq

naer: the enas oi t te e gatr ca

giig:

E

Ect'ce lirres

oa yaLr.

v,,i res n Eccordance ,,! th ihe :roir'n or ifte ins de oi the cover End thef

alo

disconneci

ire e ectrica wires

flNger

uft theyarevslbe rthepeephoe p! theaf out while Lrsing

to ctess the connection

te ease

a scte!./d.'./a

b!Tion

A Caution

aDuTing

construction, Do not give a shock, such as dropping on a product, or hitting.

A Gaution

aDuring construction, Do not give a shock, such as dropping on a product, or hitting. t may be damaged aConnect the feed-in cap and the duct linearly. aSecurely fasten the set screws. (Proper toTque:

O.9B N.m-l 32 N.m) ausing the single-wire cable is 'l.6 mm or 2 aBe sure to use an insulated pin terminal( lnsertion length: lt is Ionger than

mm,

t may be darnaged acombine the tip of a duct and connect ceTtainly. aconnect a straightly both of the duct asecurely fasten the set screws. (Proper torque:

.l

O.98 N'm-

Do ng so mav

32 N.m) tesLrt nEneectticshockorafre

awhen cutting the ducts, use a metal hacksaw(hand type)and cut with the opening in the duct facing downward as shown in the

figure.

lf a Dowea saw is !sed the nsu atlon c adding or gaound term na s coLr d be scraped or burned

aAfter cutting, if the ground terminal protrudes

slightly, correct it. aFemove any cutting chips or burrs from the cut surface.

Doing so mav fesu

1 5mm and is less than 2l mm.) when use a stranded-conductor cable. ause a triplex cable and tighten the coii to the ground terminal to connect one cable.

'? Do E o aAfter wire connection, Bind the cable with wire

ties, etc. not to apply tension to the terminal.

(Proper tofque:

l2NT.- l5i.nl

in an e ectr c shock or a fir-.

Donesow tesut naf

re

EAttaching the end cap

F

I the cap onto the end ol the duct and secure it by t ghtening the sei screw.

A Caution

aAn end cap must be attached onto the end of the duct.

Doing so rnay tesLt t n an e ectric shock aSecurely fasten the setscrew. (Torque the setscrew to not less than O.98 N.m- l 32 N.m)

Faclory Lrne

20 nstalation

Procedure

Mounting center feed-in joiners

A, Caution

. To connect the dLrct with the center feed- n joiner, be sure lo align the Polarty indication(ground s de) with each oiher. . On y to make connect on, the cover needs not to be

dismoLrnted.

aDuTing construction, Do not give dropping on a product, or hitting.

It may be damaged

shock, such as

aConnect the plug of joiner and the duct linearly. ausing the single-wire cable is l 6 mm or 2 mm. aSecurely fasten the set screws. (Froper torque: O.98

Do ng so nray resu t in an : ectric shock oa a fite. ause a triplex cable and tiAhten the coil to the ground terminal to connect one cable(Proper torque: 1.2 N.m-

N'm-'l .32 N.m)

' To make power supply connection, wjnd the power supply

cable around the termina screw.

'

To make power sLrpp y connecl on, conneci the power s!pp y cable of the grounded side to the polarity side (the terminal screw oi wh ch is p ated).

L5

N.m).

Doing so

\,r' resut fanelectrcshock.aJre.

_--- -\

:id,

1P\

v/

s de)

/"(\\

Poat! idnaroilgtuhd

lE Mounting Joiner L

. To connect the duct with the joiner L, be sure to aliqn the Polar ndicat ol(9 o rro sioeJ wlrFacholl-c

tV

' To

. Only to rnake connection, the cover needs not to be dismounted.

n'rake power supply connection, wind the power supplV cable around the term nal screw. . To make power supply connection, connect the power supply cable of the grounded s de to the Poiarity ndicat on(ground side) (the terr.inal screw of which is p ated).

A Caution

aDuring construction, Do not give a shock, such as dropping on a product, or hitting.

: me! !:

damaged

Ducl

aConnect the plug of joiner and the duct linearly. ausing the single-wire cable is .l.6 mm or 2 mm. aSecurely fasten the set scTews and the terminal screws. (Proper torque: Set screw O.9B N.m- l 32 N.m Terminal screw : ] 2 N.m- I .5 N.m ) Do ng so ,rl res! t in an electric shock afire aThe division method look at the back of a coveT according to a block of a circuit. ause a triplex cable and tighten the coil to the ground terminal to connect one cable(Proper torque: 1.2 N. m- 1.5 N'm).

Do ng so

/ , --- ld) 7\\\

-

_v/

Po

ar

ndra on

(qro!nd sdet

resLrlt in an ejectrlc shock. a fire

--\\//

47

Factory Line 20 lnsta ation

Procedurel

lll Mounting

1.

a terminal plug

lE

Procedure lor mounting and using

reler outlet plug

Remove the set screws to remove the cover.

2. Loosen the cable clamp secuTing screws and inserl 3. Connect the

ihe

To mount the ree er outlet, pull down the plug lever, andthen rotaie it clockwise by 90 deqrees.

electrica cab einto the cover. electrica v! res to the terminal board by elther uslng crianp ternrinals or by w nding the wires around the

term nais.

4. Fit the cover into the body and secure it by tighten ng the set

screws.

5.Tighten the cable clamp secLrring screws to secure the

electrical cable.

A Gaution

aSecurely fasten the terminal screws. (Proper torque: O.A N.m - I N.m)

Doing so mav resLr

Do ng

in a f re.

aDo not slide the plug with having come in the duct.

s!

may resLri n fau t\i connectlon. tlrLrs eadlng to a fire

A Caution

aDo not slide the plug with having come in the duct. Doing sc ma! resLrh in faLrJly connectiDir, tirus eEd ng to a flre

Pull up lhe plug lever, and then rotale it counterclockwise by 90 degrees.

The outlet can expand and conlract in the range of approximate y B0 to 180 crn from ihe mounting surface. Pull down lhe main body ol the outlet. lt stops in a pos tion in which pu down. To return the main body to the original position, press and ho d the pushbulton press and ho d the pushbltton lo push up the main body to a pos tion to wh ch you want to return it. (Releasing the pushbutton wil stop it on the spol.)

Hitch the cord on ihe cord hook ot the ouuet lo use the iixture.

.Do not attach the

p ug un t \rlrhere the tapD ng screw ls Lrsed the dLrct direcily

Factory Line 20 lnstallation Procedure

IEIMounting an electrical outlet plug

.N,4atching the polarity indications on the duct and the plug, nsert the pluq into the duct and roiate it clockwise 90.

aDo not slide the plug with havlng come in the duct.

Do ng so rnEy result in faLtlty connection.

thus ed ng to

a f re

.Pull down the lever on the plug,

then rotate it counterclockwise 90.

(s

Mounting fluorescent lighting fixture

14

Make the hole for the fluorescent light plug and clamp in fluorescent ligh like the right figure_

(clamp)

. As shown in the f gure, pui the clamp in the hole for bolt in the fluorescent lighting fixture, and then fasten the locknut to fix the clamp. (Fluorescent ighting p ug)

' As shown

in the f gure, put the lighting plug in the hole for power supp y cable, and then fasten the locknut to fix the plug.

lorescenl lighl ng

pLug

*.Theclamp and thelluorescent tighting ptug comewith a setolluorescent lighring Jixtu.e,

A Caution

aTo connect the cable to unthreaded terminal, use bar type crjmp-style terminal. aSecurely fasten the locknut.

Not do ng so may resu

car

Not dolng so may result in fau ty cable connect on thus eadlng to a fire

aEnsure proper Iever handling.

n a drop.Not do ng so may cause

the

dLrct

to drop.

Not do ng so may result in a drop

Put lhe c amp and fluorescent lghting plug lever in line wlth the polarilyindication(green ine) of the duct.

(To mount) Rotate clockwise until the lever no longer rotates.

( I o drsmount) Rotate counterc ockwise until the lever no longer rotates. t

49

Factory Line 20 lnstallation

Procedurel

lE Use of a poster clip

.

.

Use the poster clip to suspend a work instruction sheet or

lE Mounting a duct cover

.

lvlount the cover by fitting it into the opening in the duct.

process chart from the Factory Line 20.

Fold down about 10 mrn of the top of the work instruction sheet or process chart and slide it sideways into the poster clip.

. The work instruction sheet can be positioned in the

'

desired direction. Mount the poster clip onto the Factory Line 20 duct in the same way as a plug.

aThe maximum load weight is 1 kg.

Not doing so mav cause the hangers to drop

aNotes the installation place,

il uminator,The poster mlght dlsco or and beeins to burn because of the heat of the i lumlnator.

Whef is to be fear the

t,

UI

50

Anda mungkin juga menyukai

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDari Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsPenilaian: 4 dari 5 bintang4/5 (1)

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileDari EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileBelum ada peringkat

- 110 Waveform Generator Projects for the Home ConstructorDari Everand110 Waveform Generator Projects for the Home ConstructorPenilaian: 4 dari 5 bintang4/5 (1)

- Electrical Works - Package 2B Addendum BoQ Synefra EstimateDokumen46 halamanElectrical Works - Package 2B Addendum BoQ Synefra Estimatemsdixit2006100% (4)

- CatalogDokumen48 halamanCatalogAhmad AshrafBelum ada peringkat

- Electrical CheckListDokumen33 halamanElectrical CheckListYudo Heru PribadiBelum ada peringkat

- Western Electric Tube Manual 1963Dokumen188 halamanWestern Electric Tube Manual 1963wa4gvt5044Belum ada peringkat

- L&T CHANGEOVER SW C-Line Catalogue PDFDokumen15 halamanL&T CHANGEOVER SW C-Line Catalogue PDFchidambaram kasi67% (3)

- CQ 04 April 1946Dokumen68 halamanCQ 04 April 1946Сергей БезразличныйBelum ada peringkat

- 110 Integrated Circuit Projects for the Home ConstructorDari Everand110 Integrated Circuit Projects for the Home ConstructorPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Henry 2K-3 RF Linear AmplifierDokumen27 halamanHenry 2K-3 RF Linear Amplifierw9fe100% (1)

- 1 Drilling Engineering IIDokumen235 halaman1 Drilling Engineering IIKarwan Dilmany100% (7)

- Benjamin Lighting Outdoor HID Lighting Brochure 1974Dokumen24 halamanBenjamin Lighting Outdoor HID Lighting Brochure 1974Alan Masters100% (1)

- Earthing and Short-Circuiting Devices GuideDokumen4 halamanEarthing and Short-Circuiting Devices GuideARC Electrical Safety ConsultingBelum ada peringkat

- Western Electric Vacuum Tube Data 1941Dokumen212 halamanWestern Electric Vacuum Tube Data 1941wa4gvt5044100% (1)

- EZUGWU - Key Improvements in The Machining of Difficult-To-cut Aerospace SuperalloysDokumen15 halamanEZUGWU - Key Improvements in The Machining of Difficult-To-cut Aerospace SuperalloysLuis Fillipe Lopes TorresBelum ada peringkat

- Progress Lighting Commercial Catalog 1977Dokumen100 halamanProgress Lighting Commercial Catalog 1977Alan Masters100% (1)

- Merlin Gerin Medium Voltage Distribution Switchgear Technical ManualDokumen18 halamanMerlin Gerin Medium Voltage Distribution Switchgear Technical ManualMohammed Madi100% (1)

- Construction Claims DelaysDokumen23 halamanConstruction Claims Delaysgerx11xregBelum ada peringkat

- 0001 0 General Nobel DentonDokumen50 halaman0001 0 General Nobel DentonPeyman MznBelum ada peringkat

- Extended Warehouse Management - Flyer - ENDokumen2 halamanExtended Warehouse Management - Flyer - ENsapabap403Belum ada peringkat

- 1127 Raceway System TrainingDokumen50 halaman1127 Raceway System Training54045114Belum ada peringkat

- Design Concept of 3311 KV SubstationDokumen39 halamanDesign Concept of 3311 KV SubstationKarth IkkBelum ada peringkat

- BOM SL. No Item Technical Specification Make Unit QuantityDokumen4 halamanBOM SL. No Item Technical Specification Make Unit QuantitygohilnarendraBelum ada peringkat

- Holophane HMS Lowering System Brochure 1972Dokumen4 halamanHolophane HMS Lowering System Brochure 1972Alan MastersBelum ada peringkat

- Line Trap Function and DesignDokumen12 halamanLine Trap Function and DesignOsama AhmadBelum ada peringkat

- Appleton - CatalogDokumen138 halamanAppleton - CatalogNataliyaLukovska100% (3)

- Googleplex, Mountain View: Designing Interior Spaces at An Urban Scale - Untapped CitiesDokumen11 halamanGoogleplex, Mountain View: Designing Interior Spaces at An Urban Scale - Untapped CitiesDiogo Machado100% (1)

- Prescolite Lite-Trac (Phase III) LT-1 1967Dokumen24 halamanPrescolite Lite-Trac (Phase III) LT-1 1967Alan MastersBelum ada peringkat

- Line Trap TrenchDokumen12 halamanLine Trap Trenchindrajeet1785Belum ada peringkat

- TS - TROLLEY SYSTEM 63 - 250A: Components and AccessoriesDokumen20 halamanTS - TROLLEY SYSTEM 63 - 250A: Components and AccessoriesGustavo J Perez MBelum ada peringkat

- AppletonDokumen30 halamanAppletonDennis MagnessBelum ada peringkat

- Current transformer dimensions and connectionsDokumen3 halamanCurrent transformer dimensions and connectionsluis9004Belum ada peringkat

- LineTrapsAir Core, Dry TypeDokumen8 halamanLineTrapsAir Core, Dry TypeSINU0607IITEEEBelum ada peringkat

- Copperhead Conductor SystemDokumen24 halamanCopperhead Conductor SystembhsujanBelum ada peringkat

- Benjamin Lighting Industrial Fluorescent Brochure 1978Dokumen16 halamanBenjamin Lighting Industrial Fluorescent Brochure 1978Alan MastersBelum ada peringkat

- Sterling Lighting Fixture Catalog 1963Dokumen32 halamanSterling Lighting Fixture Catalog 1963Alan Masters100% (1)

- Quad 33-303 ManualDokumen25 halamanQuad 33-303 ManualLuke SavageBelum ada peringkat

- E-Line KAM KAPDokumen14 halamanE-Line KAM KAPatulasodekarBelum ada peringkat

- AEC MC007 ASR Nonmetallic Interlocked ReceptacleDokumen3 halamanAEC MC007 ASR Nonmetallic Interlocked ReceptaclekimiesmithBelum ada peringkat

- Holophane Wallpackette Series Brochure 8-77Dokumen4 halamanHolophane Wallpackette Series Brochure 8-77Alan Masters100% (1)

- HP 450a Manual SN 010Dokumen23 halamanHP 450a Manual SN 010Karen RathbunBelum ada peringkat

- C-Flexi Series CatalogDokumen7 halamanC-Flexi Series CatalogCharles YaoBelum ada peringkat

- Low-Cost 770W Linear Amplifier With 572Bs in Grounded GridDokumen5 halamanLow-Cost 770W Linear Amplifier With 572Bs in Grounded Gridjofra_fBelum ada peringkat

- BK Precision 1660Dokumen48 halamanBK Precision 1660JabrokaBelum ada peringkat

- C LineDokumen16 halamanC LineSunil Kumar VishwakarmaBelum ada peringkat

- Al 811Dokumen10 halamanAl 811yu3zaBelum ada peringkat

- ABB RCCB F 804Dokumen12 halamanABB RCCB F 804catalinccBelum ada peringkat

- Elastimold HV Connectors, Elbows, Joints, Splices, Terminations USADokumen37 halamanElastimold HV Connectors, Elbows, Joints, Splices, Terminations USAnagazichoyBelum ada peringkat

- Wiring ProjectDokumen10 halamanWiring ProjectGarion CharlesBelum ada peringkat

- Weidmuller Power Products CatalogueDokumen190 halamanWeidmuller Power Products Cataloguerocket-vtBelum ada peringkat

- Description Qty Unit Rate Amount LE LE 16 Electrical 1 MV Ring Main UnitDokumen5 halamanDescription Qty Unit Rate Amount LE LE 16 Electrical 1 MV Ring Main UnitWaleed Abd El-HamiedBelum ada peringkat

- Westinghouse Lighting RMA-10 Package Series Roadway Spec Sheet 3-72Dokumen2 halamanWestinghouse Lighting RMA-10 Package Series Roadway Spec Sheet 3-72Alan Masters100% (1)

- BGW Model 250 Stereo Power AmplifierDokumen22 halamanBGW Model 250 Stereo Power AmplifierRdguez KandeBelum ada peringkat

- En Drazni Pristroje VenkovniDokumen10 halamanEn Drazni Pristroje Venkovniazulgrana77Belum ada peringkat

- Austin Isolation TransformerDokumen9 halamanAustin Isolation TransformermithunprayagBelum ada peringkat

- Holophane Spherical Street Light (SSL) Series Brochure 6-78Dokumen4 halamanHolophane Spherical Street Light (SSL) Series Brochure 6-78Alan MastersBelum ada peringkat

- DLTC 2011 LowresDokumen8 halamanDLTC 2011 LowresSalvador FayssalBelum ada peringkat

- Electrical Installation Lecture No.12 DR - Mohammed Tawfeeq Al-ZuhairiDokumen10 halamanElectrical Installation Lecture No.12 DR - Mohammed Tawfeeq Al-ZuhairiTĩnh LặngBelum ada peringkat

- 210-12 Pad Mount Data Sheet PDFDokumen12 halaman210-12 Pad Mount Data Sheet PDFRonald H Santos100% (1)

- Ameritron Al 1200 User ManualDokumen14 halamanAmeritron Al 1200 User Manualmark777markBelum ada peringkat

- Mobistat Stazioni MobiliDokumen26 halamanMobistat Stazioni MobiliAnonymous 1aHRPIIFfIBelum ada peringkat

- Bulletin 6100 Canon2Dokumen4 halamanBulletin 6100 Canon2techsoBelum ada peringkat

- Basic Function and Design of Line Traps for Power Line CommunicationDokumen12 halamanBasic Function and Design of Line Traps for Power Line CommunicationpatelshishirBelum ada peringkat

- Sr10 Sr30 Srk101: 13.56Mhz Contactless Smart Card ReaderDokumen2 halamanSr10 Sr30 Srk101: 13.56Mhz Contactless Smart Card ReaderSabrina DuongBelum ada peringkat

- City Multi CatalogueDokumen51 halamanCity Multi CatalogueSabrina DuongBelum ada peringkat

- Specification For M&EDokumen6 halamanSpecification For M&ESabrina DuongBelum ada peringkat

- Painting CodeDokumen20 halamanPainting CodeSabrina DuongBelum ada peringkat

- 125 Cau Hoi Phong Van Tieng AnhDokumen89 halaman125 Cau Hoi Phong Van Tieng Anhapi-3742561100% (3)

- Cat 5e 25-Pair UTP Cable Cut Sheet (040430)Dokumen2 halamanCat 5e 25-Pair UTP Cable Cut Sheet (040430)Sabrina DuongBelum ada peringkat

- Graduate Catalog - Faculty of Engineering - Qatar University 2011-2012Dokumen71 halamanGraduate Catalog - Faculty of Engineering - Qatar University 2011-2012Maher RagehBelum ada peringkat

- Rethinking Limits - Cleaning ValidationDokumen12 halamanRethinking Limits - Cleaning ValidationSatyaaammireddyBelum ada peringkat

- Vertex Payroll Tax Q Series Integration With Oracle Fusion HCMDokumen2 halamanVertex Payroll Tax Q Series Integration With Oracle Fusion HCMsam22nowBelum ada peringkat

- Processing Guides Isbmbottlepresentation PDF 1Dokumen25 halamanProcessing Guides Isbmbottlepresentation PDF 1Jay MehtaBelum ada peringkat

- Data Modeling and Analysis Techniques True False QuestionDokumen8 halamanData Modeling and Analysis Techniques True False QuestionPeter ParkerBelum ada peringkat

- Metro RailDokumen59 halamanMetro Railகீர்த்திவாசன் தமிழன்50% (2)

- Mastering 3D PrintingDokumen2 halamanMastering 3D PrintingTamás KissBelum ada peringkat

- MMCA Kazcomak2019 Ex-List EngDokumen9 halamanMMCA Kazcomak2019 Ex-List Engadamin biriBelum ada peringkat

- QFEST Proceedings 2017Dokumen229 halamanQFEST Proceedings 2017GogyBelum ada peringkat

- Clextra For Project ManagementDokumen9 halamanClextra For Project ManagementCasper AbrahamBelum ada peringkat

- Mochiko ShoesDokumen9 halamanMochiko ShoesPraveen SehgalBelum ada peringkat

- Technical Specification Clamp Nut BoltDokumen20 halamanTechnical Specification Clamp Nut Boltpiyush_123456789Belum ada peringkat

- Improve company operations with a functional ISM projectDokumen10 halamanImprove company operations with a functional ISM projectSachin BorkkarBelum ada peringkat

- Banner Buffalo BullDokumen3 halamanBanner Buffalo Bullanon_579800775Belum ada peringkat

- V2 I4 Naniwa Newsletter OFFICIALDokumen4 halamanV2 I4 Naniwa Newsletter OFFICIALNigelBelum ada peringkat

- APW7159ADokumen23 halamanAPW7159AVoicu AdrianBelum ada peringkat

- RecordManager User GuideDokumen96 halamanRecordManager User GuidemandapatiBelum ada peringkat

- Steam Nozzles: Prepared by Venkat Chintala Asst. Prof. S.G. Mechanical Engg. Deptt., UPESDokumen50 halamanSteam Nozzles: Prepared by Venkat Chintala Asst. Prof. S.G. Mechanical Engg. Deptt., UPESRaj NarayanBelum ada peringkat

- CA7 CommandsDokumen9 halamanCA7 CommandsArvindUpadhyayBelum ada peringkat

- Practice-1 defining calendarsDokumen5 halamanPractice-1 defining calendarspramod nagmotiBelum ada peringkat

- BSRMDokumen2 halamanBSRMAbul Kalam AzadBelum ada peringkat

- 11188-04 InstructivoDokumen20 halaman11188-04 InstructivoLuis AlonsoBelum ada peringkat

- FXG (FG-FXG) : Duplex Power PumpDokumen2 halamanFXG (FG-FXG) : Duplex Power PumpJose Alberto Escalante MedinaBelum ada peringkat