Boiler Offer

Diunggah oleh

Manohar PandianJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Boiler Offer

Diunggah oleh

Manohar PandianHak Cipta:

Format Tersedia

Ennaar

ENNAAR ENERGY SYSTEMS

******************************************************************************************************************************************

ENR/ERFS/2604-1/2013-2014 To

26/04/2013

******************************************************************************************************************************************

Kind Attn: Dear Sirs,

Mr.Shyamsundar. S.

Sub: 5TPH boiler submission of offer- Reg. REF: PERSONAL DISCUSSION HAD WITH YOU

With reference to the above discussion had with you, please find herewith enclosed for the following Annexure for your consideration and scrutiny. ANNEXURE ANNEXURE ANNEXURE ANNEXURE ANNEXURE ANNEXURE ANNEXURE I II III IV V VI MAIN TECHNICAL SPECIFICATION SCOPE OF SUPPLY MAIN EXCLUSIONS BATTERY LIMITS SUB-VENDOR ITEMS MAKERS PERFORMANCE CRITERIA

VII PRICE SCHDULE

We trust the features and specifications described in the enclosed content sheet to be in line with your requirement and price wise competitive.

We hope you will favor us with your valuable order. Yours faithfully, For ENNAAR ENERGY SYSTEMS

N.Rajamanickam Managing Director. 919843030547.

Ennaar

ENNAAR ENERGY SYSTEMS

ANNEXURE - I MAIN TECHNICAL SPECIFICATION : External Furnace Water Wall and Shell Type boiler : 5 TPH (F&A100*C) : 10.54 Kg/cm2 (g) Safety Valve setoff. : Agro Waste ,Brickgates(multi Fuel)Manual Feeding : 185C (Saturated) : 3500 Kcal/kg with 10% moisture. : : : : On / Off Mobery Control. Manual Feeding. Continuous discharge thro ash feeder below MDC and other ash chutes. Manual operating leverage. Manual

1. Type of Boiler

2. Evaporation Capacity 3. Working pressure 4. Fuel

5. Steam Temperature 6. GCV of Fuel 7. Operation a. Water b. Fuel c. Ash

d. Air & gas dampers 8. Type of Fuel feeding 9. Heating Surface Area

: :

: 190 Sq m

10. PRESSURE PARTS MATERIAL SPECIFICATION Shell & End Plates Headers Water wall & Fire tubes Ductings : SA 516 GR 70/ SA 515 Gr 70 : SA 106 GR B : BS 3059 Pt-1 Gr-320 ERW : IS 2062 2 nos. (1 W + 1S) Multistage, Centrifugal, Vertical 415 V 50 Hz 3 Phase, 4 wire, AC supply.

11. Feed Water arrangement a) No. of pumps with motor : b) Type : 12. Electrical connection for panel board a) Voltage : b) Frequency : c) Type : 13. ELECTRICAL LOAD ID Fan FD Fan Feed Pump

: - 25 HP / 4P : - 7.5 HP / 2P : - 10 HP / 2P

Frame-180L Frame-200L

Ennaar

ENNAAR ENERGY SYSTEMS

ANNEXURE - II SCOPE OF SUPPLY FOR BOILER

SCOPE OF SUPPLY:

01.MAIN BOILER

1.1. Radiant Water Wall Furnace with Bottom & Top Headers. 1.2. Horizontal Multi-Tubular Shell with Valves & Fittings. 1.3. Feed delivery line from outlet of feed pump to boiler 2 nos. 1.4. Blow Down Line Up To Blow Down Valve - 1 No. 1.5. Risers And Down Comers Connecting Shell & Water Wall Headers.

02. VALVES & FITTINGS

1. Main steam stop valve 2. Air Vent Valve 3. Single post safety valve 4. Feed Line NRV(Disc Type) 5. Blow down valve with key 6. Isolation valve for blow down 7. Water level gauges 8. Steam pressure gauge 9. Isolation valve for steam pressure gauge 10. Syphon Tube with Flange 11. Header Drain Valve (Water Wall) 12. Automatic Water Level Controller 13. Isolation Valve for AWLC 14. Fusible Plug 15. Feed Pump Suction Strainer 16. AWLC Drain Valve 03. Non-Pressure Parts:

- 1 no. (150 NB) - 1 No. (25 NB) - 2 nos. (40 NB) - 2 Nos. (40 NB) - 1 no. (40 NB)

- 1 no. (40 NB) - 2 set. (20 NB) - 1 no. - 1 no. - 1 Set (10) (20 NB) (3/4)

- 2 Nos. (25 NB) - 1 No. (25 NB) (1) (40 NB)

- 2 Nos. (25 NB) - 1 No. - 1 No.

- 1 NO. (15 NB)

1. Multi tubular vertical 2 pass air Pre-heater with ash chute at the bottom. 2. Forced draught air ducting from FD fan to air preheater and from air heater to Furnace 3. Mechanical Dust Collector with ash Feeder . Auxiliaries: 1. One number FD Fan with motor. 2. One number ID Fan with motor. 3. 2 Nos. Of boiler feed water pumps with motor.

Ennaar

ENNAAR ENERGY SYSTEMS

Electrical and Instrumentation: 1. One no. fully prewired free standing combination type control Panel (Non-IBR) with input & output circuits grouped together For ease of connection to power supply consists of. - Alarm annunciation. - Hooter for alarm annunciation. - Ammeters. - Safety interlocks system. - Start / stop push buttons. - Starters for motors. 3. 1 No. of Automatic water level controller with 2 Nos. of Isolation valves and 1 No. of drain valve. 4. Pressure Switch - 1 No 04. Safety interlocks system. If water level is very low, all the fans will trip Unless ID Fan is ON, FD Fan would not run Alarm for the following conditions Water level very low Steam Level High FD & ID fan tripped Feed Pump I & II Stoped

Ennaar

ENNAAR ENERGY SYSTEMS

ANNEXURE - III EXCLUSIONS FOR SUPPLY

a. b.

Boiler house civil work and foundation. Supply, erection and commissioning of Boiler and accessories like water softening / treatment plant, Storage tanks , Pipings, Fuel / Ash han dling systems, steam piping etc., required to operate the boiler. Fuel, feed water, dosing chemicals, first charge lubricants Boiler Shell Pedestal Civil work customer scope. Incoming electrical connection to the control panel and cabling from panel to individual drives. Steam Pipe line Labor charges with material Customer Scope

c. d. e.

f.

g. h. i. i. j. k. ladder

Unloading boiler and all accessories Any other items which are not mentioned specifically in supplier scope Self Supported Chimney Suitable for this Boiler Supply of Feed Water Tank (10KL) and Structurals Supply of Flue Gas Ducting Boiler to Chimney. Structural for Water wall, APH, MDC, Plat form for Boiler Hand rails and Reversing Camper operating plat form with Structural.

l. m. n. o.

Transport and Transit Insurance IBR Formalities for Registration fees, Erection fees Feed water tank to feed water pumps Pipes, Valves and Strainer Erection of Boiler, Chimney, feed water tank with structural APH, MDC, ID , FD Fan with all inter connecting up to Chimney. Insulation of Boiler and Feed water Tank refractory materials for Boilers.

p. q.

Ennaar

ENNAAR ENERGY SYSTEMS

ANNEXURE - IV

BATTERY LIMITS FOR SUPPLY

STEAM

: - Up to outlet flange of Main Steam Stop Valve. - Upto Outlet flange of air vent & safety valve in steam drum - Upto outlet flange of auxiliary valve in steam drum. - Upto outlet flange of start up air vent valve. : - From inlet flange of feed water pump.

WATER

BLOWDOWN : - Upto outlet flange blow down valve.

DRAIN : - Drain lines from outlet of all drain valves upto ground Level (Terminated at the bottom of civil trench) AIR : - From Inlet flange of FD fan.

FUEL

: - From Inlet of Fire Door

ASH hoppers.

: - Upto Discharge flange of ash feeder below the MDC and other ash

FLUE GAS : - Upto Outlet flange of ID fan.

ELECTRICAL in control

: - Incoming and Outgoing main cable connection terminal points Panel. - Input and output terminals of individual equipments.

Ennaar

ENNAAR ENERGY SYSTEMS

ANNEXURE - V

SUB-VENDOR MAKER NAMES

6.1 6.2 6.3 6.4 6.5 6.6 6.7 6.8

Feed Pumps Motors Main steam valve Other valves Blow down valves Safety valve Water level gauge Control Panel

: CRI : Crompton : Utam : Utam : Levcon : Darling Muesco : Attam/uttam : ENNAAR : Aksan Air : H. Guru : Infos

6.9 Fans 6.10 Pressure gauge 6.11 Pressure Switch

Ennaar

ENNAAR ENERGY SYSTEMS

ANNEXURE - VI PERFORMANCE CRITERIA FUEL: The output and other performance parameters of the boiler specified in this offer hold good only if fuel of the following specification is charged to the boiler. Any variation in the specifications of fuel will alter the performance parameters. Fuel - GCV 3500Kcal/kg with 10 % moisture. WATER: The performance parameters of the boiler under this offer are based on filtered and treated Water of the following quality being available. f. Feed water and boiler water quality: Feed water analysis at the inlet of boiler (by customer): General appearance : Clear & colour less Total hardness as Cac ppm : Nil Oil & organics ppm : Nil Ph value at 25C : 8.8 to 9.2 Total dissolved solids ppm : 1.0 Silica Si02 ppm : 0.02 Boiler water analysis in the drums (by customer): Ph value at 25C : 9.8 to 10.2 Phosphate residual ppm : 15 - 25 Total dissolved solids ppm : 1500 Specific electrical conductivity : 3000 At 25C US/CM Silica Si02 ppm : 10 Sodium sulphate ppm : Nil Alkalinity max. ppm : 300

Ennaar

ENNAAR ENERGY SYSTEMS

ANNEXURE VII

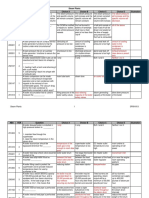

PRICE SCHEDULE

1. Design and Supply of ERFS 50 x 10.54 Kg/cm g Agro waste with above accessories as detailed in our offer would be @.Rs. 39 ,50,000/(Rupees Thirty Nine Lacs Fifty Thousand only)

2. Fabrication & supply of Self support chimney 100Ft Height suitable for above boiler 3. Fabricaton & Supply of MS Feed water 8KL With Structurals 4. Air & Flue Gas Ducting 5. Erection & Commissioning of Boiler @ Rs.2,25,000/@ Rs.90,000/@Rs.7,50,000/@ Rs.3,90,000/-

Ennaar

ENNAAR ENERGY SYSTEMS

COMMERCIAL TERMS AND CONDITIONS 1. 2. 3. BASIS OF PRICE: - Ex-works, Perundurai. EXCISE DUTY: CST: NOTE: Applicable at the Time of dispatch.

2% Applicable against C Form. Any change in the above rates of ED & CST rates at the time of delivery will be extra to your account.

4. Transportation & Transit Insurance 5.

: Buyer's Scope.

DELIVERY: - Delivery of the boiler will be within 90 -120 days from the date of receipt of your technically and commercially clear order with advance subject to force majeure conditions.

8.

PAYMENT:1. 50% advance along with the order. 2. 25% second advance after 45 days. 3. Balance Payment with Taxes before despatch against Proforma invoice.

9.

VALIDITY: - 30 days from the date of this offer. For ENNAAR ENERGY SYSTEMS N.Rajamanickam Managing Director. 9843030547.

Branch Office: No. 2, Vavila Comples, Palladam Road, Tirupur 641 605. Ph : 0421 2214618 Fax : 0421 2212147 E-mail : boiler @ennaarenergysystems.in Mobile : +91 94437 63027

TIN. : 33302923555 CST No.: 883973 dt.26.5.2006

H. O & Factory : Plot No. : C 1. Sipcot Industrial Growth Centre, PERUNDURAI 638 056. Ph : 04294 234184/234185 Fax : 04294 - 234186 Web : www.ennaarenergysystems.in Mobile : +91 98430 30547.

Anda mungkin juga menyukai

- 1 TPH 10.54 KG, Vapi Care PharmaDokumen16 halaman1 TPH 10.54 KG, Vapi Care PharmashastrysnBelum ada peringkat

- Husk Based Power Plant 6T 32 KG FBC With Single Stage Turbine - For Finance, Subsidy & Project Related Support Contact - 9861458008Dokumen28 halamanHusk Based Power Plant 6T 32 KG FBC With Single Stage Turbine - For Finance, Subsidy & Project Related Support Contact - 9861458008Radha Krishna SahooBelum ada peringkat

- 400kgs Steam Boiler Oil FiredDokumen5 halaman400kgs Steam Boiler Oil FiredManikandanBelum ada peringkat

- Boiler: Heat Sources Materials Energy Boiler EfficiencyDokumen10 halamanBoiler: Heat Sources Materials Energy Boiler EfficiencyrpercorBelum ada peringkat

- 2ND CLASS Boilers in Lahore CircleDokumen14 halaman2ND CLASS Boilers in Lahore CircleGoldenshakehandBelum ada peringkat

- Presentation of PressureDokumen44 halamanPresentation of PressureMuskan GargBelum ada peringkat

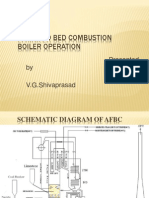

- FBC Operation II OperationDokumen21 halamanFBC Operation II Operationanbesivam87Belum ada peringkat

- Gasification and PyrolysisDokumen12 halamanGasification and Pyrolysismani kantaBelum ada peringkat

- Heat Rate of Thermal Power PlantDokumen15 halamanHeat Rate of Thermal Power Plantsameer betal100% (1)

- Bhatia Gummidipoondi WHRSG O&m Manual FinalDokumen224 halamanBhatia Gummidipoondi WHRSG O&m Manual Finalt_syamprasadBelum ada peringkat

- Boiler DataDokumen28 halamanBoiler DataMonique ThomasBelum ada peringkat

- HMBD Review Check ListDokumen4 halamanHMBD Review Check Listctraminst_81Belum ada peringkat

- Designing of A Fire Tube Boiler: Author Name/sDokumen7 halamanDesigning of A Fire Tube Boiler: Author Name/sMohit JagtapBelum ada peringkat

- Design of Incinerator Plant For Vasai-Virar RegionDokumen4 halamanDesign of Incinerator Plant For Vasai-Virar RegionVIVA-TECH IJRIBelum ada peringkat

- DraughtDokumen33 halamanDraughtNipun SabharwalBelum ada peringkat

- Claver Brooks General Boiler InformationDokumen10 halamanClaver Brooks General Boiler Informationnecio77Belum ada peringkat

- EPRF Report Com Fulton Steam BoilersDokumen13 halamanEPRF Report Com Fulton Steam BoilersBlackzero68Belum ada peringkat

- Glaxo Vol IDokumen164 halamanGlaxo Vol IPrakash WarrierBelum ada peringkat

- Bill of Quantities of M. S. Pipe Fittings (O-14027)Dokumen4 halamanBill of Quantities of M. S. Pipe Fittings (O-14027)Tanmoy DuttaBelum ada peringkat

- Chap 28 PDFDokumen30 halamanChap 28 PDFnelson escuderoBelum ada peringkat

- Miura Boilers Steam GeneratorsDokumen2 halamanMiura Boilers Steam GeneratorsDhonyAhmedPradjoegoBelum ada peringkat

- Boiler: Sabari Girish N Sr. Engineer (O)Dokumen37 halamanBoiler: Sabari Girish N Sr. Engineer (O)Deepak SinghBelum ada peringkat

- AFMC (Medical) Solved Paper 2013 PDFDokumen32 halamanAFMC (Medical) Solved Paper 2013 PDFAnkur BanerjeeBelum ada peringkat

- Afbc Vol-IiDokumen81 halamanAfbc Vol-IiVijay RajBelum ada peringkat

- List of CHP EquipmentsDokumen7 halamanList of CHP EquipmentsbrockBelum ada peringkat

- Chimney Sizing PDFDokumen13 halamanChimney Sizing PDFtitieBelum ada peringkat

- Butterfly Valve Catalogue PDFDokumen25 halamanButterfly Valve Catalogue PDFPriyanka rajpurohitBelum ada peringkat

- Eil Spec For Architechture-6-75-0051 - Rev 0Dokumen14 halamanEil Spec For Architechture-6-75-0051 - Rev 0innovativekarthiBelum ada peringkat

- Boiler (Steam Generator) : From Wikipedia, The Free EncyclopediaDokumen20 halamanBoiler (Steam Generator) : From Wikipedia, The Free EncyclopediaCarlito PantalunanBelum ada peringkat

- Overdue Document Report 07 May 22Dokumen18 halamanOverdue Document Report 07 May 22MEZOUED ALIBelum ada peringkat

- Steam Boiler ProjectDokumen32 halamanSteam Boiler ProjectSwastik BhokareBelum ada peringkat

- Compressor Inlet Piping - Compressed Air Best PracticesDokumen10 halamanCompressor Inlet Piping - Compressed Air Best PracticesBehroozRaadBelum ada peringkat

- Cogenerations of Energy From Sugar Factory BagasseDokumen8 halamanCogenerations of Energy From Sugar Factory BagasseTade GaromaBelum ada peringkat

- Z-16-412 R0 CB20SG X 1 No Boiler SupplyDokumen15 halamanZ-16-412 R0 CB20SG X 1 No Boiler SupplyBashir AliBelum ada peringkat

- Title: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectDokumen24 halamanTitle: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectRamalingam PrabhakaranBelum ada peringkat

- CDQ Layout 567Dokumen1 halamanCDQ Layout 567Amit BalotBelum ada peringkat

- Boiler O&M - DESCONDokumen218 halamanBoiler O&M - DESCONppraveenkumar79100% (1)

- Biomass (Rice Straw) Fired BoilerDokumen9 halamanBiomass (Rice Straw) Fired BoilerSnehashis MaityBelum ada peringkat

- Note - All Yellow Cells Are Manditory To Be FilledDokumen2 halamanNote - All Yellow Cells Are Manditory To Be FilledPrashant SinghBelum ada peringkat

- RooftopDokumen4 halamanRooftophjduarteBelum ada peringkat

- Sa 423Dokumen6 halamanSa 423Widya widyaBelum ada peringkat

- Instrumentation Scheme of Thermal Power PlantDokumen39 halamanInstrumentation Scheme of Thermal Power Plantgdreddy25Belum ada peringkat

- Product Specification: Forbes-Bryan Low Corrosion Tray Type Deaerator - 5Mw To 400MwDokumen3 halamanProduct Specification: Forbes-Bryan Low Corrosion Tray Type Deaerator - 5Mw To 400MwCarlos ACBelum ada peringkat

- p101516-010 Rev.1 Gland Steam Condenser Specification Stg62Dokumen2 halamanp101516-010 Rev.1 Gland Steam Condenser Specification Stg62Rais RijalBelum ada peringkat

- AccumulatorsDokumen11 halamanAccumulatorsRufus D SBelum ada peringkat

- Steam PlantsDokumen228 halamanSteam PlantsMark Allen San Antonio100% (1)

- Industrial BoilersDokumen22 halamanIndustrial BoilersAbdul Razzaq MughalBelum ada peringkat

- Waste Heat Recovery System For RefrigeratorDokumen10 halamanWaste Heat Recovery System For RefrigeratorlalkrishnaBelum ada peringkat

- SUR - Erection BOQ - ST & Geno - Rev ADokumen5 halamanSUR - Erection BOQ - ST & Geno - Rev Ashaikhsajid242Belum ada peringkat

- Crompton Price ListDokumen6 halamanCrompton Price ListVarun MalhotraBelum ada peringkat

- Boiler CalculationsDokumen16 halamanBoiler CalculationshuliplayBelum ada peringkat

- Storage CalorifiersDokumen5 halamanStorage CalorifiersVishnu ThampiBelum ada peringkat

- IND Ahmedabad.426470 ISHRAE - StatDokumen35 halamanIND Ahmedabad.426470 ISHRAE - Statnikita chawlaBelum ada peringkat

- Research Study Diesel To BiomassDokumen9 halamanResearch Study Diesel To BiomassDarrel MagnoBelum ada peringkat

- Request Form JaimonDokumen306 halamanRequest Form JaimonjaimonjoyBelum ada peringkat

- Design of Boiler Forced Draft FanDokumen5 halamanDesign of Boiler Forced Draft FanAu TagolimotBelum ada peringkat

- Boiler FormulasDokumen3 halamanBoiler FormulasCaliman SabinaBelum ada peringkat

- Boiler AnnexDokumen66 halamanBoiler Annexrenjithv_4Belum ada peringkat

- Quotation Cold Room An NAM Group - 17 Aug 2010Dokumen12 halamanQuotation Cold Room An NAM Group - 17 Aug 2010huyly34Belum ada peringkat

- Company Profile-1Dokumen11 halamanCompany Profile-1Waliyyu Muhammad RaafiBelum ada peringkat

- NFPA Liquefied Petroleum Gas Code 58 Fire Safety Analysis Plan and O&M Instructions For Propane Storage SystemsDokumen42 halamanNFPA Liquefied Petroleum Gas Code 58 Fire Safety Analysis Plan and O&M Instructions For Propane Storage Systemsquiron2014Belum ada peringkat

- 4-Engine Components and SystemsDokumen103 halaman4-Engine Components and Systemswigung tri febriantoBelum ada peringkat

- 04 DST ConceptsDokumen29 halaman04 DST ConceptsH-sam A-somethingBelum ada peringkat

- FR 91674Dokumen3 halamanFR 91674Juan Diego SarangoBelum ada peringkat

- 3-MasstoMassStoichiometryProblem1 2Dokumen3 halaman3-MasstoMassStoichiometryProblem1 2kjjkimkmkBelum ada peringkat

- E12028 PDFDokumen6 halamanE12028 PDFZamir Andres SencioBelum ada peringkat

- Material Groups API 650Dokumen2 halamanMaterial Groups API 650jojo_323100% (2)

- Industry Leader For Gas Turbine Power: Saturn Mercury MarsDokumen4 halamanIndustry Leader For Gas Turbine Power: Saturn Mercury Marsaleypa100% (1)

- Komatsu Truck 930 4 Shop Manual CEBM017904 PDFDokumen1.027 halamanKomatsu Truck 930 4 Shop Manual CEBM017904 PDFRamos Boris100% (1)

- Chemical Solutions in Everyday LifeDokumen5 halamanChemical Solutions in Everyday LifeMarcos Oyama100% (1)

- Multi Port Valve ManualDokumen2 halamanMulti Port Valve ManualJithin JamesBelum ada peringkat

- Compressor Start Up ChecklistDokumen2 halamanCompressor Start Up Checklistramy86Belum ada peringkat

- Electronic Ignition Systems: CM WP ME HA AP LG EP CS IN EL AV TO PS BVDokumen1 halamanElectronic Ignition Systems: CM WP ME HA AP LG EP CS IN EL AV TO PS BVRaju GuptaBelum ada peringkat

- MEP OnlineDokumen49 halamanMEP OnlineVyas SrinivasanBelum ada peringkat

- National Lodge: Opp. Tahseel Road, Kaiserganj, BahraichDokumen8 halamanNational Lodge: Opp. Tahseel Road, Kaiserganj, BahraichMANJUL joshiBelum ada peringkat

- Report ONGCDokumen47 halamanReport ONGCMehul SutariyaBelum ada peringkat

- Seminar Report SampleDokumen22 halamanSeminar Report SampleDhruve EBBelum ada peringkat

- Calibration Steps2 Procedure TVA2020Dokumen6 halamanCalibration Steps2 Procedure TVA2020Doug Wilson100% (1)

- Flushing Oil Flooded Rotary Screw Air Compressors Procedure enDokumen2 halamanFlushing Oil Flooded Rotary Screw Air Compressors Procedure enSergiSerrano100% (1)

- GT Mtc. PracticesDokumen59 halamanGT Mtc. PracticesAbhishek Prakash SrivastavaBelum ada peringkat

- Guidelines For Ethylene Quench Tower Rev 17Dokumen17 halamanGuidelines For Ethylene Quench Tower Rev 17totongop0% (1)

- Manual CAT 924HZDokumen681 halamanManual CAT 924HZRoger Schmidt100% (2)

- Incineration of Styrene-Butadiene Rubber: The Influence of Heating Rate and Oxygen Content On Gas Products FormationDokumen14 halamanIncineration of Styrene-Butadiene Rubber: The Influence of Heating Rate and Oxygen Content On Gas Products FormationPhilip ShihBelum ada peringkat

- Comparison of Single and Double Hull TankersDokumen9 halamanComparison of Single and Double Hull Tankersyann1982100% (2)

- KTA38 M2 010 018 KTA 50 Cooling SystemDokumen3 halamanKTA38 M2 010 018 KTA 50 Cooling SystemSpectrumRaijin0% (1)

- Azure Dynamics Emergency Response Guide PDFDokumen32 halamanAzure Dynamics Emergency Response Guide PDFwopontourBelum ada peringkat

- How To Select Your Dosing SetDokumen2 halamanHow To Select Your Dosing SetGrundfosEgyptBelum ada peringkat

- API 1104 Practice ExaminationDokumen9 halamanAPI 1104 Practice ExaminationJaime Oscanoa100% (3)