Air Inflation Method

Diunggah oleh

nsriitmHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Air Inflation Method

Diunggah oleh

nsriitmHak Cipta:

Format Tersedia

covering "Les Arenes de Nim.

es' wi tb

an air-inflated

Pa~ric

structure

Dipl.lnq. RUdolf Berqarmann Dr.lnq. Werner Sobek

situation In 1986, the municipal authority of Nimes considered to huild a new t.own hall in the center of the "ville romaine". These intentions finally could not be realized because of problems with suitable sites. Besides there was no need for a town hall during summer time: The ancient arena, built nearly 2000 years ago, still is the center of the cultural life within this period. Within the last years it even became more attractive because of a number of events and activities.

1.

Together with a team of architects, we therefore started to develop and to design a structure which should cover the central part of the arena.

2. structure The ancient arena is classified as a historical monument. Therefore all modifications of the existing structure have been prohibited. In addition, the designers have been asked to develop a structure which was not able to be seen from the

2 -

surrounding streets, and, which has to be removed totally from the arena during summertime. The structure therefore has been designed under the imperative of a quick annual erection and dismantling procedure. Reduction of deadload became a necessity. The design yielded to a lightweight structure which is able to be installed within 21 days, designed to withstand a windspeed of 200 km/h and able to carry a snow load of 360 to - more than twice the deadweight of the new building. The (loadbearing) structure is composed out of 3 parts: 30 columns with a height of 9.80 m have been placed along the perimeter of an ellipse. They carry an elliptic steel-ring which is fixed excentrically onto the top of the columns. An air inflated cushion with a span of 60 x 90 m has been arranged within the ellipse defined by the ring. Fig.l. The air inflated cushion consists out of PVc-coated PETPfabric membranes. Several single membranes may be distinguished : The upper membrane, the lower membrane (layed onto a reinforcing cable net), the sealing membrane and the hightranslucent covering membrane. Fig.2. The upper as well as the lower membrane are edged by 30 garland cables. These cables transfer the forces from the mem-

- 3 -

brane to the columns resp. the steel-ring. Therefore the steel-ring acts as a compression element. Although the ring is loaded with compression forces in the range of more than 400 tons, it could be realized as a hollow box beam with a cross-section of only 300 x 500 rom: Global stability is ensured by the cushion. The upper and the lower membrane are connected by a so called "sealing membrane". This membrane completes the cushion. It is fixed onto the upper as well as onto the lower membrane. It may be opened along its equator using a loop-fastener, and, to ensure proper air-tightness, an additional zip. Because the cushion is fixed onto the ring at only 30 points, a translucent "covering membrane" has been spanned from the upper membrane to the steel-ring, in order to close the eyeshaped openings.

An inclined facade spans from the upper steel-ring to a lower

facade-ring. It completes the building. The facade had to be transparent because we wanted to use the ancient masonry outside the new Duilding as a scenery. Therefore we developed a facade which consists out of about 450 hollow box beams. These beams show a rhombus-shaped cross-section, realized by 3 mm Polycarbonate-plates. An internal aluminium web reinforces the transparent beam. The beams have to carry the same severe wind and snow loading as the main structure. Therefore

4 -

detailed analysis and loading tests have been carried out. They showed that the deformations of the elements still remain within the limits defined by the french building codes. The beams can be rotated by 90 degrees around their axis. Because of their rhombus-shaped cross-section, the entire facade can be opened this way, crnating a natural ventilation. The loadbearing capacity of the cushion is guaranteed by the internal pressure. The level of the internal pressure has been defined in order to carry full snow loading resp. to avoid flattering of the fabric, even under heavy wind loading. While the first type of loads had been defined by the French building codes, detailed wind tunnel tests have been carried out in order to obtain the most realistic wind load distribution. studies of positive/negative pressure situations within the auditorium, caused by different opened/closed door arrangements, have completed the table of windloads finally. Nonlinear finite element analysis has been applied to evaluate the loadbearing behaviour of the structure in detail and to confirm the choice of the levels of the air-pressure within the cushion.

5 -

The pressure within the cushion is provided by four blower units. Two of them, equipped with a sound absorbing system, are powered by electric engines. The remaining two blowers are diesel-powered. one engine is sUfficient to guarantee the . proper air-pressure within the cushion. An air-pressure measurements device manages the speed of the active b~ower. During the blowing up of the cushion (end of .erection), all 4 blowers are running parallel. Caused by their huge capacity 3/hour, they are able to inflate the cushion witof 75 000 m hin 25 minutes.

3. The Membranes All membranes are composed out of PVC-coated PETP-fabrics. This material has been chosen because of its good ability to be folded and stored each year, its high loadbearing capacity and because of the qood behaviour of the material and its joints under the influence of environmental effects. Different qualities of materials have been chosen, depending on the forces they have to carry as a structural element: The upper membrane is a quality type GUWA IV. Yarn is 1670 dtex, weave is P 3/3. The greycloth-weight is about 490 gr/sqm, total weight is about 1300 gr/sqm. The tensile strength is 149/128 kN/m (short term loading, 23 degrees).

- 6 -

The strips of the cut material have been joined using an 80 rom HF-welding and, in addition, four backstitch sewings. The entire upper membrane has a surface of about 4000 sqrn. Material tests have been carried out in order to achieve a guaranteed high level of strength of the joints. For the upper membrane, tests have been done for all types of joints at 23 and 70 degrees. The lower membrane is a quality type GUWA II. Yarn is 1100 dtex, weave is P 2/2. The greycloth-weight is 275 gr/sqm, total weight is 900 gr/sqm. The tensile strength is 104/116 kN/m. The single strips have been joined using an 60 mm HFweld. The strength of the lower membrane is less then the strength of the upper one: The lower membrane is laid onto a cable net. Therefore the span of the membrane is in the range of 7 by 7 m only. The entire lower membrane with about 4000 sqm, as well as the upper one, has been delivered as one pieceo The sealing membrane also is a quality type GUWA II. It has been fixed onto the upper resp. the lower membrane using an 60 mm HF-weld. The translucent covering-membrane is a grid-fabric (widemeshed fabric). Weave is LIll, total weight is 700 gr/sqm.

7 -

Tensile strength is 40/36 kN/m. The single strips have been joined using a 40 mm HF-weld.

4. cutting pattern In order to realize the shape of the cushion as precise as possible, the evaluation of the cutting pattern has been done using computer-based methods. For these procedures, the entire surface of the cushion (incl. sealing membrane) has been transfered into a digital surface model. Based on this model, the single strips of the membrane have been designed under the aspects of their maximum width and under the aspect of an optimum seam-layout. For the upper as well as for the lower membrane, a so called "mixed-pattern" has been chosen. This means that there is a radial strip arrangement at the edges and a parallel arrangement of strips in the center area of the surfaces. Totally, the upper membrane consists out of 144 strips with a maximum length of 84 m and a maximum width of 2.50 m. The lower membrane consists out of 140 strips, the sealing membrane is composed out of 92 strips and the translucent covering ," membrane consists out of 124 strips.

- 8 -

5. List of persons and firms involved: Maitrise d'ouvrage : Ville de Nimes

Design, analysis and detailing : LAB F AC F. Geipel, by architects and engineers N. Michelin, Paris and stuttgart Schlaich Bergermann und Partner, stuttgart steel contractor : Baudin Chateauneuf, Chateauneuf sur Loire, Groupement des Metalliers du Gard, Nimes : Stromeyer Ingenieurbau, Konstanz : Verseidag, Krefeld Hammersteiner, Huckelhoven : Merlo, Torino General Electric France, Paris : IF, l<onstanz

Membranes

Material by

Facade Material by

Conception of the Montage

Fig. 1: The main parts of the structure

10 -

Sealing Membrane

Ring-beam

Column

Fig. 2: Detailing of the cushion at its edge.

Anda mungkin juga menyukai

- Crane Request FormDokumen1 halamanCrane Request FormnsriitmBelum ada peringkat

- TKBT Machinery Folder enDokumen48 halamanTKBT Machinery Folder ennsriitmBelum ada peringkat

- Hanging Other Construction From CorefloorDokumen1 halamanHanging Other Construction From CorefloornsriitmBelum ada peringkat

- Hollow CoreDokumen41 halamanHollow Corepaulo_arrieiroBelum ada peringkat

- Precast Concrete FloorslabDokumen37 halamanPrecast Concrete FloorslabBanu Umashankar100% (3)

- RCC81 Foundation PadsDokumen15 halamanRCC81 Foundation PadsnsriitmBelum ada peringkat

- 140t Telecopic CraneDokumen1 halaman140t Telecopic CranensriitmBelum ada peringkat

- Load Chart With Fly JibDokumen3 halamanLoad Chart With Fly JibnsriitmBelum ada peringkat

- 04 03Dokumen17 halaman04 03nsriitmBelum ada peringkat

- SOW BH-Geotech BH - Piezo TP PLT DCPT Ert In-Situ CBR Given by L&T (PABS Package) 8 - 5 2 1 4 1 Completed As On 28 FebDokumen1 halamanSOW BH-Geotech BH - Piezo TP PLT DCPT Ert In-Situ CBR Given by L&T (PABS Package) 8 - 5 2 1 4 1 Completed As On 28 FebnsriitmBelum ada peringkat

- Ace CraneDokumen6 halamanAce CranensriitmBelum ada peringkat

- Reparation of The Ob Ite: G I C I FP-T I RDokumen1 halamanReparation of The Ob Ite: G I C I FP-T I RnsriitmBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1091)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Organic Chemistry, Chem 231 Lab Manual S2013Dokumen69 halamanOrganic Chemistry, Chem 231 Lab Manual S2013danthetoasterBelum ada peringkat

- Heterocyclic CompoundsDokumen26 halamanHeterocyclic Compounds29decBelum ada peringkat

- Liquid ALT (SGPT) Reagent SetDokumen2 halamanLiquid ALT (SGPT) Reagent SetYahya RizkiBelum ada peringkat

- Dioxido de Titanio R-2196+ - TDSDokumen1 halamanDioxido de Titanio R-2196+ - TDSBenito JuárezBelum ada peringkat

- Technical Handbook Parker HosesDokumen620 halamanTechnical Handbook Parker HosesjoebrazBelum ada peringkat

- ItpDokumen2 halamanItpVinay YadavBelum ada peringkat

- Soil Fertility and Plant Nutrition: Rogelio R. Picart JR., Lic. AgrDokumen14 halamanSoil Fertility and Plant Nutrition: Rogelio R. Picart JR., Lic. AgrJevelyn Mendoza FarroBelum ada peringkat

- Concrete Reinforcement and Glass Fibre Reinforced PolymerDokumen9 halamanConcrete Reinforcement and Glass Fibre Reinforced PolymerchanakaBelum ada peringkat

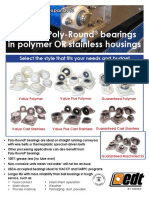

- Solution Poly-Round Bearings in Polymer OR Stainless HousingsDokumen3 halamanSolution Poly-Round Bearings in Polymer OR Stainless HousingsLeroy AraoBelum ada peringkat

- COD Anaysis and ReductionDokumen13 halamanCOD Anaysis and ReductionelaBelum ada peringkat

- 102 Na04529a IlzheDokumen12 halaman102 Na04529a IlzheIstvan MadacsyBelum ada peringkat

- Disolutions PDFDokumen28 halamanDisolutions PDFarcilalilianaBelum ada peringkat

- PLATE & SHELL Heat Exchangers: A Shell & Tube AlternativeDokumen4 halamanPLATE & SHELL Heat Exchangers: A Shell & Tube AlternativearianaseriBelum ada peringkat

- iGCSE Chemistry Revision SheetsDokumen26 halamaniGCSE Chemistry Revision SheetsPanagiotis ScordisBelum ada peringkat

- Res Guide Electromagnetic WavesDokumen8 halamanRes Guide Electromagnetic WavesbrsreddyBelum ada peringkat

- A Comprehensive Investigation On High-Pressure LDPE Manufacturing: Dynamic Modelling of Compressor, Reactor and Separation UnitsDokumen6 halamanA Comprehensive Investigation On High-Pressure LDPE Manufacturing: Dynamic Modelling of Compressor, Reactor and Separation UnitsAbdul SamadBelum ada peringkat

- ElectrochemistryDokumen24 halamanElectrochemistryZainul AbedeenBelum ada peringkat

- Enhancing The Stepped Solar Still Performance Using Internal Re EctorsDokumen6 halamanEnhancing The Stepped Solar Still Performance Using Internal Re EctorslinhBelum ada peringkat

- Chapter-6 Wall SystemDokumen102 halamanChapter-6 Wall SystemGebre Haile100% (1)

- Coconut OilDokumen12 halamanCoconut OilAniruddh KhalatkarBelum ada peringkat

- Pile Foundation DesignDokumen82 halamanPile Foundation DesignBhaskar ReddyBelum ada peringkat

- Apollo Valves 20 104 03 Instruction Installation ManualDokumen2 halamanApollo Valves 20 104 03 Instruction Installation ManualRobinson JimenezBelum ada peringkat

- Wolfson Eup3 Ch16 Test BankDokumen9 halamanWolfson Eup3 Ch16 Test BankifghelpdeskBelum ada peringkat

- Science Lab, 2013. Hal 1, 3 (MSDS Pot)Dokumen5 halamanScience Lab, 2013. Hal 1, 3 (MSDS Pot)Anggraini Hari Nur IndahsariBelum ada peringkat

- Hille B-Second Edition (For Printing)Dokumen617 halamanHille B-Second Edition (For Printing)matuskacarlosBelum ada peringkat

- NCERT Science ExemplarDokumen86 halamanNCERT Science ExemplarRishik Madan Jai100% (1)

- 2551 Blind Rev 17 English ManualDokumen16 halaman2551 Blind Rev 17 English ManualKadek Dwi PermanaBelum ada peringkat

- Student Exploration: Chemical EquationsDokumen6 halamanStudent Exploration: Chemical EquationsAndreBelum ada peringkat

- Flash Setting Info OnlyDokumen10 halamanFlash Setting Info OnlyAwais TariqBelum ada peringkat

- Horizontal Vertical Horizontal Moment Node L/C FX KN Fy KN FZ KN MX KNM My KNMDokumen7 halamanHorizontal Vertical Horizontal Moment Node L/C FX KN Fy KN FZ KN MX KNM My KNMEr Nilesh GajeraBelum ada peringkat