Io List

Diunggah oleh

Cahyanti Dwi WinartiJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

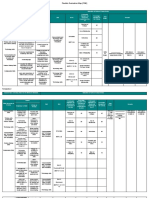

Io List

Diunggah oleh

Cahyanti Dwi WinartiHak Cipta:

Format Tersedia

Manual for Laboratory, PLC Connection.

Dublin Institute of Technology

Kevin Street

Dublin 8

Manual for Laboratory

PLC, HMI and SCADA

Version 2.0

Revision:

Version 2:

Chapter 6, Get started at some programming samples, insertion of

Module 9 Counters and incrementing the other Modules as a result,

January 2003.

Chapter 12, Analogue to Digital was added to cover A/D conversion

is based on the Mitsubishi manual FX2N 4AD.

Chapter 12, Conveyor Rig I/O list and photograph.

Lecturer: Dr. John McGrory

School of Control Systems and Electrical Engineering,

Dublin Institute of Technology, Room 10, Kevin Street, Dublin 8.

Phone:

+353-(0)1-402-2848

E-Mail:

john.mcgrory@dit.ie

Web Site: http://eleceng.dit.ie/jmcgrory/

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 1 of 122

Manual for Laboratory, PLC Connection.

Table of Contents

TABLE OF CONTENTS .................................................................................................................2

CHAPTER 1, HOW TO GET STARTED..........................................................................................5

STEP 1: HOW TO START THE PROGRAMMING TOOL ON THE PC ...........................................................5

STEP 2: HOW TO START A NEW PROJECT .........................................................................................6

STEP 3: HOW START PROGRAMMING ...............................................................................................8

STEP 4: CONVERT THE PROGRAM ...................................................................................................8

STEP 5: STOP THE PLC.................................................................................................................9

STEP 6: UP LOADING THE PROGRAM TO THE PLC........................................................................... 10

STEP 7: SWITCH THE PLC TO RUN MODE ..................................................................................... 12

STEP 8: MONITOR THE PLC ......................................................................................................... 12

CHAPTER 2, STAGES IN DEVELOPING A PLC SYSTEM .......................................................... 13

CHAPTER 3, SOME OF THE MAIN SECTIONS OF THE PLC DEVELOPER SCREEN................ 14

LADDER FUNCTION KEYS: ............................................................................................................ 14

TOGGLE BETWEEN LADDER LOGIC AND LIST OF INSTRUCTIONS ........................................................ 15

READ AND WRITE MODE ............................................................................................................... 16

MONITORING .............................................................................................................................. 16

PROJECT DATA LIST .................................................................................................................... 17

DOCUMENTATION, COMMENTS, STATEMENTS AND NOTES ............................................................... 18

PLC STATUS DIAGNOSTIC ........................................................................................................... 20

CHAPTER 4, DOWN LOAD FROM THE PLC............................................................................... 21

CHAPTER 5, GX DEVELOPER SUB SCREENS .......................................................................... 22

PROJECT SUBMENU .................................................................................................................... 22

EDIT SUBMENU ........................................................................................................................... 23

FIND/REPLACE SUBMENU ............................................................................................................ 23

CONVERT SUBMENU .................................................................................................................... 24

VIEW SUBMENU .......................................................................................................................... 24

ONLINE SUBMENU ....................................................................................................................... 24

DIAGNOSTICS SUBMENU .............................................................................................................. 25

TOOLS SUBMENU ........................................................................................................................ 25

CHAPTER 6, GET STARTED AT SOME PROGRAMMING SAMPLES ....................................... 26

DONT FORGET THE FOLLOWING.................................................................................................... 26

MODULE 1, ON/OFF INPUT AND OUTPUT ....................................................................................... 27

MODULE 2, IN SERIES INPUT AND OUTPUT (AND) .......................................................................... 28

MODULE 3, IN PARALLEL INPUT AND OUTPUT (OR)......................................................................... 28

MODULE 4, UNIVERSAL STARTING HANDLE .................................................................................... 30

MODULE 5, INTERLOCKS .............................................................................................................. 31

MODULE 6, INTERNAL FLAGS ........................................................................................................ 32

MODULE 7, SET/RESET AND PULSE.......................................................................................... 33

MODULE 8, TIMERS ..................................................................................................................... 34

Operation of delay ON timer .................................................................................................. 35

Operation of delay OFF timer ................................................................................................ 35

MODULE 9, COUNTERS ................................................................................................................ 36

MODULE 10, INTERLOCKS II THE EXCLUSIVE OR ......................................................................... 37

MODULE 11, MULTIPLE BRANCH OUTPUTS ..................................................................................... 38

MODULE 12, SPECIAL RELAYS...................................................................................................... 39

M8013, 1 second clock pulse................................................................................................. 39

M8014, 1 minute clock pulse ................................................................................................. 39

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 2 of 122

Manual for Laboratory, PLC Connection.

MODULE 13, DANGER, FORCE ON/OFF ......................................................................................... 40

MODULE 14, MASTER CONTROL AND MASTER CONTROL RESET ...................................................... 41

CHAPTER 7, QUESTIONS TO GIVE YOU EXPERIENCE ........................................................... 42

EXERCISE 1, DOOR BELL ............................................................................................................. 42

EXERCISE 2, MOTOR START/STOP................................................................................................ 43

EXERCISE 3, OPERATOR HAND PADS ............................................................................................ 44

EXERCISE 4, OPERATOR HAND PADS, EMERGENCY STOP AND GUARD ............................................. 45

EXERCISE 5, PUMPING TANK ........................................................................................................ 46

EXERCISE 6, LABEL STAMPING ..................................................................................................... 47

EXERCISE 7, MOTOR JOGGING ..................................................................................................... 48

EXERCISE 8, ALARM SENSOR ....................................................................................................... 49

EXERCISE 9, CONVEYOR DELAY ................................................................................................... 50

EXERCISE 10, W ASHING MACHINE ................................................................................................ 51

EXERCISE 11, TRAFFIC LIGHTS I ................................................................................................... 52

EXERCISE 12, TRAFFIC LIGHTS II .................................................................................................. 53

EXERCISE 13, CONVEYOR BOTTLE COUNTER ................................................................................. 54

EXERCISE 14, 24 HOUR CLOCK USING COUNTERS AND SPECIAL RELAYS .......................................... 55

EXERCISE 15, CONVEYOR TIMER .................................................................................................. 56

EXERCISE 16, ORANGE CONCENTRATE PLANT ............................................................................... 57

CHAPTER 8, HOW THE PLC IS WIRED UP TO THE OUTSIDE WORLD.................................... 58

CHAPTER 9, HMI, MMI AND OMI................................................................................................ 59

STEP 2: START A NEW PROJECT ................................................................................................... 63

STEP 3: GETTING STARTED.......................................................................................................... 64

STEP 4: MORE INVOLVED HMI, DISPLAY ANALOGUE DATA .............................................................. 69

STEP 5: BAR CHARTS .................................................................................................................. 70

STEP 6: FORCE OUTPUTS ............................................................................................................ 73

CHAPTER 10, OPC SERVER ...................................................................................................... 78

STEP 1:

STEP 2:

STEP 3:

STEP 4:

STEP 5:

STEP 6:

STEP 7:

LOAD UP THE SOFTWARE ............................................................................................... 78

ADD A CHANNEL ........................................................................................................... 79

ADD A DEVICE .............................................................................................................. 80

ADD A GROUP .............................................................................................................. 83

ADD A TAG ................................................................................................................... 84

RUN OPC CLIENT ......................................................................................................... 86

GENESIS ...................................................................................................................... 87

CHAPTER 11, SCADA ................................................................................................................ 90

W HAT DOES A SCADA PACKAGE DO? ........................................................................................... 90

STEP1: GETTING STARTED .......................................................................................................... 90

STEP2: GRAPHICAL REPRESENTATION........................................................................................... 91

STEP3: DYNAMICS ...................................................................................................................... 93

STEP4: STANDARD GAUGES ........................................................................................................ 97

STEP5: CHECK BOXES ................................................................................................................ 98

STEP6: GRAPHICAL REPRESENTATION........................................................................................... 99

STEP7: DIGITAL DISPLAY ........................................................................................................... 100

STEP8: DATE AND TIME DISPLAY................................................................................................. 101

STEP9: BUTTONS ...................................................................................................................... 102

STEP10: SYMBOL LIBRARY ........................................................................................................ 103

STEP12: MULTI FUNCTION ......................................................................................................... 105

STEP13: ARITHMETIC ................................................................................................................ 106

GOOD W ORKING PRACTICE ....................................................................................................... 110

Consistency ........................................................................................................................ 110

Storyboard .......................................................................................................................... 111

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 3 of 122

Manual for Laboratory, PLC Connection.

EXERCISE LABORATORY 1 ......................................................................................................... 112

EXERCISE LABORATORY 2 ......................................................................................................... 113

EXERCISE LABORATORY 3 ......................................................................................................... 114

EXERCISE LABORATORY 4 ......................................................................................................... 115

CHAPTER 12, ANALOGUE TO DIGITAL PLC MODULES ........................................................ 116

CHAPTER 13, LABORATORY CONVEYOR RIG ...................................................................... 122

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 4 of 122

Manual for Laboratory, PLC Connection.

Chapter 1, How to get started

Step 1: How to start the programming tool on the PC

Direct the mouse screen pointer to the Start icon at the bottom of the screen in

the windows menu bar. Press the Start icon once with the left mouse key as

shown in the diagram below.

A pop up menu should have been displayed as shown above. Now select the

program icon from the popped up menu.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 5 of 122

Manual for Laboratory, PLC Connection.

Direct the mouse pointer down to the MELSOFT Application icon, continuing on to

the GX Developer, where you click the mouse left button while hovering over the

GX Developer icon. A screen similar to the diagram below will be loaded.

Step 2: How to start a new project

At the top left of the screen close to the blue bar, select the Project text button and

the menu below will be displayed. Select a New Project.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 6 of 122

Manual for Laboratory, PLC Connection.

When the New Project Icon is selected you will be asked to select the PLC to

which the software is connected. The room K044 the PC is connected to the

FXO(S) PLC so this option should be chosen. Make sure Ladder is chosen under

the program type area.

Then click OK and the following screen will be displayed.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 7 of 122

Manual for Laboratory, PLC Connection.

Step 3: How start programming

The operator of the system can then construct the ladder logic they wish to be

loaded on to the PLC. See the end of this document for more information.

Ladder Logic

Step 4: Convert the program

Once the ladder logic is constructed it needs to be converted. When the code is

converted the ladder rung numbers appear automatically. If there are any ladder

construction faults in the code the software will give a warning at this time. Note

however that the ladder logic may be wrong but its construction may be correct

and thus no errors appear. If the converting is not completed when changing from

this screen the last converted ladder logic will be reloaded and all new changes will

be lost.

Convert

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 8 of 122

Manual for Laboratory, PLC Connection.

Step 5: Stop the PLC

On the PLC where the programming lead is attached there is a Run/Stop switch.

The when ever you are going to change the program you need to switch the PLC

into Stop mode and the green run light will be turned off.

Input Terminals

Input LED

Indicators

The Switch

for Run/Stop

Power, Run/Stop and

CPU LEDs

Output LED

Indicators

Output Terminals

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 9 of 122

Manual for Laboratory, PLC Connection.

Step 6: Up Loading the program to the PLC

The converted program can now be transferred to the PLC by clicking on the

Online option on the main bar at the top and click on to Write to PLC.

When the Write to PLC is clicked you should see the dialogue box as shown

below.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 10 of 122

Manual for Laboratory, PLC Connection.

Before you click Execute make sure all the boxes are checked (or use Select All).

As you become expert and aware of the software limitations you can select only

the items you wish to change.

Make sure to click all the boxes

When Execute is pressed your program will then be written to the PLC.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 11 of 122

Manual for Laboratory, PLC Connection.

Step 7: Switch the PLC to RUN mode

See step 5 above and return the switch to the Run position.

Step 8: Monitor the PLC

It is standard practice to make sure the newly uploaded program is working

correctly before leaving the PLC. By selecting Online and then Monitor the

operator is able to start the monitoring of the PLC. The operator will see the ladder

logic and at the contacts and coils a blue bar will be in place if the status is on and

blank if the status is off. Remember to turn off the monitoring if you wish to alter the

code.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 12 of 122

Manual for Laboratory, PLC Connection.

Chapter 2, Stages in Developing a PLC System

All projects will follow the same seven steps so it is worth your while noting them in

your head.

1.

List the Inputs and Outputs and include a descriptive text of what they are.

2.

Construct the ladder logic of the system using the developer software.

3.

Convert the ladder logic.

4.

Switch the PLC into Stop Mode.

5.

Up load the program to the PLC

6.

Switch the PLC into Run Mode.

7.

Set the development software to monitor and make sure program is working

before leaving it.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 13 of 122

Manual for Laboratory, PLC Connection.

Chapter 3, Some of the main sections of the PLC developer screen.

Ladder Function Keys:

These buttons allow the

ladder logic to be constructed

The buttons highlighted in the diagram above allow for the logic block used in the

ladder logic to be constructed.

From left to right we have

1.

Normally Open Contact

2.

Branched (parallel) Normally Open Contact

3.

Normally Closed Contact

4.

Branched (parallel) Normally Closed Contact

5.

Action (Output)

6.

Instruction such as timer, counter etc

7.

Insert vertical line

8.

Insert horizontal line

9.

Remove vertical line

10.

Remove horizontal line

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 14 of 122

Manual for Laboratory, PLC Connection.

Toggle between Ladder Logic and List of Instructions

If the operator wishes to view the list of instruction used to construct the current

logic then the button shown can be used to toggle between them.

Toggle between Ladder Logic

and List of instructions

The diagram below shows the instruction list for ladder logic.

List of instructions

and not Ladder Logic

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 15 of 122

Manual for Laboratory, PLC Connection.

Read and write mode

If the operator wishes to put some of the ladder logic routine into read mode it will

prevent the code from being changed accidentally. The code can be put back into

the run mode if desired for changes to be made.

Read and write modes can be

selected using these buttons

Monitoring

The development software can be used for monitoring the operation of the PLC.

The operator can connect on to the PLC and monitor the PLCs logic. For technical

reasons the operator cannot make changes to the logic while the system is in run

mode and/or being monitored.

Monitor of the PLC current status

can be selected using these buttons

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 16 of 122

Manual for Laboratory, PLC Connection.

Project Data List

The project data list can be used for toggling between a wider logic screen and the

project data list. This list contains key components in relation to the project:

Project Data List

1.

2.

Program

This is where the ladder logic stored. The main program to run is usually

called main and any other subroutines would be given relevant names.

Device Comment

At the beginning of the projects design it is usual practice to complete a list

of the inputs and outputs that

are going to be required on the

project. The operator can then

type in at this location at the

start and avoid having to insert

them directly into the ladder

logic which can be time

consuming.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 17 of 122

Manual for Laboratory, PLC Connection.

Documentation, Comments, Statements and Notes

A good system is one that works and a great system is one that works and is well

documented. The documentation of your code should be short, sweet and

understandable. When using the PLC developer software the operator can view

the device name and comments associated with them. The operator can also add

Statements and Notes associated with the ladder logic they are designing so any

person viewing the program can see what they have done and why!

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 18 of 122

Manual for Laboratory, PLC Connection.

In the screen shot below the green text in the ladder logic is the statement entered

so an understanding of why the code was constructed and some of its dangers or

benefits could also be included.

Statement for the ladder run below it

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 19 of 122

Manual for Laboratory, PLC Connection.

PLC Status Diagnostic

If the operator wishes to view current status of the PLC without having to look at it

(perhaps it is in a control panel) the PLC diagnostic screen can be utilised. By

selecting Diagnostic from the top menu you will see the screen as detailed below.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 20 of 122

Manual for Laboratory, PLC Connection.

Chapter 4, Down Load from the PLC

In some cases the ladder logic code may not be available on the computer system

the GX Developer is located. (Although we recommend backups of all work are

saved onto floppy drives or better regularly). In these extreme cases it is possible

for the ladder logic to be read from the PLC.

At this stage it is important to note that all the comments and text will not be

retrieved as they were never uploaded to the PLC in the first place to save space

and improve speed.

By switching the PLC to Stop and the using the Online and Read from PLC we

can then ask the existing code on the PLC to be downloaded to the development

software. Remember only the Address, Data and ladder rungs are available.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 21 of 122

Manual for Laboratory, PLC Connection.

Chapter 5, GX Developer Sub Screens

Project Submenu

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 22 of 122

Manual for Laboratory, PLC Connection.

Edit Submenu

Find/Replace Submenu

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 23 of 122

Manual for Laboratory, PLC Connection.

Convert Submenu

View Submenu

Online Submenu

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 24 of 122

Manual for Laboratory, PLC Connection.

Diagnostics Submenu

Tools Submenu

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 25 of 122

Manual for Laboratory, PLC Connection.

Chapter 6, Get started at some programming samples

Dont forget the following

When the ladder logic is completed remember to complete the following:

1.

Convert the program, (Choose Convert from the top menu bar and drill

down)

2.

Switch the PLC to STOP mode (Actually on the PLC itself)

3.

Write the program to the PLC (Choose Online from the top menu bar and

drill down to Write to PLC)

4.

If you wish to monitor the PLC (Choose Online from the top menu bar and

drill down to Monitor then drill across to Start Monitor)

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 26 of 122

Manual for Laboratory, PLC Connection.

Module 1, On/Off Input and Output

The first PLC program is stated below with a ladder logic and electrical equivalent.

It is one input switch X001 and one output switch Y001.

X007

Y001

Switch

1

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Ground

Page 27 of 122

Manual for Laboratory, PLC Connection.

Module 2, In Series Input and Output (AND)

The second PLC program is stated below with a ladder logic and electrical

equivalent. This has three input switches X001, X002 and X003 wired in series and

one output switch Y001. Note all three switches need to be closed if the system is

to work.

X001 X002 X003

Y001

Switch Switch Switch

1

2

3

Ground

Module 3, In Parallel Input and Output (OR)

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 28 of 122

Manual for Laboratory, PLC Connection.

The first PLC program is stated below with a ladder logic and electrical equivalent.

This has three input switches X001, X002 and X003 wired in parallel and one

output switch Y001. Note only one of the three switches needs to be closed if the

system is to work.

X001

Y001

X002

X003

Switch 1

Switch 2

Ground

Switch 3

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 29 of 122

Manual for Laboratory, PLC Connection.

Module 4, Universal Starting handle

The fourth PLC program is stated below with a ladder logic and electrical

equivalent. The circuit is set up so when X001 is closed electricity goes through

X002 and on to power the light. At this stage the relay is activated closing the

Normally Open contact as Y001. Note that Y001 is both input and an output.

With contact Y001 now closed the circuit stays lit until the Normally closed contact

X002 is opened.

This would be the same as pressing in a start button allowing the system to start

and then stopping the system by pressing a stop switch.

X001

Y001

X002

Y001

Switch

1

Switch

2

Ground

Relay

Relay

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 30 of 122

Manual for Laboratory, PLC Connection.

Module 5, Interlocks

On some occasions it is necessary to provide a link between two processes in

order that they are related in some say, this is call Interlock. In the example below

you can see the first rung of the ladder. X001 closes and assuming activity Y002 is

not activated then the contact Y002 stays normally closed and Y001 is activated.

When this happens the normally closed contact Y001 in the second rung of the

ladder opens ensuring Y002 does not start at the same time. (Remember a rung

on a ladder diagram moves from the left vertical rail to the right vertical rail and not

the branches that dont make it fully across)

The same can be said for the second ladder rung. X002 closes and assuming

activity Y001 is not activated then the contact Y001 stays normally closed and

Y002 is activated. When this happens the normally closed contact Y002 in the first

rung of the ladder opens ensuring Y001 does not start at the same time.

X001

Y002

Y001

Y001

Y002

Y001

X002

Y002

Switch1

Relay 2

Ground

Relay 1

Relay 1

Switch 2

Relay 1

Ground

Relay 2

Relay 2

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 31 of 122

Manual for Laboratory, PLC Connection.

Module 6, Internal Flags

As well as inputs and outputs, the PLC will need to hold internal signals for data

such as "ready to run" or "system healthy" and so on. It would be wasteful to

allocate real outputs for these signals, so the PLC is provided with areas of internal

data storage for this purpose. Depending on the manufacturer and the background

of the user, these areas for holding data are known, by names which are

associated with hard-wired relays e.g. auxiliary coils and internal relays, or with

microprocessors e.g. working areas, internal operation flags or just simply flags.

Internal flags are used in exactly the same way as inputs and output. Just as

inputs are identified by an X reference and outputs by a Y,

INTERNAL FLAGS are identified by an M.

In the example below; When X001 is closed M1 is activated which closes the

normally open contact M1 and activates Y001.

X001

M1

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

M1

Y001

Page 32 of 122

Manual for Laboratory, PLC Connection.

Module 7, SET/RESET and PULSE

The SET and RESET commands allows you to Latch and Delatch any ladder

rung. The PULSE facility enables a short pulse to be generated within the PLC

which is often used to carry out the RESET command. A control procedure

requires that an output Y5 is Latched and delatched. Input X1 is used to set

Latch-on output Y5.

Input X2 when activated makes the PLC send a pulse to an internal flag M1.

The internal flag M1 is then used to RESET output Y0

X001

SET Y005

X002

PLS M1

M1

RST Y005

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 33 of 122

Manual for Laboratory, PLC Connection.

Module 8, Timers

A PLC must be able to control systems which have a time component in their

operation. For example a traffic light system or even a duty/stand-by cycle

changer. Time is a major aspect of control systems and the following text should

be covered.

The FX0(S) has 56 timers which have the identification code of T0 to T55. All the

timers function with 100msec clock pulses, but timers T32 to T55 can also be set

to 10msec pulses. The longest period which can be pre-set to is:

K32767 X100Msec =3276.7 seconds = 54 minutes, 36 seconds.

The timer number Txx where xx is the timers no. and the timer duration Kxx where

xx is the number of pulses.

X001

T1 K120

In the example above Timer No.1 has a pre set value of K120. One clock pulse K

is equal to 100msec so 120 x 100msec is equal to 12000msec which is equal to 12

seconds.

A timer falls in to two categories.

1.

Delay ON timer

2.

Delay OFF timer

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 34 of 122

Manual for Laboratory, PLC Connection.

Operation of delay ON timer

The timer set up below starts counting when X001 is on and after 12 seconds have

elapsed the normally open contact of T1 closes activating Y1. Note that the time is

a non-retentive timer. If X001 is released before the 12 seconds is completed then

the timer resets its self.

X001

T1 K120

T1

Y1

Operation of delay OFF timer

The timer set up below starts counting when X001 is on and after 12 seconds have

elapsed the normally closed contact of T1 opens deactivating Y1. Note that the

time is a non-retentive timer. If X001 is released before the 12 seconds is

completed then the timer resets its self.

X001

T1 K120

T1

Y1

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 35 of 122

Manual for Laboratory, PLC Connection.

Module 9, Counters

A powerful feature of PLCs is there ability to count. In simple terms it is a pulse

counter.

The construction of the counter system has a similar format to that of the timers,

however, the K value is not multiplied by anything (i.e. the K for timers means

multiply by 10ms or 100ms depending on the system being used).

The Counter Identifier identifies the counter chosen. This can be assigned to

device comment in the same way as the inputs, timers, outputs and internal flags.

In this example C12 is used. The second number is the quantity of pulses before

the C12 counter activates. In this case K7 is shown meaning that after 7 pluses the

counter C12 will be activated.

The memory storage of the value in the counter is retentive (i.e. it retains the value

until reset or the PLC is switched into the stop mode.

Counter Identifier

C12 K7

Quantity before activation

In the ladder logic shown below the button X006 is used to pulse the C12 timer.

After 7 pulses the C12 timer will switch to the activate state. The only way to

deactivate this timer is to reset the C12 timer using the RST C12 instruction. You

can see that this reset instruction is connected to the X007 switch. An important

note to keep in mind is that if during counting the X007 is pressed it will reset the

C12 counter erasing what number was being stored at the time.

X007

RST C12

X006

C12 K7

C12

Y3

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 36 of 122

Manual for Laboratory, PLC Connection.

Module 10, Interlocks II the Exclusive OR

In some cases the OR gate needs to be refined to give a more definitive output.

Assume that you have two outputs and you have two inputs and you have been

asked to design a system to let one or the other operate but not both at the same

time.

In the example given below if the normally open X007 contact on the top is closed

the second normally closed X007 will open stopping the lower rung being activated

thus stopping Y001 from starting. Thus Y000 is the only one to start.

Alternatively, if the normally open X004 contact on the top is closed the second

normally closed X004 will open stopping the lower rung being activated thus

stopping Y000 from starting. Thus Y001 is the only one to start.

X007

X004

Y000

X004

X007

Y001

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 37 of 122

Manual for Laboratory, PLC Connection.

Module 11, Multiple branch outputs

On occasion it is necessary to have multiple outputs from a single input. To

achieve this a layout similar to the ladder logic shown below should be used.

In this example X007 would switch Y000, Y001, Y002 and Y003 at the same time.

X007

Y000

Y001

Y002

Y003

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 38 of 122

Manual for Laboratory, PLC Connection.

Module 12, Special Relays

As we have seen the FX0(s) has flags (auxiliary relays) available for the

programmer to use. These flags can hold the status of part of a programme without

using up a scarce output. There are also special flags which can be equally as

useful especially when used with counters or outputs that need to pulse. They are

the M8013 and M8014 devices

M8013, 1 second clock pulse

This contact will close in 1 second cycles, therefore any output controlled by

M8013 will pulse on for 0.5 seconds and off for 0.5 seconds.

M8013

Y000

1

0

0s

0.5s

1.0s

1.5s

2.0s

Time->

M8014, 1 minute clock pulse

This contact will close in 60 second (1 minute) cycles, therefore any output

controlled by M8014 will pulse on for 30 seconds and off for 30 seconds.

M8014

Y000

1

0

0s

30s

60s

90s

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

120s

Time->

Page 39 of 122

Manual for Laboratory, PLC Connection.

Module 13, Danger, Force On/Off

In the PLC there is a facility to force a coil on or off.

This forces the Output to the on or off status without a need for the complete logic

protection sequence it in the ladder logic being used. The PLC can be in Run or

Stop mode which makes this facility a potential hazard. By entering Online then

down to Debug and then on to Device Test you enter the lower screen below. It

now allows you enter a coil and force it on or off.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 40 of 122

Manual for Laboratory, PLC Connection.

Module 14, Master Control and Master Control Reset

The master control and master control reset is used to switch on and odd levels of

instruction within an sequential programme. The levels used in the MC instruction

start from 0 and can go up to 8. In our following example programme there is only

level of master control so n = 0. If there was another level of master control the

same programme we would use n=1 for it and so on.

The symbol for Master Control is

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 41 of 122

Manual for Laboratory, PLC Connection.

Chapter 7, Questions to give you experience

Exercise 1, Door Bell

Design a small direct circuit used in a door bell application. The doorbell is only to

rung when the push button is pressed. Use an I/O list, sketch the ladder logic and

written description.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 42 of 122

Manual for Laboratory, PLC Connection.

Exercise 2, Motor Start/Stop

Design a small PLC circuit to start a motor using a start button and keep the motor

running until the stop button is pressed. Use an I/O list, sketch the ladder logic and

written description.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 43 of 122

Manual for Laboratory, PLC Connection.

Exercise 3, Operator Hand Pads

On some machines the operator could be duped into placing their hands in danger

during the operation of the equipment.

You have been asked to develop a specification for Operator Hand Pads that allow

the operator of a 100-ton press close the die tool only when both his hands are

free from the tool. Use an I/O list, sketch the ladder logic and written description.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 44 of 122

Manual for Laboratory, PLC Connection.

Exercise 4, Operator Hand Pads, Emergency Stop and Guard

As in question 3 above some machines the operator could be duped into placing

their hands in danger during the operation of the equipment.

You have been asked to develop a specification for Operator Hand Pads that allow

the operator of a 100-ton press close the die tool only when both his hands are

free from the tool. The press on your instructions is now fitted with an emergency

stop and safety guard which need to be taken into consideration. Use an I/O list,

sketch the ladder logic and written description. (Should the emergency stop be

hardwired or soft wired?)

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 45 of 122

Manual for Laboratory, PLC Connection.

Exercise 5, Pumping Tank

In the diagram below you can see pump system feeding a tank.

You have been asked to develop a specification to allow the pump start when a

low level probe X001 is activated and stop the pump when the high level probe

X002 is activated. You can assume that the pump is on/off and a stop/start

arrangement is required

Use an I/O list, sketch the ladder logic and written description.

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 46 of 122

Manual for Laboratory, PLC Connection.

Exercise 6, Label Stamping

In the diagram below you can see a product running on a conveyor. The conveyor

drive motor, Optical sensors and label stamping cylinder can be assumed on/off

control.

You have been asked to develop a specification to allow the conveyor start and

stop with two buttons and only label the product when it presents its self at the

position correct sensor and up right sensor together. Assume Optical sensor No2

is the correct position sensor and Optical sensor No1 is the up right sensor.

Label Stamping

cylinder

Product

Optical Sensor No 1

Optical Sensor No 2

Conveyor

Conveyor

Drive Motor

Use an I/O list, sketch the ladder logic and written description.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 47 of 122

Manual for Laboratory, PLC Connection.

Exercise 7, Motor Jogging

During a factory maintenance shut-down conveyor motors which locate

components are checked for correct position. Design a specification to jog the

motor forward and reverse. Assume that the motor has a forward controller and

reverse controller. Place interlocks in the programme which will prevent the motor

from being jogged in two directions at the same time. Use an I/O list, sketch the

ladder logic and written description.

Conveyor

Conveyor

Drive Motor

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 48 of 122

Manual for Laboratory, PLC Connection.

Exercise 8, Alarm Sensor

A movement sensor is to be used to switch on a security light. The light will stay on

for 20 seconds and then go off. The sensor is to be connected to input X1, it will

only give a momentary pulse as it detects movement. The security light is

connected to Y2 and is controlled by T1 which is programmed as a delay off timer.

Design a system using the PLC to control the above circuit.

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 49 of 122

Manual for Laboratory, PLC Connection.

Exercise 9, Conveyor Delay

A process has been developed which requires the conveyor to stop for 7 seconds

when the container hits the LED proximity sensor (i.e. the first sensor on the rig).

Using the conveyor rig design and implement you system. Use an I/O list, sketch

the ladder logic and written description.

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 50 of 122

Manual for Laboratory, PLC Connection.

Exercise 10, Washing Machine

A customer has asked your company to renovate an old machine and replace the

spin cycle timers and relays with a PLC control. It is your task to create a

programme which will carry out the specified time sequenced operation and to test

it out using your laboratory rig.

Specification

Pressing a push button starts the spin cycle. The motor will spin the drum slowly

for 15 seconds sat the end of this period the drum will spin quickly for 30 seconds,

then decelerate and turn slowly for 10 seconds before coming to a halt.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 51 of 122

Manual for Laboratory, PLC Connection.

Exercise 11, Traffic Lights I

You have been asked to develop and implement a traffic lights sequence using the

following outputs.

Red Light is

Yellow Light is

Green Light is

Y003

Y004

Y005

Specification

Red is on for 10 seconds, Amber is on for 5 seconds and Green is on for 15

seconds and then the cycle starts again.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 52 of 122

Manual for Laboratory, PLC Connection.

Exercise 12, Traffic Lights II

You have been asked to develop and implement a traffic lights sequence using the

following outputs.

Red Light is

Yellow Light is

Green Light is

Y003

Y004

Y005

Specification

Red is on for 10 seconds, Amber on for 5 seconds and Green is on for 15 seconds

and then the cycle starts again.

When a push button is pressed the sequence changes to Blue on for 12 seconds,

Amber and Green is on for 15 seconds and then the cycle starts again and after

one cycle the lights revert back to the original operation.

FX PLC

Relay

From

Y1

Relay

From

Y2

Relay

From

Y3

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 53 of 122

Manual for Laboratory, PLC Connection.

Exercise 13, Conveyor Bottle counter

You have been asked to develop a system to package bottles to the following

specification.

Steel trays travel down the conveyor. When the tray is sensed by the first proximity

sensor the conveyor should stop and the red light should be switched on

(highlighting a danger and the same signal is use to initiate a pick and place

machine). The separate pick and place machine then loads the bottles into the tray

one by one. As each bottle is loaded the signal X007 (green push button) emulates

a bottle detect and counter (Say push the button six times to fill the tray). When the

tray is full the red light should be turned off and the conveyor started moving the

tray away and delivering another tray to the loading system.

McGrory

McGrory

Use an I/O list, sketch the ladder logic and written description.

Conveyor

Conveyor

Drive Motor

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 54 of 122

Manual for Laboratory, PLC Connection.

Exercise 14, 24 Hour Clock using Counters and special relays

You have been asked to develop a system to package bottles to the following

specification.

A twenty 24 hour clock is to be designed using M8013 and M8014 special relays.

Construct the ladder logic so when viewed in monitor mode the counter registers

show the hours, minutes and seconds that have elapsed.

Use an I/O list, sketch the ladder logic and written description.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 55 of 122

Manual for Laboratory, PLC Connection.

Exercise 15, Conveyor Timer

You have been asked to develop a system to package bottles to the following

specification.

Steel trays travel down the conveyor. When the tray is sensed by the first proximity

sensor the conveyor should stop and the red light should be switched on. A

process unknown to you will be performed on the tray for 12 seconds. After this

time red light should be turned off and the conveyor started moving the tray away

and delivering another tray to the loading system.

Use an I/O list, sketch the ladder logic and written description.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 56 of 122

Manual for Laboratory, PLC Connection.

Exercise 16, Orange Concentrate Plant

You have been asked to develop a system to manufacture orange juice from

concentrate. Tank 1 contains water and Tank 2 contains concentrated orange

juice. Both tanks have low level probes which should stop the respective pumps

when the tank is empty (indicated by the loss of signal of the low level probe)

Both pumps are to be automated so they can only work together (at the same time)

and never alone or the resultant product would be too strong or weak. Tank 3

contains the diluted orange juice and has a low level probe and a high level probe.

When the high level is actuated both pumps feeding Tank 3 should stop. The

conveyor should be connected to a stop/start switch arrangement. When a

container is present the conveyor should stop and Pump 3 should operate for 10

seconds then stop and allow the conveyor move the container on.

Use an I/O list, sketch the ladder logic and written description.

Low Level Probe

Tank 1

Low Level Probe

Pump 1

Tank 2

Pump 2

Low Level Probe

High Level Probe

Tank 3

Pump 3

Product

Conveyor

Conveyor

Drive Motor

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 57 of 122

Manual for Laboratory, PLC Connection.

Chapter 8, How the PLC is wired up to the outside world

The PLC has particular wiring arrangements. The diagram below highlights how

the system is wired up. As you can see the inputs are driven from a 24V supply

directly into the contact terminals. This could be in some cases 12V, 110V or 220V

on other similar product manufactures equipment.

It is important to isolate the inputs using a fuse or better to avoid the PLC getting

damaged. However the Outputs are only Volt Free Contacts so a relay is needed

to complete the control action and in this case up to 220V can be wired in but

usually for safety 24V should be used.

X001

X000

Mains

Address Data

X000 0

X001

Y000

Y000

24V

Switch wired

in from a 24V

supply

Relay

Outputs must be isolated from

the PLC using a relay to protect

the PLC

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 58 of 122

Manual for Laboratory, PLC Connection.

Chapter 9, HMI, MMI and OMI

As you have seen from the laboratory session so far the PLC is a very powerful

piece of equipment. The PLC itself however has a downfall. It displays very little

information on the operation its controlling. Without the monitoring software

running on a PC or Laptop we would have to depend on the Input and Output

LEDs which tell us only if the signal is on or off (analogue values are non existent)

but nothing specific about the process itself.

Input LEDs

Output LEDs

One way of overcoming this is by using the operator panel usually called any of the

three titles below.

HMI Human Machine Interface

MMI Man Machine Interface

OMI Operator Machine Interface

A digital image of the E200 HMI as used in the Laboratory is shown below.

Dont worry about all the different names as they all in essence mean the same

thing. The HMI is a component to assist the processing automation system that

allows the operator view the process and interact with it.

Some of the standard features of the HMI is as follows;

Viewing and changing of I/O

Displaying of analogue values

Alarms

Bar Graphs

Information text

Full graphical screens (similar to monitors) are being used in industry.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 59 of 122

Manual for Laboratory, PLC Connection.

To design a good system its always a good idea to construct a storyboard from

which the system will be developed.

It is important to note at this point that the HMI and the PLC are both connected to

the one port at the back of the computer. It is therefore impossible to have the PLC

in monitoring mode and upload the E-Designer files at the same time. You will see

an error appear stating that the port is being used by another package.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 60 of 122

Manual for Laboratory, PLC Connection.

It would be advisable to set up a simple ladder logic code running on the PLC

before running the E-Designer Software.

In this case X007 the green button starts the conveyor Y001. X006 the red button

stops the conveyor. Of course the universal starting switch will keep the conveyor

running for us.

X004 will be used for the Counter C1. Every time the X004 button is pressed it will

increment the C1 counter by one. If you wish to put in a reset for the counter that is

up to you but not needed for this example.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 61 of 122

Manual for Laboratory, PLC Connection.

Step 1: How to load the E-Designer Programme

From the main desktop screen press the Start button using the mouse pointer

and progress up to Program then across to E-Designer and finally to the EDesigner icon.

From there the following screen should be loaded on to the computer screen

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 62 of 122

Manual for Laboratory, PLC Connection.

Step 2: Start a new project

From the file menu on the top bar choose New and click on the text.

The following screen will be displayed and you will be able to choose the model of

the HMI unit installed in the Laboratory

Remember the Terminal is a E200 6.0x and the Controller system is a FX0(S)CPU.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 63 of 122

Manual for Laboratory, PLC Connection.

When the above is completed you will then be shown the screen below:

Step 3: Getting Started

Instead of jumping in and programming loads of screens lets take a little time to

explore the functions available to us using the HMI

If you double click on the Main block in the middle of the screen the following

screen will appear.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 64 of 122

Manual for Laboratory, PLC Connection.

The screen displays an emulation of what the user will see when their code is

uploaded to the HMI.

Start by clicking the large white area and type in Main

Conveyor. If the program was now uploaded the text Main

Conveyor would be displayed. But lets add a little to system

before we do that. Click on the Main Conveyor and move the

cursor to the end of the r and press return. Type in something

like Conveyor followed by a space and using the small O/I box

in the Icon selection set as shown to the right and the following

screen appears.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 65 of 122

Manual for Laboratory, PLC Connection.

Enter in something like Y1 (Which we know is the conveyor running signal, on the

PLCs provided) and when it is at off we want the Stopped word to appear and

when it is on we want the Running words to appear. Then press Apply and OK.

You can then see the software would have placed in a piece of text as shown

below.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 66 of 122

Manual for Laboratory, PLC Connection.

Transfer the code to the HMI unit by choosing Transfer from the top menu and

Project from the sub menu.

The following screen will appear and allow you send your programme up to the

HMI

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 67 of 122

Manual for Laboratory, PLC Connection.

When Send is pressed the you will be asked to confirm if you want to upload and

when yes is pressed the code is then transferred across to the HMI

At the same time you will see the HMI screen change indicating that the code is

changing.

When this is completed you will see.

Main Conveyor

Conveyor Off

If you now start the conveyor by pressing the green button the following text is

displayed:

Main Conveyor

Conveyor On

This simple program shows us two important things about HMIs.

1.

We can add descriptive text about processes for the operator to see.

2.

We can have a dynamic changing of text linked to a changing process.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 68 of 122

Manual for Laboratory, PLC Connection.

Step 4: More involved HMI, Display Analogue Data

It is not only possible to have a descriptive text and dynamic changing of text in

two states, but we can also display data contained within registers such as the

Timer or Counter.

If we return to the Main screen on the E-Developer and continue to a new line we

can add a little more text. Type in Counter and after that press the 0.3 Icon from

the right menu and the following will be displayed

Type in C1 (at the beginning of this section I asked you to upload a simple ladder

logic program to the PLC, C1 was the counter, a number between 1 and 20 linked

to X004) and leave the rest the same as shown.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 69 of 122

Manual for Laboratory, PLC Connection.

Transfer the code to the HMI unit by choosing Transfer from the top menu and

Project from the sub menu.

Now your system will operate as before and you will see.

Main Conveyor

Conveyor Off

Counter 0

As you start the system you will then be able to have the conveyor change from Off

to On using X007 and X006 and increment the counter by pressing X004.

Step 5: Bar Charts

If you wish to place a bar chart it can also be completed using the HMI. This would

be used where a number is just not enough. Consider the following example. A

tank of liquid ranges between 0 and 10 meters in height. By just stating that the

height is 2 to an unfamiliar operator would mean nothing but when the graph

shows 2 out of 10 it would mean more.

Return to the E-Designer Main screen and at the end of the counter number

information press return. Then click on the --# icon.

Dr. J.McGrory, DIT Kevin Street. Version 2.0, File: plc_manual_laboratory V02

Page 70 of 122

Manual for Laboratory, PLC Connection.

When the dialogue box appears put C1 in the Analogue Signal section and click on