516 en

Diunggah oleh

Selvamani TJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

516 en

Diunggah oleh

Selvamani THak Cipta:

Format Tersedia

Technical Data Sheet

LOCTITE 516

February-2007

PRODUCT DESCRIPTION LOCTITE 516 provides the following product characteristics: Technology Acrylic Chemical Type Acrylic Appearance (uncured) Burnt orange to brown liquidLMS Components One component - requires no mixing Viscosity High, thixotropic Cure Dries Application Thread sealing Specific Benefit Excellent environmental resistance LOCTITE 516 is a high viscosity, non-toxic, thixotropic, preapplied, water-based thread sealant for automatic dispensing applications. When dried, it becomes a resilient, tight clinging, non-curing sealant for tapered or straight threads . LOCTITE 516 provides positive sealing and resistence to vibrational loosening. The thread-filling ability and prevailing torque characteristics of this product are effective for use on sealing applications, particularly where re-adjustments are required, e.g. rear axle filler plugs, bearing adjuster nuts, pressure gauges and sensors, brake fittings, pipe fittings, and compressor pipe plugs. Other devices that this product is designed for includes; cable connectors, screws for plastic assemblies, adjustment screws, overhead fire sprinklers, shower heads, and door closure hardware. This product is typically used in applications with an operating range of -54 C to +150 C. TYPICAL PROPERTIES OF UNCURED MATERIAL

Specific Gravity @ 25 C Flash Point - See MSDS Viscosity, Brookfield - RVT, 25 C, mPas (cP): Spindle 7, speed 20 rpm Solids/Non-Volatile Content, % On Part Life, years 1.1 to 1.4LMS

Prevail Torque, : 3/8 x 16 nuts and bolts

Nm (lb.in.)

2.4 (21)

Chemical/Solvent Resistance Test performed on 12.7mm NPT tee's and malleable plugs test at 830 kPa air after 30 days immersion in solvents indicated.

% of initial strength Environment Motor oil (10W30) Water/glycol 1:1 Diesel fuel Dextron III C 120 100 50 120 Results h No leakage No leakage No leakage No leakage No leakage

Hydraulic Steering Fluid 120

GENERAL INFORMATION This product is not recommended for use in pure oxygen and/or oxygen rich systems and should not be selected as a sealant for chlorine or other strong oxidizing materials. For safe handling information on this product, consult the Material Safety Data Sheet (MSDS). Directions for use LOCTITE 516 is applied to threaded parts by authorized process centers who have automatic fastener cleaning, feeding, coating, rust proofing and drying equipment. Quantities can be handled promptly with minimum turnaround time. Sample fittings should be sent to the nearest authorized process center where they will coat your parts and return them to you for evaluation. SAMPLE TESTS ARE RECOMMENDED TO OBTAIN DESIRED RESULTS ON YOUR PARTS. Contact the nearest Loctite Sales Representative for the authorized process center nearest to you. Loctite Material SpecificationLMS LMS dated February-28, 2001. Test reports for each batch are available for the indicated properties. LMS test reports include selected QC test parameters considered appropriate to specifications for customer use. Additionally, comprehensive controls are in place to assure product quality and consistency. Special customer specification requirements may be coordinated through Henkel Quality.

20,000 to 40,000LMS 35.5 to 47.3LMS 4

TYPICAL PERFORMANCE OF CURED MATERIAL

Adhesive Properties Instant seal 12.7 mm NPT fittings to 830 kPa Torque Strength Seating Torque, : 3/8 x 16 nuts and bolts Breakloose Torque, : 3/8 x 16 nuts and bolts

Nm (lb.in.) Nm (lb.in.)

40.7 (369) 19.8 (175)

TDS LOCTITE 516, February-2007 Storage Store product in the unopened container in a dry location. Storage information may be indicated on the product container labeling. Optimal Storage: 8 C to 21 C. Storage below 8 C or greater than 28 C can adversely affect product properties. Material removed from containers may be contaminated during use. Do not return product to the original container. Henkel Corporation cannot assume responsibility for product which has been contaminated or stored under conditions other than those previously indicated. If additional information is required, please contact your local Technical Service Center or Customer Service Representative. Conversions (C x 1.8) + 32 = F kV/mm x 25.4 = V/mil mm / 25.4 = inches m / 25.4 = mil N x 0.225 = lb N/mm x 5.71 = lb/in N/mm x 145 = psi MPa x 145 = psi Nm x 8.851 = lbin Nm x 0.738 = lbft Nmm x 0.142 = ozin mPas = cP Note The data contained herein are furnished for information only and are believed to be reliable. We cannot assume responsibility for the results obtained by others over whose methods we have no control. It is the user's responsibility to determine suitability for the user's purpose of any production methods mentioned herein and to adopt such precautions as may be advisable for the protection of property and of persons against any hazards that may be involved in the handling and use thereof. In light of the foregoing, Henkel Corporation specifically disclaims all warranties expressed or implied, including warranties of merchantability or fitness for a particular purpose, arising from sale or use of Henkel Corporations products. Henkel Corporation specifically disclaims any liability for consequential or incidental damages of any kind, including lost profits. The discussion herein of various processes or compositions is not to be interpreted as representation that they are free from domination of patents owned by others or as a license under any Henkel Corporation patents that may cover such processes or compositions. We recommend that each prospective user test his proposed application before repetitive use, using this data as a guide. This product may be covered by one or more United States or foreign patents or patent applications. Trademark usage Except as otherwise noted, all trademarks in this document are trademarks of Henkel Corporation in the U.S. and elsewhere. denotes a trademark registered in the U.S. Patent and Trademark Office. Reference 0.0

Henkel Loctite Americas +860.571.5100

Henkel Loctite Europe +49.89.9268.0

Henkel Loctite Asia Pacific +81.45.758.1810

For the most direct access to local sales and technical support visit: www.loctite.com

Anda mungkin juga menyukai

- Loctite Nickel High Purity N-5000HPAS-EnDokumen2 halamanLoctite Nickel High Purity N-5000HPAS-EnmarciofelipessantosBelum ada peringkat

- Loctite 592™: % of Initial Strength Environment °C 720 HDokumen2 halamanLoctite 592™: % of Initial Strength Environment °C 720 HAndy ChongBelum ada peringkat

- Oxygen System - Thread SealantDokumen2 halamanOxygen System - Thread SealantMoamenBelum ada peringkat

- Loctite 5182Dokumen3 halamanLoctite 5182ccorp0089Belum ada peringkat

- Loctite 324™: Technical Data SheetDokumen3 halamanLoctite 324™: Technical Data SheetUgan Git PadayacheeBelum ada peringkat

- Loctite 567Dokumen3 halamanLoctite 567Nandani MangaleeBelum ada peringkat

- Loctite LB 771-Nickel AntiseizeDokumen2 halamanLoctite LB 771-Nickel AntiseizeChuckBelum ada peringkat

- Loctite 7471Dokumen2 halamanLoctite 7471ksdjuhsdkjvBelum ada peringkat

- Loctite 242: Product Description TechnologyDokumen3 halamanLoctite 242: Product Description TechnologyRuiBelum ada peringkat

- Loctite 5699™: Technical Data SheetDokumen3 halamanLoctite 5699™: Technical Data Sheetgazwang478Belum ada peringkat

- Loctite LB 8504: Technical Data SheetDokumen2 halamanLoctite LB 8504: Technical Data SheetMridu Ranjan SrivastavaBelum ada peringkat

- Loctite 567 Thread Sealant Data SheetDokumen3 halamanLoctite 567 Thread Sealant Data SheetJoseph BernardBelum ada peringkat

- Locktite 8104 Data SheetDokumen2 halamanLocktite 8104 Data SheetNyoman RakaBelum ada peringkat

- Ficha Tecnica LubricanteDokumen2 halamanFicha Tecnica LubricanteArmando JoyaBelum ada peringkat

- Loctite 518™: Technical Data SheetDokumen3 halamanLoctite 518™: Technical Data Sheetsaurabhjerps231221Belum ada peringkat

- Loctite 603: Technical Data SheetDokumen3 halamanLoctite 603: Technical Data SheetRuiBelum ada peringkat

- Loctite 2701: Technical Data SheetDokumen3 halamanLoctite 2701: Technical Data SheethendrabudimanBelum ada peringkat

- Loctite 641: Technical Data SheetDokumen3 halamanLoctite 641: Technical Data SheetRuiBelum ada peringkat

- Loctite 648: Technical Data SheetDokumen3 halamanLoctite 648: Technical Data SheetRuiBelum ada peringkat

- Loctite Food Grade Anti-Seize TdsDokumen2 halamanLoctite Food Grade Anti-Seize TdsheroBelum ada peringkat

- Loctite 330: Technical Data SheetDokumen2 halamanLoctite 330: Technical Data SheetRuiBelum ada peringkat

- Loctite 518 2011Dokumen3 halamanLoctite 518 2011Boss_enqBelum ada peringkat

- Tds of Loctite 41411Dokumen1 halamanTds of Loctite 41411ken philipsBelum ada peringkat

- Loctite Chisel Paint Stripper TechDokumen2 halamanLoctite Chisel Paint Stripper TechJuan Chavez ViladegutBelum ada peringkat

- Loctite 262: Product Description TechnologyDokumen3 halamanLoctite 262: Product Description TechnologyrajaramBelum ada peringkat

- Henk Loctite Gasket Seal 2 TdsDokumen1 halamanHenk Loctite Gasket Seal 2 TdsGabo TellezBelum ada peringkat

- Henk Multicore Macromelt Mm6208s TdsDokumen2 halamanHenk Multicore Macromelt Mm6208s TdsAbohicham AbhBelum ada peringkat

- Betaforce ™ 2850S: Technical DatasheetDokumen3 halamanBetaforce ™ 2850S: Technical Datasheetenrico_andreoli88Belum ada peringkat

- Loctite MR 5923™: Technical Data SheetDokumen2 halamanLoctite MR 5923™: Technical Data Sheetraffabox84yahoo.itBelum ada peringkat

- Loctite 2700™: Product DescriptionDokumen4 halamanLoctite 2700™: Product DescriptionvuvuvuvBelum ada peringkat

- HYSOL® FP4323 (ES4323) : Technical Data SheetDokumen2 halamanHYSOL® FP4323 (ES4323) : Technical Data SheetAsad NaeemBelum ada peringkat

- HysolDokumen2 halamanHysoljorgequijanoBelum ada peringkat

- Sila Tech RD TdsDokumen2 halamanSila Tech RD TdsChemicalProgrammerBelum ada peringkat

- Loctite 542: Product Description Technology Cure Speed vs. Bond GapDokumen4 halamanLoctite 542: Product Description Technology Cure Speed vs. Bond GapbabshuagBelum ada peringkat

- Loctite 7075 TdsDokumen1 halamanLoctite 7075 TdsSurajPachhadeBelum ada peringkat

- TDS Loctite Nickel LB 771-EnDokumen2 halamanTDS Loctite Nickel LB 771-EnGregory Alan Francisco IIBelum ada peringkat

- Assembly SolutionsDokumen14 halamanAssembly SolutionsAhmed Emad AhmedBelum ada peringkat

- Loctite SF 8046 en UsDokumen2 halamanLoctite SF 8046 en UsEdu Ochoa ArceBelum ada peringkat

- Aa 324Dokumen3 halamanAa 324darshan.hegdebBelum ada peringkat

- Product Description Sheet Hysol® Product 9460F: Industrial Products, August 2001Dokumen2 halamanProduct Description Sheet Hysol® Product 9460F: Industrial Products, August 2001engpontelliBelum ada peringkat

- Interclene 5012Dokumen4 halamanInterclene 5012Trịnh Minh KhoaBelum ada peringkat

- Loctite 7386: Technical Data SheetDokumen2 halamanLoctite 7386: Technical Data SheetIbrahim SamadBelum ada peringkat

- Loctite SF 790™: Technical Data SheetDokumen2 halamanLoctite SF 790™: Technical Data SheetEdwin GallegosBelum ada peringkat

- Loctite 1Dokumen2 halamanLoctite 1Antonio GonzaleBelum ada peringkat

- Plexus Selector GuideDokumen8 halamanPlexus Selector GuideLodewykbronnBelum ada peringkat

- Loctite SF 8046: Technical Data SheetDokumen2 halamanLoctite SF 8046: Technical Data Sheeterick daniel veraBelum ada peringkat

- 4105 DatasheetDokumen2 halaman4105 DatasheetAsad NaeemBelum ada peringkat

- 587 enDokumen2 halaman587 enabhayundaleBelum ada peringkat

- DK15 0934Dokumen1 halamanDK15 0934Dileep SettyBelum ada peringkat

- Product Data 232 Ceilcote FlakelineDokumen3 halamanProduct Data 232 Ceilcote FlakelineMohd MustafhaBelum ada peringkat

- DOW FILMTEC™ Membranes: Product Data SheetDokumen3 halamanDOW FILMTEC™ Membranes: Product Data SheetPT Tirtapure EnvirotekBelum ada peringkat

- Interbond 600Dokumen4 halamanInterbond 600Trịnh Minh KhoaBelum ada peringkat

- Loctite 596™: SurfacesDokumen2 halamanLoctite 596™: Surfaces楼淼森Belum ada peringkat

- Adhesives Cyanoacrylates Apollo 2150Dokumen2 halamanAdhesives Cyanoacrylates Apollo 2150Vinaya Almane DattathreyaBelum ada peringkat

- 659H Chockfast OrangeDokumen2 halaman659H Chockfast OrangeManodaya ShirodkarBelum ada peringkat

- Loctite Ea 9203 AeroDokumen2 halamanLoctite Ea 9203 AeroHenryBelum ada peringkat

- Parker O RingDokumen0 halamanParker O RingRazvan C GoranBelum ada peringkat

- Adhesives Technology for Electronic Applications: Materials, Processing, ReliabilityDari EverandAdhesives Technology for Electronic Applications: Materials, Processing, ReliabilityBelum ada peringkat

- Astro 429 Assignment 2 AlbertaDokumen2 halamanAstro 429 Assignment 2 AlbertatarakBelum ada peringkat

- TP260SR Tier 3 TC002-1037Dokumen1 halamanTP260SR Tier 3 TC002-1037Jorge GalarceBelum ada peringkat

- Post-Installed Rebars Design and Analysis: Singapore, 11.03.2016Dokumen44 halamanPost-Installed Rebars Design and Analysis: Singapore, 11.03.2016SewGuanBelum ada peringkat

- Whirlpool Adg 789Dokumen22 halamanWhirlpool Adg 789Laurentiu GramaBelum ada peringkat

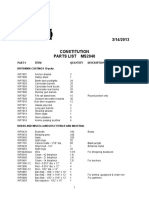

- MS2040 Constitution Parts ListDokumen6 halamanMS2040 Constitution Parts ListTemptationBelum ada peringkat

- Optimizing With eGaN FETsDokumen6 halamanOptimizing With eGaN FETskhsniperBelum ada peringkat

- Role of Packaging in Sales of FMCG Products and Its TrendsDokumen57 halamanRole of Packaging in Sales of FMCG Products and Its TrendsSaurabh0% (1)

- Vocal TractDokumen16 halamanVocal TractniroelBelum ada peringkat

- 9500 MPR Wireless TransmissionDokumen46 halaman9500 MPR Wireless TransmissionMahdi AhmadiBelum ada peringkat

- The Poet of NatureDokumen31 halamanThe Poet of NaturejulyBelum ada peringkat

- Second Term English Exam: Level TCST June 2021Dokumen6 halamanSecond Term English Exam: Level TCST June 2021benfaresBelum ada peringkat

- Wheatley Hp600 Quintuplex Plunger PumpDokumen2 halamanWheatley Hp600 Quintuplex Plunger Pumpmetasoniko2014Belum ada peringkat

- 1 N117Geriatric Nursing Lecture 1 BABY BOOMERSDokumen4 halaman1 N117Geriatric Nursing Lecture 1 BABY BOOMERSqygwfvbysgbcnntgrvbBelum ada peringkat

- Today! 2 Activity Book AKDokumen10 halamanToday! 2 Activity Book AKMark Arenz Corixmir80% (5)

- Worksheet 3 (Partial Pressures)Dokumen2 halamanWorksheet 3 (Partial Pressures)Jose Ruben SortoBelum ada peringkat

- Pearson Correlation ValueDokumen7 halamanPearson Correlation ValuemarianaBelum ada peringkat

- Remote Control Based Home Appliances Final ReportDokumen22 halamanRemote Control Based Home Appliances Final ReportVishal Vn50% (2)

- PX 150 UsaDokumen138 halamanPX 150 UsaramiroBelum ada peringkat

- T/PR/DIS/5.10.1: Work Procedure ForDokumen38 halamanT/PR/DIS/5.10.1: Work Procedure ForAnant RubadeBelum ada peringkat

- MECH0018.1 Assignment 2 QP Fall 2021Dokumen17 halamanMECH0018.1 Assignment 2 QP Fall 2021saleem razaBelum ada peringkat

- Gem WK6/WK8 Service ManualDokumen18 halamanGem WK6/WK8 Service Manualalex_seidiu100% (5)

- Mardi Gras Recipe Sampler by Mitchell Rosenthal, Author of Cooking My Way Back HomeDokumen13 halamanMardi Gras Recipe Sampler by Mitchell Rosenthal, Author of Cooking My Way Back HomeThe Recipe Club100% (1)

- Low - Pass FilterDokumen8 halamanLow - Pass FilterSaurabh BhiseBelum ada peringkat

- Dave Graham Literature CatalogDokumen640 halamanDave Graham Literature CatalogPierce PetersonBelum ada peringkat

- Manual CaladoraDokumen32 halamanManual CaladoraMiguel Angel Vega TrejoBelum ada peringkat

- Netrunner AllCardsDokumen154 halamanNetrunner AllCardsIvo PantaleaoBelum ada peringkat

- 05 Astm Grain Size MeasurementsDokumen27 halaman05 Astm Grain Size MeasurementsnareshBelum ada peringkat

- Smart City Scheme GuidelinesDokumen48 halamanSmart City Scheme GuidelinesKarishma Juttun100% (1)

- Buk Uuuuuu UuuuuuuDokumen92 halamanBuk Uuuuuu UuuuuuuJanaliyaBelum ada peringkat

- Cambridge IGCSE: MATHEMATICS 0580/41Dokumen20 halamanCambridge IGCSE: MATHEMATICS 0580/41TatiannahBelum ada peringkat