Aga Spec 412010

Diunggah oleh

Pawan ChaturvediJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Aga Spec 412010

Diunggah oleh

Pawan ChaturvediHak Cipta:

Format Tersedia

ANGLOGOLD ASHANTI SPECIFICATION

THERMAL INSULATION SYSTEM FOR CHILLED WATER PIPING

COPYRIGHT ANGLOGOLD ASHANTI 2002 APPROVED 2002-10-04

412/10 ISSUE 4 PAGE 1 OF 15

CONTENTS 1.0 2.0 3.0 4.0 4.1 4.2 4.3 4.4 4.5 SCOPE TECHNICAL REQUIREMENTS TO BE SPECIFIED BY THE ENGINEER DEFINITIONS REQUIREMENTS General Materials Insulation system Construction Design

PAGE 2 2 2 3 3 4 7 7 7 9 9 9 9 10 11 11 11 11 11 11 12 RELATED DOCUMENTS RECORD OF AMENDMENTS DATA SHEET 13 14 15

5.0 QUALITY ASSURANCE REQUIREMENTS 5.1 Sampling

6.0 INSPECTION AND TESTING 6.1 6.2 6.3 Type tests Production tests Acceptance certificates and tests

7.0 MARKING, PACKING, TRANSPORT AND STORAGE 7.1 7.2 7.3 7.4 7.5 Marking Packing Transport Storage Training : : :

APPENDIX A APPENDIX B APPENDIX C

ANGLOGOLD ASHANTI SPECIFICATION

THERMAL INSULATION SYSTEM FOR CHILLED WATER PIPING

COPYRIGHT ANGLOGOLD ASHANTI 2002 APPROVED 2002-10-04

412/10 ISSUE 4 PAGE 2 OF 15

1.0

SCOPE This specification details the requirements for the thermal insulation of chilled water pipes including flanges, valves and other fittings installed underground, and covers pre-insulation on surface and in-situ applications underground. NOTE: THIS DOCUMENT REPLACES ANGLOGOLD ASHANTI SPECIFICATIONS 412/1, 412/9 AND 412/10 (Issue 3).

2.0

TECHNICAL REQUIREMENTS TO BE SPECIFIED BY THE ENGINEER Pipe outside diameter Insulation section lengths Total length of piping Bend or pipe fitting details Pipe material Pipe joint details (flanged or shouldered, outside diameter and bolt lengths) Required life and type of corrosion protection for complete system The prevailing ambient conditions affecting corrosion Packaging, transport and storage requirements Whether pipes are to be pre-insulated on surface or insulation to be installed in-situ underground

3.0

DEFINITIONS ANGLOGOLD ASHANTI ASTM : : AngloGold Ashanti Limited : American Society for Testing and Materials Agreed in writing by the head of the appropriate AngloGold Ashanti Corporate Office discipline or nominated representative

PPROVED

: :

British Standard As defined in the General Conditions of Contract : Council for Scientific and Industrial Research Building Technology Council for Scientific and Industrial Research Miningtek : Deutsches Institute Fr Normung : AngloGold Ashanti Head of Engineering or the nominated representative : Material providing thermal insulation through low heat transfer : Combination of one or more of sleeve, water vapour barrier, sealant and insulant so providing required properties

CONTRACTOR

CSIR BOUTEK : DIN ENGINEER INSULANT INSULATION SYSTEM

CSIR MININGTEK

ANGLOGOLD ASHANTI SPECIFICATION

THERMAL INSULATION SYSTEM FOR CHILLED WATER PIPING

COPYRIGHT ANGLOGOLD ASHANTI 2002 APPROVED 2002-10-04

412/10 ISSUE 4 PAGE 3 OF 15

LDPE NBS NES : PE QSP : : :

: Low density polyethylene : National Building Standards : Naval Engineering Standard (Royal Navy) Water reticulation pipe : Polyethylene : An AngloGold Ashanti Quality System Procedure South African Bureau of Standards Outer covering which provides protection to the insulant and vapour barrier Unplasticised polyvinyl chloride : Layer of continuous impermeable material or compound covering all sides of the insulation.

IPE

ABS

LEEVE

UPVC

APOUR BARRIER 4.0 4.1

REQUIREMENTS General Insulation produced by the chemical reaction of two or more components, which during the chemical action produce a water vapour or contain an acid shall not be injected or cast into a closed void. Insulation produced by the chemical reaction of two or more constituents, one of which is an acid, shall not be used as slab stock in voids which have metallic walls unless a vapour barrier covers the insulation. The Data Sheet in Appendix C shall be completed and submitted with the tender. If the Data Sheet is not supplied the tender will be disqualified.

ANGLOGOLD ASHANTI SPECIFICATION

THERMAL INSULATION SYSTEM FOR CHILLED WATER PIPING

COPYRIGHT ANGLOGOLD ASHANTI 2002 APPROVED 2002-10-04

412/10 ISSUE 4 PAGE 4 OF 15

4.2 4.2.1

Materials Protective cover: A protective cover (made of either UPVC, stainless steel, galvanised steel or rockshield reinforced cloth) shall be located on the external surface of the insulation systems and shall comply with the requirements specified in Table 1. TABLE 1 Protective Cover Requirements 2 REQUIREMENTS 1. Thickness 3.2 mm and non-combustible 2. Comply with AECI Specification No. 130/S/03 or Approved equivalent 4. UPVC sleeves shall be colour coded blue Steel (Grade 430 stainless steel) Steel (hot dip galvanised) Rockshield reinforced cloth Minimum thickness 0.3 mm Minimum thickness 0.8 mm for pipes installed in shafts (Grade Z600). Minimum thickness 0.5 mm for pipes installed in haulages (Grade Z275) 1. 50% linear LDPE / 50% Polypropyleyne reinforced cloth 2. Flame retardant added 3. Minimum thickness 0.8 mm SABS ISO 4998 3 TEST METHOD UL 214 CSIR Test Method, Modified

1 MATERIAL UPVC (See note below)

UL 214 CSIR Test Method, Modified.

Note:

Where uPVC or rockshield covered piping is routed closer than 6.0 m from fuelling bays oil stores, conveyor belts, oil-filled transformers and switchgear, timber supports, etc, external steel cladding shall be applied, see AngloGold Ashanti Drawing No. Y1903. The combination of an UPVC cover and phenolic foam or nitrile rubber insulation is not acceptable as the toxicity index exceeds 5.

ANGLOGOLD ASHANTI SPECIFICATION

THERMAL INSULATION SYSTEM FOR CHILLED WATER PIPING

COPYRIGHT ANGLOGOLD ASHANTI 2002 APPROVED 2002-10-04

412/10 ISSUE 4 PAGE 5 OF 15

4.2.2

Water vapour barrier: The water vapour barrier shall comply with the requirements specified in Table 2. TABLE 2 1 PROPERTY/ MATERIAL Water vapour transmission (includes bonding/sealing compounds) Water vapour barrier requirements 2 REQUIREMENTS 1. 0.0 g maximum per m/24 h at 38C dry bulb 2 % and 90 % 5 % R.H. 2. The vapour barrier shall cover the entire insulation section from all sides and be thermally sealed along the seam and not glued. 3. Minimum width of thermal seal shall be at least 6 mm. Not less than 2.24 N/mm To breaking point Elongation In machine direction not less than 30 % In cross direction not less than 22 % Joint seal (if applicable) Breaking strength not less than 1.6 N/mm In machine direction not less than 1 120 mN/sheet Tear strength In cross direction not less than 1 870 mN/sheet Pass A 35 m aluminium foil (not metalized and guaranteed pinhole free) with a 300 m (70% LDPE and 30% Polypropylene) co-extruded outer layer and a 35 m PE inner layer. BS 782, Part 3, Method 360B SABS 952 1985 Subsection 5.6 SABS 952 - 1985 Subsection 5.6 3 TEST METHOD

ASTM E96

Tensile strength

SABS 952 1985 Subsection 5.6

Combustibility Vapour barrier construction and minimum thickness of material

UL214 CSIR Test Method, modified Using a dial gauge for thickness. Using a microscope for pinholes.

Note: Foam glass and nitrile rubber insulation do not require a vapour barrier as these materials have a closed cell structure and are not affected when in contact with water.

ANGLOGOLD ASHANTI SPECIFICATION

THERMAL INSULATION SYSTEM FOR CHILLED WATER PIPING

COPYRIGHT ANGLOGOLD ASHANTI 2002 APPROVED 2002-10-04

412/10 ISSUE 4 PAGE 6 OF 15

4.2.3

Insulation: The insulation shall comply with the requirements specified in Table 3 TABLE 3 1 PROPERTY/ MATERIAL Combustibility Maximum thermal conductivity at 10C Insulation requirements 2 REQUIREMENTS Pass Phenolic foam:--------------------0.022 W/mC Rock wool:-------------------------0.035 W/mC Foam Glass (T4):----------------0.039 W/mC Nitrile rubber:----------------------0.040 W/mC Polyethylene foam:--------------0.048 W/mC Phenolic foam:-------------------- 60 kg/m3 Rock wool:-------------------------160 kg/m3 Foam Glass (T4):----------------120 kg/m3 Nitrile rubber(superlon):--------- 77 kg/m3 Polyethylene foam:----------------40 kg/m3 For insulation systems that do not use a water vapour barrier: a maximum of 0.05 g per m/24 h at 32C dry bulb 2 % and 90 % 5 % R.H. 3 TEST METHOD UL 214 CSIR Test Method, modified ASTM C177 (read in conjunction with ASTM C518)

Density (allowing a 5% tolerance) Water vapour transmission (includes bonding/sealing compounds)

SABS Method 79

ASTM E96

Note: Any insulation, which physically or chemically decomposes when in contact with water must be covered with a water vapour barrier.

ANGLOGOLD ASHANTI SPECIFICATION

THERMAL INSULATION SYSTEM FOR CHILLED WATER PIPING

COPYRIGHT ANGLOGOLD ASHANTI 2002 APPROVED 2002-10-04

412/10 ISSUE 4 PAGE 7 OF 15

4.3

Insulation system The insulation system shall comply with the requirements specified in Table 4. TABLE 4 1 PROPERTY/ MATERIAL System requirements (for piping and flange covers) 2 REQUIREMENTS Toxicity index = 5 maximum Flame spread = pass For the complete system as installed (Insulation / water vapour barrier / joint seal / cover) 3 TEST METHOD SABS Method T1 / NES 713; CSIR Boutek, Fire Engineering Sciences full scale test CSIR Boutek, Fire Engineering Sciences small scale test

Smoke production max index = pass Smouldering combustion = not allowed

Minimum thickness of insulation based on insulation properties in table 3, allowable heat gains in Table 6 and conditions specified in Table 5 Thermal conductivity Note: 4.4 4.4.1 4.4.2

Phenolic foam:--------------------15 mm Rock wool:-------------------------20 mm Foamglass:------------------------25 mm Nitrile rubber (Superlon):-------25 mm Polyethylene foam:--------------30 mm As given in table 3

SABS approved measuring tape

ASTM C177

The overall length of insulation system on pre-insulated pipes shall allow adequate access to flange bolt holes to prevent damage during bolt on/off action.

Construction Insulant: The insulation shall be homogenous, free of voids and shall occupy all cavities with. Water vapour protection: Water vapour protection of the insulation shall be such that the insulation is encapsulated in a material which complies with the requirements of a water vapour barrier detailed in Table 2. Where this material is joined, it shall be thermally sealed and not glued. Products of organic nature: Polyurethane or polystyrene-based materials shall not be used. Design The Contractor shall provide dimensioned drawings, completed data sheet (as given in appendix C) and certified test certificates (as required by this specification) with his tender. The Contractor shall also provide for Approval, the methods and materials to be used for fixing insitu type insulation to the pipes.

4.4.2 4.5

ANGLOGOLD ASHANTI SPECIFICATION

THERMAL INSULATION SYSTEM FOR CHILLED WATER PIPING

COPYRIGHT ANGLOGOLD ASHANTI 2002 APPROVED 2002-10-04

412/10 ISSUE 4 PAGE 8 OF 15

4.5.1

Calculations: The parameters detailed in Table 5 shall be used for design purposes. TABLE 5 Calculations parameters (standard at test site) 1 PARAMETER Water velocity Water temperature Pipe diameter range Pipe wall thickness Pipe thermal conductivity Air temperature Air velocity 2 VALUES 1 m/s 5C 100 mm 300 mm 6 mm 45 W/mC (mild steel) 32C dry bulb 5 m/s

Note:

If pipes of different thermal conductivity pipe diameter and wall thickness are used, this shall be specified by the company. 4.5.2 Design performance requirements: The maximum heat gain per linear metre of insulated pipe shall not exceed the value given in Table 6. Note: The value given is for the combined insulating value of pipe wall, vapour barrier and sleeve and is based on a dry clean sleeve outer surface. Calculations parameters 2 HEAT GAIN (W/linear m) 17 25 32 39 45 3 TEST METHOD

TABLE 6

1 PIPE : NOMINAL SIZE (mm) 100 150 200 250 300

See Clause 6.1.2 of this specification

ANGLOGOLD ASHANTI SPECIFICATION

THERMAL INSULATION SYSTEM FOR CHILLED WATER PIPING

COPYRIGHT ANGLOGOLD ASHANTI 2002 APPROVED 2002-10-04

412/10 ISSUE 4 PAGE 9 OF 15

4.5.3

Designed maximum outside diameter: The designed maximum diameter of the insulation shall comply with the requirements of Table 7. TABLE 7 Maximum insulation system outside diameters (including sleeve) 1 NOMINAL STEEL PIPE SIZE (mm) 100 150 200 250 300 1 NOMINAL uPVC PIPE SIZE (mm) OD 105 155 210 250 ID 88.6 130.8 177.2 211.0 2 INSULATIONS SYSTEM OUTSIDE DIAMETER (mm) 225 290 350 420 470 2 INSULATIONS SYSTEM OUTSIDE DIAMETER (mm) 216 266 321 361

5.0

QUALITY ASSURANCE REQUIREMENTS The requirements of QSP 101 shall apply.

5.1

Sampling Sampling for type testing shall be as determined by the AngloGold Ashanti Manager Occupational Environment. Sampling for production testing shall be in accordance with the requirements detailed in the Approved Quality Plan.

6.0 6.1 6.1.1

INSPECTION AND TESTING Type tests Full scale fire test (CSIR Boutek, Fire Engineering Sciences): Full-scale pipe insulation tests shall be performed on two 200 mm diameter insulated pipes complete with vapour barriers, bonding and external protective cover. The pipes shall be installed in parallel.

ANGLOGOLD ASHANTI SPECIFICATION

THERMAL INSULATION SYSTEM FOR CHILLED WATER PIPING

COPYRIGHT ANGLOGOLD ASHANTI 2002 APPROVED 2002-10-04

412/10 ISSUE 4 PAGE 10 OF 15

6.2

Production tests Production tests shall be performed on samples as detailed in the Quality Plan and at the frequency specified in Table 8. TABLE 8 Sampling plans for test Clause 6.2 1 LOT SIZE 3 5 8 2 SAMPLE SIZE 3 DEFECTIVE ACCEPTABLE 0 0 0

Up to and including 25 26 50 51 - 150 Extracted from BS 6001 AQL 6.5) 6.2.1 6.2.2 6.2.3 6.2.4 6.2.5 6.2.6 6.2.7 6.2.8 6.2.9

Small scale flame spread: Combustibility shall be tested in accordance with the requirements of UL 214 CSIR Method, Modified. Toxicity: Toxicity shall be tested in accordance with the requirements of SABS Method T1 (NES 713). Conductivity: The conductivity of a sample of the insulation shall be tested according to ASTM C177. Water vapour transmission: The water vapour transmission values of the water vapour barrier shall be tested according to ASTM E96. Tensile strength: The tensile strength shall be tested in accordance with SABS 952-1985 subsection 5.6. Elongation: The elongation shall be tested in accordance with SABS 952-1985 Subsection 5.6. Joint heat seal breaking strength: The joint heat seal breaking strength shall be tested in accordance with SABS 952-1985 Subsection 5.6. Tear strength: The tear strength shall be tested in accordance with BS 2782, Part 3, Method 360B. Mass: The mass shall be tested in accordance with SABS Method 79.

6.2.10 Thickness: The thickness shall be tested in accordance with SABS 952-1985 Subsection 5.6. 6.2.11 Density of insulant: Remove a cube from an insulated pipe and determine its mass. Calculate the volume of the cube and determine the density of the insulant by dividing the mass by the volume. Express the result in kg/m. The result shall comply with the requirements of Table 3.

ANGLOGOLD ASHANTI SPECIFICATION

THERMAL INSULATION SYSTEM FOR CHILLED WATER PIPING

COPYRIGHT ANGLOGOLD ASHANTI 2002 APPROVED 2002-10-04

412/10 ISSUE 4 PAGE 11 OF 15

6.2.12 Thickness of insulant: The thickness of the insulant shall be measured prior to encapsulation in the vapour barrier and outside protective sleeve for in-situ type insulation. For pre-insulated pipes, the circumference of the pipe and the outside circumference of the protective sleeve of the insulated pipe shall be measured. 6.3 Acceptance certificates and tests The following tests are required per batch of insulation / insulation system produced: Small scale flame spread (UL 214 CSIR Method) Toxicity SABS Method T1 (NES 713) Conductivity (ASTM C177)

If any of these tests do not pass the specifications, then the batch shall be rejected. When the insulation is delivered, a batch certificate with acceptable test results, shall be provided to AngloGold Ashanti before payment can be made. The batch number shall be clearly and permanently marked on the insulation. The batch number shall give the date of manufacture and the run number. Additional testing shall be performed as determined by the Manager Occupational Environment or his representative(for example thickness tests, conductivity, vapour barrier composition, etc.). These additional tests will be for AngloGold Ashantis account. If the insulation does not pass one of the test, all delivered insulation shall be taken back by the supplier and AngloGold Ashanti shall be refunded for insulation which has already been paid for. 7.0 7.1 MARKING, PACKING, TRANSPORT AND STORAGE Marking The outer surface of all insulation sections and the water vapour barrier shall be marked with the following information: 7.2 The Contractor's name or logo The Batch number (with the date of manufacture and run number)

Packing Packing shall provide protection during transit from the place of manufacture to the underground installation site. All insulation sections which have water vapour barriers, shall be contained in a reinforced bag which will prevent damage during transit.

7.3

Transport Transport, loading and unloading shall be performed in a manner which will prevent any damage to the insulation system. Damaged items will not be accepted from the Contractor.

7.4

Storage

ANGLOGOLD ASHANTI SPECIFICATION

THERMAL INSULATION SYSTEM FOR CHILLED WATER PIPING

COPYRIGHT ANGLOGOLD ASHANTI 2002 APPROVED 2002-10-04

412/10 ISSUE 4 PAGE 12 OF 15

Pipes shall be stored so that damage to the insulation system by mechanical means or by adverse weather conditions is prevented. 7.5 Training Awareness training shall be given for the transportation, storage, installation and maintenance of the insulation system offered, by the Contractor.

ANGLOGOLD ASHANTI SPECIFICATION

THERMAL INSULATION SYSTEM FOR CHILLED WATER PIPING

COPYRIGHT ANGLOGOLD ASHANTI 2002 APPROVED 2002-10-04

412/10 ISSUE 4 PAGE 13 OF 15

APPENDIX A : RELATED DOCUMENTS The latest issues of the following documents shall be deemed to form part of this specification: ASTM C177 ASTM C518 : : Test method of steady-state heat flux measurements and thermal transmission properties by means of guarded-hot-plate apparatus Test method of steady-state heat flux measurements and thermal transmission properties by means of guarded-hotPlate apparatus Specification for PVC formulation Cladding Quality requirements for minor products and standard stock consumable items Recommended practice for heat ageing of plastics without load Test for water vapour transmission of materials Determination of tear strength of sheet and sheeting Full scale fire test Testing of plastics, tensile impact test Determination of the toxicity index of the products of Combustion from shall specimens of materials Polyolefin film for damp-proofing and water-proofing in buildings Quality management systems Mass / unit area of conditioned textile fabrics Fire testing of materials, components and elements

AECI 130/5/03

AngloGold Ashanti Drawing Y1903 : AngloGold Ashanti QSP 101 ASTM D304 ASTM E96 BS 782 Part 3 Method 360B CSIR Boutek Fire Engineering Sciences Test DIN 53448 NES 713 (Royal Navy) SABS 952 SABS ISO 9001 SABS Method 79 UL 214 CSIR Method Modified : : : : : : : : : : :

ANGLOGOLD ASHANTI SPECIFICATION

THERMAL INSULATION SYSTEM FOR CHILLED WATER PIPING

COPYRIGHT ANGLOGOLD ASHANTI 2002 APPROVED 2002-10-04

412/10 ISSUE 4 PAGE 14 OF 15

APPENDIX B : RECORD OF AMENDMENTS Issue 3 : Tables 1, 2, 4 amended Clauses 4.5, 7.3 amended Clause 7.5 added Appendix C sleeve, vapour barrier, and system requirements amended (M. Karsten 2001-02-28) Table 1,2,3,4,6,7 amended Clauses 4.1, 4.2.1, 4.4.1, 4.5, 7.1, 7.2, amended Clauses 6.1.2, 4.4.5 removed Appendix C amended (C Hegermann 2002-09-25)

Issue 4:

ANGLOGOLD ASHANTI SPECIFICATION

THERMAL INSULATION SYSTEM FOR CHILLED WATER PIPING

COPYRIGHT ANGLOGOLD ASHANTI 2002 APPROVED 2002-10-04

412/10 ISSUE 4 PAGE 15 OF 15

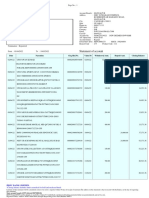

APPENDIX C : DATA SHEET (to be completed as part of the tender document) CONFORMANCE TO SPECIFICATION 412/10 Issue 4 1 COMPONENT 2 REQUIREMENTS 3 TEST METHOD 1. UL 214 CSIR Test Method, modified 2. SABS ISO 4998 1. ASTM E96 2. UL 214 CSIR Test Method, modified 1. UL 214 CSIR Test Method, modified 2. ASTM C177 (in conjunction with ASTM C518) 3. ASTM E96 4. SABS Method 79 1. SABS Method T1 / NES 713 2. CSIR, Full scale fire test 3. CSIR, Small scale test 1. SABS approved measuring tape 4 SUPPLIER CONFORMANCE Yes or No?

Protective Cover

As per table 1 of Spec 412/10 Issue 4

Water vapour barrier

As per table 2 of Spec 412/10 Issue 4

Insulation

As per table 3 of Spec 412/10 Issue 4

Insulation System

As per table 4 of Spec 412/10 Issue 4

Installed sizes

As per table 7 of Spec 412/10 Issue 4

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- ARPM Handbook Rev April 2015 PDFDokumen194 halamanARPM Handbook Rev April 2015 PDFKavir RamdassBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- API 571 Training CourseDokumen140 halamanAPI 571 Training Courseapply1984237197% (29)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Hydrant Dispenser 1000gpmDokumen2 halamanHydrant Dispenser 1000gpmJèfrì PìnémBelum ada peringkat

- DPSB Cir Not 2023 24 001Dokumen2 halamanDPSB Cir Not 2023 24 001Pawan ChaturvediBelum ada peringkat

- Plasma and OxifuelDokumen20 halamanPlasma and OxifuelPawan ChaturvediBelum ada peringkat

- ThesisDokumen128 halamanThesisPawan ChaturvediBelum ada peringkat

- DPSB Cir Not 2023 24 001Dokumen2 halamanDPSB Cir Not 2023 24 001Pawan ChaturvediBelum ada peringkat

- AIGA 046 - 08 Periodic Inspection of Static Cryogenic Vessels - Reformated Jan 12Dokumen13 halamanAIGA 046 - 08 Periodic Inspection of Static Cryogenic Vessels - Reformated Jan 12aliBelum ada peringkat

- Class 5BDokumen1 halamanClass 5BPawan ChaturvediBelum ada peringkat

- Unit 1 - A - Improper IntegralDokumen8 halamanUnit 1 - A - Improper IntegralPawan ChaturvediBelum ada peringkat

- Mutual Fund Tracker IndiaDokumen979 halamanMutual Fund Tracker IndiaMahesh NaikBelum ada peringkat

- Ecan 19112QZ00NDokumen2 halamanEcan 19112QZ00NPawan ChaturvediBelum ada peringkat

- DPSB Cir Not 2022 23 019Dokumen2 halamanDPSB Cir Not 2022 23 019Pawan ChaturvediBelum ada peringkat

- OIL Cleanliness FundamentalsDokumen43 halamanOIL Cleanliness FundamentalsPawan ChaturvediBelum ada peringkat

- AssignmentDokumen1 halamanAssignmentPawan ChaturvediBelum ada peringkat

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDokumen3 halamanStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalancePawan ChaturvediBelum ada peringkat

- Claim Form PDFDokumen5 halamanClaim Form PDFmeghaBelum ada peringkat

- Astm B88 2009 PDFDokumen7 halamanAstm B88 2009 PDFAntonio JBelum ada peringkat

- Foster BUTYLAR NXT PDS R1019Dokumen2 halamanFoster BUTYLAR NXT PDS R1019Pawan ChaturvediBelum ada peringkat

- Is 1200 15Dokumen12 halamanIs 1200 15ramachandra_20012040Belum ada peringkat

- Astm A420a420m 16Dokumen6 halamanAstm A420a420m 16Chistian AcostaBelum ada peringkat

- Fine Filter BrochureDokumen6 halamanFine Filter BrochurePawan ChaturvediBelum ada peringkat

- A648Dokumen4 halamanA648Hanibale Nuril HakimBelum ada peringkat

- General Partner Information and Project Scope Definition Natural Gas TransmissionDokumen6 halamanGeneral Partner Information and Project Scope Definition Natural Gas TransmissionPawan Chaturvedi100% (1)

- Mechanical Maintennace PlansDokumen168 halamanMechanical Maintennace PlansPawan ChaturvediBelum ada peringkat

- SC119 - Umoja Plant Maintenance Overview - CBT PPT - V5Dokumen67 halamanSC119 - Umoja Plant Maintenance Overview - CBT PPT - V5graemesquires85Belum ada peringkat

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDokumen5 halamanStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalancePawan ChaturvediBelum ada peringkat

- Using BOM's To Gain Planning & Scheduling Efficiencies: Jeff SmithDokumen27 halamanUsing BOM's To Gain Planning & Scheduling Efficiencies: Jeff SmithPawan ChaturvediBelum ada peringkat

- SAP Super User Should KnowDokumen90 halamanSAP Super User Should Knowkumar N100% (2)

- Hydraulic Hoses V2Dokumen96 halamanHydraulic Hoses V2Taufiq WibawaBelum ada peringkat

- I.Manual For FSADokumen11 halamanI.Manual For FSAVu DangBelum ada peringkat

- Swann Direct Catalogue Wall Ties and Restraint FixingsDokumen34 halamanSwann Direct Catalogue Wall Ties and Restraint FixingsHASEEBBelum ada peringkat

- Abreviaturas ValvulasDokumen3 halamanAbreviaturas ValvulasROBINSONBelum ada peringkat

- Piping StandardDokumen425 halamanPiping StandardJitendra Bhosale100% (3)

- Consolidated Safety Valve 19110 PDFDokumen48 halamanConsolidated Safety Valve 19110 PDFJose FloresBelum ada peringkat

- Ddec V EgrDokumen46 halamanDdec V EgrKevin VargasBelum ada peringkat

- VCPBR 05043 en PRV OverviewDokumen24 halamanVCPBR 05043 en PRV OverviewmagveyBelum ada peringkat

- Hyspan Installation & Maintenance Instructions Type N Style II, OW 1500 Style II, ASME ClassDokumen4 halamanHyspan Installation & Maintenance Instructions Type N Style II, OW 1500 Style II, ASME ClasskrazygreaseBelum ada peringkat

- MQ SP M 4001 PDFDokumen25 halamanMQ SP M 4001 PDFjaseelBelum ada peringkat

- 3400 Series SeniorSonic JuniorSonic Data Sheet PDFDokumen16 halaman3400 Series SeniorSonic JuniorSonic Data Sheet PDFprihartono_dias100% (1)

- TENDER CLARIFICATION NO. 1 - HYDRANT AND FOAM PIPELINE REPLACEMENT AT LBT at LB1 AND LB2Dokumen6 halamanTENDER CLARIFICATION NO. 1 - HYDRANT AND FOAM PIPELINE REPLACEMENT AT LBT at LB1 AND LB2Sathya SeelanBelum ada peringkat

- Mep Specifications - 5Dokumen20 halamanMep Specifications - 5Imran AzizBelum ada peringkat

- Masoneilan 21000 Series: Top Guided Globe Valve With Lo-dB /anti-Cavitation CapabilitiesDokumen24 halamanMasoneilan 21000 Series: Top Guided Globe Valve With Lo-dB /anti-Cavitation CapabilitiesManoj KumarBelum ada peringkat

- Elster Rotary Gas Meter: I Connected IndustrialDokumen6 halamanElster Rotary Gas Meter: I Connected IndustrialAlvaro Joel Quinteros RochaBelum ada peringkat

- Cat StreetrodDokumen132 halamanCat StreetrodMaxisys AutelBelum ada peringkat

- Backward Curved High Pressure Composite Fans: ModelDokumen44 halamanBackward Curved High Pressure Composite Fans: ModelJairo FigueroaBelum ada peringkat

- BUSCHJOSTDokumen116 halamanBUSCHJOSTgbr.moreira12Belum ada peringkat

- HiVAWT - DS07-User Manual - EN-Ver4-20200611Dokumen50 halamanHiVAWT - DS07-User Manual - EN-Ver4-20200611Rene Alexander Barrera CardenasBelum ada peringkat

- X-Mode 100 (Sj20ba)Dokumen117 halamanX-Mode 100 (Sj20ba)张连杉0% (1)

- VALFLON Sheet Gasket: Valqua No. 7010 Food Product Name VALFLON Pure PTFE GasketDokumen4 halamanVALFLON Sheet Gasket: Valqua No. 7010 Food Product Name VALFLON Pure PTFE GasketMỹ Phạm AnhBelum ada peringkat

- How Do I Determine Bolt Torque For Flanged ConnectionsDokumen6 halamanHow Do I Determine Bolt Torque For Flanged Connectionsloq100% (1)

- Document PDFDokumen11 halamanDocument PDFPrakash ChidambaramBelum ada peringkat

- FV Flash Vessel-Technical Information-1Dokumen3 halamanFV Flash Vessel-Technical Information-1Vanessa Elizabeth BeshaiesBelum ada peringkat

- LESER High Efficiency Catalog enDokumen68 halamanLESER High Efficiency Catalog enandy131078Belum ada peringkat

- 6EY26 CatalogDokumen111 halaman6EY26 CatalogTarek Massimo100% (2)

- Final PRDSDokumen7 halamanFinal PRDSdgmBelum ada peringkat

- Iso 6002-1992Dokumen20 halamanIso 6002-1992GT-LUCAS BARCIBelum ada peringkat

- 43210-0001 Jabsco PumpDokumen5 halaman43210-0001 Jabsco PumpRon CooperBelum ada peringkat

- UL MASTECO ALARM VALVE Instruction ManualDokumen4 halamanUL MASTECO ALARM VALVE Instruction ManualNguyễn Thống NhấtBelum ada peringkat