Quality - Slagging

Diunggah oleh

NoviandryDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Quality - Slagging

Diunggah oleh

NoviandryHak Cipta:

Format Tersedia

SLAGGING

1. Influence of ash fusion temperature : Slagging is a phenomenon that ash melts in combustion furnace (boiler) and stick to radiation walk in liquid form. It is judged by the fact that whether ash fusion temperature is higher or lower than gas temperature around radiation wall. It is generally believed that coal having ash fusion temperature higher than 1300oC would not have slagging. Influence of ash content : For the coal with high slagging propensity, amount of slaggs building up on radiation wall has linear relationship with amount of ash to be fed into boiler. Special consideration is to be taken when low calorific coal with high ash content is to be burned. Ash Slagging index (see attached exhibit 17) For your information Berau Coal is categorized in lignitic type ash coal. Influence of Sulphur content: If sulphur content is high slagging propensity would increase because Sulphur (S) combines with alkaline ingradients and form sulphate with low fusion temperature. Sulphur content less than 20% would be desirable in terms of preventing slagging problem.

2.

3.

4.

A. Bituminous type ash ( Fe2O3 > CaO + MgO ) Slagging Index Rs =

B x S content A

Where:

B Fe2O3 + CaO + MgO + Na2O + K 2O = A SiO2 + Al2O3 + TiO2

Index Rs < 0.6 0.6 - 1.9 2.0 - 2.6 > 2.6

Slagging Propensity Low Medium High Severe

B. Lignitic type ash ( Fe2O3 < CaO + MgO) Slagging Index Where:

TH + 4TID 5 TH: Hemisphere ash fusion temperature (higher of oxidizing or reducing atm.) TID: Initial deformation temperature (lower of oxidizing or reducing atm.)

Rs =

Index Rs > 1350 1350 - 1231 1230 - 1150 < 1150

Slagging Propensity Low Medium High Severe

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

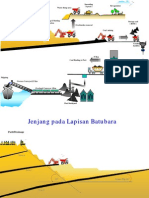

- Coal Mining ActivityDokumen8 halamanCoal Mining ActivityNoviandryBelum ada peringkat

- Sales Plan TemplateDokumen8 halamanSales Plan TemplateAgung UdaraBelum ada peringkat

- OCR Physics A: 11 Waves 1 Exam-Style Mark SchemeDokumen3 halamanOCR Physics A: 11 Waves 1 Exam-Style Mark SchemeSam PulsfordBelum ada peringkat

- Topic 2 - Vapor Compression and Air, Refrigeration CyclesDokumen77 halamanTopic 2 - Vapor Compression and Air, Refrigeration CyclesOk SokBelum ada peringkat

- Bsen 121110 - 2014 Cabinas PresionDokumen31 halamanBsen 121110 - 2014 Cabinas Presionfelipe farias100% (1)

- Quote TemplateDokumen7 halamanQuote TemplateNoviandryBelum ada peringkat

- Quality - Ash Fusion TempDokumen30 halamanQuality - Ash Fusion TempNoviandryBelum ada peringkat

- Emt327 328Dokumen11 halamanEmt327 328NoviandryBelum ada peringkat

- Quality - FoulingDokumen1 halamanQuality - FoulingNoviandryBelum ada peringkat

- Purchase Order 25Dokumen1 halamanPurchase Order 25NoviandryBelum ada peringkat

- Quality - EspDokumen3 halamanQuality - EspNoviandryBelum ada peringkat

- Purchase Order 37Dokumen1 halamanPurchase Order 37NoviandryBelum ada peringkat

- Request For Items To Be Purchased Date Requested:: Vendor InformationDokumen3 halamanRequest For Items To Be Purchased Date Requested:: Vendor InformationNoviandryBelum ada peringkat

- Purchase Order 36Dokumen2 halamanPurchase Order 36NoviandryBelum ada peringkat

- Quality - Spontaneous Combustion ReportDokumen26 halamanQuality - Spontaneous Combustion ReportNoviandryBelum ada peringkat

- Quality - GrindabilityDokumen3 halamanQuality - GrindabilityNoviandryBelum ada peringkat

- Quality - Power PlantDokumen3 halamanQuality - Power PlantNoviandryBelum ada peringkat

- Quality de SoxDokumen1 halamanQuality de SoxNoviandryBelum ada peringkat

- Quality - Dust ControlDokumen20 halamanQuality - Dust ControlNoviandryBelum ada peringkat

- Quality - CombustibilityDokumen1 halamanQuality - CombustibilityNoviandryBelum ada peringkat

- Quality - Concept of CombustionDokumen3 halamanQuality - Concept of CombustionNoviandryBelum ada peringkat

- Quality - Coal GasificationDokumen1 halamanQuality - Coal GasificationNoviandryBelum ada peringkat

- Quality de NoxDokumen2 halamanQuality de NoxNoviandryBelum ada peringkat

- Quality - Ash Fusion Temp2Dokumen1 halamanQuality - Ash Fusion Temp2NoviandryBelum ada peringkat

- 5 Rock QualityDokumen22 halaman5 Rock QualityJerrard YXBelum ada peringkat

- Miniscape UtilizationDokumen9 halamanMiniscape UtilizationNoviandry100% (1)

- Dust ControlDokumen20 halamanDust ControlNoviandryBelum ada peringkat

- Jorc - Slide1Dokumen35 halamanJorc - Slide1NoviandryBelum ada peringkat

- Geotech - OpenpitDokumen82 halamanGeotech - OpenpitNoviandryBelum ada peringkat

- Geotech - Rockmass ClassDokumen65 halamanGeotech - Rockmass ClassNoviandryBelum ada peringkat

- Coal UtilizationDokumen50 halamanCoal UtilizationNoviandryBelum ada peringkat

- FMP Prospekt PB-XFC EnglishDokumen8 halamanFMP Prospekt PB-XFC Englishparahu ariefBelum ada peringkat

- Design Guide - LV Circuit Breaker and Panels: April 2022Dokumen38 halamanDesign Guide - LV Circuit Breaker and Panels: April 2022RFBelum ada peringkat

- Training Course: International Oil Supply, Transportation, Refining & TradeDokumen10 halamanTraining Course: International Oil Supply, Transportation, Refining & TradeIbrahim SalahudinBelum ada peringkat

- Servisni Manual Gree en Fairy 12 BGDokumen92 halamanServisni Manual Gree en Fairy 12 BGVictor Marcell Oliveira MesquitaBelum ada peringkat

- CV Wasis Dwi AryawanDokumen3 halamanCV Wasis Dwi AryawanAgus DanielBelum ada peringkat

- SYMPHOS 2015 - Bittner FinalDokumen11 halamanSYMPHOS 2015 - Bittner FinalTattiana Aracelli Melo CifuentesBelum ada peringkat

- Adv Hydraulics Master's Course NotesDokumen3 halamanAdv Hydraulics Master's Course NotesKrishna GhimireBelum ada peringkat

- Ban Goc Read 5Dokumen2 halamanBan Goc Read 5Linh TrâmBelum ada peringkat

- Lec 5 ME161 - 2022 Electromechanical SystemDokumen14 halamanLec 5 ME161 - 2022 Electromechanical SystemSabbirBelum ada peringkat

- Ac 03Dokumen1 halamanAc 03Ajit ShettyBelum ada peringkat

- PWR Basics and Safety FeaturesDokumen35 halamanPWR Basics and Safety FeaturesReda OsamaBelum ada peringkat

- 10mva GTP - 01.04.2019Dokumen5 halaman10mva GTP - 01.04.2019Shahriar AhmedBelum ada peringkat

- Adi Artech: DescriptionDokumen1 halamanAdi Artech: DescriptionkumarBelum ada peringkat

- Guedi Capeluto Climate and Energy Lab in Architecture, Faculty of Architecture and Town Planning. Technion, Israel Institute of Technology, IsraelDokumen7 halamanGuedi Capeluto Climate and Energy Lab in Architecture, Faculty of Architecture and Town Planning. Technion, Israel Institute of Technology, IsraelChanna RajBelum ada peringkat

- Rancang Bangun Buck-Boost Converter Berbasis Arduino Pada Pembangkit Listrik Tenaga Surya 8x10 WPDokumen11 halamanRancang Bangun Buck-Boost Converter Berbasis Arduino Pada Pembangkit Listrik Tenaga Surya 8x10 WPAnamBelum ada peringkat

- PEGSON - 'M' Series JAW Crusher (Curvas de Produccion) (+++)Dokumen8 halamanPEGSON - 'M' Series JAW Crusher (Curvas de Produccion) (+++)Juan CarlosBelum ada peringkat

- Manuel Des Donnã©es Techniques AQUACIAT LD 150-600 (SEER LT)Dokumen12 halamanManuel Des Donnã©es Techniques AQUACIAT LD 150-600 (SEER LT)umarmirza83Belum ada peringkat

- Chapter 4 - Additive and Chemical AdmixturesDokumen42 halamanChapter 4 - Additive and Chemical Admixtureseyob yohannesBelum ada peringkat

- PHYSICS 101 - Exam Sample QuestionsDokumen13 halamanPHYSICS 101 - Exam Sample QuestionsHassan AideedBelum ada peringkat

- Ethiopia - 1-Electric Stove Standard 2020Dokumen20 halamanEthiopia - 1-Electric Stove Standard 2020Mulugeta AbrhaBelum ada peringkat

- 521G, 621G, 721G, 821G, 921G, 1021G, 1121G Wheel Loader ElectricalDokumen6 halaman521G, 621G, 721G, 821G, 921G, 1021G, 1121G Wheel Loader ElectricalEl Perro100% (1)

- Science DirectDokumen13 halamanScience DirectLê DuyBelum ada peringkat

- Week 011-012 Chemical ThermodynamicsDokumen8 halamanWeek 011-012 Chemical ThermodynamicsFigh terBelum ada peringkat

- Pyroban C15 HazpakDokumen4 halamanPyroban C15 Hazpakcacalot93Belum ada peringkat

- Hgns / Aps / CNT / RST: (Porosity Tools)Dokumen13 halamanHgns / Aps / CNT / RST: (Porosity Tools)Wualdir Martin Vivas ChungaBelum ada peringkat

- Enabling PV Russia ENDokumen100 halamanEnabling PV Russia ENhui cathyBelum ada peringkat

- SMA Mini-Grid InvertersDokumen30 halamanSMA Mini-Grid InvertersKasirBelum ada peringkat