Distributed Generation in Developing Countries

Diunggah oleh

Zara.FHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Distributed Generation in Developing Countries

Diunggah oleh

Zara.FHak Cipta:

Format Tersedia

Distributed Generation in Developing Countries

Edward M. Petrie and H. Lee Willis (ABB) and Masaki Takahashi (World Bank)

Introduction In developing countries around the world, more than 2 billion people lack access to electricity. Distributed generation represents an opportunity to quickly increase the quality of life for these individuals. Distributed generation for on-site power offers several advantages when compared to centralized, conventional models for power generation. This paper discusses the relevant issues and aims at illuminating the opportunities when distributed generation should be the preferred source of power. Distributed generation, or DG, includes the application of small generators, typically ranging in capacity from 5kW to 10MW, at or near to the end-user to provide the electric power needed. As applied in this paper, DG includes the complete power generation and distribution system for small villages. This includes generation, energy storage, on-site management (i.e., dispatch, control, communications), and all ancillary devices and services. The bulk of the DG equipment today is reciprocating engines that can run on various fuels but most often are run on diesel fuel. Although relatively inexpensive and readily available from multiple suppliers, these small reciprocating engine generators are generally considered degrading to the environment (high greenhouse gas emissions and noise levels), and they have high maintenance requirements. The expectations are that emerging technologies will play a significant future role in DG especially with regard to village electrification. Microturbines, fuel cells, solar, and wind-powered generation are all now in the early commercial or field-prototype stage. These technologies were originally developed for defense and non-polluting transportation applications. The stationary power market appears to be the first large-scale commercial opportunity for these devices. Distributed generation plants are increasing their popularity around the world, and village power electrification programs are widespread throughout Africa, Asia, and South America. More than $30 billion per year is spent on home heating fuels, batteries and candles in rural parts of the world, along with annual investments in 10-15 GW of diesel generation capacity. [1] DG aims to capture a large fraction of this rural market. Table 1 shows the forecasted annual installed MW for prime power applications (stand-by or emergency power applications are not included). The significant annual growth of 16% is very attractive to the developers of distributed generation equipment, and there is significant investment in these technologies. Value of Distributed Generation Where there is no power, any source of power generation is, of course, of significant value to the end-user, to the regional government, and to the prospective energy service company. However, from the electricity industry perspective, distributed generation is attractive because it has multiple other values. These values include the following: The generator can be sited close to the end-user, thus decreasing transmission and distribution costs and electrical losses. Sites for small generators are easier to find. Distributed generators offer reduced planning and installation time.

Because the DG units are distributed, the systemmay be more reliable. One unit can be removed for maintenance or service with only a moderate effect on the rest of the power distribution system. This is especially important for new technologies where the long-term reliability is not proven. Newer distributed generation technologies offer an environmentally clean and low noise source of power. Newer distributed generators can run on multiple types of fuels. This allows flexibility and reduction in cost of the infrastructure required to get the fuel to the generator. The preferred fuel source differs in various parts of the world. However, the required quality of the selected fuel may be more important with certain new DG technologies. Newer distributed generators can run on fuels generated from biogasification. Biomass (e.g., wood, hog waste, agricultural byproducts) is a truly renewable source of fuel in most developing countries and especially in agricultural regions. From the end-user perspective, distributed generation is also attractive for several reasons. Power is readily available and the power has improved quality and reliability over power produced from central generating stations. Depending on the nature of fuel used, electricity prices are often lower than power from central plants. Some DG technologies provide cogeneration possibilities, which allow site recovery of heat and / or hot water. This has the potential to raise energy efficiency to around 90%. In rural villages, the recovered heat can be used for hot water, space heating, industrial processes and even space cooling (adsorption air conditioners). The above advantages of DG can be realized as a result of technical improvements in the development of small-scale electricity generators. The specific details are provided in a following section. Comparison with Conventional Central Generation The bulk of electric power now used worldwide is produced by central station power plants, most of them using large, fossil-fired combination or nuclear boilers to produce steam that drives steam turbine generators. A majority of these plants are greater than 100 MW making them relatively large in both physical size and facilities requirements, and often making site selection and procurement a real challenge. These large plants also need a significant infrastructure both to get fuel and supplies to the plant and for transmitting and distributing the power once it is generated. One can make a comparison of DG with central generation on two levels: (1) new installations, (2) incremental capacity additions. For new installations the most direct comparison between DG and central generation is by efficiency. The plant efficiency of existing large central generation units could be in the 28-35% range depending on the age of the plant. This means that they convert between 28-35% of the energy in their fuel into useful electric power. By contrast, efficiencies of 40-50% are attributed to small fuel cells and to various new gas turbine and combined cycle units suitable for DG applications. Certain novel technologies, such as a fuel cell / gas turbine hybrid, is claimed to offer electrical efficiencies about 70%. Of course, these claims still need to be proven with full size pre-production and production units. Perhaps one of the most important values provided by DG is the short time in which a system can be installed. As Figure 1 shows, the elapsed time for most DG projects is significantly less than that for coal and gas plants. Speed of implementation and the modular nature of this technology allow developing countries to efficiently invest in power generation as the population grows.

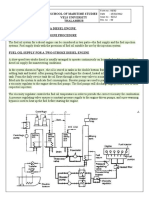

Typical large central plants must be over-designed to allow for future capacity and consequently they run most of their life in a very inefficient manner. A transmission and distribution infrastructure represents a significant cost in initial capital and continuing operations and maintenance. A DG unit does not have this T&D burden because it is already at the site of electrical use. In addition the T&D infrastructure is often responsible for a good deal of the service reliability problems experienced by electrical users. By avoiding those costs and reliability problems, DG can provide better service at lower cost in many applications. The effect of the T&D infrastructure on the price of electricity to users along the system is illustrated in Figure 2. Purchase of electricity is less expensive the nearer you are to the source of generation. With DG, the electricity user is at the source of generation. One of the fundamental factors considering the design of conventional T&D systems is that it costs more to upgrade most facilities to a high capacity than it does to build that capacity in the original construction. This factor contributes to generation and T&D infrastructure being built with considerable margin (50%) above existing load to allow for growth. The very high cost per kW for upgrading a T&D system (Table 2) creates one of the best perceived opportunities for DG applications. Thus, planners often look at areas of the system where slow, continuing load growth has increased load to the point that local delivery facilities are considerably taxed as areas where DG can deliver significant savings. Note that in rural or developing countries the incremental T&D expansion cost is greatest due to the dispersion of the load. Distributed Generation and Related Technologies The newly developed DG systems typically range from 5kW to 5 MW, have a foot print size of between 0.01 and 59 kW / square meter, have capital costs ranging from $200 to $6000 / kW, and are capable of producing electricity in the 3-20 / kWh range. These characteristics are ideal for distributed power generation systems. Table 3 provides important technical parameters of distributed generation technologies that are now commercially available. This section offers a short description of the most promising DG technologies for application in developing countries. Microturbines Microturbines operate on the same principles as traditional gas turbines. Air is drawn into the compressor where it is pressurized and forced into the cold side of the recuperator. Here, exhaust heat is used to preheat the air before it enters the combustion chamber. The combustion chamber then mixes the heated air with fuel and burns it. This mixture expands through the turbine, which drives the compressor and generator (typically at high speeds such as 70,000 to 120,000 RPM). Since the generator is mounted on the same shaft as the turbine, it rotates at the same speed. The combusted air is then exhausted through the recuperator before being discharged at the exhaust outlet. The generator thus produces high frequency AC power that is converted to 50/60Hz by power electronics. Typical power ratings range from 25 500 kW although multiple units may be directly interconnected to provide up to 10 MW. Typical capital costs are in the 500-1000 $/kW range and electrical efficiencies range from 27-32%. Utilising the exhaust heat can improve the overall efficiency up to 80%. Footprint size is in the 60 kW/m2 area, operating costs (i.e., cost to produce electricity) are estimated between 6 and 8 / kWh and NOx emissions are around 0.1 lb / BTU. Typically, micro-turbines use natural gas as fuel, but other fuels such as diesel, propane, and kerosene are possible. Flare gas from well heads has even been used as a source of fuel. However, the quality of the fuel (particulates, etc.) must be controlled due to the narrow paths within the turbine.

Fuel Cells Fuel cells are electric batteries able to convert hydrogen and oxygen into electricity, heat and water. Fuel cells are similar to batteries in that they both use an electrochemical process to produce a DC current. Both batteries and fuel cells consist of two electrodes separated by an electrolyte. Unlike batteries, fuel cells electrochemically convert the energy in a hydrogen-rich fuel directly into electricity and operate as long as the fuel stream lasts. Fuel cells are characterized by the type of electrolyte used; examples include alkaline, proton exchange membrane, phosphoric acid, molten carbonate and solid oxide. Depending on the electrolyte the fuel cell operates between 80 and 1000 C, ignoring this produced heat fuel cell efficiency can range between 35-65%. Utilizing the produced heat can raise the efficiency to over 80%. Target capital costs (assuming large volume manufacturing) range from 800-1300 $ / kW and footprint size ranges from 1-3 kW/m2. Operating costs are estimated at between 8-10 / kWh and emissions of NOx gasses are extremely low at 0.003-0.03 lb / BTU. Fuel cells are typically aimed at single installation sites (i.e., one bank of fuel cells) that require between 50 and 1000 kW, e.g., high rise office buildings, hospitals, schools, hotels, restaurants, etc. However, new small fuel cell developers (e.g., Plug Power and Ballard) who were previously aiming at the transportation markets see residential generation at about 5-10 kW power rating as a lucrative market Wind Power Windmills or wind energy converters convert wind power to electrical power. Typical systems range from 30 kW for individual units to 1.5 MW for wind farms of multiple units. Hub-heights are around 80 meters, and rotor diameters are 65 m. Rotor construction is either variable blade angle (pitch regulation) or non-variable, conversion from mechanical to electrical energy is via either synchronous or induction generators. Synchronous generators are usually equipped with pulse width modulated converters, control of these converters is essential for regulating the behaviour of the windmill on the electric grid. Windmills are often installed in groups, or wind farms, and are seldom used in isolation. Techniques for using HVDC links to connect wind farms to transmission grids are being investigated. A disadvantage of wind power is its irregularity; this further complicates connection to power grids. Typical costs are around 1000 $ / kW, and electrical efficiencies around 25%. However, it must be noted that efficiency should not be compared with fuel cell or micro-turbine efficiency due to 2 the renewable fuel source. Footprint sizes are in the order of 0.01 kW/m and operating costs between 4 and 12 / kWh. Solar Power Conversion of solar energy to electrical energy has been technically possible since the late 1930 s. The main difficulty is the high cost of photovoltaic systems, 6000 $ / kW is typical. Additionally the power output is directly proportional to the surface area of the cells and footprint 2 sizes are hence relatively large (0.02 kW/m ). As with windmills the electrical efficiency is relatively low (6-20%) but should not be compared with non-renewable systems. Operating costs are estimated at 18 20 / kWh. Typical applications of photovoltaic cells include small installations of < 10 kW on building rooftops or remote systems that can not be connected to the electricity grid. There are, however, programs to test larger capacity systems, e.g., 1 MW EU Joule program in Spain. When connected to the grid, the connection is usually made through an inverter and the grid accepts all power from the photovoltaic system. Energy storage is often required for periods when there is no wind. The cost of the energy storage component could be significant.

Reciprocating Engines Use of diesel and petrol engines to provide standby power for commercial and small industrial customers is not new. Recently engines operating on natural gas have been developed. Typical efficiencies range from 33 to 36% and capacities from 50 kW to 6 MW. Costs are in the 200-350 $ / kW range and footprint sizes are in the order of 50 kW/m2. Operating costs are estimated at 6 9 / kWh and NOx emissions are around 0.3 lb / BTU. Disadvantages of combustion engines are pollution (both emissions and noise) and relatively high maintenance and operation costs. Previously these systems were connected to the electricity grid for standby power only, studies show that conversion to peak shaving or base loads require new designs and power conversion systems than conventionally used for emergency power generators. These newer systems are now coming onto the market from several suppliers. Hydroelectric Power Small hydroelectric plants are fairly common, being actively manufactured and installed in more than 100 countries. The smaller size plants include microhydro (<100 kW) and minihydro (100 kW to 1 MW). Typically plants less than 100 kW use an induction generator to generate the electricity. Plants larger than 100 kW can use either induction or synchronous generators depending on design and cost analysis. Many of these smaller plants do not include a dam, but they are run by a flowing river or stream. They are then dependent on the variation of water flow in the river than those with a storage reservoir. Hybrid Power The term hybrid power is used to describe any power system with more than one type of generator. Hybrid power systems usually consist of a conventional generator powered by a diesel or gas engine / turbine and a renewable energy source such as solar, wind, or hydroelectric. Batteries are often included in conventional hybrid systems. There are several of these systems in use today for village electrification. The hybrid sources can be installed on a microgrid or in a single site. For example, a single residence may have several photovoltaic modules added to an existing genset to reduce the noise and inconvenience of having the generator running all the time. The advantage of a hybrid system is that one can exploit the strong points of multiple technologies and design a system that is close to optimal in both performance and cost. The main disadvantage is the capital cost usually resulting form the high cost of solar and the maintenance cost of batteries. Microgrids Microgrids are small electrical distribution systems that connect multiple customers to multiple sources of generation and storage. Microgrids are typically characterized by multipurpose electrical power service to communities with populations ranging up to 500 households with overall energy demand ranging up to several thousand kWh per day. The primary advantage of the microgrid is that reliability is greatly improved by having multiple sources of generation connected to the user. The primary drawback of course is the cost of the distribution or interconnection system and the need for control and dispatch on a system level. Other Enabling Technologies It is not enough to develop a DG system that only produces electric power. A fully automated DG system that requires little or no human intervention is ideal. Technologies bundled into the DG system, therefore, should include interfaces for connection to local supervisory control and data acquisition (SCADA), distributed control systems (DCS) and or Internet / Intranet systems. Other technologies that are necessary for a complete DG system may include developments in:

Metering Protection and control Remote monitoring and fault diagnosis Automated dispatch and control Site optimization of electrical / thermal outputs.

Examples of Distributed Generation Systems There are examples of distributed generation systems in dozens of developing countries. These systems use all of the generation technology options listed above. Although the primary source of power is reciprocating engines fueled by diesel fuel or natural gas, renewable energy sources (e.g., solar, wind, hydroelectric) have surged because of advances in technology and reduction in costs. For example, the explosive growth of photovoltaics in the developing world has driven down PV costs, as manufacturers take advantage of the economies of mass production. An excellent example of the focus on distributed generation is in South Africa. Approximately 20% of South Africa s rural population is not expected to get utility grid electricity for at least the next 20 years. The South African government recognizes the importance of distributed generation and renewable energy technologies and has approved the use of photovoltaic systems for the electrification of 2000 clinics and 16,800 schools. Photovoltaic systems are eventually expected to electrify an estimated 2.5 million homes and 100,000 small businesses in a comprehensive South African grid electrification program. [6] Other examples of distributed generation show the emphasis by governments to provide electric power to remote communities. In India, the government plans to electrify 100,000 villages with renewable energy and install solar powered telephones in every one of the nations 500,000 villages. Mexico plans to electrify 60,000 villages using photovoltaics by the year 2000. In Zaire, several major hospitals depend on photovoltaic solar energy. In Mongolia, the government plans the distribution of 240 small wind / photovoltaic systems for household use as the first phase in a larger implementation plan. In Nepal, 1500 photovoltaic systems have been installed and are currently supplying village homes. Villages on islands in the Caribbean and Mediterranean are looking at distributed generation to provide the power required to desalinated drinking water for drinking. An extensive database on distributed power for village applications is located on the Renewables for Sustainable Village Power (RSVP) World Wide Web site at http://www.revp.nrel.gov. The information contained at this site is updated to maintain its usefulness and to help develop and foster village power projects throughout the world. The database contains more than 140 international village power projects from more than 20 countries. It is searchable by technology, application, sector (e.g., residential, commercial), and geographical region. Management of Distributed Generation Systems The management of distributed generation systems will depend on the nature of the application, the dispersion of the generation sources, the type of generation used, and whether the sources are attached in a microgrid or individually to only the end-user. Small scale distributed generation systems are mainly designed to operate independently. For example, most wind turbine operation systems will stop power production automatically as soon

as frequency or voltage of the grid is below or above certain thresholds. The nature of the management system will greatly depend on whether the generators are dispatchable or nondispatchable. Dispatchable units such as gensets, fuel cells, and microturbines, can be controlled by a central intelligence and relied on to generate according to the needs of the power system. Non-dispatchable technologies generate not as a function of power system needs, but rather as a function of intermittent availability of their energy source. Most renewable energy systems (e.g., wind and solar) are non-dispatchable. The fact that non-dispatchable technologies cannot be controlled or dispatched by central control has made them historically less popular and less understood than other technologies. However, with the advent of hybridsystems the time that the renewable power generation is unavailable is replaced by dispatchable generation. This seems to offer the most promise when considering the multiple needs of environment, system performance, and overall cost. One of the primary elements in a distributed generation management system is the dispatch strategy: the aspect of control strategy that pertains to the sources and destinations of energy flows. Existing systems models offer limited choices of component configuration and of dispatch strategy, and therefore have limited ability to determine optimal systems designs. However, an idealized predictive dispatch strategy based on assumed knowledge of future loads and power availability is being developed through analytical modeling. Such advanced modeling tools are currently being developed by the University of Massachusetts and NREL. With these models, various types of generation, energy storage, and load characteristics can be analyzed to determine the optimal system and dispatch methodology. Key Considerations in Comparing Distributed and Central Generation The results of any DG evaluation study are dependent on both the actual situation, including location, layout, type of demands, economic factors and on the scope of the planning methods available. Several rules of thumbare useful in determining when DG will be economically attractive over central generation. [5] The cost of delivering energy to an area, in one for or another, is a major factor in the total cost of electricity, and often the determiner of which option winsin the planning for a developing region. The larger the scale (greater the number of customer sites), the more economically viable various infrastructure-intensive solution, like tradition electric systems or DG in combinations with a significant distribution system, will be relative to other options. The higher the load density, the more economically viable various infrastructure-intensive solutions, like traditional electric systems or DG in combination with a significant distribution system will be relative to other options. Assumptions about the level and change over time in the cost of fuel can make a tremendous deference in the computed cost of a fossil fuel operation. Traditionaltypes of electric system alternatives tend to have a economic advantage when the location is close to existing electrical facilities; the situation involves a large customer base; or per capita consumption is high. Dispersed DG tends to have the economic advantage only when customer locations are very remote or expensive to reach; the number of customers is quite small and they are far apart; and / or per capita usage is very low. Conclusion Without energy, there can be little economic development, clean water, refrigerated foods and medicines, no telephones, radios, televisions, or the most basic forms of sustainability. Many rural areas are too remote or too poor to support energy systems that are connected to the

electricity grid. Many developing countries face population growth that far exceeds planned rates of grid connection, so that many will either remain without energy, or be forced to migrate to urban areas where the infrastructure is already over burdened. Developing countries are expected to account for over half of the increase in global energy consumption during the next 30 years. The demands of industry and a growing population put tremendous pressure on leaders to raise the standard of living in villages. New distributed generation technologies, using small scale generators near to the end-user of electricity, may offer a lower cost, environmentally kind alternative to traditional central power plants and associated transmission and distribution infrastructure. Distributed generation could be a reasonable alternative for electric power needs in remote or sparsely populated situations such as villages in developing countries. In rural areas where electric service points are far apart, even a power distribution system of modest capacity will cost a great deal. By contrast, DG placed at just a few sites, as needed, can be less than half the total cost of more traditional power systems. Fuel delivery may be a problem in developing countries, but where it is truly burdensome, power generation from renewable resources may be justifiable. References 1. Distributed Generation from Baseload to Backyard , Chapter 20, International Electric Power Encyclopedia, PennWell, 1999. 2. Cambridge Energy Research Associates, Cambridge, MA. 3. Leeper, J. D., and Barich, J. T., Technology for Distributed Generation in a Global Market Place , American Power Conference, Chicago, April 14-16, 1998. 4. Philipson, L., and Willis, H. L., Understanding Electric Utilities and Deregulation, Marcel Dekker, 1988. 5. Willis, H. L., and Scott, W. G., Distributed Power Generation, Marcel Dekker, 2000. 6. Rural Electrification in South Africa , Project Brief, Renewables for Sustainable Village Power (RSVP), NREL, 1998.

Table 1 Total Installed Annual MW for Prime Power Applications (Stand-by Power Applications not Included). [2]

Market Worldwide

Site Size 0.3 - 5 MW < 0.3 MW 0.3 - 5 MW < 0.3 MW

1996 10,267 2,080 1,180 79

2000 12,092 2,433 1,301 96

2005 14,942 2,960 1,468 122

2010 18,592 3,602 1,658 156

North American Market

Table 2 Incremental T&D Expansion Cost in $ / kW of New Peak Load for Several Electric Utility Systems. [5]

Utility United States - Northeast United States - Southeast United States - Central Plains United States - West Coast Central America - Urban System Central America - Rural System South America - Urban System Caribbean Europe - North Central Urban System Southeast Asia - Urban System Southeast Asia - Rural System

Low 166 45 82 64 51 51 129 65 290 29 40

High 925 729 336 610 300 920 438 518 846 400 2000

Table 3

Distributed Generation Technology Options. Engine Generator Gas Turbine Generator Yes Gas 29-42 59 450-870 Microturbine Generator Photovoltaics Wind Turbine Fuel Cells

Dispatchable Fuel Efficiency, % (1) Energy Density, kW/m2 Capital Cost, $/kW

Yes Diesel or Gas 35 50 200-350

Yes Multiple Gas or Liquids 27-32 59 500-1000 (500 in 2001)

-Sun 6-19 0.02 6600

-Wind 25 0.01 1000

Yes Gas 40-57 1-3 3000 (1000 expected when fully commercialized) 0.0017 0.06-0.08

O&M Cost, $/kWh (2) Electrical Energy Cost, $/kWh (3) Energy Storage Required NOx (lb/BTU) Nat Gas Oil Heat Rates, Mills BTU/kWh Expected Operating Life, Hrs. Technology Status

0.01 0.07-0.09

0.0050.0065 0.06-0.08

0.005-0.0065 0.06-0.08

0.001-0.004 0.18-0.20

0.01 0.03-0.04

No

No

No

Yes

Yes

No

0.3 3.7 10-15 40,000

0.01 0.17 5-10 40,000

0.01 0.17 5-10 40,000

N/A N/A N/A --

N/A N/A N/A --

0.003-0.02 -5-10 10,000-40,000

Commercial

Commercial

Commercial

Commercial

Commercial

Commercial in 2001

Notes: 1. Efficiencies of renewable energy technologies should not be compared directly with those of fossil fuel technologies since the fuel is limited. 2. O&M costs exclude cost of fuel. There are no fuel costs for wind systems or photovoltaics. 3. Natural gas fuel is used for calculating energy costs except for wind and solar power.

Figure 1

Development time for various power plant projects. [3]

Identify Project

Develop and Negotiate

Build Project

Start-Up

Total Elapsed Time Coal IPP Large Gas IPP Distributed Generation

5-7 years 3-5 years 6-18 months

Figure 2 Electric power costs less if bought from the system closer to the generating plant. Prices shown correspond to price per kWh paid by a user of electricity at the site shown. [4]

Anda mungkin juga menyukai

- Deployment of Hybrid Renewable Energy Systems in MinigridsDari EverandDeployment of Hybrid Renewable Energy Systems in MinigridsBelum ada peringkat

- Decentralized GenerationDokumen5 halamanDecentralized GenerationAakashBelum ada peringkat

- Distributed GenerationDokumen6 halamanDistributed GenerationBibhudatta PatnaikBelum ada peringkat

- Distributed Generation JenkinsDokumen9 halamanDistributed Generation JenkinsSandeep KumarkjBelum ada peringkat

- Distributed Renewable Energy Generation in IndiaDokumen20 halamanDistributed Renewable Energy Generation in Indiakeinhuat79Belum ada peringkat

- Gravity Power GenerationDokumen22 halamanGravity Power GenerationHari650Belum ada peringkat

- Electrical Power GenerationDokumen11 halamanElectrical Power GenerationVikram Rao0% (2)

- Solar Thermal Power Generation SystemsDokumen17 halamanSolar Thermal Power Generation SystemsyrikkiBelum ada peringkat

- Automatic Generation ControlDokumen2 halamanAutomatic Generation ControlgbaludbBelum ada peringkat

- Co GenerationDokumen14 halamanCo GenerationDairo Ruiz-LogreiraBelum ada peringkat

- Generation System Adequacy EvaluationDokumen85 halamanGeneration System Adequacy EvaluationdarshanraghuBelum ada peringkat

- Power StationDokumen10 halamanPower Stationletter_ashish4444Belum ada peringkat

- Energy Conversion PDFDokumen20 halamanEnergy Conversion PDFpushpendra singhBelum ada peringkat

- Zoran Stevic-New Generation of Electric Vehicles-InTech (2012) PDFDokumen384 halamanZoran Stevic-New Generation of Electric Vehicles-InTech (2012) PDFvladimir_bozic_2Belum ada peringkat

- First GenerationDokumen2 halamanFirst GenerationAlan RoxasBelum ada peringkat

- New Generation of Cisco SwitchingDokumen50 halamanNew Generation of Cisco SwitchingSalis AlvarezBelum ada peringkat

- Third Generation of ComputersDokumen15 halamanThird Generation of ComputersHainah Kariza LeusBelum ada peringkat

- ELC003 Renewable Energy Course NotesDokumen231 halamanELC003 Renewable Energy Course Notesravith88100% (1)

- Smart GridsDokumen9 halamanSmart GridsAshleyBelum ada peringkat

- Fuel CellsDokumen6 halamanFuel CellsJayan PillaiBelum ada peringkat

- Final Year Project SynopsisDokumen3 halamanFinal Year Project SynopsisEngr Majid Ali BaigBelum ada peringkat

- Chapter 2 Solar SystemDokumen8 halamanChapter 2 Solar SystemavocadocolorBelum ada peringkat

- HVAC GenerationDokumen29 halamanHVAC GenerationAlfred OkacheBelum ada peringkat

- Designing Low Carbon Electricity Futures For African and Other Developing CountriesDokumen20 halamanDesigning Low Carbon Electricity Futures For African and Other Developing CountriesInternational RiversBelum ada peringkat

- The New Generation of ETRM SystemsDokumen10 halamanThe New Generation of ETRM SystemsCTRM CenterBelum ada peringkat

- Hybrid Power Generation SlideDokumen23 halamanHybrid Power Generation SlideCnp1 Cnp1Belum ada peringkat

- Solar PV Basics - How Do Solar Panels Work?Dokumen21 halamanSolar PV Basics - How Do Solar Panels Work?rohinibhaskarBelum ada peringkat

- Smart GridDokumen8 halamanSmart Gridraj0744Belum ada peringkat

- Desai Harshad Suresh B050254EEDokumen37 halamanDesai Harshad Suresh B050254EEvikkyymsnbBelum ada peringkat

- Distributed GenerationDokumen414 halamanDistributed GenerationemyimranBelum ada peringkat

- Fuel CellsDokumen10 halamanFuel CellsEshaBelum ada peringkat

- Distributed Energy StorageDokumen3 halamanDistributed Energy StoragejuevesBelum ada peringkat

- Hybrid Power Systems PDFDokumen29 halamanHybrid Power Systems PDFFinn BalorBelum ada peringkat

- Density of Individual Airborne Wind Energy Systems in AWES FarmsDokumen6 halamanDensity of Individual Airborne Wind Energy Systems in AWES FarmsEnrique MartinezBelum ada peringkat

- Hybrid wind-solar energy systemDokumen7 halamanHybrid wind-solar energy systemPiyush SinghBelum ada peringkat

- SMART GRID TECHNOLOGIES EXPLAINEDDokumen61 halamanSMART GRID TECHNOLOGIES EXPLAINEDgag aaBelum ada peringkat

- Elum Energy Monitoring & Control Solutions for Solar Hybrid PlantsDokumen17 halamanElum Energy Monitoring & Control Solutions for Solar Hybrid PlantsCyrilColinBelum ada peringkat

- Transient Stability Analysis of Hybrid Power System: ElectricalDokumen15 halamanTransient Stability Analysis of Hybrid Power System: ElectricalSumit DubeyBelum ada peringkat

- Potential of Solar Energy in Developing Countries For Reducing EnergyDokumen3 halamanPotential of Solar Energy in Developing Countries For Reducing EnergyPrashannaBelum ada peringkat

- A Project Report On Sizing and Costing of PVDokumen4 halamanA Project Report On Sizing and Costing of PVpatrickBelum ada peringkat

- FR2 Cat Hybrid Microgrids 2015manilaDokumen49 halamanFR2 Cat Hybrid Microgrids 2015manilajuan dela cruzBelum ada peringkat

- Energy Storage: Solving Challenges inDokumen51 halamanEnergy Storage: Solving Challenges inJon DiGiacomandreaBelum ada peringkat

- Navigant Microgrid Multi Client Final Report 2015 12 04 Public Release Version PDFDokumen29 halamanNavigant Microgrid Multi Client Final Report 2015 12 04 Public Release Version PDFRodrigo Ignacio Rodriguez MerinoBelum ada peringkat

- Solar Panel Tracking and Monitoring SystemDokumen8 halamanSolar Panel Tracking and Monitoring SystemGRD JournalsBelum ada peringkat

- Smart power management for solar PV-DG synchronizationDokumen8 halamanSmart power management for solar PV-DG synchronizationSunil SinghBelum ada peringkat

- Topics: - Potential and - UtilizationDokumen41 halamanTopics: - Potential and - UtilizationUtkarsh MishraBelum ada peringkat

- Dual Power Generation SystemDokumen92 halamanDual Power Generation SystemAnjuhnBelum ada peringkat

- Photovoltaics Systems and ApplicationsDokumen19 halamanPhotovoltaics Systems and Applicationsvishrao1984100% (1)

- Power market operation-발표Dokumen37 halamanPower market operation-발표sjcgraceBelum ada peringkat

- Power Generation BookDokumen7 halamanPower Generation BookHassan MalghaniBelum ada peringkat

- Introduction To Microgrids - Securicon - 2013 - 1Dokumen13 halamanIntroduction To Microgrids - Securicon - 2013 - 1Wyatt HurleyBelum ada peringkat

- EPRI MicroGridDokumen9 halamanEPRI MicroGridAndrei HorhoianuBelum ada peringkat

- Solar Energy CompendiumfDokumen86 halamanSolar Energy Compendiumfjchavez3221Belum ada peringkat

- Presentation KyabraDokumen27 halamanPresentation KyabraNew England WindBelum ada peringkat

- Why Smart Grid Is EssentialDokumen7 halamanWhy Smart Grid Is Essentialkaushik4endBelum ada peringkat

- ELENS Online PDF VersionDokumen28 halamanELENS Online PDF VersionDaniel PrataBelum ada peringkat

- Micro Grid Module 1FINALDokumen98 halamanMicro Grid Module 1FINALketan bhereBelum ada peringkat

- Solar PanelDokumen61 halamanSolar PanelSandeep Hnayak0% (1)

- Photovoltaic System ManagementDokumen72 halamanPhotovoltaic System Managementanandpandiyan39Belum ada peringkat

- LectureFive HybridSystemDokumen25 halamanLectureFive HybridSystemmuluken eliasBelum ada peringkat

- Wireless Sensor Netwroks For Smart Grid ApplicationsDokumen11 halamanWireless Sensor Netwroks For Smart Grid ApplicationsZara.FBelum ada peringkat

- Renewable Electricity and The Grid The Challenge of VariabilityDokumen244 halamanRenewable Electricity and The Grid The Challenge of VariabilityAlper KoçerBelum ada peringkat

- The Power GridDokumen10 halamanThe Power GridZara.FBelum ada peringkat

- Policies To Support Distributed EnergyDokumen41 halamanPolicies To Support Distributed EnergyZara.FBelum ada peringkat

- Distributed Generation and The Grid Integration IssuesDokumen9 halamanDistributed Generation and The Grid Integration IssuesZara.FBelum ada peringkat

- Role of Energy Monitors in Primary School EducationDokumen3 halamanRole of Energy Monitors in Primary School EducationZara.FBelum ada peringkat

- Smart Grids Best Practice Fundamentals For A Modern Energy SystemDokumen28 halamanSmart Grids Best Practice Fundamentals For A Modern Energy SystemZara.FBelum ada peringkat

- Distributed Generation and The Grid Integration IssuesDokumen9 halamanDistributed Generation and The Grid Integration IssuesZara.FBelum ada peringkat

- Comparison of DG and CG in West AfricaDokumen23 halamanComparison of DG and CG in West AfricaZara.FBelum ada peringkat

- Invesgitagtion of Four LandslidesDokumen6 halamanInvesgitagtion of Four LandslidesZara.FBelum ada peringkat

- Conversion of Methanol To Light Olefins On Sapo-34 Kinetic Modeling and Reactor DesignDokumen167 halamanConversion of Methanol To Light Olefins On Sapo-34 Kinetic Modeling and Reactor DesignHassan BahaaBelum ada peringkat

- Numerical Simulation of Cavitation Process in Diesel InjectorsDokumen226 halamanNumerical Simulation of Cavitation Process in Diesel Injectorsfivos_rgBelum ada peringkat

- 5919 Musyafa Ep Ali M Ciencinia UploadDokumen13 halaman5919 Musyafa Ep Ali M Ciencinia UploadFurqon Gilang NugrahaBelum ada peringkat

- Sebu7173-12 BDokumen7 halamanSebu7173-12 BSantos Junnior Hipolito SandovalBelum ada peringkat

- Abdul Rasheed. N: B. Tech Mechanical Engg. 4.5 YearsDokumen4 halamanAbdul Rasheed. N: B. Tech Mechanical Engg. 4.5 YearsAbdul RasheedBelum ada peringkat

- Alpha Call-Ups A330Dokumen18 halamanAlpha Call-Ups A330János Rédei100% (4)

- 06084.001 Electrofishing Boat ManualDokumen53 halaman06084.001 Electrofishing Boat ManualMarko ĆaletaBelum ada peringkat

- 8 Ways Monitor Measure Marine Engine PerformanceDokumen3 halaman8 Ways Monitor Measure Marine Engine PerformanceDwein Ocampo AguilarBelum ada peringkat

- Study On Fuel Economy Improvement by Low Pressure Water-Cooled EGR System On A Downsized Boosted Gasoline EngineDokumen12 halamanStudy On Fuel Economy Improvement by Low Pressure Water-Cooled EGR System On A Downsized Boosted Gasoline Engineraghu7862Belum ada peringkat

- 14h Manhour GuideDokumen33 halaman14h Manhour GuideMORTEMBelum ada peringkat

- Magnesium and Aluminum Alloys in Automotive Industry PDFDokumen11 halamanMagnesium and Aluminum Alloys in Automotive Industry PDFΝΙΚΟΛΑΟΣ ΚΑΡΑΓΚΙΑΟΥΡΗΣBelum ada peringkat

- Eneria Product List: Design Conditions Fuel Gas DataDokumen1 halamanEneria Product List: Design Conditions Fuel Gas DataPocola AdrianBelum ada peringkat

- Cola VolvoDokumen102 halamanCola Volvovicente100% (1)

- Every Load.: Cummins Euro 4 Engines 280-400PsDokumen6 halamanEvery Load.: Cummins Euro 4 Engines 280-400PsFernando BatistaBelum ada peringkat

- Increased Capacity and Flexibility: Key Advantages of Electric TrainsDokumen43 halamanIncreased Capacity and Flexibility: Key Advantages of Electric TrainsthreephasefaultBelum ada peringkat

- Operator ManualDokumen398 halamanOperator ManualMuhammad Musthofa100% (1)

- Hyundai D6GA Engine Mechanical System PDFDokumen97 halamanHyundai D6GA Engine Mechanical System PDFbrayandparavicinoBelum ada peringkat

- Stress in Boiler DrumDokumen8 halamanStress in Boiler DrummuhdjusriBelum ada peringkat

- School of Maritime Studies Vels University Thalambur The Fuel Oil System For A Diesel Engine Internal Combustion Engine ProcedureDokumen2 halamanSchool of Maritime Studies Vels University Thalambur The Fuel Oil System For A Diesel Engine Internal Combustion Engine ProcedureAayush Agrawal100% (2)

- Fuel Metering For Diesel Engines: Mixture RequirementsDokumen6 halamanFuel Metering For Diesel Engines: Mixture Requirementsallan lariosaBelum ada peringkat

- Boiler Mountings and AccessoriesDokumen17 halamanBoiler Mountings and AccessoriesYogesh ChaudhariBelum ada peringkat

- ACS11Dokumen3 halamanACS11Ebby OnyekweBelum ada peringkat

- Model ESC QPDokumen2 halamanModel ESC QPGowda KadurBelum ada peringkat

- Book 11Dokumen662 halamanBook 11SOG1806100% (1)

- Crude Oil Grades and Refinery TypesDokumen5 halamanCrude Oil Grades and Refinery TypesibrahimkhansahilBelum ada peringkat

- Small Machinery - 01.03.2012Dokumen227 halamanSmall Machinery - 01.03.2012Janki VernekarBelum ada peringkat

- Improve Your Knowledge of the Reliable 4A-FE EngineDokumen13 halamanImprove Your Knowledge of the Reliable 4A-FE EnginecjtrybiecBelum ada peringkat

- Dominar 400 Abs Non Abs SPCDokumen82 halamanDominar 400 Abs Non Abs SPCAlex Philip0% (1)

- Top Drive Tesco 250 Hmis 475Dokumen2 halamanTop Drive Tesco 250 Hmis 475Draghiceanu VasileBelum ada peringkat

- 923 - 2653BPrecisionCut2-Operator ManualDokumen9 halaman923 - 2653BPrecisionCut2-Operator ManualJohn ZBelum ada peringkat

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionDari EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionPenilaian: 3 dari 5 bintang3/5 (1)

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksDari EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksBelum ada peringkat

- The Cyanide Canary: A True Story of InjusticeDari EverandThe Cyanide Canary: A True Story of InjusticePenilaian: 4 dari 5 bintang4/5 (51)

- The Rights of Nature: A Legal Revolution That Could Save the WorldDari EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldPenilaian: 5 dari 5 bintang5/5 (1)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksDari EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksBelum ada peringkat

- Introduction to Ecology and Environmental Laws in IndiaDari EverandIntroduction to Ecology and Environmental Laws in IndiaBelum ada peringkat

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionDari Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionBelum ada peringkat

- Principles of direct and superior responsibility in international humanitarian lawDari EverandPrinciples of direct and superior responsibility in international humanitarian lawBelum ada peringkat

- The Long Hangover: Putin's New Russia and the Ghosts of the PastDari EverandThe Long Hangover: Putin's New Russia and the Ghosts of the PastPenilaian: 4.5 dari 5 bintang4.5/5 (76)

- Ukraine: What Everyone Needs to KnowDari EverandUkraine: What Everyone Needs to KnowPenilaian: 4.5 dari 5 bintang4.5/5 (117)

- Introduction to Ecology and Environmental Laws in IndiaDari EverandIntroduction to Ecology and Environmental Laws in IndiaBelum ada peringkat

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933Dari EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933Belum ada peringkat

- Down to the Wire: Confronting Climate CollapseDari EverandDown to the Wire: Confronting Climate CollapsePenilaian: 4.5 dari 5 bintang4.5/5 (8)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontDari EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontPenilaian: 4.5 dari 5 bintang4.5/5 (9)

- Environmental Education in Practice: Concepts and ApplicationsDari EverandEnvironmental Education in Practice: Concepts and ApplicationsBelum ada peringkat

- New Paradigms in Environmental Biomonitoring Using PlantsDari EverandNew Paradigms in Environmental Biomonitoring Using PlantsSupriya TiwariBelum ada peringkat

- Obstacles to Environmental Progress: A U.S. perspectiveDari EverandObstacles to Environmental Progress: A U.S. perspectiveBelum ada peringkat

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Dari EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Penilaian: 5 dari 5 bintang5/5 (2)

- Stand Up That Mountain: The Battle to Save One Small Community in the Wilderness Along the Appalachian TrailDari EverandStand Up That Mountain: The Battle to Save One Small Community in the Wilderness Along the Appalachian TrailPenilaian: 3 dari 5 bintang3/5 (3)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaDari EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaPenilaian: 4 dari 5 bintang4/5 (1)