Build Your Own Axle: Read All Instructions Before Starting

Diunggah oleh

gamini ranaweeraDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Build Your Own Axle: Read All Instructions Before Starting

Diunggah oleh

gamini ranaweeraHak Cipta:

Format Tersedia

Build Your Own Axle

Weld your own custom axle using Tie Down Engineerings axle tube and spindles

WARNING Welding an axle requires that you have the proper equipment and have the skill to apply a proper weld. If you are not comfortable with your welding capabilities, have a qualied welder assemble you axle.

Instructions

READ ALL INSTRUCTIONS BEFORE STARTING

1. Determine the axle capacity required for your trailer. Trailer capacity is based on the lowest capacity of the trailer components. This includes but is not limited to: frame, axle, spindles, hubs, bearings, wheels, tires, springs and all hardware. #124991 1.5 x 1.5 x 72 axle tube, up to 1,500 lb. capacity Use with: #128006 - 4 Lug Hub & Spindle End Unit #128007 - 5 Lug Hub & Spindle End Unit #124993 - 1350 lb. Spindle with Flange (2 per pack, for hubs with 1-1/16 inner & outer bearings & 1.25 seals) #124997 2 x 2 x 72 axle tube, up to 3,500 lb. capacity Use with: #128008 - 5 Lug Hub & Spindle End Unit. #124994 - 1750 lb. Spindle with Brake Flange (2 per pack, for hubs with 1-1/16 & 1-3/8 bearings & 1.72 seals)

2. Determine the Hub Face measurements required for your trailer. a. If you are replacing an axle, measure the distance from the outside face of each hub. b. If you are building a new trailer/axle, consider the space required for the wheel/tire combination to properly t the trailer frame.

Springs (centers)

Hub Face

Hub Face:

Springs & Hangers Axle Hub Face Spring Centers Track

Distance between hub face to hub face Distance between center tire to center tire

Track:

Instruction Sheet #08109

013108,F996

Spring Center: Distance between the center of springs & hangers (if used)

3.

Calculate your axle tube length: Tube Length = Hub Face minus Hub to Flange Width Hub to Flange Width (distance between hub face + rear of the spindle ange) x 2 (both hubs)

1.5 Tube Calculation

Hub Face Needed: Hub to Flange Width: Cut Tube to Length: 5-7/8

2 Tube Calculation

Hub Face Rear of the spindle flange

Hub Face Needed: Hub to Flange Width: Cut Tube to Length: 6-5/8

When used with Tie Down Engineerings Spindles and Hubs listed on these pages the hub to ange width equals:

1.5 Tube: 5-7/8 (2-15/16x 2)

2.0 Tube: 6-5/8 (3-5/16 x 2)

TIP: Place spindle or end unit in one end of the axle tube. Place axle on trailer to get a visual of where to cut tube. Make sure the tube is close to your math calculations. 4. Cut tube to required length (measure twice, cut once!). Special care should be taken to make sure the cut is Square at 90 degrees. Remove any burrs inside and outside the tube. 5. Clamp tube to a secure welding table. 6. Insert round spindle or end unit (hub/spindle) into the square tube so that the brake ange or circular ange is ush against the end of the tube. 7. Support the spindle or end unit so that it does not move during the welding operation. 8. Weld a 1/4 llet weld on all sides of the surface joint. 9. Allow to cool before using. 10. Determine spring center location. Drill 9/16 holes for the center spring bolt head to t in. Use spring hanger kit to complete axle. Drill two 9/16 holes 1/4 Fillet Weld Tube Mount spindle ush to the axle tube Flange

Square Axle Tube Spindle Square Tube

Spindle

Anda mungkin juga menyukai

- Mitsubishi Lancer EX (MX) (GLX. Manual, Automatic) PDFDokumen4 halamanMitsubishi Lancer EX (MX) (GLX. Manual, Automatic) PDFStanley Robinson67% (3)

- 3D Tool ManualDokumen127 halaman3D Tool ManualIulius Ionut CotîrgăBelum ada peringkat

- DIY Cornhole Board Plans - Printable PDFDokumen7 halamanDIY Cornhole Board Plans - Printable PDFuga100% (1)

- Dew PointDokumen2 halamanDew PointAvimiled Manosalva RincónBelum ada peringkat

- Pages From Rules of Thumb For Chemical Engineers, 4th EdDokumen10 halamanPages From Rules of Thumb For Chemical Engineers, 4th EdRicardo RamírezBelum ada peringkat

- 229 254HarmonicBalancersDokumen26 halaman229 254HarmonicBalancersAndy WilsonBelum ada peringkat

- B31.3 Process Piping Course - 05 Valve SelectionDokumen18 halamanB31.3 Process Piping Course - 05 Valve SelectionRyan Goh Chuang HongBelum ada peringkat

- Windsorone Farmhouse Style 2022b WebDokumen16 halamanWindsorone Farmhouse Style 2022b WebStephen Mark Garcellano DalisayBelum ada peringkat

- Solid Works Training MaterialDokumen124 halamanSolid Works Training Materialkamikyou100% (11)

- Warner Ball ScrewsDokumen45 halamanWarner Ball ScrewssaddlemanBelum ada peringkat

- Tail-Vise InstructionsDokumen22 halamanTail-Vise InstructionsIulian MihaiBelum ada peringkat

- Metadata SchemaDokumen6 halamanMetadata Schemaapi-242606824Belum ada peringkat

- 04 Trailer Sauce - Tongue & Sub Chassis Components PDFDokumen4 halaman04 Trailer Sauce - Tongue & Sub Chassis Components PDFRodrigo OtávioBelum ada peringkat

- Audi 80 1988 PDFDokumen11 halamanAudi 80 1988 PDFZoran TrajkovicBelum ada peringkat

- American Society of Civil Engineers - Los Angeles Section: 100 Years of Civil Engineering Excellence 1913- 2013Dari EverandAmerican Society of Civil Engineers - Los Angeles Section: 100 Years of Civil Engineering Excellence 1913- 2013Belum ada peringkat

- Wire DrawingDokumen47 halamanWire DrawingKamlesh Kumar100% (3)

- The Infinite Oval: Tools For WoodworkingDokumen2 halamanThe Infinite Oval: Tools For Woodworkingoqab18Belum ada peringkat

- Magnus Piping Design & EquipmentDokumen5 halamanMagnus Piping Design & EquipmentbalaasenthilBelum ada peringkat

- Process Engineering Properly Protect Centrifugal Pumps Chemical Processing PDFDokumen2 halamanProcess Engineering Properly Protect Centrifugal Pumps Chemical Processing PDFAndri SaputraBelum ada peringkat

- Step of Concrete SlabDokumen5 halamanStep of Concrete SlabMine MienBelum ada peringkat

- BELT CALCULATIONS Smart Motion Cheat SheetDokumen6 halamanBELT CALCULATIONS Smart Motion Cheat Sheetpavan222eeeBelum ada peringkat

- 5' X 8' Single Axle TrailerDokumen34 halaman5' X 8' Single Axle Trailertony9waldronBelum ada peringkat

- Brompton Technical DescriptionDokumen4 halamanBrompton Technical DescriptionoliwekBelum ada peringkat

- Building A Powdercoat Oven: Construction Page Material List ContactDokumen17 halamanBuilding A Powdercoat Oven: Construction Page Material List ContactOuellette Greg100% (1)

- 4 Foot Westerner p4Dokumen4 halaman4 Foot Westerner p4Negru CiprianBelum ada peringkat

- Catalogo Toberas Common RailDokumen14 halamanCatalogo Toberas Common Raillennon r100% (1)

- Blackmagic Studio Camera ManualDokumen672 halamanBlackmagic Studio Camera ManualMinisterio De MeDios EcoFamiliarBelum ada peringkat

- Router Table Building With Cabinet StorageDokumen17 halamanRouter Table Building With Cabinet StorageLonebeavBelum ada peringkat

- Gardner2005 TheuseofstainlesssteelinstructuresDokumen39 halamanGardner2005 Theuseofstainlesssteelinstructuresherdi sutanto adigunaBelum ada peringkat

- FTIR Studies of The Changes in Wood Chemistry Following Decay by Brown-Rot and White-Rot Fungi - International Biodegradation 2003Dokumen10 halamanFTIR Studies of The Changes in Wood Chemistry Following Decay by Brown-Rot and White-Rot Fungi - International Biodegradation 2003Farid AouladBelum ada peringkat

- Theory of Wire DrawingDokumen27 halamanTheory of Wire Drawinggamini ranaweera80% (5)

- Theory of Wire DrawingDokumen27 halamanTheory of Wire Drawinggamini ranaweera80% (5)

- WTI UK Screw Thread Inserts and Kits CatalogueDokumen16 halamanWTI UK Screw Thread Inserts and Kits CatalogueThor InternationalBelum ada peringkat

- Trailblazer 28288123 PDFDokumen300 halamanTrailblazer 28288123 PDFkamote ka0% (1)

- Promotional Line: 362: Library SeriesDokumen26 halamanPromotional Line: 362: Library Serieszackwayne100% (1)

- Body and Interior VolvoDokumen99 halamanBody and Interior Volvovanapeer0% (1)

- Price ListDokumen40 halamanPrice ListAnonymous b0gP6mDaqBelum ada peringkat

- Unlock-B31.3 Process Piping Course - 07 Layout and SupportDokumen15 halamanUnlock-B31.3 Process Piping Course - 07 Layout and SupportProkopBelum ada peringkat

- Rivnut GBDokumen36 halamanRivnut GBJeffry KarundengBelum ada peringkat

- Blackmagic MultiView ManualDokumen22 halamanBlackmagic MultiView ManualSyed Danish HasanBelum ada peringkat

- MD VI Shaft DesignDokumen11 halamanMD VI Shaft DesignShatendra SahuBelum ada peringkat

- Vehicle Standards Bulletin 01Dokumen37 halamanVehicle Standards Bulletin 01LizardladBelum ada peringkat

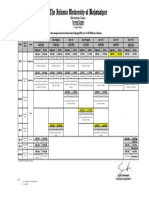

- ONE ONE: SemesterDokumen26 halamanONE ONE: SemesterKarl GookeyBelum ada peringkat

- Complete Guide To ChainDokumen230 halamanComplete Guide To ChainVijay GohilBelum ada peringkat

- Pressure Vessel Design12Dokumen85 halamanPressure Vessel Design12Victor Rizal Filosofi100% (9)

- 99 Pneumatic ApplicationsDokumen121 halaman99 Pneumatic Applicationsapi-3731420100% (7)

- Roller Chain GuideDokumen5 halamanRoller Chain GuidechikoopandaBelum ada peringkat

- Nissan D22 Navara BrochureDokumen11 halamanNissan D22 Navara Brochure1664936Belum ada peringkat

- Workshop Technology (JJ104) ExerciseDokumen4 halamanWorkshop Technology (JJ104) Exerciseadib1991Belum ada peringkat

- LPG Standard SpecificationDokumen1 halamanLPG Standard Specificationayuda_dBelum ada peringkat

- Display and Graphics Commonality StandardDokumen368 halamanDisplay and Graphics Commonality StandardngibbinsBelum ada peringkat

- AutoCad 2012 Tutorial, 2d FundamentalDokumen24 halamanAutoCad 2012 Tutorial, 2d FundamentalajBelum ada peringkat

- Autocad Architecture 2009Dokumen31 halamanAutocad Architecture 2009Sunil KalwaniyaBelum ada peringkat

- 2600series PRV Catalog 304C R2Dokumen96 halaman2600series PRV Catalog 304C R2vikzefgBelum ada peringkat

- Ib Research Journal TemplateDokumen4 halamanIb Research Journal Templateapi-571704328Belum ada peringkat

- MOD 109 Process Piping B31-3Dokumen27 halamanMOD 109 Process Piping B31-3Du Xuan BinhBelum ada peringkat

- OHV USDA Spark ArresterDokumen203 halamanOHV USDA Spark ArresterJenny PellettBelum ada peringkat

- Helical Strakes Are Aerodynamic Stabilizers Which Are Sometimes Used To Reduce TheDokumen1 halamanHelical Strakes Are Aerodynamic Stabilizers Which Are Sometimes Used To Reduce TheameybarveBelum ada peringkat

- Architecture Design Handbook - Flashings and Copings - Coping CoversDokumen5 halamanArchitecture Design Handbook - Flashings and Copings - Coping CoversDukeBelum ada peringkat

- Handbook MogliceDokumen63 halamanHandbook MoglicesolidsverigeBelum ada peringkat

- Safety Realief Valve ManualDokumen14 halamanSafety Realief Valve ManualFlo MarineBelum ada peringkat

- Static Analysis of Tractor Trolley AxleDokumen5 halamanStatic Analysis of Tractor Trolley AxleseventhsensegroupBelum ada peringkat

- Autodesk Inventor - Skill Builder-Derived Parts 2Dokumen5 halamanAutodesk Inventor - Skill Builder-Derived Parts 2Ndianabasi UdonkangBelum ada peringkat

- Taper Dowel Pin ANSIDokumen4 halamanTaper Dowel Pin ANSIadzrinBelum ada peringkat

- ProjectWise Users Guide V8iDokumen75 halamanProjectWise Users Guide V8itriluuBelum ada peringkat

- DIY For Rebuilding An S2000 Transmission by Ronnuke of S2ki - Com (7.30.13)Dokumen38 halamanDIY For Rebuilding An S2000 Transmission by Ronnuke of S2ki - Com (7.30.13)Bruce BruceBelum ada peringkat

- Fairchild Keyserts - Thread Repair InsertsDokumen12 halamanFairchild Keyserts - Thread Repair InsertsgeorgeBelum ada peringkat

- HAMILTON, D. 1999. Methods of Conserving Archaeological Material From Underwater Sites PDFDokumen110 halamanHAMILTON, D. 1999. Methods of Conserving Archaeological Material From Underwater Sites PDFrubenBelum ada peringkat

- RodSmith Build-It! KitsDokumen1 halamanRodSmith Build-It! KitsCamil BwoyBelum ada peringkat

- C W P A E: Ompleted ELL ADS ND QuipmentDokumen2 halamanC W P A E: Ompleted ELL ADS ND QuipmentImmanuel Lumban GaolBelum ada peringkat

- GLOMACS Materials of Constr. For Process Equipment and Piping SystemsDokumen6 halamanGLOMACS Materials of Constr. For Process Equipment and Piping SystemsRoo FaBelum ada peringkat

- PDFDokumen2 halamanPDFNEELBelum ada peringkat

- Worm Gear DriveDokumen6 halamanWorm Gear Drivegamini ranaweeraBelum ada peringkat

- Bevel GearsDokumen5 halamanBevel Gearsgamini ranaweeraBelum ada peringkat

- Helical GearsDokumen12 halamanHelical Gearsgamini ranaweera100% (1)

- Power Transmission BeltsDokumen54 halamanPower Transmission Beltsgamini ranaweeraBelum ada peringkat

- Engineering Materials and Their PropertiesDokumen23 halamanEngineering Materials and Their Propertiesgamini ranaweeraBelum ada peringkat

- Treatment Plant PresentationDokumen103 halamanTreatment Plant Presentationgamini ranaweeraBelum ada peringkat

- Power Transmission BeltsDokumen54 halamanPower Transmission Beltsgamini ranaweeraBelum ada peringkat

- Bevel GearsDokumen3 halamanBevel Gearsgamini ranaweeraBelum ada peringkat

- Theory of Gears r3Dokumen53 halamanTheory of Gears r3gamini ranaweeraBelum ada peringkat

- Elvax Extrusion GuideDokumen19 halamanElvax Extrusion Guidehon101Belum ada peringkat

- SPANCO Jib Crane BrochureDokumen16 halamanSPANCO Jib Crane Brochurehessam_seifiBelum ada peringkat

- Me1302 NolDokumen107 halamanMe1302 NolCKDinakarrajBelum ada peringkat

- Yaris 2006+ Remote Start Wiring GuideDokumen8 halamanYaris 2006+ Remote Start Wiring GuideALBelum ada peringkat

- Fuses For STD D&E On PCB 48 PinDokumen3 halamanFuses For STD D&E On PCB 48 PinFauan SBelum ada peringkat

- F (Instrument Panel) (LHD) : J/B No.3Dokumen1 halamanF (Instrument Panel) (LHD) : J/B No.3eurotaller Calderon calderonBelum ada peringkat

- Cayenne E1Dokumen1 halamanCayenne E1Deepal ShahBelum ada peringkat

- Log WAUZZZ4B02N107792 298310km 185361miDokumen3 halamanLog WAUZZZ4B02N107792 298310km 185361miGSGSBelum ada peringkat

- Shopping Tools - Booking Service - PT. Toyota Astra Motor - Mobil Terbaik Keluarga IndonesiaDokumen1 halamanShopping Tools - Booking Service - PT. Toyota Astra Motor - Mobil Terbaik Keluarga IndonesiaAUTO TECHBelum ada peringkat

- Presentation On AutoDokumen66 halamanPresentation On AutomallusamBelum ada peringkat

- Data Sheet TF 7C15 DDokumen4 halamanData Sheet TF 7C15 Dandi yusufBelum ada peringkat

- Maruti 800Dokumen9 halamanMaruti 800Ravinder BangerBelum ada peringkat

- Tiago - Urban Toughroader: Ee YtodomoreDokumen4 halamanTiago - Urban Toughroader: Ee YtodomoresvperumalBelum ada peringkat

- Understanding Suspension: Written By: C HughesDokumen14 halamanUnderstanding Suspension: Written By: C HughesJorge AlziroBelum ada peringkat

- ARAI Format ResumeDokumen3 halamanARAI Format Resume9096664279Belum ada peringkat

- SSP 536 The Golf SVDokumen52 halamanSSP 536 The Golf SVMario S.M.Belum ada peringkat

- STC75Dokumen16 halamanSTC75Otto Heinrich WehmannBelum ada peringkat

- Updated-BUS Time Table - 11-03-2022Dokumen1 halamanUpdated-BUS Time Table - 11-03-2022Xhakeel RajpoOtBelum ada peringkat

- Class Racing Specification FINAL 2023Dokumen5 halamanClass Racing Specification FINAL 2023gabriel90ccBelum ada peringkat

- List of Motorcycle Manufacturers (Approved) For New Jersey: by VINDokumen5 halamanList of Motorcycle Manufacturers (Approved) For New Jersey: by VINSteve Rubakh100% (3)

- Jeep Wrangler Command Vehicle: EngineDokumen3 halamanJeep Wrangler Command Vehicle: EngineSebastian RentschBelum ada peringkat

- Faurecia PDFDokumen2 halamanFaurecia PDFFranklin Javier Colmenares LopezBelum ada peringkat

- News Item TextDokumen1 halamanNews Item TextOzora XerxesBelum ada peringkat

- 2005 Hyundai Santa Fe Vs 2005 Hyundai Tucson Vs 2002 Volkswagen Passat - The Car ConnectionDokumen6 halaman2005 Hyundai Santa Fe Vs 2005 Hyundai Tucson Vs 2002 Volkswagen Passat - The Car ConnectionDejan PanticBelum ada peringkat

- Katalog Ini Hanya Sebagai Panduan Dan Bukan Sebagai Acuan Untuk Mengajukan Komplain "Harap Melakukan Pengecekan Fisik & Dokumen Unit Yang Dilelang"Dokumen4 halamanKatalog Ini Hanya Sebagai Panduan Dan Bukan Sebagai Acuan Untuk Mengajukan Komplain "Harap Melakukan Pengecekan Fisik & Dokumen Unit Yang Dilelang"Addrian SyahBelum ada peringkat

- At Iva Gear Up CatalogueDokumen12 halamanAt Iva Gear Up Cataloguewave umaBelum ada peringkat