Pressure Vessel Design Charts

Diunggah oleh

Priyanathan ThayalanHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pressure Vessel Design Charts

Diunggah oleh

Priyanathan ThayalanHak Cipta:

Format Tersedia

Pressure Vessel Design Charts

This Section is Under Development Commentary:

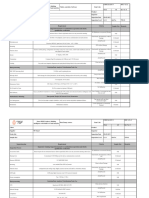

Although not suited for final vessel calculations, design charts can be very useful for preliminary design and quotation purposes. The charts on this page provide pressure ratings, weight and volume for various sizes and wall thicknesses of components. The charts on this page are in pdf format - adobe pdf reader version 4.0 or later is required to view or print them. To use these charts, you will need to know the rated stress for the materials you will be using. Currently, the rated stresses for pressure vessels are found in the Boiler and Pressure Vessel Code Section II part D - about 6 pounds of paper covering thousands of materials. The material design temperature is also required to lookup material properties. You will also need to know what joint efficiency to use - a deep and difficult subject.

Example:

Your task is to quote a vessel made of SA-516 70 material that will operate at 100 psi at 200F. The tank needs to have a volume of 100 cubic feet. The customer prefers elliptical heads. What is the best diameter and size to use? How much will it weigh? How long will it be? Step 1 - Material Ratings - from ASME IID, at 200F, SA-516 70 has a rating of 20,000 psi. So the 20,000 psi charts will be used. Step 2 - Efficiency - from previous jobs, you know that radiography will not be used, The efficiencies used in past jobs have been 0.85 for the head and 0.7 for the circ and long seam welds on the rolled shell. Step 3 - Get the correct charts - 20,000psi rating charts for Rolled or Machined Cylinders, and 2:1 Semi Elliptical Heads Step 4 - Choose Diameter - Ignoring the heads, how long would the shell have to be get 100 cubic feet volume? 36" dia - aprox 7 cuft per ft - or 14 ft long. 48" dia - aprox 12 cuft per ft = 8.3 ft long. 60" dia - aprox 19.5 cuft per ft or 5 ft long. The 4 ft diameter tank seems a good start. Step 5 - Pick a shell wall thickness - According to the Rolled or Machined Cylinders chart, at 48" diameter, E = 0.7, a 3/16" wall is adequate for 110 psi. Based on previous experience, you decide that a 1/4" shell will be easier to fabricate. Step 6 - Pick a head thickness - According to the 2:1 Semi Elliptical Heads chart, at 48" diameter, E = 0.85, a a 3/16" wall head is good for 134 psi. note: this is the guaranteed minimum thickness after forming. The head fabricator will normally need a thicker plate to guarantee the after forming thickness. In this case, they might use a 1/4" flat plate prior to forming. Step 7 - Volume and Weight - 48" 2:1 SE head made from 1/4" plate - volume = 8.1cuft, weight = 178lbs. Required volume of shell = 100cuft - 2*8.1 = 83.8 cuft. for 1/4" shell, volume = 12.3cuft/ft. Required length = 83.8/12.3 = 6.8ft - use 7ft = 84" - volume of shell = 86.1 cuft. Weight of shell = 127.6lbs/ft x 7 = 893 lbs. Total weight = 127.6lbs (shell) + 2*178 (head) = 483 lbs. Total volume = 86.1 cuft (shell) + 2*8.1 cuft (heads) = 102.3 cuft. Step 8 - Length - 7 ft of shell = 84" = 2*12.13 head height = 108.26" Step 9 - Skirt on Heads - Heads are normally made with a straight skirt. The head in this example is often made with a 1 1/2" skirt. To keep the length, volume and weight

calculated above, the shell would have to be shortened by 3" to compensate for the skirts.

F&D Head Notes:

The F&D heads in these charts are based on the ASME specification from ASME Boiler and Pressure vessel code Section VIII-1 UG-32(d). These heads have an inside crown radius = outside diameter of the skirt. Other crown radii are allowe under ASME VIII-1 Appendix 1-4(d). A crown radius 6" less than the outside diameter is fairly common, but this and any other variation on the head dimensions will not work with these charts.

Semi Elliptical Head Notes:

Like the F&D heads, a large variety of elliptical height to diameter ratios are allowed in ASME VIII 1-4(c). The 2:1 Semi Elliptical charts only work with heads formed to a 2:1 ratio per ASME VIII-1 UG-32(d).

Pipe Notes:

ANSI/ASME B36.10M - 1995 covers the dimensions of pipe. The diameters and wall thickness in the charts on this web page are based on the presentation of this standard found in the twenty-sixth edition of the Machinery's Handbook pages 2504-2506. Trivia from the handbook: [The] OD was originally selected so that pipe with a standard OD and having a wall thickness that was typical of the period would have an inside diameter (ID) approximately equal to the nominal size. although there is now no such relation between the existing standard thicknesses, ODs and nominal sizes, these nominal sizes and standard ODs continue in use as "standard" The ANSI/ASME B36.10M - 1995 standard does not cover all of the commonly used wall thickness - especially thin wall pipes. My collection of pipe charts also disagrees on what to call items such as schedule 5, 10, 10S, and sometimes, what the wall thickness should be. My solution is to leave the names off of some of the wall thicknesses. Remember to check with your vendor to make sure that the pipe that meets your pressure requirement is really available. For many common pipe specs, mills are allowed a generous under-tolerance on the wall thickness. Ie, the wall can be thinner than specified when purchasing the product. The most commonly allowed under-tolerance is 12.5%. A pipe specified with a 1" thick wall and a 12.5% undertolerance could be shipped with a wall of 0.875 inches. This 12.5% under-tolerance has been removed from the pipe wall thickness in the pipe charts. Allowable under-tolerance varies from from 5% to 15%, or is sometimes specified as a fixed dimension. See specs SA-530 and SA-450 from ASME Boiler and Pressure Vessel Code Section IIA. The Pipe and Shell Spreadsheet contains under-tolerance charts for most common pipe and tube specs.

ASME Ratio Flanged and Dished Heads (F&D):

Flanged and Dished Head made of 20,000 psi rated materials Flanged and Dished Head made of 18,000 psi rated materials Flanged and Dished Head made of 16,000 psi rated materials Flanged and Dished Head made of 14,000 psi rated materials Flanged and Dished Head made of 12,000 psi rated materials Flanged and Dished Head made of 10,000 psi rated materials Flanged and Dished Head made of 8,000 psi rated materials Flanged and Dished Head made of 6,000 psi rated materials Flanged and Dished Head made of 4,000 psi rated materials Flanged and Dished Head made of 2,000 psi rated materials

2:1 Semi Elliptical Heads:

Semi Elliptical made of 20,000 psi rated materials Semi Elliptical made of 18,000 psi rated materials Semi Elliptical made of 16,000 psi rated materials

Semi Elliptical made of 14,000 psi rated materials Semi Elliptical made of 12,000 psi rated materials Semi Elliptical made of 10,000 psi rated materials Semi Elliptical made of 8,000 psi rated materials Semi Elliptical made of 6,000 psi rated materials Semi Elliptical made of 4,000 psi rated materials Semi Elliptical made of 2,000 psi rated materials

Rolled Plate or Machined Cylinders:

Rolled Plate or Machined Cylinder made of 20,000 psi rated materials Rolled Plate or Machined Cylinder made of 18,000 psi rated materials Rolled Plate or Machined Cylinder made of 16,000 psi rated materials Rolled Plate or Machined Cylinder made of 14,000 psi rated materials Rolled Plate or Machined Cylinder made of 12,000 psi rated materials Rolled Plate or Machined Cylinder made of 10,000 psi rated materials Rolled Plate or Machined Cylinder made of 8,000 psi rated materials Rolled Plate or Machined Cylinder made of 6,000 psi rated materials Rolled Plate or Machined Cylinder made of 4,000 psi rated materials Rolled Plate or Machined Cylinder made of 2,000 psi rated materials

Pipe:

- Pressure rating for wall thickness at E = 1.0 - Pressure rating for wall thickness at E = 0.85 - Volume per foot - Weight per foot (for carbon steel) Pipe made of 20,000 psi rated materials Pipe made of 18,000 psi rated materials Pipe made of 16,000 psi rated materials Pipe made of 14,000 psi rated materials Pipe made of 12,000 psi rated materials Pipe made of 10,000 psi rated materials Pipe made of 8,000 psi rated materials Pipe made of 6,000 psi rated materials Pipe made of 4,000 psi rated materials Pipe made of 2,000 psi rated materials

80:10 Flanged and Dished Heads (F&D):

80:10 Flanged and Dished Head made of 20,000 psi rated materials 80:10 Flanged and Dished Head made of 18,000 psi rated materials 80:10 Flanged and Dished Head made of 16,000 psi rated materials 80:10 Flanged and Dished Head made of 14,000 psi rated materials 80:10 Flanged and Dished Head made of 12,000 psi rated materials 80:10 Flanged and Dished Head made of 10,000 psi rated materials 80:10 Flanged and Dished Head made of 8,000 psi rated materials 80:10 Flanged and Dished Head made of 6,000 psi rated materials 80:10 Flanged and Dished Head made of 4,000 psi rated materials 80:10 Flanged and Dished Head made of 2,000 psi rated materials

Hemispherical Heads:

Hemispherical Heads Head made of 20,000 psi rated materials Hemispherical Heads Head made of 18,000 psi rated materials Hemispherical Heads Head made of 16,000 psi rated materials Hemispherical Heads Head made of 14,000 psi rated materials Hemispherical Heads Head made of 12,000 psi rated materials Hemispherical Heads Head made of 10,000 psi rated materials Hemispherical Heads Head made of 8,000 psi rated materials

Hemispherical Heads Head made of 6,000 psi rated materials Hemispherical Heads Head made of 4,000 psi rated materials Hemispherical Heads Head made of 2,000 psi rated materials

Anda mungkin juga menyukai

- Checklist GD BandlockDokumen3 halamanChecklist GD BandlockdeogmozyxBelum ada peringkat

- DESCON Engineering Limited: Cost Centers List Civil WorksDokumen11 halamanDESCON Engineering Limited: Cost Centers List Civil Worksasif iqbalBelum ada peringkat

- Basics of Pressure Piping For Junior EngineersDokumen36 halamanBasics of Pressure Piping For Junior Engineersتدریس زبان ESLBelum ada peringkat

- WELCOME To Cost & Evaluation Workbook by Peters, Timmerhaus and West. Accompanying Plant Design and Economics For Chemical Engineers, 5th EditionDokumen15 halamanWELCOME To Cost & Evaluation Workbook by Peters, Timmerhaus and West. Accompanying Plant Design and Economics For Chemical Engineers, 5th Editionxhche7Belum ada peringkat

- Vdocuments - MX Petroleum Development Oman LLC Petroleum Development Oman LLC Er DocumentsDokumen60 halamanVdocuments - MX Petroleum Development Oman LLC Petroleum Development Oman LLC Er DocumentsOussama BaddadiBelum ada peringkat

- ICARUS ReferenceDokumen66 halamanICARUS Referencerylar999Belum ada peringkat

- Tank DesignDokumen7 halamanTank Designbektiwidi1060Belum ada peringkat

- Template in Excel For PE's (By CPDEP)Dokumen36 halamanTemplate in Excel For PE's (By CPDEP)BibizhanKadyrberliBelum ada peringkat

- Sample2 DrawingDokumen1 halamanSample2 DrawingSourav HaitBelum ada peringkat

- SOW For Heat Exchanger RFQ 29868 UZB1005 Revised 2017-06-01 PDFDokumen19 halamanSOW For Heat Exchanger RFQ 29868 UZB1005 Revised 2017-06-01 PDFMallu BroBelum ada peringkat

- Aspen Shell & Tube Mechanical Product BrochureDokumen2 halamanAspen Shell & Tube Mechanical Product BrochureThitikorn WassanarpheernphongBelum ada peringkat

- Tank Design and DetailingDokumen17 halamanTank Design and DetailingFuatBelum ada peringkat

- Mechanical Design For Pressure VesselDokumen26 halamanMechanical Design For Pressure VesselibicengBelum ada peringkat

- TCAEMM EmptyvaluesdocumentDokumen241 halamanTCAEMM EmptyvaluesdocumentJithinBelum ada peringkat

- GRP Tank Data SheetDokumen10 halamanGRP Tank Data SheetdaprcBelum ada peringkat

- ASME CheckDokumen14 halamanASME Checkfuransu777Belum ada peringkat

- Datasheet For FiltersDokumen13 halamanDatasheet For FiltersAntonio MendesBelum ada peringkat

- 1 Process VesselsDokumen4 halaman1 Process VesselsARIANA NICOLE RELIGIOSOBelum ada peringkat

- Sa-516 70 TDCDokumen2 halamanSa-516 70 TDCshazan100% (1)

- Hemispherical HeadDokumen5 halamanHemispherical HeadPuRuiSen HelathchemicalBelum ada peringkat

- Valve & Flange Box FundamentalsDokumen20 halamanValve & Flange Box Fundamentalsautin3:16Belum ada peringkat

- Petrofac E&C Oman LLC Petroleum Development Oman Datasheet For Globe Valves Rabab Harweel Integrated Project Petrofac Job No.: Es-00002 Pdo Contract No. C311-321Dokumen21 halamanPetrofac E&C Oman LLC Petroleum Development Oman Datasheet For Globe Valves Rabab Harweel Integrated Project Petrofac Job No.: Es-00002 Pdo Contract No. C311-321raj_hp2000Belum ada peringkat

- KEPA Air RegulationsDokumen42 halamanKEPA Air RegulationsAmmar Yahia100% (1)

- Charts of Stainless Steel Pipe Fittings' WeightsDokumen6 halamanCharts of Stainless Steel Pipe Fittings' WeightsHao ZhouBelum ada peringkat

- Nps Table Welded Seamless Stainless Steel PipeDokumen3 halamanNps Table Welded Seamless Stainless Steel PipeOmar HasounBelum ada peringkat

- Stress Analysis and Design Optimization of A Pressure Vessel Using Ansys PackageDokumen12 halamanStress Analysis and Design Optimization of A Pressure Vessel Using Ansys Packageanthony zegarra ochoaBelum ada peringkat

- Static Equipment EngineerDokumen2 halamanStatic Equipment Engineersagar1503Belum ada peringkat

- Pneumatic Vs Electric Cost CalculatorDokumen7 halamanPneumatic Vs Electric Cost CalculatorArindam GhosalBelum ada peringkat

- Pipe Steel BookDokumen449 halamanPipe Steel BookAlonzo MedinaBelum ada peringkat

- PED-Design Preliminaries-Mechanical Aspects - MergedDokumen87 halamanPED-Design Preliminaries-Mechanical Aspects - Mergedsudhanshu shekharBelum ada peringkat

- RAW WATER TANK - CAP.289 M SPECIFICATION DRAWINGDokumen1 halamanRAW WATER TANK - CAP.289 M SPECIFICATION DRAWINGIskandar 'muda' AdeBelum ada peringkat

- ACI 318-11 Appedix DDokumen2 halamanACI 318-11 Appedix DJonathan SchauderBelum ada peringkat

- Pipe Wall Thickness CalculationDokumen1 halamanPipe Wall Thickness Calculationfarhad soopithodiBelum ada peringkat

- Boq Pekerjaan Pondasi 500 KV Lot 1.: Foundation For 500 KV Two Circuit TowersDokumen8 halamanBoq Pekerjaan Pondasi 500 KV Lot 1.: Foundation For 500 KV Two Circuit TowersErick SavrinaldoBelum ada peringkat

- How To Do A Tie-InDokumen2 halamanHow To Do A Tie-Inrenjithv_4100% (1)

- API 510 Hydrostatic Head PressureDokumen40 halamanAPI 510 Hydrostatic Head PressureHarmish mewadaBelum ada peringkat

- Kontur Pipeflow BaruDokumen33 halamanKontur Pipeflow BaruAngga Lionix ManullangBelum ada peringkat

- Steam Tracing SpecificationDokumen1 halamanSteam Tracing Specificationgpskumar22Belum ada peringkat

- Pipeline Equipment and ConstructionDokumen16 halamanPipeline Equipment and ConstructionHansLopezBelum ada peringkat

- 1.tank Monitoring StatusDokumen3 halaman1.tank Monitoring StatusDuan TokcerBelum ada peringkat

- InchDia Cal. For SqPadDokumen2 halamanInchDia Cal. For SqPadparthBelum ada peringkat

- 2016 Front End SampleDokumen12 halaman2016 Front End SampleB GirishBelum ada peringkat

- Introduction To Piping EngineeringDokumen33 halamanIntroduction To Piping EngineeringkysucoBelum ada peringkat

- Cu Ni CatalogDokumen48 halamanCu Ni CatalogbureqqBelum ada peringkat

- Chapter # 11: - Project Risk ManagementDokumen24 halamanChapter # 11: - Project Risk ManagementSyed FarazBelum ada peringkat

- PV QCDokumen1 halamanPV QCrameshqcBelum ada peringkat

- ASME Section I and VIII-Div-1 Training Course OutlineDokumen2 halamanASME Section I and VIII-Div-1 Training Course OutlineKarthikeyan ShanmugavelBelum ada peringkat

- Autopipe Vessel Guide 1-5Dokumen5 halamanAutopipe Vessel Guide 1-5fiuto_rights_1404802Belum ada peringkat

- Structural Estimate BasisDokumen8 halamanStructural Estimate BasisKaloyBelum ada peringkat

- D.M.Plant OperatorsDokumen5 halamanD.M.Plant OperatorsTiu TonBelum ada peringkat

- Presentasi EPCDokumen34 halamanPresentasi EPCtiantaufikBelum ada peringkat

- CRP Lined Pipe BrochureDokumen44 halamanCRP Lined Pipe Brochurekrishna_piping100% (2)

- Equipment Design BasisDokumen4 halamanEquipment Design BasisAnjani GantiBelum ada peringkat

- Model 10 10fb 11 Carbon HousingsDokumen4 halamanModel 10 10fb 11 Carbon HousingsrezBelum ada peringkat

- Fabrication and Erection Piping Manhour Work SheetDokumen2 halamanFabrication and Erection Piping Manhour Work SheetRuelBelum ada peringkat

- Pressure Vessel PresentationDokumen18 halamanPressure Vessel Presentationlaleye_olumide0% (1)

- Notes For Spreedsheet Calculator SoftwareDokumen8 halamanNotes For Spreedsheet Calculator SoftwareniginpBelum ada peringkat

- Local IcddrbDokumen14 halamanLocal IcddrbShamsul ArefinBelum ada peringkat

- Pipe LossesDokumen2 halamanPipe LossesSaurabh PariharBelum ada peringkat

- Rathish ResumeDokumen6 halamanRathish ResumePriyanathan ThayalanBelum ada peringkat

- Site FacilitiesDokumen1 halamanSite FacilitiesPriyanathan ThayalanBelum ada peringkat

- Design of Shell & Tube HXDokumen40 halamanDesign of Shell & Tube HXprateek_bhoirBelum ada peringkat

- Shell and Tube Heat ExchangerDokumen19 halamanShell and Tube Heat Exchangerhuangjl33% (3)

- EXAMPLE - METHOD 2 (Statistical) Depth of Engagement - Pipe - Pressure ApplicationDokumen6 halamanEXAMPLE - METHOD 2 (Statistical) Depth of Engagement - Pipe - Pressure ApplicationdakidofdaboomBelum ada peringkat

- BeamsDokumen21 halamanBeamsSrinivas TanarapuBelum ada peringkat

- Shell & Tube HX Design (Rev1)Dokumen32 halamanShell & Tube HX Design (Rev1)Priyanathan ThayalanBelum ada peringkat

- Thermal Expansion CalculatorDokumen2 halamanThermal Expansion CalculatorPriyanathan ThayalanBelum ada peringkat

- Clarified Water PumpDokumen1 halamanClarified Water PumpPriyanathan ThayalanBelum ada peringkat

- Surge TankDokumen1 halamanSurge TankPriyanathan ThayalanBelum ada peringkat

- Sizing Air ReceiverDokumen3 halamanSizing Air ReceiverAnkon Mukherjee100% (3)

- 620Dokumen33 halaman620ccricaBelum ada peringkat

- SBES Organization ProfileDokumen9 halamanSBES Organization ProfilePriyanathan ThayalanBelum ada peringkat

- Dolby HomeTheaterSetupGuide 5.1Dokumen5 halamanDolby HomeTheaterSetupGuide 5.1Milan MijailovicBelum ada peringkat

- 360brake BrakingTips 73564ADDD04FADokumen3 halaman360brake BrakingTips 73564ADDD04FAPriyanathan ThayalanBelum ada peringkat

- Sbes Profile PDFDokumen7 halamanSbes Profile PDFPriyanathan ThayalanBelum ada peringkat

- Base Silencers For Rotary Positive Blowers: Building Sound SolutionsDokumen4 halamanBase Silencers For Rotary Positive Blowers: Building Sound SolutionsPriyanathan ThayalanBelum ada peringkat

- R134 ADokumen59 halamanR134 ABing TzuanBelum ada peringkat

- Air Cooler Design Sheiko PDFDokumen22 halamanAir Cooler Design Sheiko PDFJason ThomasBelum ada peringkat

- Fan SilenserDokumen6 halamanFan SilenservrgohilBelum ada peringkat

- Steel: 1) Carbon SteelsDokumen2 halamanSteel: 1) Carbon SteelsPriyanathan ThayalanBelum ada peringkat

- 4) Power Plants 5) Hydraulic Equipments: ManpowerDokumen1 halaman4) Power Plants 5) Hydraulic Equipments: ManpowerPriyanathan ThayalanBelum ada peringkat

- VB and PB GA DrawingDokumen1 halamanVB and PB GA DrawingPriyanathan ThayalanBelum ada peringkat

- How To Calculate Duty and Surface Area of Heat Ex ChangersDokumen7 halamanHow To Calculate Duty and Surface Area of Heat Ex ChangersJohn Obidi100% (2)

- Basic Piping DesignDokumen4 halamanBasic Piping DesignPriyanathan ThayalanBelum ada peringkat

- North: 100.30 Avg - GL 100.00 Avg - GL 100.30Dokumen1 halamanNorth: 100.30 Avg - GL 100.00 Avg - GL 100.30Priyanathan ThayalanBelum ada peringkat

- 14033Dokumen2 halaman14033Priyanathan ThayalanBelum ada peringkat

- Chemical and Physical Information: Fuel Oils 105Dokumen6 halamanChemical and Physical Information: Fuel Oils 105Priyanathan ThayalanBelum ada peringkat

- Hydro EnggDokumen11 halamanHydro EnggPriyanathan ThayalanBelum ada peringkat

- Practical Guide To Industrial Boiler SystemsDokumen375 halamanPractical Guide To Industrial Boiler Systemssumeet0827100% (19)

- NHD Process PaperDokumen2 halamanNHD Process Paperapi-122116050Belum ada peringkat

- Quality Assurance Plan-75FDokumen3 halamanQuality Assurance Plan-75Fmohamad chaudhariBelum ada peringkat

- Ryff's Six-Factor Model of Psychological Well-BeingDokumen7 halamanRyff's Six-Factor Model of Psychological Well-BeingYogi Sastrawan100% (1)

- Major Stakeholders in Health Care SystemDokumen5 halamanMajor Stakeholders in Health Care SystemANITTA S100% (1)

- FBISE Grade 10 Biology Worksheet#1Dokumen2 halamanFBISE Grade 10 Biology Worksheet#1Moaz AhmedBelum ada peringkat

- List of Practicals Class Xii 2022 23Dokumen1 halamanList of Practicals Class Xii 2022 23Night FuryBelum ada peringkat

- Electronic Waste Management in Sri Lanka Performance and Environmental Aiudit Report 1 EDokumen41 halamanElectronic Waste Management in Sri Lanka Performance and Environmental Aiudit Report 1 ESupun KahawaththaBelum ada peringkat

- How Should We Allocate Scarce Resources Over Our Business Portfolio?Dokumen20 halamanHow Should We Allocate Scarce Resources Over Our Business Portfolio?Vivek AryaBelum ada peringkat

- Angeles City National Trade SchoolDokumen7 halamanAngeles City National Trade Schooljoyceline sarmientoBelum ada peringkat

- Dr. Babasaheb Ambedkar Technological UniversityDokumen3 halamanDr. Babasaheb Ambedkar Technological UniversityalfajBelum ada peringkat

- JSA FormDokumen4 halamanJSA Formfinjho839Belum ada peringkat

- Agile in ISO 9001 - How To Integrate Agile Processes Into Your Quality Management System-Springer (2023)Dokumen67 halamanAgile in ISO 9001 - How To Integrate Agile Processes Into Your Quality Management System-Springer (2023)j.paulo.mcBelum ada peringkat

- Prosocial Behaviour: Hans W. BierhoffDokumen20 halamanProsocial Behaviour: Hans W. BierhoffSahil Mushaf100% (1)

- Week 1-2 Module 1 Chapter 1 Action RseearchDokumen18 halamanWeek 1-2 Module 1 Chapter 1 Action RseearchJustine Kyle BasilanBelum ada peringkat

- Unit 2 Module 2 Combined-1Dokumen14 halamanUnit 2 Module 2 Combined-1api-2930012170% (2)

- Facts About The TudorsDokumen3 halamanFacts About The TudorsRaluca MuresanBelum ada peringkat

- LhiannanDokumen6 halamanLhiannanGreybornBelum ada peringkat

- An Analysis of The Cloud Computing Security ProblemDokumen6 halamanAn Analysis of The Cloud Computing Security Problemrmsaqib1Belum ada peringkat

- AnkitKumar InternshalaResume PDFDokumen2 halamanAnkitKumar InternshalaResume PDFkusha010Belum ada peringkat

- Trading Rules To Successful ProfitsDokumen89 halamanTrading Rules To Successful ProfitsOuattaraBelum ada peringkat

- ISP SFD PDFDokumen73 halamanISP SFD PDFNamo SlimanyBelum ada peringkat

- How To Build Yam Chips Production PlantDokumen11 halamanHow To Build Yam Chips Production PlantVu Thieu TuanBelum ada peringkat

- 1 s2.0 S0378432004002465 MainDokumen20 halaman1 s2.0 S0378432004002465 MainMuhammad JameelBelum ada peringkat

- Matrix CPP CombineDokumen14 halamanMatrix CPP CombineAbhinav PipalBelum ada peringkat

- As I Lay Writing How To Write Law Review ArticleDokumen23 halamanAs I Lay Writing How To Write Law Review ArticleWalter Perez NiñoBelum ada peringkat

- Interceptor Specifications FinalDokumen7 halamanInterceptor Specifications FinalAchint VermaBelum ada peringkat

- Glory in The Cross - Holy Thursday - Schutte PDFDokumen1 halamanGlory in The Cross - Holy Thursday - Schutte PDFsharon0murphyBelum ada peringkat

- Design and Analysis of DC-DC Boost Converter: September 2016Dokumen5 halamanDesign and Analysis of DC-DC Boost Converter: September 2016Anonymous Vfp0ztBelum ada peringkat

- Narrative FixDokumen6 halamanNarrative Fixfitry100% (1)

- Growth Kinetic Models For Microalgae Cultivation A ReviewDokumen16 halamanGrowth Kinetic Models For Microalgae Cultivation A ReviewJesús Eduardo De la CruzBelum ada peringkat