Lab 2 Fall 2010

Diunggah oleh

Saad Al HelyHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Lab 2 Fall 2010

Diunggah oleh

Saad Al HelyHak Cipta:

Format Tersedia

AMERICAN UNIVERSITY IN CAIRO MECHANICAL ENGINEERING DEPARTMENT MENG 475 Lab 2: Vibration Severity Objective The objective of this

lab is to understand the term vibration severity and the precautions necessary to the assessment of vibration severity in a machine, in accordance with the international standard ISO 10816-1 1995*. The concept of machine condition monitoring is introduced. A portable accelerometer is used to measure the vibration levels of a machine. The results are used to assess the vibration severity of an air conditioner pump unit. Equipment Portable accelerometer Chilled water pump in Parcel 7 pump room Background Rotating machinery, such as the motorpump unit shown, are very common in the industry. A practicing mechanical engineer is often faced with duty of maintaining the safe operation of these units in order to avoid delays or accidents. Preventive maintenance is essential to guarantee the sound and long-life operation of machines. Maintaining vibration levels below specified acceptable limits is a measure of preventive maintenance. Once vibrations exceed these limits, it becomes necessary to cease operation, and carry out detailed trouble-shooting vibration measurements, where the major vibration frequencies are identified to provide insight to the sources of vibration. Corrective measures are then taken to minimize or, if possible, eliminate these vibrations. The above process is referred to as machine condition monitoring. Monitoring the levels of vibration or vibration severity therefore provides the basis for the decision to employ detailed troubleshooting vibration measurements. Vibration severity is defined as a comprehensive and simple characteristic unit for describing the vibratory state of a machine. According to ISO 10816, it is common practice, based on experience, when evaluating broad-band vibration of rotating machinery to consider the RMS value of vibration velocity as the unit of measurement for indicating vibration severity. The validity of the rules provide by the above ISO standard is restricted to vibrations measured at machine surfaces, and within the frequency range 10-1000 HZ and the speed range 10-200 rev/s. Examples of these types of machines include electric motor and pumps, generators, steam and gas turbines, turbo-compressors and fans. Points of measurement are chosen where the vibration energy is transmitted to the resilient mountings or to other parts of the system. For machines including rotating masses, the bearings and mounting points are the preferred points of measurement. Succeeding vibration severity ranges have a ratio of 1:1.6 giving a step of 4dB between severity levels. A difference of 4dB represents a significant change in the vibratory response in most machines. Examining the vibration criterion chart will show that an increase of 8dB (about 2.5 times) in the vibration level will move the condition from good to allowable, to just tolerable, to not permissible. A machine must be classified into a particular machine class before its vibration severity can be assessed.

It is worthwhile to conduct trend comparisons, to compare the current values of vibration levels at the same points over a period of time, or to make mutual comparisons with other existing machines.

ISO vibration severity standard 10816: Mechanical vibrationEvaluation of machine vibration by measurements on non-rotating parts.

Experimental Procedure Measure the vibration levels at the feet of the machine in order to assess the vibration severity. There are several machines that can be used in the pump room of the buildings air conditioning system. An assessment of the vibration severity should then be concluded from the measurements and documented in a technical report.

The table below shows the vibration severity criterion chart, taken from ISO 10816. The chart specifies machinery vibration limits based on machine power and foundation type. The criteria are based upon the RMS value of vibration velocity for operating speeds of 600 to 12,000 rpm.

Vibration Severity According to ISO 10816 Class I Class II Class III Small Medium Large, Rigid Foundation A B B C C C D D D C D B B A A A

Machine mm/s 0.28 0.45 0.71 1.12 1.8 2.8 4.5 7.1 11.2 18 28 45

Class IV Large, Soft Foundation

A: Good, B: Allowable, C: Just tolerable, D: Not permissible

Machinery class designations are as follows: Class l: Individual parts of engines and machines, integrally connected with the complete machine in its normal operating condition. (Production electrical motors of up to 20 HP (15 kW) are typical examples of machines in this category.) Class ll: Medium-sized machines typically, electric motors with 20 to 75 HP (15-75 kW) without special foundations, rigidly mounted engines, or machines on special foundations up to 400 HP (300 kW). Class lll: Large prime movers and other large machines with rotating masses mounted on rigid and heavy foundations which are relatively stiff in the direction of vibration measurement. Class lV: Large prime movers and other large machines with rotating masses mounted on foundations which are relatively soft in the direction of vibration measurement (for example, turbo-generator sets, especially those with lightweight sub-structures).

RMS Vibration Velocity

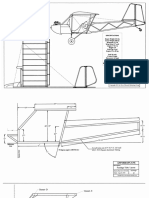

Report The report should include a description of the measurements taken and how they were taken, the measured values of RMS vibration velocity, the vibration severity, and the concluded assessment of vibration severity. Document your readings for each machine in the following format: Sketch of machine Machine

MOTOR

PUMP

Speed and power Special features Measuring instrument Location

1 Horizontal Vertical Axial Machine class according to ISO 10816 Quality judgment

Limit values 1________ 3________ mm/s

2________ 4________ m

Good Just tolerable

Allowable Not permissible

Anda mungkin juga menyukai

- Ali BadiDokumen234 halamanAli BadiSaad Al HelyBelum ada peringkat

- Non Linear Analysis of Spur Gear Using Matlab CodeDokumen105 halamanNon Linear Analysis of Spur Gear Using Matlab CodehazemismaeelradhiBelum ada peringkat

- Ali BadiDokumen234 halamanAli BadiSaad Al HelyBelum ada peringkat

- AnnaDokumen99 halamanAnnaSaad Al HelyBelum ada peringkat

- Finite Element Analysis of Stresses Caused by External Holes in Hydraulic CylindersDokumen11 halamanFinite Element Analysis of Stresses Caused by External Holes in Hydraulic CylindersSaad Al HelyBelum ada peringkat

- NimaDokumen110 halamanNimaSaad Al HelyBelum ada peringkat

- Inventor Professional 2010 Installation InstructionsDokumen8 halamanInventor Professional 2010 Installation InstructionsSaad Al HelyBelum ada peringkat

- My LifeDokumen4 halamanMy LifeSaad Al HelyBelum ada peringkat

- Illustrator Cs 5Dokumen19 halamanIllustrator Cs 5Saad Al HelyBelum ada peringkat

- AbbrevaitionDokumen155 halamanAbbrevaitionSaad Al HelyBelum ada peringkat

- Out 2Dokumen6 halamanOut 2Saad Al HelyBelum ada peringkat

- Advance Steel 2015 Starting GuideDokumen40 halamanAdvance Steel 2015 Starting Guidegranjero_mxBelum ada peringkat

- 08 Plasticity 01 IntroductionDokumen11 halaman08 Plasticity 01 Introductionabhi16Belum ada peringkat

- Finite Element Formulation For BeamsDokumen27 halamanFinite Element Formulation For BeamsPalash JainBelum ada peringkat

- Corel Draw 2010Dokumen33 halamanCorel Draw 2010Saad Al HelyBelum ada peringkat

- Full Text 01Dokumen60 halamanFull Text 01Saad Al HelyBelum ada peringkat

- Illustrator Cs 5Dokumen19 halamanIllustrator Cs 5Saad Al HelyBelum ada peringkat

- As User Guide 2015 en Metric 140408Dokumen170 halamanAs User Guide 2015 en Metric 140408Saad Al HelyBelum ada peringkat

- Corel Draw 2010Dokumen33 halamanCorel Draw 2010Saad Al HelyBelum ada peringkat

- Weld Geometry 1Dokumen127 halamanWeld Geometry 1Saad Al Hely100% (1)

- Modeling and Visualization Analysis Reference: Abaqus/CAE User's Guide Abaqus Analysis User's GuideDokumen1 halamanModeling and Visualization Analysis Reference: Abaqus/CAE User's Guide Abaqus Analysis User's GuideSaad Al HelyBelum ada peringkat

- Advance Steel 2015 Starting GuideDokumen40 halamanAdvance Steel 2015 Starting Guidegranjero_mxBelum ada peringkat

- Bs Steel CodeDokumen14 halamanBs Steel CodeA.K.A. HajiBelum ada peringkat

- StructEngII Connections 276-327Dokumen52 halamanStructEngII Connections 276-327Saad Al HelyBelum ada peringkat

- Chapter 9 - Welding DefectsDokumen18 halamanChapter 9 - Welding Defectsbibin2010100% (1)

- Design Girder Bridge EurocodeDokumen139 halamanDesign Girder Bridge Eurocodetomnubi100% (2)

- SimXpert2013 ThermalDokumen230 halamanSimXpert2013 ThermalSaad Al HelyBelum ada peringkat

- LS DynaLab2Dokumen15 halamanLS DynaLab2Mohammed A. Maher100% (1)

- Mohammad SarairehDokumen176 halamanMohammad SarairehamilcarsoaresBelum ada peringkat

- Ansys Lab2Dokumen16 halamanAnsys Lab2Saad Al HelyBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Liver: Anatomy & FunctionsDokumen18 halamanLiver: Anatomy & FunctionsDR NARENDRABelum ada peringkat

- Dusta ManaDokumen16 halamanDusta ManamahaphalaBelum ada peringkat

- Course Registration SlipDokumen2 halamanCourse Registration SlipMics EntertainmentBelum ada peringkat

- Electric ScootorDokumen40 halamanElectric Scootor01fe19bme079Belum ada peringkat

- Sustainable Events Guide May 30 2012 FINAL PDFDokumen118 halamanSustainable Events Guide May 30 2012 FINAL PDFInter 4DMBelum ada peringkat

- The Indian Mining Sector: Effects On The Environment & FDI InflowsDokumen10 halamanThe Indian Mining Sector: Effects On The Environment & FDI InflowsMehul MandanakaBelum ada peringkat

- Manual PipsDokumen5 halamanManual PipsOzzyBelum ada peringkat

- Course Syllabus: Course Code Course Title ECTS CreditsDokumen3 halamanCourse Syllabus: Course Code Course Title ECTS CreditsHanaa HamadallahBelum ada peringkat

- Oil Whirl and Whip Instabilities - Within Journal BearingsDokumen27 halamanOil Whirl and Whip Instabilities - Within Journal BearingsTalha AamirBelum ada peringkat

- Therapeutic Nutrition: Khien S. Sasi, RN, ManDokumen33 halamanTherapeutic Nutrition: Khien S. Sasi, RN, ManKhien Sasi100% (4)

- Math COT 3Dokumen18 halamanMath COT 3Icy Mae SenadosBelum ada peringkat

- Bible World History Timeline - 4004-3004BCDokumen1 halamanBible World History Timeline - 4004-3004BCSagitonette DadapBelum ada peringkat

- SAT Practice TestDokumen77 halamanSAT Practice TestfhfsfplBelum ada peringkat

- Awakened Citizen Programme-Report-class VII-2014Dokumen4 halamanAwakened Citizen Programme-Report-class VII-2014bhsgeneral r m saraswathi50% (4)

- Eng DS Epp-2314 1410Dokumen2 halamanEng DS Epp-2314 1410MarkusAldoMaquBelum ada peringkat

- Semi Finals in Tle 2015Dokumen3 halamanSemi Finals in Tle 2015LoraineTenorioBelum ada peringkat

- 123 09-Printable Menu VORDokumen2 halaman123 09-Printable Menu VORArmstrong TowerBelum ada peringkat

- CBSE DetailsDokumen6 halamanCBSE DetailsNARESH KUMARBelum ada peringkat

- Bulacan Agricultural State College: Lesson Plan in Science 4 Life Cycle of Humans, Animals and PlantsDokumen6 halamanBulacan Agricultural State College: Lesson Plan in Science 4 Life Cycle of Humans, Animals and PlantsHarmonica PellazarBelum ada peringkat

- Soldier of Fortune PDFDokumen208 halamanSoldier of Fortune PDFNixel SpielBelum ada peringkat

- NF en Iso 5167-6-2019Dokumen22 halamanNF en Iso 5167-6-2019Rem FgtBelum ada peringkat

- Innerwear Industry Pitch PresentationDokumen19 halamanInnerwear Industry Pitch PresentationRupeshKumarBelum ada peringkat

- Inferring The Speaker's Tone, ModeDokumen31 halamanInferring The Speaker's Tone, Modeblessilda.delaramaBelum ada peringkat

- Cobalamin in Companion AnimalsDokumen8 halamanCobalamin in Companion AnimalsFlávia UchôaBelum ada peringkat

- Plans PDFDokumen49 halamanPlans PDFEstevam Gomes de Azevedo85% (34)

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDokumen3 halamanDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoBelum ada peringkat

- Scanner and Xcal Comperative Analysis v2Dokumen22 halamanScanner and Xcal Comperative Analysis v2Ziya2009Belum ada peringkat

- Better - Homes.and - Gardens.usa - TruePDF December.2018Dokumen136 halamanBetter - Homes.and - Gardens.usa - TruePDF December.2018MadaMadutsaBelum ada peringkat

- Reviews: The Global Epidemiology of HypertensionDokumen15 halamanReviews: The Global Epidemiology of Hypertensionrifa iBelum ada peringkat

- Port Name: Port of BaltimoreDokumen17 halamanPort Name: Port of Baltimoremohd1khairul1anuarBelum ada peringkat