9A03504 Design of Machine Elements I 1

Diunggah oleh

slv_prasaadHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

9A03504 Design of Machine Elements I 1

Diunggah oleh

slv_prasaadHak Cipta:

Format Tersedia

Code: 9A03504 III B.

Tech I Semester (R09) Supplementary Examinations, May 2012 DESIGN OF MACHINE ELEMENTS I (Mechanical Engineering) Time: 3 hours Design books are not permitted in the examination hall. Answer any FIVE questions All questions carry equal marks ***** 1 (a) What are the important considerations that govern the choice of a material? (b) What is meant by ductility, malleability and plasticity?

R09

Max Marks: 70

A cantilever of span 500 mm carries a vertical downward load of 6 kN at its free end. Assume yield strength of 350 MPa and factor of safety as 3. Find the economical cross section for cantilever, among: (i) Circular section of diameterd. (ii) Rectangular cross section with depth twice the width, and (iii) I-section of depth 5t and flange 4t, where t is the thickness. Specify the dimensions and cross-sectional area of the economic section. (a) What are the criteria of failure for ductile material subjected to: (i) Static load and (ii) varying load. (b) A flat plate subjected to a tensile force of 5 kN is shown in figure-3.1. The plate material is grey cast iron FG 200 and the factor f safety is 2.5. Determine the thickness of the plate. Take the stress concentration factor as 1.8 at the hole and as 2.16 for the fillet radius. (a) What are the advantages and disadvantages of riveted joints? (b) A triple riveted lap joint is to be made between 6.5 mm plates. The allowable stresses are 35 N/mm2 in tensile, 29 N/mm2 in shear, and 52.5 N/mm2 in compression. Calculate the rivet diameter, rivet pitch and back pitch, zig - zag riveting is to be used. Indicate how the joint will fail. Several members are bolted together in such a manner that the deflection per unit load for the bolted members is the same as for the bolt. Determine: (i) if the initial tightening load on the bolt is 40 kN, what axial external load has to be applied to the bolt to cause separation of the bolted members? (ii) What is the resultant bolt load for an external load of 50 kN? (iii) What is the resultant bolt load for an external load of 100 kN? Two rods having 30 mm x 30 mm square cross-section are connected using a gib and cotter. Calculate the leading dimensions of the joint so as to have the strength of the joint same as the strength of the rods in tension. For all the parts of the joint take the allowable stresses as follows: Tensile Strength = 120 N/mm2 Shear Strength = 70 N/mm2 and Compression strength = 240 N/mm2. Contd. in Page 2

Code: 9A03504 Page 2 7

R09

A machine shaft turning at 600 rev/min, is supported on bearings 1000 mm apart as shown in figure-7.4. 15 KW is supplied to the shaft through a 450 mm pulley located 250 mm to the left of the right bearing. The power is transmitted from the shaft through a 200 mm spur gear located 250 mm to the right of the left hand bearing. The belt drive is at angle of 600 above the horizontal. The pulley weighs 800 N to provide some flywheel effect. The ratio of the belt tensions is 3:1. The gear has a 200 tooth form and mates with another gear located directly above the shaft. If the shaft material selected has an ultimate strength of 500 MN/m2 and a yield point of 310 MN/m2 determine the necessary diameter using the shock and fatigue factors as Kb = 1.5 and Kt = 1.0 in bending and torsion respectively.

Design and sketch the dimensioned view of the rigid coupling for heavy duty with the following data: (i) Power (KW) to Speed (rpm) ratio =1.5; (ii) Maximum shear strength is 80 N/mm2, and (iii) Assume suitable any missing data. *****

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- 2017 09Dokumen164 halaman2017 09sowabar100% (1)

- Radiation Safety Officers Handbook A PDFDokumen100 halamanRadiation Safety Officers Handbook A PDFAlejandro Zubiate100% (1)

- Measure RPA ROI with KPIsDokumen4 halamanMeasure RPA ROI with KPIsAdnan FarooqBelum ada peringkat

- Design of Machine Elements Exam QuestionsDokumen8 halamanDesign of Machine Elements Exam Questionsslv_prasaadBelum ada peringkat

- Design of Machine Elements Exam QuestionsDokumen8 halamanDesign of Machine Elements Exam Questionsslv_prasaadBelum ada peringkat

- Design of Machine Elements Exam QuestionsDokumen8 halamanDesign of Machine Elements Exam Questionsslv_prasaadBelum ada peringkat

- Northern Hemisphere Electronic Navigation Resources: Day Skipper and Watch LeaderDokumen8 halamanNorthern Hemisphere Electronic Navigation Resources: Day Skipper and Watch LeaderSean DolanBelum ada peringkat

- Potentiometric TitrationDokumen12 halamanPotentiometric TitrationTien Haminh100% (1)

- Expansion Joint Treatment Materials and TechniquesDokumen15 halamanExpansion Joint Treatment Materials and TechniquesMAHAK GUPTABelum ada peringkat

- Detailed Scheduling Planning Board Technical HelpDokumen6 halamanDetailed Scheduling Planning Board Technical Helpmanojnarain100% (1)

- DLL Theorems On RectangleDokumen5 halamanDLL Theorems On RectanglePatrick Guerra100% (1)

- JNTUA Mechanical Engineering (R09) Syllabus BookDokumen147 halamanJNTUA Mechanical Engineering (R09) Syllabus Bookslv_prasaad0% (1)

- 9A03504 Design of Machine ElementsDokumen2 halaman9A03504 Design of Machine Elementsslv_prasaadBelum ada peringkat

- R7310305-Design of Machine Members-I2Dokumen4 halamanR7310305-Design of Machine Members-I2slv_prasaad100% (1)

- Worm GearsDokumen4 halamanWorm Gearsnitesh_n2840Belum ada peringkat

- Curved BeamsDokumen8 halamanCurved BeamsAnonymous EKqkRJsJNBelum ada peringkat

- r7320101 Geotechnical Engineering IDokumen1 halamanr7320101 Geotechnical Engineering Iprasaad08Belum ada peringkat

- Me1302 LP ADokumen3 halamanMe1302 LP ACKDinakarrajBelum ada peringkat

- R7310305-Design of Machine Members-IDokumen1 halamanR7310305-Design of Machine Members-Islv_prasaadBelum ada peringkat

- r7320102 Environmental EngineeringDokumen4 halamanr7320102 Environmental Engineeringslv_prasaadBelum ada peringkat

- ME2303Dokumen7 halamanME2303slv_prasaadBelum ada peringkat

- 9A03504 Design of Machine Elements IDokumen4 halaman9A03504 Design of Machine Elements Islv_prasaadBelum ada peringkat

- Performance and emission characteristics of Karanja biodiesel and its blends in a variable compression ignition engineDokumen52 halamanPerformance and emission characteristics of Karanja biodiesel and its blends in a variable compression ignition engineslv_prasaadBelum ada peringkat

- Ajas53189 196Dokumen8 halamanAjas53189 196slv_prasaadBelum ada peringkat

- RCC Slab Estimation and Bending ScheduleDokumen4 halamanRCC Slab Estimation and Bending Scheduleslv_prasaadBelum ada peringkat

- Lecture 26aDokumen12 halamanLecture 26aslv_prasaadBelum ada peringkat

- CFD Optimization With Altair Hyperworks: in This Issue July 2006Dokumen6 halamanCFD Optimization With Altair Hyperworks: in This Issue July 2006slv_prasaadBelum ada peringkat

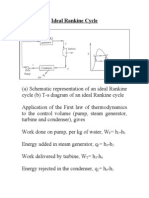

- Ideal Rankine CycleDokumen27 halamanIdeal Rankine Cycleslv_prasaadBelum ada peringkat

- .. TenthClass BitBanks MathsEM 7geomentryDokumen4 halaman.. TenthClass BitBanks MathsEM 7geomentryslv_prasaadBelum ada peringkat

- 1zzfe Technical DataDokumen13 halaman1zzfe Technical Datacris5001100% (1)

- CH 4 1Dokumen48 halamanCH 4 1slv_prasaadBelum ada peringkat

- The Z Engine - A New Type of Low Emission Diesel EngineDokumen9 halamanThe Z Engine - A New Type of Low Emission Diesel Engineslv_prasaadBelum ada peringkat

- Extraction and Visualization of Swirl and Tumble Motion From Engine Simulation DataDokumen15 halamanExtraction and Visualization of Swirl and Tumble Motion From Engine Simulation Dataslv_prasaadBelum ada peringkat

- CH 9 1 2Dokumen46 halamanCH 9 1 2slv_prasaadBelum ada peringkat

- Engineering Optimization Ch 1 IntroductionDokumen21 halamanEngineering Optimization Ch 1 Introductionslv_prasaadBelum ada peringkat

- Extraction and Visualization of Swirl and Tumble Motion From Engine Simulation DataDokumen15 halamanExtraction and Visualization of Swirl and Tumble Motion From Engine Simulation Dataslv_prasaadBelum ada peringkat

- CFD Optimization With Altair Hyperworks: in This Issue July 2006Dokumen6 halamanCFD Optimization With Altair Hyperworks: in This Issue July 2006slv_prasaadBelum ada peringkat

- GCMS-QF 15 - Calibration (IMTE) Form - MPSDokumen7 halamanGCMS-QF 15 - Calibration (IMTE) Form - MPSMobin Thomas AbrahamBelum ada peringkat

- Chapter Six: Capital Allocation To Risky AssetsDokumen26 halamanChapter Six: Capital Allocation To Risky AssetsjimmmmBelum ada peringkat

- Frequently Asked Questions (Faq) FOR New Unifi Mobile Prepaid #BebasDokumen1 halamanFrequently Asked Questions (Faq) FOR New Unifi Mobile Prepaid #BebasNgHanSeongBelum ada peringkat

- LGBT Workplace Equality Policy and Customer Satisfaction: The Roles of Marketing Capability and Demand InstabilityDokumen20 halamanLGBT Workplace Equality Policy and Customer Satisfaction: The Roles of Marketing Capability and Demand InstabilityFatima ZafarBelum ada peringkat

- Watertown City Manager's Status and Information Report Sept. 6, 2019Dokumen8 halamanWatertown City Manager's Status and Information Report Sept. 6, 2019NewzjunkyBelum ada peringkat

- Nervous System Reaction PaperDokumen3 halamanNervous System Reaction PaperJohn Ruel Sanchez IIBelum ada peringkat

- Floor Heating Controls Wiring Instructions for FS and BA Master Weather CompensationDokumen12 halamanFloor Heating Controls Wiring Instructions for FS and BA Master Weather Compensationjamppajoo2Belum ada peringkat

- Quote: Quotation Prepared By: Sloan SellersDokumen2 halamanQuote: Quotation Prepared By: Sloan SellersRubén CastañoBelum ada peringkat

- Issues in Diaphragm Forming of Continuous Fiber Reinforced Thermoplastic CompositesDokumen11 halamanIssues in Diaphragm Forming of Continuous Fiber Reinforced Thermoplastic CompositesclaradwisBelum ada peringkat

- INCaDokumen47 halamanINCaMehdi SoltaniBelum ada peringkat

- ECO Report 03Dokumen96 halamanECO Report 03ahmedshah512Belum ada peringkat

- Mass Transfer in Industrial ApplicationsDokumen1 halamanMass Transfer in Industrial ApplicationsMPD19I001 VITHISHA MBelum ada peringkat

- Bursting and Collapsing Pressures of ASTM A312 Stainless Steel PipesDokumen1 halamanBursting and Collapsing Pressures of ASTM A312 Stainless Steel PipesManuKumarMittalBelum ada peringkat

- Number Recognition 1 10 2Dokumen14 halamanNumber Recognition 1 10 2api-450467649Belum ada peringkat

- t-030f Spanish p35-48Dokumen4 halamant-030f Spanish p35-48Juan ContrerasBelum ada peringkat

- Quenching & TemperingDokumen4 halamanQuenching & Temperingkgkganesh8116Belum ada peringkat

- Writing Theory DraftDokumen18 halamanWriting Theory Draftapi-488391657Belum ada peringkat

- Openroads Designer User ManualDokumen112 halamanOpenroads Designer User ManualNilay BhavsarBelum ada peringkat

- Gpee6.0T01Tibbgde: Technical Data SheetDokumen2 halamanGpee6.0T01Tibbgde: Technical Data SheetHope SangoBelum ada peringkat

- REV 0 Material Selection Diagram MSD Blueprint IncDokumen5 halamanREV 0 Material Selection Diagram MSD Blueprint IncJohn Patrick Sanay NunezBelum ada peringkat

- Critical Thinking Handout PDFDokumen1 halamanCritical Thinking Handout PDFAnoosh IqraBelum ada peringkat

- Nb7040 - Rules For Pipe Connections and Spools: Acc. Building Specification. Rev. 2, November 2016Dokumen4 halamanNb7040 - Rules For Pipe Connections and Spools: Acc. Building Specification. Rev. 2, November 201624142414Belum ada peringkat