Safety Compl - SS Earthing Design

Diunggah oleh

Rahul SinganiaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Safety Compl - SS Earthing Design

Diunggah oleh

Rahul SinganiaHak Cipta:

Format Tersedia

World Academy of Science, Engineering and Technology 60 2011

Safety Compliance of Substation Earthing Design

A. Hellany, M.Nagrial, M. Nassereddine, J. Rizk

II. EARTHING DESIGN; SCOPE OF WORKS AbstractAs new challenges emerge in power electrical

workplace safety, it is the responsibility of the systems designer to seek out new approaches and solutions that address them. Design decisions made today will impact cost, safety and serviceability of the installed systems for 40 or 50 years during the useful life for the owner. Studies have shown that this cost is an order of magnitude of 7 to 10 times the installed cost of the power distribution equipment. This paper reviews some aspects of earthing system design in power substation surrounded by residential houses. The electrical potential rise and split factors are discussed and a few recommendations are provided to achieve a safety voltage in the area beyond the boundary of the substation.

KeywordsEPR, Split Factor, Earthing Design I. INTRODUCTION

HE benefits of electricity are numerous but mishandling it can cause damages to properties and may inflict injuries and fatalities. Electrical management is the key element in human safety, also not underestimating the importance of protection equipment in the wide area of electrical infrastructure can be another added factor in raising the risk factor. Earthing must be the primary concern during the design and operations of electrical infrastructure. People often assume that any grounded object can be safely touched. A low substation ground resistance is not, in itself, a guarantee of safety. Step and Touch voltage need to be assessed in and around the substation boundaries. A serious hazard may result during a ground fault from the transfer of potential between the substation ground grid area and outside locations. This transferred potential may be transmitted by communication circuits, conduits, pipes, metallic fences, lowvoltage neutral wires, etc. The danger is usually from contact of the touch type. An investigation into possible transferred potential hazards is essential in the design of a safe substation grounding network. This paper discusses the management of earthing system design to meet the safety requirements as per the Australian and IEEE standards. In addition this paper investigates the area of concerns when dealing with the earthing system and what factors should be taken into when reviewing the design

Dr. Ali Hellany is with the University of Western Sydney, Locked Bag 1797 Penrith South DC 1797 NSW Australia (e-mail: a.hellany@uws.edu.au). M. Nassereddine, Research student at the University of Western Sydney, Australia (e-mail: m.nassereddine@uws.edu.au) Professor M. Nagrial is with the University of Western Sydney, Locked Bag 1797 Penrith South DC NSW Australia (e-mail: m.nagrial@uws.edu.au) Dr Jamal Rizk is with the University of Western Sydney, Locked Bag 1797 Penrith South Dc 1797, NSW Australia (e-mail: j.rizk@uws.edu.au)).

The high demand on electricity and expansion of the power grid nowadays made it essential to have high voltage (HV) substations within the residential area and in some cases some zone substations and transmission substation are surrounded with residential houses. It is important to remember that the earthing design scopes can be summarised in the followings but not limited to: Grid Resistance Current Split Study Earth Potential Rise (EPR) Touch Voltage Step Voltage Voltage Transfer The neighbouring between the HV substations and the residential houses will force the designer and the reviewer to pay extra attention on the EPR contour of the substations under malfunction and fault conditions. Also this neighbouring will highlight the touch voltage on pipeline. Usually in an earthing design, the main safety criteria will be determined using the clearance time and the surface soil resistivity of the area to compute the touch and step voltage. It is a common practice to use IEEE 80:2000 or AS/NZS 60479:2002 standards and the recommended calculation method to determine the safety requirement for touch and step voltage. The close neighbouring will raise the requirement for the pipeline safety, as determined in the Australian and New Zeeland Standards AS/NZS 4853:2000, Table 5.3 in this standards state the safety requirements for different clearance time but it doesnt specify or relate this to soil resistivity value [1-2]. Normally such substations are supplied either by underground cable (UG) or overheard conductor (OH). These feeders can have pole electrodes or joint bay earthing system. The neighboring between the substation and residential houses, force the pole electrodes to be sometimes in the public footpath. For the same reason the joint bay earthing system can be located in an area accesses by children, pregnant women and bare foot passing by residents. These electrodes and the whole earthing system will facilitate and assist in transferring the EPR from the substations to the surrounding area frequented by the community and closer to residents. This will require from the designer and the reviewer to carry more extensive study and analysis around these electrodes and to apply the coordination design technique stated in the substation Earthing Guide which is the equivalent of IEEE80 in Australia that is accomplished through 23 steps. It is not recommended in some cases to use an electrode with

525

World Academy of Science, Engineering and Technology 60 2011

less 10 or 5 or even less than 1 to ensure the safety and the compliance of the earthing system. In some cases these 10 or 5 do not meet the safety requirement, since the touch and step voltage may have a value that above the safety limit. There is a need to follow step by step the coordination design technique and to ensure that safety aspects are fully considered during the design and the commissioning of the system. This paper is addressing only the EPR aspect of the earthing design and exploring how EPR can lead to unsafe conditions III. EPR AND SAFETY CRITERIA In an urban substation-Feeder systems, where there is no houses near by, applying the IEEE and AS standards formula can generate a limit for safety criteria. Taking as example a zone substation of 132/11kV with an EPR contour of 500V at around 150 meters radius outside the boundary fence. If we consider that the substation is in an area with a uniform soil resistivity of 100 m and a if we take the clearance time to be 500ms, after applying the IEEE and AS formulas then table

TABLE I

REPRESENTS THE SAFETY THRESHOLD FOR THE DESIGN

The fault current at the substation can be divided into subcurrents: Current flow in the earth grid Current flow in the auxiliary earthing system Auxiliary earthing system can be represented by Over Head Earth Wire (OHEW) knows as a ground wire, and by the cable sheath of the cable. This auxiliary path acts as a path for partial of the fault current, and reduces the current that flow into the ground. The return current value can be determined after calculating the slip factor. The split factor determines the percentage of the current that flow into the ground the portion that flow into the auxiliary path. A. Split Factor Split factor S f , is vital to be determined when designing an earthing system that have an auxiliary path for the fault current. Split factor is essential for determining the actual EPR at the substation and gives an indication of the EPR around the auxiliary path. In addition, it ensures the compliance of any transfer voltage or EPR along the auxiliary path. The split factor can be determined using equation 1:

Soil Resistivity /m h 100

50 Kg Person V V step Touc 188.6 264.4

70 Kg Person V V step Touch 255.41 355.2

Z gm S f = 1 Z gw

Where:

(1)

6 8 5 Based on table I, the design needs to be limited to 188.66V for the touch voltage and 262.48V for the step voltage. Moving this substation to a residential area where there are water pipe line connected to houses where people resides with the possibility of having children, elderly with bare feet living inside these house. Using AS/NZS 4853:2000 standard, the Australian standards which contain the allowable voltage under different clearance time, yields a maximum touch voltage on any pipe line for un-skilled people to be 100V [34]. Now the new maximum limit for the touch voltage outside the substation is 100V as per AS/NZS 4853:2000 requirement. The EPR contour of the 100V should be plotted and assessed to ensure that there is no pipe line within the boundary of this contour. If water pipe exists within the 100V contour, a touch simulation should be conducted to ensure that the touch voltage will be under the acceptable 100V limit. Due to the feeding arrangement, not only the area within the 100V contour need to be studied, also the area along the feeding route need to be assessed as each pole electrode and joint bay earthing system will create an EPR that can give rise to touch voltage issue [5-8]. The fault current at the HV infrastructure will be split into the ground system and the auxiliary system. This split will create an EPR in the Auxiliary earthing system that needs to be studied to ensure the compliance with the corresponding standards and regulations. Split Study

Z gw Z gm

is the self impedance of the OHEW in /m.

is the mutual impedance per meter between OHEW and phase conductors in /m. The Ground current is determined using equation 2:

Ig = S f I f

(2)

The auxiliary path current is determined using equation 3:

Ie = I f I g

(3)

The auxiliary path current value will assist in assessing the safety of the auxiliary path under any fault at the nominated HV infrastructure. The split factor is used to determine the final impedance of the line as shown in equation 4 [3]:

Z total =

S f Rg 1 S f

(4)

B. EPR and Split Factor The EPR at the substation is determined using the earth grid resistance and the fault current. Equation 5 shows the EPR calculation, This EPR is under the assumption that there is no auxiliary system which mean the split current is 1:

526

World Academy of Science, Engineering and Technology 60 2011

EPRsubstation = I f R g

(5)

Recalculating EPR Using the Split Factor, shows how the split factor value can reduce the EPR value at the nominated HV infrastructure. This EPR is for the substation EPR under the existence of auxiliary path for the fault current

EPR = S f I f R g

(6)

The maximum possible value for the split factor is 1, Figure 1 shows a simulation value for the EPR under grid resistance of 1 ohm and fault current of 1000 amperes.

EPR 1200

1000

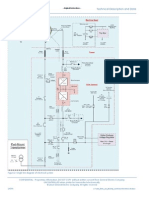

auxiliary earthing path, Figure 2 and 3 shows the fault current in the OHEW under a fault condition. Figure 2 clearly shows that the fault current in the first 10 electrodes is high. In addition, it is possible to determine the value of the current flowing in each electrode. The calculated current is used to determine the EPR around each electrode. Figure 2 shows the need tor the earthing system at the first few poles, due to high current, to be assessed more than the poles between section 10 and section 60 [11-12]. Figure 3 shows the section current magnitude that is flowing in the OHEW and returning to the fault source. Figure4 shows the magnitude of the current that flows in the electrode at pole No 3, the value is around 300A, this value will assist in controlling the EPR around this pole, the designer can target an earthing system for this electrode to meet the safety requirement. Equation 8 is used to determine the maximum grid resistance for this electrode to ensure the compliance with safety voltage Vsafe.

800 EPR (V)

600

EPR

400

200

0 0 0.1 0.2 0.3 0.4 0.5 Split Factor 0.6 0.7 0.8 0.9 1

Fig. 1 EPR Vs Split Factor

Figure 1 clearly shows how the split factor values impact on the EPR at the Substation, it is vital to determine this value as it will reduce the EPR at the nominated HV infrastructure which will lead to a less expensive earth grid. The auxiliary current depend on the split factor and can create an unsafe condition along the auxiliary path,. for more information refer [9-10] IV. SPLIT FACTOR AND AUXILIARY PATH The split factor depend on the type and configuration of the auxiliary path, for example if the auxiliary path represented by an OHEW, then different type of OHEW will result in different value of split factor For more information refer to [4]. The EPR at the Auxiliary earthing system is determined using equation 7, this EPR is for the auxiliary system. A part of the fault current uses the auxiliary system as a path to the source, the auxiliary system has resistance value, then EPR can be determined taking into account the auxiliary current and the auxiliary resistance

Fig. 2 Shunt Current Magnitude

RElectrode =

Vsafe I electrode

(8)

EPR = I f (1 S f ) RAux

(7)

For example if the safety voltage is 100V and the current is 300A, an electrode system of 0.33 will insure the safety compliance of the system. In some cases and due to practical reasons this value cannot be met. Then it is recommended to conduct more analysis as required under the EG1 coordination design technique [13].

The auxiliary earthing path is normally including a number of electrodes running along the transmission feed. A current distribution study and analysis needs to be conducted in order to determine the shunt and section current in each electrode along the line. Current Distribution, Electromagnetic Fields, Grounding and Soil Structure Analysis (CDEGS) software is used to determine the flowing current in each section of the

527

World Academy of Science, Engineering and Technology 60 2011

Terminal ground system (magn./angle) Total Earth Current 1558.9 Amps/163.77 deg. Earth Potential Rise 779.45 Volts/163.77 deg. Total Fault Current 5000.0 Amps Total Neutral Current 3995.7 Amps/6.9190 degrees Total Earth Current 1140.0 Amps/24.977 degrees

Ground Potential Rise (GPR) 1140.0 Volts / 24.977 degrees

Figures 5 and 6 show that the 100V contour will exist around the first 20 pole from Toufikia Zone Substation ZS, and in the last 15 poles to Harbata Transmission Substation TS. For a metallic pipeline running three meter from the electrode, CDEGS simulation gives the following results: Earth Potential Computations

Fig. 3 Section Current Magnitude

Main Electrode Potential Rise (GPR) 1000.0 volts Buried Metallic Structure Potential Rise (GPR) 246.89 volts

Fig. 5 shunt Current Magnitude Fig. 4 Pole number 3 shunt current magnitude

V. CASE STUDY Toufikiya is a 132/11kV zone substation that fed from Harbata transmission substation situated 60 spans away; each span is 100 meters in length. Toufikiya earthing system is 1 and the Harbata earthing system is 0.5 . The maximum single line to ground fault is 5000 amperes with 0.5s clearance time. Each electrode at the bottom of each pole is a 5 system. Using CDEGS engineering software to compute the split factors give the followings:

The EPR at the metallic line will be 246.89 V, this value exceed the 100V value, then more analysis is required to ensure that this transfer EPR does not create an unsafe condition. This can be achieved studying the current flow in the ground to determine the amount that is impacting on the pipeline; more details can be found in EG1, IEEE80, publication [1-4] Figures 7 and 8 show the EPR contour around the pole electrode and the touch contour. A close look at these figures shows that the 100V contour will include the pipe line.

528

World Academy of Science, Engineering and Technology 60 2011

VI.

CONCLUSION

This paper shows that high voltage substation earthing design in a residential area need to take into account the area beyond the boundary fence of the substations. Further study need to take place to ensure that the auxiliary path of the fault condition is not creating unsafe conditions. This paper recommends the following steps to be included in the design process of an earthing system of power substation: Spilt study even when the substation is compliance under any fault condition Examine the EPR around each auxiliary path Assess the EPR along the auxiliary path REFERENCES

[1] [2] [3] IEEE guide to safety in AC substation grounding, 2000 (IEEE, New York, 2000). AS/NZS 4853:2000 electrical hazards on metallic pipelines Nassereddine M, Hellany A, Rizk J, 2009, How to design an effective earthing system to ensure the safety of the people, 2009 International Conference on Advances in Computational Tools for Engineering Applications, pp 416-421 Nassereddine M, Hellany A, 2009, AC Interference Study on Pipeline: the Impact of the OHEW under Full Load and Fault Current, Proceeding in the 2009 International Conference on Computer and Electrical Engineering, pp 497Nassereddine M, Hellany A, 2009, Designing a Lightning Protection System Using the Rolling Sphere Method, Proceeding in the 2009 International Conference on Computer and Electrical Engineering, pp 502-506 Hellany A, Nassereddine M, Nagrial M, 2010, Analysis of the impact of the OHEW under full load and fault current, International Journal of Energy and Environment, vol 1, no. 4, pp 727-736 Nassereddine M, Hellany A, 2010, OHEW Earthing Design Methodology of Traction Substation, World Academy of Science, Engineering and Technology. Proceedings, vol 1, no. 66, pp 13591363,Paris, France ISSN 2070-3724 Nassereddine M, Hellany A, 2010, Earthing Design Improvement: correlation between Design and Construction, World Academy of Science, Engineering and Technology. Proceedings, no. 66, pp 13641367 Paris, France ISSN 2070-3724 C.N. Chang, computation of current-division factors and assessment of earth-grid safety at 161/69kV indoor-type and outdoor-type substations IEE proc.-Gener. Transm. Distrib., Vol. 152, No. 6, November 2005. A. Campoccia, A method to evaluate voltages to earth during an earth fault in an HV network in a system of interconnected earth electrodes of MV/LV substations IEEE transactions on power delivery,Vol 23, No. 4, Oct 2008 S. Mangione, A simple method for evaluation ground fault current transfer at the transition station of a combined overhead-cable line, IEEE transaction on power delivery, Vol, 23, No, 3, July 2008 E. Viel, Fault current distribution in HV cable systems IEE procGener. Transmission distribution, Vol. 147, No. 4, July 2000 F. Dawalibi, Measurements and computations of fault current distribution on overhead transmission lines IEEE on transactions on power apparatus and systems, Vol. PAS-103, No. 3, March 1984.

Fig. 6 Shunt Potential Magnitude

[4]

[5]

[6]

[7]

[8]

[9]

Fig. 7 Simulated contour around the pole electrode

Touch Voltages (All - 2D Spot) [ID:Scenario1]

LEGEND

[10]

912.788 0.246

12.5

Maximum Value : Minimum Value :

912.79 821.53 730.28

7.5

[11]

2.5

Y AXIS (METERS)

639.03 547.77

-2.5

[12] [13]

456.52 365.26

-7.5

274.01 182.75 91.50

-12.5

-10

-5

0

X AXIS (METERS)

10

15

Touch Voltage Magn. (Volts) [Near]

Fig. 8 Touch Voltage Contour

529

Anda mungkin juga menyukai

- Knowledge is "Real Power": Introduction to Power QualityDari EverandKnowledge is "Real Power": Introduction to Power QualityBelum ada peringkat

- Safe Separation Distance Between 132kv Power LinesDokumen5 halamanSafe Separation Distance Between 132kv Power LineselsayedBelum ada peringkat

- دراسة عن تأثير ابراج الضغط العالىDokumen26 halamanدراسة عن تأثير ابراج الضغط العالىEslam MouhamedBelum ada peringkat

- Substation Ventilation Openings Sizing GuideDokumen3 halamanSubstation Ventilation Openings Sizing GuideGilberto SanchezBelum ada peringkat

- Siemens Power Engineering Guide 7E 138Dokumen1 halamanSiemens Power Engineering Guide 7E 138mydearteacherBelum ada peringkat

- Substations - Volume X - GroundingDokumen52 halamanSubstations - Volume X - GroundingAbdul Wadood GharsheenBelum ada peringkat

- Energy Substation Cat Epp 2978 Simaflex enDokumen80 halamanEnergy Substation Cat Epp 2978 Simaflex endip461Belum ada peringkat

- Percentage ImpedanceDokumen2 halamanPercentage Impedancetaha88Belum ada peringkat

- TB001 - Substation BatteriesDokumen3 halamanTB001 - Substation BatteriesMohsen_a57100% (1)

- EDS 05-2010 Main Substation Feeder and Ring Main Unit Protection Settings (LPN) PDFDokumen14 halamanEDS 05-2010 Main Substation Feeder and Ring Main Unit Protection Settings (LPN) PDFLimuel EspirituBelum ada peringkat

- Insulation Coordination Study of 275kV AIS Substation in Malaysia PDFDokumen6 halamanInsulation Coordination Study of 275kV AIS Substation in Malaysia PDFSer 345Belum ada peringkat

- 1vga671048 - Internal Arc Containment, Resistance and Arc Flash MitigationDokumen6 halaman1vga671048 - Internal Arc Containment, Resistance and Arc Flash MitigationdienlangchuBelum ada peringkat

- JE-2004 Building Risk Assessment Lightning Protection DesignDokumen3 halamanJE-2004 Building Risk Assessment Lightning Protection Designblack_3289Belum ada peringkat

- Documents For 66 KV Switch Yard & Main Control Room 1Dokumen28 halamanDocuments For 66 KV Switch Yard & Main Control Room 1Ramesh AnanthanarayananBelum ada peringkat

- ENA ER G81 Part 1 Issue 2 Amendment 1 080109Dokumen19 halamanENA ER G81 Part 1 Issue 2 Amendment 1 080109Tony AppsBelum ada peringkat

- PDS BentleyRacewayCableMgmt LTR en HRDokumen2 halamanPDS BentleyRacewayCableMgmt LTR en HRbibiana8593Belum ada peringkat

- Simulation Studies of JeJu AC Power System ModelingDokumen4 halamanSimulation Studies of JeJu AC Power System ModelingsiamaeBelum ada peringkat

- Ecs 03 0054 Connection of LV Large Services To Secondary Distribution SubstationsDokumen23 halamanEcs 03 0054 Connection of LV Large Services To Secondary Distribution SubstationsRadulescu AndreiBelum ada peringkat

- Eds 02-0041Dokumen42 halamanEds 02-0041daegerteBelum ada peringkat

- Electric Welding: Some of The Advantages of Welding AreDokumen11 halamanElectric Welding: Some of The Advantages of Welding ArePriyadarshi MBelum ada peringkat

- TR0902: Report On Matched-Melt Co-Ordination As Used For Selecting Wind Farm FusesDokumen7 halamanTR0902: Report On Matched-Melt Co-Ordination As Used For Selecting Wind Farm FusesPCTMarketingBelum ada peringkat

- Substation GroundingDokumen19 halamanSubstation GroundingDev SwainBelum ada peringkat

- STATCOMDokumen5 halamanSTATCOMVenkateshBelum ada peringkat

- System Substation BatteryDokumen15 halamanSystem Substation BatteryCarlos Martinez100% (1)

- Grid Integration To Weak GridsDokumen23 halamanGrid Integration To Weak Gridsanoopeluvathingal100100% (1)

- 66 kV Neutral Grounding Resistor SpecsDokumen2 halaman66 kV Neutral Grounding Resistor SpecssesabcdBelum ada peringkat

- Quick Guide On CDEGS CRDokumen28 halamanQuick Guide On CDEGS CRrian0201100% (1)

- Restricted Earth-Fault Protection in REF 542plus: Application and Setting GuideDokumen20 halamanRestricted Earth-Fault Protection in REF 542plus: Application and Setting GuideSandeep PanigrahiBelum ada peringkat

- Electrotechnical NoteDokumen3 halamanElectrotechnical Noteeddisonfh0% (1)

- Lighting Circuits Guide: Selection, Dimensioning and Management With Simple SolutionsDokumen76 halamanLighting Circuits Guide: Selection, Dimensioning and Management With Simple Solutionsjiwani87100% (1)

- PRM DesignGuideComplete v1Dokumen257 halamanPRM DesignGuideComplete v1Sunil SinghBelum ada peringkat

- WG CF&E-CoronaGuideKuffel July2012Dokumen33 halamanWG CF&E-CoronaGuideKuffel July2012vairam_eee01Belum ada peringkat

- eVD4 - Breaker Integrated Protection RBX615 - Engineering Manual PDFDokumen100 halamaneVD4 - Breaker Integrated Protection RBX615 - Engineering Manual PDFHans MortenBelum ada peringkat

- Overview of Grid Code and Operational Requirements of Grid-Connected Solar PV Power Plants-NOTA TECNICADokumen7 halamanOverview of Grid Code and Operational Requirements of Grid-Connected Solar PV Power Plants-NOTA TECNICAEdgardo Kat ReyesBelum ada peringkat

- Lowering The Limits For Earth-Fault Detection: Abstract-Current Flowing To Earth Has Only TwoDokumen5 halamanLowering The Limits For Earth-Fault Detection: Abstract-Current Flowing To Earth Has Only TwoDeepak GehlotBelum ada peringkat

- REF Fuse Application GuideDokumen17 halamanREF Fuse Application GuidemuskanumeedBelum ada peringkat

- Lecture-3: EE 407 Renewable Electrical Energy ResourcesDokumen34 halamanLecture-3: EE 407 Renewable Electrical Energy ResourcesjameelahmadBelum ada peringkat

- Substations - Volume II - PhysicalDokumen50 halamanSubstations - Volume II - PhysicalAbdul Wadood GharsheenBelum ada peringkat

- Earthing Is AbstractDokumen3 halamanEarthing Is AbstractShrikant KajaleBelum ada peringkat

- Ena Doc 012-2006 PDFDokumen15 halamanEna Doc 012-2006 PDFM.Ubaid Ullah Khalid100% (1)

- SafeGrid Reference ManualDokumen16 halamanSafeGrid Reference Manualrajarao1234Belum ada peringkat

- Effect of Load Shedding Strategy On Interconnected Power Systems Stability When A Blackout OccursDokumen6 halamanEffect of Load Shedding Strategy On Interconnected Power Systems Stability When A Blackout OccursMoon3pellBelum ada peringkat

- DAR Engineering Provides Comprehensive Power System StudiesDokumen4 halamanDAR Engineering Provides Comprehensive Power System StudiesCoreg ToBelum ada peringkat

- Schneider Electric Cahier Technique 151Dokumen24 halamanSchneider Electric Cahier Technique 151Anonymous BwLfvuBelum ada peringkat

- SLD of WTGDokumen1 halamanSLD of WTGbhargavram1987Belum ada peringkat

- HVDC TRANSMISSION OVERVIEWDokumen27 halamanHVDC TRANSMISSION OVERVIEWSahithkumar ThodupunuriBelum ada peringkat

- Substations - Volume V - CircuitDokumen44 halamanSubstations - Volume V - CircuitAbdul Wadood GharsheenBelum ada peringkat

- EarthingDokumen87 halamanEarthingAkhil Gangwar100% (1)

- Optimal Neutral Ground Resistor Rating of The Medium Voltage Systems in Power Generating StationsDokumen10 halamanOptimal Neutral Ground Resistor Rating of The Medium Voltage Systems in Power Generating StationsGirish OniyilBelum ada peringkat

- % Impedance of Power Transformer PDFDokumen9 halaman% Impedance of Power Transformer PDFtobyBelum ada peringkat

- Thermal Analysis of Indoor SubstationDokumen8 halamanThermal Analysis of Indoor SubstationEnriqueGD100% (1)

- EDOC-Surge Arrester Sizing For SubDokumen14 halamanEDOC-Surge Arrester Sizing For SubEl Comedor BenedictBelum ada peringkat

- Selection of Surge Protective Device (SPD) - (Part 1)Dokumen5 halamanSelection of Surge Protective Device (SPD) - (Part 1)supermannonBelum ada peringkat

- BIL Levels For Switchgear - Siemens Tech Topics Rev 0Dokumen2 halamanBIL Levels For Switchgear - Siemens Tech Topics Rev 0Peter DyckBelum ada peringkat

- P 3 U 30Dokumen120 halamanP 3 U 30ArcoolBelum ada peringkat

- ATPDesigner Protection Modeling CourseDokumen33 halamanATPDesigner Protection Modeling CourseGesiel SoaresBelum ada peringkat

- Emtp Etap PDFDokumen1 halamanEmtp Etap PDFAdhyartha KerafBelum ada peringkat

- ISA 61010-031-2002 - Safety Req - Hand Held Probe AssembDokumen78 halamanISA 61010-031-2002 - Safety Req - Hand Held Probe AssembRahul SinganiaBelum ada peringkat

- Tutorial SIMARIS Project enDokumen100 halamanTutorial SIMARIS Project enElói LimaBelum ada peringkat

- 2013 49 Winter Wiring Matters Complete AdvertsDokumen36 halaman2013 49 Winter Wiring Matters Complete AdvertsRahul SinganiaBelum ada peringkat

- ENA S34 - GPR AssessmentDokumen0 halamanENA S34 - GPR AssessmentRahul SinganiaBelum ada peringkat

- ABB Shore-To-Ship Power - Brochure - 11.2010 - LR PDFDokumen8 halamanABB Shore-To-Ship Power - Brochure - 11.2010 - LR PDFRahul SinganiaBelum ada peringkat

- ABB Shore-To-Ship Power - Brochure - 11.2010 - LR PDFDokumen8 halamanABB Shore-To-Ship Power - Brochure - 11.2010 - LR PDFRahul SinganiaBelum ada peringkat

- ENA 41-24 - Earthing MaintDokumen0 halamanENA 41-24 - Earthing MaintRahul SinganiaBelum ada peringkat

- ECP 11 0507 - Compact & Micro SS Comm ProcedureDokumen6 halamanECP 11 0507 - Compact & Micro SS Comm ProcedureRahul Singania100% (1)

- ABB Shore-To-Ship Power - Brochure - 11.2010 - LR PDFDokumen8 halamanABB Shore-To-Ship Power - Brochure - 11.2010 - LR PDFRahul SinganiaBelum ada peringkat

- ECP 11-0506 - Dist Txmer Comm ProcedureDokumen6 halamanECP 11-0506 - Dist Txmer Comm ProcedureRahul SinganiaBelum ada peringkat

- Auto-Txmer Starter PDFDokumen6 halamanAuto-Txmer Starter PDFRahul SinganiaBelum ada peringkat

- Guide - LV Embedded Gen ConnDokumen63 halamanGuide - LV Embedded Gen ConnRahul SinganiaBelum ada peringkat

- D.G Size Calculation (22.8.12)Dokumen1 halamanD.G Size Calculation (22.8.12)Rahul SinganiaBelum ada peringkat

- BS EN 61330-1996 HV-LV Prefabricated SS PDFDokumen42 halamanBS EN 61330-1996 HV-LV Prefabricated SS PDFRahul Singania50% (2)

- BS EN 50464-1-2007 - Gen Req PDFDokumen18 halamanBS EN 50464-1-2007 - Gen Req PDFRahul SinganiaBelum ada peringkat

- Gen Set - Config - MonDokumen49 halamanGen Set - Config - MonRahul SinganiaBelum ada peringkat

- Motor and Generator Terminals REM 543/545Dokumen2 halamanMotor and Generator Terminals REM 543/545Rahul SinganiaBelum ada peringkat

- UL 1449 Changes in 3rd Ed - DeHNDokumen3 halamanUL 1449 Changes in 3rd Ed - DeHNRahul SinganiaBelum ada peringkat

- 2013 National Electrical EstimatorDokumen88 halaman2013 National Electrical EstimatorFrancis Owusu83% (6)

- Veam PowerlockDokumen36 halamanVeam PowerlockRahul SinganiaBelum ada peringkat

- 2013 National Electrical EstimatorDokumen88 halaman2013 National Electrical EstimatorFrancis Owusu83% (6)

- Contents and Scope ANSI C84!1!2011Dokumen9 halamanContents and Scope ANSI C84!1!2011Rahul SinganiaBelum ada peringkat

- SPC 11000 - Substation Earthing System SpecificationDokumen9 halamanSPC 11000 - Substation Earthing System SpecificationRahul SinganiaBelum ada peringkat

- Etap Product OverviewDokumen9 halamanEtap Product OverviewRahul SinganiaBelum ada peringkat

- SPC 6000 - DC UPS System - Docx - Rev 1Dokumen15 halamanSPC 6000 - DC UPS System - Docx - Rev 1Rahul SinganiaBelum ada peringkat

- NEMA TS2-2003 - Traffic Controller AssembDokumen246 halamanNEMA TS2-2003 - Traffic Controller AssembRahul SinganiaBelum ada peringkat

- Eritech - H.N - Iec 62305Dokumen92 halamanEritech - H.N - Iec 62305Rahul SinganiaBelum ada peringkat

- What Is AGI32 Datasheet v14Dokumen8 halamanWhat Is AGI32 Datasheet v14Rahul SinganiaBelum ada peringkat

- UKTI Innovation ReportDokumen34 halamanUKTI Innovation ReportNETParkNetBelum ada peringkat

- Exam Program Nov 2022 (Civil Engg)Dokumen4 halamanExam Program Nov 2022 (Civil Engg)PRC BaguioBelum ada peringkat

- Process DesignDokumen89 halamanProcess Designdejhan stankobicBelum ada peringkat

- Curriculum Vitae: Bio DataDokumen3 halamanCurriculum Vitae: Bio DataMwesigye Batatwenda Peterson100% (1)

- Software MeasurementDokumen38 halamanSoftware MeasurementBilal BaberBelum ada peringkat

- MEC522 PBL - ArduinoDC - MotorEncoder - Close LoopDokumen3 halamanMEC522 PBL - ArduinoDC - MotorEncoder - Close Loopzaiful hakimBelum ada peringkat

- A FPGA Paint Brush 1applicationDokumen7 halamanA FPGA Paint Brush 1applicationPradeep Kumar ReddyBelum ada peringkat

- Assignemt2 IT8029Dokumen11 halamanAssignemt2 IT8029AlexBelum ada peringkat

- UG Syllabus - Reg 2016-Full SyllabusDokumen185 halamanUG Syllabus - Reg 2016-Full SyllabusBaskar SinghBelum ada peringkat

- Technocrat Automation Training and Placements in Industrial AutomationDokumen16 halamanTechnocrat Automation Training and Placements in Industrial AutomationsushantadharBelum ada peringkat

- Availability 99 999Dokumen6 halamanAvailability 99 999Luis Jesus Malaver GonzalezBelum ada peringkat

- Controllogix Power Supplies: Installation InstructionsDokumen14 halamanControllogix Power Supplies: Installation InstructionsneoflashBelum ada peringkat

- Geotechnical Investigation SpecificationDokumen39 halamanGeotechnical Investigation Specificationelnaqa176Belum ada peringkat

- PHD Ferrario PDFDokumen263 halamanPHD Ferrario PDF8790922772Belum ada peringkat

- Pearl River Tower Fire Protection StrategiesDokumen7 halamanPearl River Tower Fire Protection StrategiesDorin DavidBelum ada peringkat

- Pipelines and Buried PipesDokumen22 halamanPipelines and Buried PipesjwochBelum ada peringkat

- Urban Infrastructure and Development: by Liza Cirolia and Philipp RodeDokumen18 halamanUrban Infrastructure and Development: by Liza Cirolia and Philipp RodeFulu NemasetoniBelum ada peringkat

- Software Engineering Course MaterialDokumen29 halamanSoftware Engineering Course Materialvikas desaleBelum ada peringkat

- 2017 Postgraduate Convocation ListDokumen11 halaman2017 Postgraduate Convocation ListCheckBelum ada peringkat

- Four C FinalDokumen2 halamanFour C Finalshalini sBelum ada peringkat

- Evaluating Alternatives For Requirements, Environment, and ImplementationDokumen31 halamanEvaluating Alternatives For Requirements, Environment, and ImplementationpearlkikBelum ada peringkat

- Hydraulics - Part3 - HydraulicsDokumen23 halamanHydraulics - Part3 - Hydraulicsahm531Belum ada peringkat

- Adaptación BIM A La Educación de IngenieríaDokumen16 halamanAdaptación BIM A La Educación de IngenieríaJoha PradoBelum ada peringkat

- Em - 1110 2 2610Dokumen652 halamanEm - 1110 2 2610David LeviBelum ada peringkat

- Concrete Technology Assignment BriefDokumen5 halamanConcrete Technology Assignment BriefOmar AlajoulenBelum ada peringkat

- Universal Beam and Column Properties SheetDokumen11 halamanUniversal Beam and Column Properties SheetkalpanaadhiBelum ada peringkat

- BCM Report (16c01c4003)Dokumen31 halamanBCM Report (16c01c4003)Lakshman Sai100% (1)

- Bachelor of Civil Engineering - An Official Site of Pokhara UniversityDokumen1 halamanBachelor of Civil Engineering - An Official Site of Pokhara UniversityaayushBelum ada peringkat

- Aeronautical Engineers Board Exam Room Assignments - November 2013Dokumen11 halamanAeronautical Engineers Board Exam Room Assignments - November 2013ScoopBoyBelum ada peringkat

- Fyp Mid Presentation Final Report DoneDokumen16 halamanFyp Mid Presentation Final Report DoneSajjad gulBelum ada peringkat