Elda

Diunggah oleh

Eldayadi Nefty Rizky ArismawanDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Elda

Diunggah oleh

Eldayadi Nefty Rizky ArismawanHak Cipta:

Format Tersedia

Steel UTOP3 (Mat.No. 1.

2606, DIN X37CrMoW5-1, AISI H12)

Designation by Standards Brand Name UTOP3 Ravne No. 851 Mat. No. 1.2606 DIN X37CrMoW5-1 EN AISI H12

Chemical Composition (in weight %) C 0.37 Si 1.05 Mn 0.45 Cr 5.30 Mo 1.45 Ni V 0.28 W 1.30 Others -

Description H12 hot work tool steel is a 5% chromium, general-purpose hot work steel that is characterized by excellent impact toughness. It contains less vanadium than the widely-used H13 hor work tool steel. Steel is a deep-hardening, air-hardening steel that exhibits minimal size change during heat treatmnet. It has good resistance to thermal fatique cracking (heat cracking) and excellent resistnce to gross cracking and thermal shock when water cooled in service.

Applications H12 hot work steel is recommended for hot tooling aplications where maximum resistance to cracking is required. Such applications include hot puches, die casting dies, forgins diw, hot shear baldes, and extrusion tooling.

Physical properties (avarage values) at ambient temperature Modulus of elasticity [103 x N/mm2]: 207 Density [g/cm3]: 7.84 Thermal conductivity [W/m.K]: 18.9

Coefficient of Linear Thermal Expansion 10-6 oC-1 20-100oC 9.8 20-200oC 11.0 20-400oC 12.1 20-600oC 13.0

Soft Annealing Heat to 820-840oC, cool slowly in furnace. Time is 4-6 hours. This will produce a maximum Brinell hardness of 220.

Stress Relieving Stress relieving to remove machining stresses should be carried out by heating to approx.650 oC, holding for 1-2 hours at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

Hardening Harden from a temperature of 1000-1050oC followed by oil, air quenching or warm bath quenching

approx. 540oC. Hardness after quenching is 54 HRC.

Tempering Tempering temperature: 520-700oC, at least 2-3x.

Tempering Diagram

Click the image to enlarge the diagram.

Forging Hot forming temperature: 1100-850oC.

Machinability 75-80% of a 1% carbon steel.

Corrosion Resistance Corrosion resistance of this alloy is better than that of plain carbon steels. However it will rust unless given protective treatment.

Forms manufactured: Please see the Dimensional Sales Program.

Disclaimer The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other puposes. There is no representation that the recipient of this literature will receive updated editions as the become available.

Steel 13CRMO44 (Mat.No. 1.7335, DIN 13CrMo44, AISI A182 Grade F11)

Designation by Standards Brand Name 13CRMO44 Ravne No. 762 Mat. No. 1.7335 DIN 13CrMo44 EN 13CrMo4-5 AISI A 182 Grade F11

Chemical Composition (in weight %) C 0.14 Si max. 0.40 Mn 0.55 Cr 0.98 Mo 0.60 Ni V W Others max. Cu = 0.30

Description Alloy special structural steels. Cr-Mo-steels with > 0.35% Mo.

Applications High-temperature structural steel: Collectors, water boiler and superheater tubes (530oC).

Physical properties (avarage values) at ambient temperature Modulus of elasticity [103 x N/mm2]: 210 Density [g/cm3]: 7.85

Soft Annealing Heat to 680-720oC, cool slowly in furnace.

Hardening Harden from a temperature of 910-940oC followed by oil or air quenching.

Tempering Tempering temperature: 650-720oC.

Mechanical Properties in Hardened and Tempered Condition Diameter in mm up to 60 61-90 91-150 0.2 % proof stress (N/mm2) 295 285 275 Tensile strength (N/mm2) 440-590 440-590 440-590 Elongation (%) 20 20 20 Impact strength (J) 44 44 44

0.2 % Proof Stress (N/mm2) vs. Temperature 100oC 260 250 250 150oC 245 240 235 200oC 240 230 220 250oC 230 220 210 300oC 215 205 195 350oC 200 190 180 400oC 190 180 170 450oC 180 170 160 500oC 175 165 155

1 % Creep Limit (N/mm2) vs. Temperature (oC) Hours 10 000 100 000 450oC 245 191 460oC 228 172 480oC 193 133 500oC 157 98 520oC 122 70 540oC 90 46 560oC 64 30

Creep Rapture Strength (N/mm2) vs. Temperature (oC) Hours 10 000 100 000 200 000 450oC 370 285 260 460oC 348 251 226 480oC 304 190 167 500oC 239 137 115 520oC 179 94 76 540oC 129 61 50 560oC 91 40 32

Forging Hot forming temperature: 1100-850oC.

Machinability No data.

Forms manufactured: Please see the Dimensional Sales Program.

Disclaimer The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other puposes. There is no representation that the recipient of this literature will receive updated editions as the become available.

Steel OC100EX (DIN 100V1, AISI W2)

Designation by Standards Brand Name OC100EX Ravne No. 654 Mat. No. DIN 100V1 EN AISI W2

Chemical Composition (in weight %) C 1.02 Si 0.20 Mn 0.23 Cr Mo Ni V 0.10 W Others -

Description Low alloyed water-hardening tool steel.

Applications Cold working tools for steels and metals when hard surface and tough core are demanded - tap drills, dies, broaching tools, stone working tools.

Physical properties (avarage values) at ambient temperature Modulus of elasticity [103 x N/mm2]: 210 Density [g/cm3]: 7.85 Thermal conductivity [W/m.K]: 45.0 Electric resistivity [Ohm mm2/m]: 0.20 Specific heat capacity[J/g.K]: 0.46

Coefficient of Linear Thermal Expansion 10-6 oC-1 20-100oC 11.1 20-200oC 12.1 20-300oC 12.9 20-400oC 13.5 20-500oC 13.9

Soft Annealing Heat to 680-720oC, cool slowly. This will produce a maximum Brinell hardness of 213.

Stress Relieving Stress relieving to remove machining stresses should be carried out by heating to approx. 600650oC, holding for 1-2 hours at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

Hardening Harden from a temperature of 760-800oC followed by water quenching. Hardness after quenching is 65 HRC.

Tempering Tempering temperature: See the data bellow.

Tempering Temperature (oC) vs. Hardness (HRC) 100oC 66 200oC 64 300oC 56 400oC 48 450oC 45

Tempering Diagram

Click the image to enlarge the diagram.

Forging Hot forming temperature: 1000-800oC.

Machinability No data.

Forms manufactured: Please see the Dimensional Sales Program.

Disclaimer The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other puposes. There is no representation that the recipient of this literature will receive updated editions as the become available.

Low Alloyed cold work tool steel Steel OC100 (Mat.No. 1.1545, DIN C105W1, AISI W1)

Designation by Standards Brand Name OC100 Ravne No. 653 Mat. No. 1.1545 DIN C105W1 EN AISI W1

Chemical Composition (in weight %) C 1.05 Si 0.20 Mn 0.25 Cr Mo Ni V W Others -

Description This alloy is one of the common water hardening tool steel grades available. W1 is basically a simple high carbon steel and is easily hardened by heating and quenching in water, just as with plain carbon steel alloys. The W series of tool steels are a very simple alloy group, low cost, and responsive to simple heating and water quenching for hardening. The alloy does undergo considerable distortion during quenching.

Applications W1 is commonly used for hand operated metal cutting tools, cold heading, embossing taps and reamers as well as cutlery.

Physical properties (avarage values) at ambient temperature Modulus of elasticity [103 x N/mm2]: 210 Density [g/cm3]: 7.85 Thermal conductivity [W/m.K]: 45.0 Electric resistivity [Ohm mm2/m]: 0.20 Specific heat capacity[J/g.K]: 0.46

Coefficient of Linear Thermal Expansion 10-6 oC-1 20-100oC 11.1 20-200oC 12.1 20-300oC 12.9 20-400oC 13.5 20-500oC 13.9

Continuous Cooling Transformation (CCT) Diagram

Click the image to enlarge the diagram.

Time-Temperature Transformation (TTT) Diagram

Click the image to enlarge the diagram.

Soft Annealing Heat to 680-720oC, cool slowly in furnace. This will produce a maximum Brinell hardness of 213.

Stress Relieving Stress relieving to remove machining stresses should be carried out by heating to approx. 600650oC, holding for 1-2 hours at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

Hardening Harden from a temperature of 760-800oC followed by water. Hardness after quenching is 65 HRC.

Tempering Tempering temperature: See the data bellow.

Tempering Temperature (oC) vs. Hardness (HRC) 100oC 67 200oC 64 300oC 56 400oC 48 450oC 45

Tempering Diagram

Click the image to enlarge the diagram.

Forging Hot forming temperature: 1050-800oC.

Machinability W1 is a plain carbon steel and machines with ease. It is the base line of 100% machinability on which machinability of the other tool steels is compared.

Corrosion Resistance This is a plain carbon steel and it will corrode unless protected.

Welding W1 may be welded by all of the standard techniques.

Forms manufactured: Please see the Dimensional Sales Program.

Disclaimer The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other puposes. There is no representation that the recipient of this literature will receive updated editions as the become available.

Alloyed carbon steel Steel VCNMO200 (Mat.No. 1.6580, DIN 30CrNiMo8, AISI 4340)

Designation by Standards Brand Name VCNMO200 Ravne No. 750 Mat. No. 1.6580 DIN 30CrNiMo8 EN 30CrNiMo8 AISI 4340

Chemical Composition (in weight %) C 0.30 Si max. 0.40 Mn 0.45 Cr 2.00 Mo 0.40 Ni 1.90 V W Others -

Description VCNMO200 is a heat treatable, low alloy steel containing nickel, chromium and molybdenum. It is known for its toughness and capability of developing high strength in the heat treated condition while retaining good fatigue strength.

Applications For permanently stressed components with large cross sections for automotive and mechanical engineering. For economic performance under severe dynamic stress, parts must be designed for optimum strength or toughness.

Physical properties (avarage values) at ambient temperature Modulus of elasticity [103 x N/mm2]: 210 Density [g/cm3]: 7.82

Soft Annealing Heat to 650-700oC, cool slowly. This will produce a maximum Brinell hardness of 248.

Normalizing Temperature: 850-880oC.

Hardening Harden from a temperature of 830-880oC followed by oil quenching.

Tempering Tempering temperature: 540-680oC.

Mechanical Properties in Hardening and Tempering Condition Diameter (mm) <16 17-40 41-100 Tensile 0.2 % proof strength 2 stress (N/mm ) (N/mm2) 1050 1250-1450 1050 900 1250-1450 1100-1300 Elongation (%) 9 9 10 Reduction of area (%) 40 40 45 Notch impact energy (J) 35 35 40

101-160 161-250

800 700

1000-1200 900-1100

11 12

50 50

50 50

Diagram Tempering Temperature - Mechanical Properties

Click the image to enlarge the diagram.

Forging Hot forming temperature: 1050-850oC.

Machinability Machining is best done with this alloy in the annealed or normalized and tempered condition. It can be machined by all conventional methods.

Corrosion Resistance This is a low alloy steel and not a corrosion resistant alloy. Protective coating should be used.

Welding The alloy can be fusion or resistance welded. Preheat and post heat weld procedures should be followed when welding this alloy by established methods.

Cold working The VCNMO200 alloy may be cold worked, in the annealed condition, by conventional methods and tooling. It has good ductility.

Forms manufactured: Please see the Dimensional Sales Program.

Disclaimer The information and data presented herein are typical or average values and are not a guarantee of

maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other puposes. There is no representation that the recipient of this literature will receive updated editions as the become available.

Aisi 4340

deskripsi VCNMO200 adalah diobati panas, baja paduan rendah yang mengandung nikel, kromium dan molibdenum. Hal ini dikenal karena ketangguhan dan kemampuan mengembangkan kekuatan tinggi dalam kondisi panas yang diobati sementara tetap mempertahankan kekuatan kelelahan baik.

aplikasi Untuk permanen menekankan komponen dengan penampang besar untuk teknik otomotif dan mekanik. Untuk kinerja ekonomi di bawah tekanan dinamis yang parah, bagian harus dirancang untuk kekuatan optimal atau ketangguhan.

Sifat fisik (nilai rata) pada suhu ambien Modulus elastisitas [103 x N/mm2]: 210 Kepadatan [g/cm3]: 7.82

lembut Annealing Panas 650-700oC, dingin perlahan-lahan. Ini akan menghasilkan kekerasan Brinell maksimum 248.

normalisasi Suhu: 850-880oC.

pengerasan

Harden dari suhu 830-880oC diikuti dengan pendinginan minyak.

percampuran Tempering suhu: 540-680oC.

penempaan Hot membentuk suhu: 1050-850oC.

machinability Machining paling baik dilakukan dengan paduan dalam kondisi anil atau normalisasi dan marah. Hal ini dapat mesin oleh semua metode konvensional.

korosi Perlawanan Ini adalah baja paduan rendah dan bukan paduan tahan korosi. Lapisan pelindung harus digunakan.

Welding Paduan dapat fusi atau resistensi dilas. Panaskan dan panas pasca las prosedur harus diikuti ketika pengelasan paduan ini dengan metode yang ditetapkan.

dingin kerja Paduan VCNMO200 mungkin dingin bekerja, dalam kondisi anil, dengan metode konvensional dan perkakas. Ini memiliki daktilitas yang baik.

Bentuk diproduksi: Silakan lihat Program Penjualan Dimensi.

sangkalan Informasi dan data yang disajikan di sini adalah nilai-nilai khas atau rata-rata dan bukan merupakan jaminan dari nilai maksimum atau minimum. Aplikasi khusus disarankan untuk bahan yang dijelaskan

di sini dibuat semata-mata untuk tujuan ilustrasi untuk memungkinkan pembaca untuk membuat evaluasi sendiri dan tidak dimaksudkan sebagai jaminan, baik yang tersurat maupun tersirat, dari kesesuaian untuk aspek dari model ini atau lainnya. Tidak ada representasi bahwa penerima literatur ini akan menerima edisi diperbarui sebagai tersedia menjadi.

Low Alloyed cold work tool steel Steel OH237 (AISI S5)

Designation by Standards Brand Name OH237 Ravne No. 237 Mat. No. DIN EN AISI S5

Chemical Composition (in weight %) C 0.57 Si 2.00 Mn 0.80 Cr 0.30 Mo 0.78 Ni V 0.25 W Others -

Description Cold work tool steel. Shock resisting tool steel with good toughness at high strength levels.

Applications Different cutting parts, chisels, rivet sets, punches, driver bits.

Physical properties (avarage values) at ambient temperature Density [g/cm3]: 7.74

Coefficient of Linear Thermal Expansion 10-6 oC-1 20-100oC 13.1 20-200oC 13.7 20-300oC 14.4 20-400oC 14.4 20-500oC 14.7 20-600oC 14.9 20-700oC 15.0

Continuous Cooling Transformation (CCT) Diagram

Click the image to enlarge the diagram.

Time-Temperature Transformation (TTT) Diagram

Click the image to enlarge the diagram.

Soft Annealing Heat to 770-800oC, cool slowly in furnace. This will produce a maximum Brinell hardness of 229.

Stress Relieving Stress relieving to remove machining stresses should be carried out by heating to 650 oC, holding for one hour at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

Hardening Harden from a temperature of 880-920oC followed by oil quenching. Hardness after quenching is 63 HRC.

Tempering Tempering temperature: See the data bellow.

Tempering Temperature (oC) vs. Hardness (HRC) 100oC 62 200oC 60 300oC 58 400oC 56 500oC 50 550oC 48

Tempering Diagram

Click the image to enlarge the diagram.

Forging Hot forming temperature: 1050-900oC.

Machinability No data.

Forms manufactured: Please see the Dimensional Sales Program.

Disclaimer The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other puposes. There is no representation that the recipient of this literature will receive updated editions as the become available.

Steel UTOPMO6

Designation by Standards Brand Name UTOPMO6 Ravne No. 863 Mat. No. DIN EN AISI A8

Chemical Composition (in weight %) C 0.73 Si 1.00 Mn 0.55 Cr 5.50 Mo 1.35 Ni max. 0.25 V 0.65 W 1.20 Others -

Description This alloy is one of the cold work, medium air hardening type tool steels.

Applications Used for impact resistant tools such as hammers, chisels, rivet sets, Sendzimir rolls.

Physical properties (avarage values) at ambient temperature Modulus of elasticity [103 x N/mm2]: 210 Density [g/cm3]: 7.76

Coefficient of Linear Thermal Expansion 10-6 oC-1 20-100oC 20-200oC 20-300oC 20-400oC 20-500oC 20-600oC 20-700oC 20-800oC 11.7 11.5 11.7 12.1 13.0 13.4 13.9 14.1

Continuous Cooling Transformation (CCT) Diagram

Time-Temperature Transformation (TTT) Diagram

Click the image to enlarge the diagram.

Soft Annealing Heat to 830-850oC, cool slowly. This will produce a maximum Brinell hardness of 250.

Stress Relieving Stress relieving to remove machining stresses should be carried out by heating to 650 oC, holding for one hour at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

Hardening Harden from a temperature of 1000-1040oC followed by oil, air quenching or warm bath quenching. Hardness after quenching is 60-63 HRC (oil), 59-62 HRC (warm bath).

Tempering Tempering temperature: 150-600. Average hardness after tempering is 50-61 HRC.

Tempering Diagram

Click the image to enlarge the diagram.

Forging Hot forming temperature: 1080-900oC.

Machinability This alloy has reasonably good machinability with a rating of 85% that of the W group water hardening simple alloy tool steels.

Corrosion Resistance Corrosion resistance of this alloy is better than that of plain carbon steels. However it will rust unless given protective treatment.

Forms manufactured: Please see the Dimensional Sales Program.

Disclaimer The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other puposes. There is

no representation that the recipient of this literature will receive updated editions as the become available.

aluminium 7075-T6, 7075-T651

Subkategori: 7000 Seri Aluminium Alloy, Paduan Aluminium, Logam, Logam Nonferrous Tutup Analog: Catatan Komposisi : A Zr + Ti batas maksimum 0,25 persen dapat digunakan dengan sebutan paduan untuk produk diekstrusi dan ditempa saja, tapi hanya jika pemasok atau produsen dan pembeli harus saling jadi setuju. Perjanjian dapat diindikasikan, misalnya, dengan mengacu pada standar, dengan surat, dengan catatan pesanan, atau cara lain yang memungkinkan Zr + batas Ti. Aluminium konten dilaporkan dihitung sebagai sisa. Informasi Komposisi diberikan oleh Asosiasi Aluminium dan tidak untuk desain. Kata Kunci: Aluminium 7075-T6, Aluminium 7075-T651, UNS A97075, ISO AlZn5.5MgCu, Aluminium 7075-T6, Aluminium 7075-T651, AA7075-T6

Komponen Wt. % Komponen Wt. % Komponen Wt. %

Al Cr Cu Fe

87,1-91,4 0,18-0,28 1,2-2 Max 0.5

Mg Mn

2,1-2,9 Max 0.3

Si Ti Zn

Max 0.4 Max 0.2 5,1-6,1

Lainnya, masing-masing Max 0,05 Lainnya, total Max 0,15

Catatan Bahan:

Umum 7075 karakteristik dan penggunaan (dari Alcoa): Sangat tinggi kekuatan bahan yang digunakan untuk bagian struktural sangat menekankan. The marah T7351 menawarkan peningkatan stres-tahan korosi retak. Aplikasi: Pesawat fitting, roda gigi dan poros, bagian sekering, meter poros dan roda gigi, bagian rudal, mengatur bagian katup, roda gigi cacing, kunci, aplikasi pesawat, kedirgantaraan dan pertahanan, frame sepeda, semua kendaraan medan (ATV) sprockets. Data poin dengan catatan AA telah disediakan oleh Aluminium Association, Inc dan TIDAK UNTUK DESAIN. Fisik Properti Metrik Inggris Komentar

Kepadatan

2.81 g / cc

0,102 / di

AA; Khas

Mekanik Properti

Kekerasan, Brinell

150

150

AA; Khas, 500 g beban, bola 10 mm Dikonversi dari Nilai Kekerasan Brinell Dikonversi dari Nilai Kekerasan Brinell Dikonversi dari Nilai Kekerasan Brinell Dikonversi dari Nilai Kekerasan Brinell AA; Khas AA; Khas AA; Khas, 1/16 inci (1,6 mm) Tebal AA; Khas, 1/2 inci (12,7 mm) Diameter AA; Khas, rata-rata ketegangan dan kompresi. Kompresi modulus adalah sekitar 2% lebih besar dari modulus tarik.

Kekerasan, Knoop

191

191

Kekerasan, Rockwell A

53.5

53.5

Kekerasan, Rockwell B

87

87

Kekerasan, Vickers

175

175

Ultimate Tensile Strength Tarik Yield Strength Perpanjangan Istirahat

572 MPa 503 MPa 11%

83000 psi 73000 psi 11%

Perpanjangan Istirahat

11%

11%

Modulus Elastisitas

71,7 GPa

10400 ksi

Rasio Poisson Kelelahan Kekuatan

0.33 159 MPa

0.33 23000 psi AA; 500.000.000 siklus benarbenar terbalik stres, RR mesin Moore / spesimen K (IC) di Arah SL K (IC) di Arah TL K (IC) di Arah LT 0-100 Skala Paduan Aluminium

Fraktur Fraktur Fraktur Machinability

20 MPa-m 25 MPa-m 29 MPa-m 70%

18,2 ksi-in 22,8 ksi-in 26,4 ksi-in 70%

Shear Modulus Kekuatan geser

26,9 GPa 331 MPa

3900 ksi 48000 psi AA; Khas

Sifat Kelistrikan

Listrik Tahanan

5.15e-006 ohm-cm

5.15e-006 ohm-cm

AA; Khas pada 68 F

Thermal Properti

CTE, linier 68 F

23,6 m/m- C

13,1 in/in- F

AA; Khas, rata-rata lebih dari 68-212 F jangkauan. Rata-rata di atas kisaran 20300 C

CTE, linier 250 C

25,2 m/m- C

14 in/in- F

Spesifik Kapasitas Panas Thermal Konduktivitas Titik lebur

0.96 J/g- C

0.229 BTU/lb- F AA; Khas pada 77 F AA; rentang Khas berdasarkan komposisi khas untuk produk tempa ketebalan 1/4 inci atau lebih besar.Homogenisasi dapat meningkatkan mencair temperatur eutektik 20-40 F tetapi biasanya tidak menghilangkan pencairan eutektik. AA; Khas AA; Khas

130 W / mK 900 BTU-in/hr-ft - F 477-635 C 890 - 1175 F

Solidus Likuidus

477 C 635 C

890 F 1.175 F

Pengolahan Properti

Temperatur Annealing Solusi Suhu Penuaan Suhu

413 C 466-482 C 121 C

775 F 870-900 F 250 F

Anda mungkin juga menyukai

- South Bend Lathe TrainingDokumen68 halamanSouth Bend Lathe TrainingSMWilson100% (2)

- Fastener Torque Table SAE Grade - Engineers Edge PDFDokumen1 halamanFastener Torque Table SAE Grade - Engineers Edge PDFnate anantathatBelum ada peringkat

- AISI 1015: Digest DDokumen2 halamanAISI 1015: Digest DGovinda RajBelum ada peringkat

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantDari EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Durehete 950Dokumen5 halamanDurehete 950ellisforheroes100% (1)

- Super Duplex Stainless Steel: Excellent Engineering SolutionsDokumen4 halamanSuper Duplex Stainless Steel: Excellent Engineering SolutionsTXUSBelum ada peringkat

- Spiral Illusions ArticleDokumen5 halamanSpiral Illusions Articleapi-440057778100% (2)

- Duplex Stainless Steel DetailDokumen12 halamanDuplex Stainless Steel DetailessnelsonBelum ada peringkat

- AVESTA How To Weld Duplex SteelDokumen20 halamanAVESTA How To Weld Duplex SteelGMacella100% (1)

- Alloy SteelDokumen7 halamanAlloy SteelRavinJohnBelum ada peringkat

- 17-7 PH Data BulletinDokumen16 halaman17-7 PH Data Bulletinmeckup123Belum ada peringkat

- 904LDokumen5 halaman904LManish542Belum ada peringkat

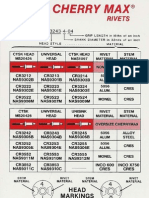

- Cherry Max ChartDokumen2 halamanCherry Max ChartDiego Alfonso JImenez50% (4)

- Stock Strip LayoutDokumen3 halamanStock Strip LayoutSwaran Singh67% (3)

- Alloy Steels 8620: Chemistry DataDokumen6 halamanAlloy Steels 8620: Chemistry DataVijay PalBelum ada peringkat

- Material Specification Sheet Saarstahl - 51Crv4 (50Crv4)Dokumen3 halamanMaterial Specification Sheet Saarstahl - 51Crv4 (50Crv4)anilBelum ada peringkat

- OCR12VMDokumen4 halamanOCR12VMcvgfgBelum ada peringkat

- X210CR12 GradeDokumen3 halamanX210CR12 GradekartsoftBelum ada peringkat

- UTOPEX2Dokumen4 halamanUTOPEX2emregnesBelum ada peringkat

- BRM2Dokumen3 halamanBRM2王向荣Belum ada peringkat

- 1.4922 SteelDokumen2 halaman1.4922 Steeldnageshm4n244Belum ada peringkat

- 1.2436 (62-63HRc)Dokumen3 halaman1.2436 (62-63HRc)Michel PortalBelum ada peringkat

- SIHARD 2243 Steel: Designation by StandardsDokumen3 halamanSIHARD 2243 Steel: Designation by StandardswalkerbhoBelum ada peringkat

- SINOXX 4116 Steel: Designation by StandardsDokumen2 halamanSINOXX 4116 Steel: Designation by StandardsSamirBelum ada peringkat

- PK2SPDokumen3 halamanPK2SPEmanuelValenciaHenaoBelum ada peringkat

- 25CR20NIDokumen2 halaman25CR20NIShariq KhanBelum ada peringkat

- AN ISO 9001: 2000: ProductsDokumen2 halamanAN ISO 9001: 2000: ProductsKamlesh DalavadiBelum ada peringkat

- Otel de Scule - GBDokumen37 halamanOtel de Scule - GBColta VictorBelum ada peringkat

- SINOXX 4435 Steel: Designation by StandardsDokumen2 halamanSINOXX 4435 Steel: Designation by StandardsMohammad MaroufkhaniBelum ada peringkat

- Designation by Standards: Steel Vcmo230 (Mat - No. 1.7707, Din 30crmov9, Aisi 4340)Dokumen5 halamanDesignation by Standards: Steel Vcmo230 (Mat - No. 1.7707, Din 30crmov9, Aisi 4340)janjicbojanBelum ada peringkat

- Data SAF2205 04Dokumen8 halamanData SAF2205 04il_yoo_1Belum ada peringkat

- X20 CR Mo 13 KGDokumen2 halamanX20 CR Mo 13 KGBonthala BadriBelum ada peringkat

- 20160323093435-52CrMoV4 (51CrMoV4) PDFDokumen1 halaman20160323093435-52CrMoV4 (51CrMoV4) PDFMartin HristovBelum ada peringkat

- 20160323093435-52CrMoV4 (51CrMoV4)Dokumen1 halaman20160323093435-52CrMoV4 (51CrMoV4)Martin HristovBelum ada peringkat

- X5CrNiCuNb 16-41.4542Dokumen2 halamanX5CrNiCuNb 16-41.4542nuesteBelum ada peringkat

- Astm A 453 Grade 660Dokumen4 halamanAstm A 453 Grade 660Bruno_jfBelum ada peringkat

- 1 4021 PDFDokumen2 halaman1 4021 PDFSarah FitzgeraldBelum ada peringkat

- FinDokumen3 halamanFinTVP_contechBelum ada peringkat

- Dievar D20140715Dokumen16 halamanDievar D20140715Keattikhun ChaichanaBelum ada peringkat

- Cast Materials: Sulzer PumpsDokumen6 halamanCast Materials: Sulzer PumpsElmey Bin JulkeplyBelum ada peringkat

- Tool Steel Alloy Cr12MoVDokumen5 halamanTool Steel Alloy Cr12MoVMujjo Sahb100% (1)

- XAR 450 (WB 710) EnglischDokumen3 halamanXAR 450 (WB 710) EnglischMario MoranBelum ada peringkat

- Austenitic Standard GradesDokumen6 halamanAustenitic Standard Gradesfierro44Belum ada peringkat

- PB Uddeholm Sleipner EnglishDokumen12 halamanPB Uddeholm Sleipner EnglishAlfya ChinikamwalaBelum ada peringkat

- Balancing Wear, StrengthDokumen4 halamanBalancing Wear, StrengthStephen MontelepreBelum ada peringkat

- 1.4462 Duplex PropertiesDokumen2 halaman1.4462 Duplex PropertiesEROL30Belum ada peringkat

- S31803Dokumen2 halamanS31803Elliott RussellBelum ada peringkat

- Aco AISI 1020 PDFDokumen1 halamanAco AISI 1020 PDFIbsonhBelum ada peringkat

- Cswip - Section 20-Heat TreatmentDokumen9 halamanCswip - Section 20-Heat TreatmentNsidibe Michael Etim100% (1)

- Aisi A2: Cold Work Tool SteelDokumen21 halamanAisi A2: Cold Work Tool SteelRahul NambiarBelum ada peringkat

- ST523Dokumen1 halamanST523سعد شحودBelum ada peringkat

- 1.4006 en PDFDokumen2 halaman1.4006 en PDFdiego.peinado8856Belum ada peringkat

- Stainless Steel 304 Material Property Data SheetDokumen2 halamanStainless Steel 304 Material Property Data SheetRahul SrivastavaBelum ada peringkat

- 304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless SteelDokumen2 halaman304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless SteelTomy GeorgeBelum ada peringkat

- Ficha Tecnica Anillos Oval RingDokumen8 halamanFicha Tecnica Anillos Oval RingAndres AlfonsoBelum ada peringkat

- Sandvik SAF 2205: Duplex Stainless SteelDokumen8 halamanSandvik SAF 2205: Duplex Stainless SteelIuliu HurducaciBelum ada peringkat

- MaterialData - Aço 1045Dokumen2 halamanMaterialData - Aço 1045Victhor AraujoBelum ada peringkat

- AL201LNDokumen6 halamanAL201LNCastoriadisBelum ada peringkat

- 201 Data SheetDokumen3 halaman201 Data SheetDjunanda E PrasetyaBelum ada peringkat

- Alluminium SheetsDokumen7 halamanAlluminium SheetsVaibhav ShuklaBelum ada peringkat

- 380.1 PropiedadesDokumen3 halaman380.1 PropiedadesNini CortesBelum ada peringkat

- Kaiser Aluminum Shapes Soft Alloy PDFDokumen18 halamanKaiser Aluminum Shapes Soft Alloy PDFgerrzen64Belum ada peringkat

- Heat Treatment: Mild SteelDokumen2 halamanHeat Treatment: Mild SteelAnand SarvaiyaBelum ada peringkat

- SS 304Dokumen5 halamanSS 304Nirav PatelBelum ada peringkat

- Faculty of Mechanical Engineering Universiti Teknologi Mara (Uitm) Report FormDokumen7 halamanFaculty of Mechanical Engineering Universiti Teknologi Mara (Uitm) Report Formafif lah100% (1)

- Hss Grades PDFDokumen3 halamanHss Grades PDFAnonymous yshOO0tEjKBelum ada peringkat

- c15 Catia v5r17Dokumen76 halamanc15 Catia v5r17Shubham HarleBelum ada peringkat

- Involute IGW PRESENTATION JUNE 2017Dokumen31 halamanInvolute IGW PRESENTATION JUNE 2017prakash 3Belum ada peringkat

- Basic CNC ProgrammingDokumen68 halamanBasic CNC ProgrammingAkash Kumar SinghBelum ada peringkat

- Chlorine Free Neat Cutting OilsDokumen2 halamanChlorine Free Neat Cutting OilsDANIEL ZORROBelum ada peringkat

- Ppce MCQDokumen210 halamanPpce MCQjeevan ram vBelum ada peringkat

- Metric Bolt Dimensions - Atlanta Rod and Manufacturing - Atlanta Rod and ManufacturingDokumen1 halamanMetric Bolt Dimensions - Atlanta Rod and Manufacturing - Atlanta Rod and ManufacturingRodrigo CelesBelum ada peringkat

- Bending Operations: Chapter 19/sheet MetalworkingDokumen6 halamanBending Operations: Chapter 19/sheet MetalworkingSalih Burak GÜLENBelum ada peringkat

- 4mitsubishi DB-130EDokumen25 halaman4mitsubishi DB-130EDiego De La FuenteBelum ada peringkat

- Project Report FOR Casting Iron & Copper: PromoterDokumen11 halamanProject Report FOR Casting Iron & Copper: PromoterdjchiragBelum ada peringkat

- Me8451 QB2Dokumen32 halamanMe8451 QB2Jayaram R S [MECH]Belum ada peringkat

- NBC PPT - RamlakhanDokumen40 halamanNBC PPT - RamlakhanramBelum ada peringkat

- CHMDokumen40 halamanCHMzeya_12345Belum ada peringkat

- Our Stainless Steels Solutions, The Most Complete Range Available On The MarketDokumen7 halamanOur Stainless Steels Solutions, The Most Complete Range Available On The MarketKalpesh JainBelum ada peringkat

- Week6 - Rolling and ExtrusionDokumen27 halamanWeek6 - Rolling and ExtrusionMuhammed Mustafa SezginBelum ada peringkat

- Shaper Machine DefinitionDokumen16 halamanShaper Machine Definitionمحمد عادلBelum ada peringkat

- BoltDokumen6 halamanBoltDJoko Trend RedsBelum ada peringkat

- Arm SubassemblyDokumen4 halamanArm Subassemblyapi-541897663Belum ada peringkat

- Printed CNC Brutus ManualDokumen55 halamanPrinted CNC Brutus ManualGustavoGuevaraBelum ada peringkat

- Electro Spark Metal Engraving PensDokumen1 halamanElectro Spark Metal Engraving Pensdjordjes123100% (1)

- Wps 2-8Dokumen1 halamanWps 2-8Anonymous XYt4Y9qBelum ada peringkat

- A Built-Up: BOQ. NO.: 1 Project: REV - No. R0 Date: 11-Jul-18 Detailer: Priya Designer: Anuj Grand Total in KG.Dokumen2 halamanA Built-Up: BOQ. NO.: 1 Project: REV - No. R0 Date: 11-Jul-18 Detailer: Priya Designer: Anuj Grand Total in KG.Vishal kumarBelum ada peringkat

- Non Traditional Method IntroductionDokumen7 halamanNon Traditional Method IntroductionAjay KumarBelum ada peringkat

- WWW Scribd Com Document 415705066 HMT Machine Tools LTD Internship ReportDokumen20 halamanWWW Scribd Com Document 415705066 HMT Machine Tools LTD Internship Reporthigom17162Belum ada peringkat