The Multiple Roots of Machinery Failures PDF

Diunggah oleh

Abdulrahman AlkhowaiterHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

The Multiple Roots of Machinery Failures PDF

Diunggah oleh

Abdulrahman AlkhowaiterHak Cipta:

Format Tersedia

Understanding the Multiple Roots of Machinery Failures

Looking at the newspapers we frequently see statistics on the cause of some group of failure events shown as a pie chart or other chart adding up to 100%. Also, we frequently hear television announcers citing the latest study where they say things like X percent of all home accidents are caused by poor lighting or Y percent of deaths are caused by cigarette smoking. The idea that an accident occurred or a piece of equipment broke down because of the error of a single person or a simple design error would be nice but usually it doesnt hold up to scrutiny in the real world. Certainly, it would simplify preventing future equipment and machinery failures if they did occur in that once cause vacuum but the real roots are usually much deeper than a single metallurgical problem or one error on the part of the maintenance mechanic or even the fact that the machine is being run at far above the design load. When all the human errors and management system deficiencies are included, the typical machine breakdown is generally the result of somewhere between five and ten significant contributors. The depth of the analysis into the roots of the failure is the key to accurately unearthing all of the sources. Looking at machinery breakdowns one finds that there are:

Physical Roots The physical reasons why the parts failed. Human Roots The human errors of omission or commission that resulted in the physical roots.

Understanding the Multiple Roots of Machinery Failures

Management System Latent Roots The deficiencies in the management systems or the management approaches that allow the human errors to continue unchecked.

The more detailed the analysis, the better we can understand all the events and mechanisms that contribute as the roots of the problem. These analyses are usually divided into three categories in order of complexity and depth of investigation. They are: 1. Component Failure Analysis CFA Conducted in a laboratory and looks at the piece of the machine that failed, for example, a bearing or a gear, to determine that it resulted from a specific mechanism such as fatigue, overload, or corrosion and that there were these x, y, and z significant influences. Root Cause Investigation RCI Includes a field investigation in addition to the CFA and is conducted in much greater depth than the CFA. The RCI goes substantially beyond the physical roots of a problem, but is usually stops at the major human causes and doesnt involve the latent system deficiencies. Root Cause Analyses RCA Includes everything the RCI covers plus the minor human error causes, and more importantly, the management system that allows the human errors and other system weaknesses to exist.

2.

3.

Although the cost increases as the analyses become more complex, the benefit is a much more complete recognition of the causes. Using a CFA to solve the causes of a component failure answers why the specific part or machine failed and can be used to prevent similar future failures. However, conducting a RCA and correcting the major causes, the system weaknesses, will eliminate huge groups of problems. An example of the benefits of an RCA can be seen in those situations where the failure relates to replacement components. While we were part of a large corporation, the corporate reliability group, using a Root Cause Analysis, determined that improper replacement parts were contributing to a significant portion of our maintenance problems. As a result, in our plant and several others, we began a receiving inspection program for the materials used in maintenance. In the first year this found that more than 20% of the materials received were not what was specified on the purchase orders. With time the vendors initiated their own inspections and we corrected our purchasing specifications and the number of improper components decreased. Over six plants the average eventually leveled out at about 4%. Certainly this was a huge improvement, but think about the production and maintenance affects of installing that 4% if they were not detected.

Understanding the Multiple Roots of Machinery Failures

In our company we get involved in all three levels of analyses but most of our work is centered around CFAs and RCIs. In an attempt to better understand the specifics and the interactions between the various causes we decided to look at three years of our project reports and sort for what the major failure contributors were. The source of our data was the reports sent to our clients. In these reports the technique we use to discover the failure roots generally involves the use of a logic tree. In developing these trees the contributions of the site operating and maintenance personnel are critical for an accurate analysis. Over the three years there were a total of 131 RCIs that we were involved with and we list the primary failure mechanisms below. Corrosion Fatigue Wear Corrosion fatigue Overload 18% 44% 10% 13% 15%

Note These are the primary failure mechanisms and frequently there is more than one mechanism involved. In defining these five categories there is the possibility of confusion between corrosion fatigue and fatigue. What we did was to assign fatigue as the mechanism in those cases where the component would have eventually failed and corrosion was not needed to effect the failure. In those situations where the component would not have failed without the action of the corrosion, i.e., there was cyclic loading but it was not severe enough to cause cracking without corrosion, the cause was considered as corrosion fatigue. After analyzing those failures for the mechanisms we then looked at them to determine the major human error causes. These are defined as those causes that were readily apparent from the component inspection, field analysis, and discussions with plant hourly and salaried personnel. Based on experience we selected six error categories, operational, design, maintenance practice, situation blindness, manufacturing, and original equipment installation, and sorted the causes. In sorting for these causes we used the following definitions:

Understanding the Multiple Roots of Machinery Failures

Operational errors These are situations where the machine or process was operated beyond the normal or accepted design boundaries. Two examples are:

The machine was not cleaned properly and the resultant corrosion reduced the thickness of the structural members to the point where significant distortion occurred. The specified operating practice for the perforating machine called for three sheets at a time, but the operators ran up to six sheets in an effort to get more productions. This contributed to a failure that destroyed the perforating machine drive system in about three months operating time.

Design errors There were two categories of design errors. The most common occurred when the design of the machine or the system did not meet the needs of the operation. However there were also situations where the machine performance requirements were changed without a sound design review. Before citing the examples we should note that these were not all the result of errors committed by engineers. There were examples where the design of a piece of equipment was the work of a maintenance planner or a vendor sales representative and the equipment was installed without competent oversight review. There were also situations where the machine operating rate was increased by plant personnel with tacit engineering approval but no realistic design analysis. Three examples of design errors are:

The dryer felt roll failed from fatigue that originated at a stress concentration where a stiffener was welded into position. The design oversight yielded a high stress concentration at the site of significant residual stresses and the parts fatigued. The pump impeller failed from cavitation, a corrosion mechanism. The cavitation resulted from poor piping design and the rapid failure from the use of a material that was not cavitation resistant. The system design had the pump operating at well below the minimum NPSH. The paper machine operating speed was increased by 5% without a serious engineering review. Consequently, some components were operating at resonant frequencies and failed repeatedly with the result that the total production capability remained constant while maintenance costs increased tremendously.

Understanding the Multiple Roots of Machinery Failures

Maintenance errors The maintenance mechanics did not properly repair or properly install the machine or component after a repair. Examples:

The pump shaft had loose bearing resulting from poor fitting practice. The resultant fretting corrosion reduced the fatigue strength of the shaft and the shaft fractured rapidly. A crankshaft on a large reciprocating compressor failed from bending fatigue. The crankshaft was supported by three plain bearings and the bearing alignment was not checked prior to crankshaft installation. Several months later the shaft failed as a result of the loading.

Manufacturing errors The components were improperly manufactured and as a result failed prematurely. Examples:

The manufacturer of large vertical shaft pumps used in waste treatment plants had torsional resonance in both the drive shafts and the pump bases. As a result the drive shafts would fracture from torsional fatigue after 4000 to 8000 operating hours. The manufacturer of an expansion joint specified for use at 180 psi actually supplied one designed for use at 120 psi. (There were errors in their internal procedures.) The joint failed during operation shortly after startup.

Original installation errors At the time of the installation a properly manufactured piece of equipment was installed incorrectly and, as a result, failed prematurely. Two examples are:

A vertical pump motor that was misaligned, causing stress on the shaft and directly contributing to the shaft failures. The copper water line that was installed without the specified dielectric union, resulting in corrosion that caused a leak approximately 15 months later.

Situation Blindness A situation where plant personnel, supervisors and hourly, recognize the severe problems exist, but no action is taken and the result is a significant failure. Two examples are:

Supercalenders drive failures that occurred when the reducer ran out of oil. This critical 2000 hp reducer had been leaking for 18 months but no corrective action had been taken. The gears melted when it was allowed to run out of oil and a spare was not readily available.

Understanding the Multiple Roots of Machinery Failures

A critical bearing that failed when the lubricant supply system failed. There was a monitoring system on the lubricant line and, even though the machine diagnostic report noted that the monitoring system had failed several months earlier, it had not been repaired. As a result, when the lubricant supply failed the bearing was destroyed and substantial downtime resulted.

In developing these categories the first five were relatively straightforward. However Situation Blindness was created during the review when we decided that another category was needed to categorize those failures where the gross neglect of a relatively minor problem allowed it to grow into an expensive and catastrophic failure. The supercalender drive failure is an example of this lack of action. It was in a plant where every operator was responsible for checking the lubricant level on every machine on every shift. The reducer was located in an area that was remote from the control room and awkward to get to, down a flight of stairs, across the operating floor, and up a ladder. It had been leaking heavily for more than a year and both the area around the reducer and the sides of the pedestal were saturated with oil. Certainly the direct cause was the leaky seal, but we felt there had to be some recognition of the general lack of problem awareness on the part of both plant supervision (failure to schedule the repair of a serious oil leak) and the operators (failure to replenish the oil in a known critical operation). There were a total of 276 major human errors and hundreds of minor contributory causes listed in the reports over those three years. The values below indicate the number of times the specific human error caused occurred. Note that there is almost always more than one contributory cause and a typical example is the Calciner shell failure that was caused by pitting corrosion. The pitting resulted from the combined effects of a welding error during fabrication and an operating error. The total number of major errors in each category shows: 34 90 93 28 20 11 Operational errors Design errors Maintenance errors Manufacturing errors Original installation errors Situation Blindness

Understanding the Multiple Roots of Machinery Failures

Recognizing that the distribution of the failures wasnt uniform we then looked at the actual number of failures affected by each category, i.e. we sorted to see how many failures involved design errors, maintenance errors, or operating errors. This showed: 59% Design errors 38% Maintenance errors 24% Operating errors 16% Installation errors 12% Manufacturing errors 10% Situation Blindness During this same period we were also deeply involved with several true Root Cause Analyses. These generally indicate that when an industrial failure is taken to the point where all the possible causes are examined there are somewhere between 6 and 12 roots. The distribution generally falls along the same lines of what we saw in the RCIs except there seemed to be more situation blindness. We dont have a good explanation of the apparent inconsistency between the general public practice of showing a single cause for accidents or failures and the reality that there are almost always multiple contributors. Looking at well-studied situations such as airplane crashes, one sees that the NTSB states that there are generally 12 and 14 events that have to coincide before a failure occurs. Yet the general public and many of us tends to believe that a failure is the result of a single individuals actions. If this erroneous thought process is used in conducting failure analyses, it results in the detection and elimination of only one contributing cause and the frequent recurrence of the failure.

Neville Sachs, P.E., is President of Sachs, Salvaterra & Associates, Inc. The consulting firm specializes in improved plant and equipment reliability and technical support services. Previously, Neville was Supervisor, Reliability Engineering for AlliedSignal Corporation where he was instrumental in developing one of the first large predictive maintenance inspection programs in the nation. Mr. Sachs received a Bachelor of Engineering Degree in both Mechanical and Chemical Engineering from Stevens Institute of Technology. Mr. Sachs is also one of RCI's co-presenters of their Root Cause Analysis Techniques Seminar and is one of their source experts for their RCA Facilitation Services.

Anda mungkin juga menyukai

- Productivity and Reliability-Based Maintenance Management, Second EditionDari EverandProductivity and Reliability-Based Maintenance Management, Second EditionBelum ada peringkat

- Gearmotor Sizing Guide PDFDokumen5 halamanGearmotor Sizing Guide PDFAnonymous Hy5Ir9QXBelum ada peringkat

- Structural Health MonitoringDari EverandStructural Health MonitoringDaniel BalageasBelum ada peringkat

- LAC - Air Oil Cooler With AC Motor For Industrial Use - HY10-6001 UKDokumen12 halamanLAC - Air Oil Cooler With AC Motor For Industrial Use - HY10-6001 UKMorgan PalmaBelum ada peringkat

- Energy-saving Principles and Technologies for Induction MotorsDari EverandEnergy-saving Principles and Technologies for Induction MotorsBelum ada peringkat

- 4.1 DC Motor SpecificationDokumen6 halaman4.1 DC Motor SpecificationAsgher KhattakBelum ada peringkat

- Additive Manufacturing A Complete Guide - 2020 EditionDari EverandAdditive Manufacturing A Complete Guide - 2020 EditionBelum ada peringkat

- PM Optimisation Maintenance Analysis of The FutureDokumen36 halamanPM Optimisation Maintenance Analysis of The Futurehetanshu24Belum ada peringkat

- Design of Miniature GearboxDokumen32 halamanDesign of Miniature GearboxSatish HSBelum ada peringkat

- Failure Analysis of Belt Conveyor SystemsDokumen17 halamanFailure Analysis of Belt Conveyor SystemsGogyBelum ada peringkat

- UNIT.1: Maintenance, Maintenance Planning, & Maintenance Activity For Machine ToolsDokumen51 halamanUNIT.1: Maintenance, Maintenance Planning, & Maintenance Activity For Machine Toolsjulakanti1Belum ada peringkat

- AC10P Catalog 5.41Dokumen16 halamanAC10P Catalog 5.41cocacolapepsiBelum ada peringkat

- White Paper On Condition Based Maintenance at Cement IndustryDokumen2 halamanWhite Paper On Condition Based Maintenance at Cement Industryheru984Belum ada peringkat

- The Design of Belt ConveyorDokumen10 halamanThe Design of Belt Conveyormihai90Belum ada peringkat

- Design Manufacturing of A CamshaftDokumen1 halamanDesign Manufacturing of A Camshaftsudhacarhr100% (1)

- Analysis of Process Fan Failure & Bearing Housing Case - StudyDokumen16 halamanAnalysis of Process Fan Failure & Bearing Housing Case - Studytylerdurdane100% (1)

- Industrial Gearbox Service ManualDokumen36 halamanIndustrial Gearbox Service ManualNovriansyah Brian100% (1)

- Assembly LineDokumen20 halamanAssembly LineSrikanth Vasantada0% (1)

- Pulveriseren Atriton PDFDokumen8 halamanPulveriseren Atriton PDFAntonBelum ada peringkat

- MS 2002 Cold Rolling Mill Speed OptimizationDokumen7 halamanMS 2002 Cold Rolling Mill Speed Optimizationsurajit7guptaBelum ada peringkat

- Rootcause Failure AnalysisDokumen3 halamanRootcause Failure Analysiskannan25% (4)

- Rotary Kiln Tire Support Pad Lubrication PDFDokumen3 halamanRotary Kiln Tire Support Pad Lubrication PDFMuhammadShoaibBelum ada peringkat

- Evolution of Maintenance StrategiesDokumen10 halamanEvolution of Maintenance StrategiesmusaveerBelum ada peringkat

- Structural Vibration Problem SolvingDokumen0 halamanStructural Vibration Problem Solvingilmu2Belum ada peringkat

- Presentation DC DrivesDokumen42 halamanPresentation DC Drivesfaizan100% (1)

- Abrasive ProcessesDokumen63 halamanAbrasive ProcessesmohdhmBelum ada peringkat

- Electrical Rotating Machine Asset Performance Management: GE PowerDokumen13 halamanElectrical Rotating Machine Asset Performance Management: GE PowerMuhammad Tilal AshrafBelum ada peringkat

- PDAP A Guide For ManagersDokumen15 halamanPDAP A Guide For ManagersPriyanka JaiswalBelum ada peringkat

- Chute Design Considerations For Feeding and TransferDokumen19 halamanChute Design Considerations For Feeding and TransferovunctezerBelum ada peringkat

- The Basic Oxygen Steelmaking (BOS) ProcessDokumen7 halamanThe Basic Oxygen Steelmaking (BOS) Processaecsuresh35Belum ada peringkat

- Failure of An Intermediate Gearbox of A HelicopterDokumen16 halamanFailure of An Intermediate Gearbox of A HelicopterAPIBelum ada peringkat

- Gear Box ReportDokumen39 halamanGear Box ReportNisar HussainBelum ada peringkat

- Total Plant Monitoring For An Integrated Steel Plantfin PDFDokumen15 halamanTotal Plant Monitoring For An Integrated Steel Plantfin PDFJohnBelum ada peringkat

- Fretting PDFDokumen8 halamanFretting PDFRohan MalkarBelum ada peringkat

- Fan Inlet System EffectsDokumen4 halamanFan Inlet System EffectsEzrizal Yusuf100% (1)

- Maintenance Presentation SlideDokumen56 halamanMaintenance Presentation Slidekapun kumar nayakBelum ada peringkat

- Requisition: FOR Hot Kiln Alignment & Girth Gear InspectionDokumen5 halamanRequisition: FOR Hot Kiln Alignment & Girth Gear InspectionAhmad Husni RizalBelum ada peringkat

- RCA en Fajas - 2 PDFDokumen6 halamanRCA en Fajas - 2 PDFVíctor Fernández Narváez100% (1)

- Design ProjectDokumen61 halamanDesign ProjectSami DeorajBelum ada peringkat

- Pulveriseren Atriton PDFDokumen8 halamanPulveriseren Atriton PDFEmre AfacanBelum ada peringkat

- Selection of Stirring and Shrouding Gases For Steelmaking Applications PDFDokumen20 halamanSelection of Stirring and Shrouding Gases For Steelmaking Applications PDFRasul BzBelum ada peringkat

- Hydraulic Actuator SpecificationsDokumen3 halamanHydraulic Actuator SpecificationsRizky RamadhaniBelum ada peringkat

- Industrial Report On Production Process of Steel Mills LTD: A Study On Ratanpur Steel Re-Rolling MillsDokumen21 halamanIndustrial Report On Production Process of Steel Mills LTD: A Study On Ratanpur Steel Re-Rolling MillsAbid HasanBelum ada peringkat

- Brochure BriquettingDokumen24 halamanBrochure Briquettingssmith2007Belum ada peringkat

- Designing of Screw ConveyorDokumen6 halamanDesigning of Screw ConveyorErickk RoqueeBelum ada peringkat

- Case Study - Reliability at Chemical PlantDokumen2 halamanCase Study - Reliability at Chemical PlantganeshdhageBelum ada peringkat

- A Reliability Analysis For Grinding ProcessDokumen68 halamanA Reliability Analysis For Grinding ProcessBenBelum ada peringkat

- 5.0 Theory of Motorized Valve Actuator ControlsDokumen20 halaman5.0 Theory of Motorized Valve Actuator ControlsParameswararao BillaBelum ada peringkat

- Reliability Analysis of Pharmaceutical PlantDokumen8 halamanReliability Analysis of Pharmaceutical Plantmexx007Belum ada peringkat

- A Parametric Study of Spur Gear Dynamics PDFDokumen88 halamanA Parametric Study of Spur Gear Dynamics PDFCan CemreBelum ada peringkat

- Outage Management ProcessDokumen2 halamanOutage Management ProcessSofian NasrBelum ada peringkat

- Girth Gear RunoutDokumen1 halamanGirth Gear RunoutvinodsnBelum ada peringkat

- Ludeca Best Practices Machinery Alignment ShimmingDokumen7 halamanLudeca Best Practices Machinery Alignment ShimmingTimber RamBelum ada peringkat

- Gitrh Gear VibrationsDokumen5 halamanGitrh Gear Vibrationsgullipalli srinivasa raoBelum ada peringkat

- Landing Gear Failure ReportDokumen10 halamanLanding Gear Failure ReportFarisz MalekBelum ada peringkat

- DALOG BusyBee MKM Viewer ManualDokumen16 halamanDALOG BusyBee MKM Viewer ManualGilberto PérezBelum ada peringkat

- TRANSCO Profile - English 2012Dokumen24 halamanTRANSCO Profile - English 2012Zaher Mhd SharafBelum ada peringkat

- Bearing NotesDokumen6 halamanBearing NotesabhivpcoeBelum ada peringkat

- Cmms CSDP TrainingDokumen44 halamanCmms CSDP TrainingRudyard ZednanrefBelum ada peringkat

- Read Acknowledgement Based Routing Misbehavior in Mobile Ad-Hoc Networks (RACK)Dokumen7 halamanRead Acknowledgement Based Routing Misbehavior in Mobile Ad-Hoc Networks (RACK)Aravinda GowdaBelum ada peringkat

- Making The Case For Plant-Wide Condition MonitoringDokumen8 halamanMaking The Case For Plant-Wide Condition MonitoringAbdulrahman Alkhowaiter100% (1)

- ISS Space Station Reliability Impacted by Cooling Pump FailureDokumen6 halamanISS Space Station Reliability Impacted by Cooling Pump FailureAbdulrahman AlkhowaiterBelum ada peringkat

- Gear Design & ManufacturingDokumen12 halamanGear Design & ManufacturingAbdulrahman AlkhowaiterBelum ada peringkat

- Notes11 Floating Ring Seals 09 PDFDokumen18 halamanNotes11 Floating Ring Seals 09 PDFsaravananknpcBelum ada peringkat

- Preventive Maintenance On Industrial GearboxesDokumen10 halamanPreventive Maintenance On Industrial GearboxesAbdulrahman AlkhowaiterBelum ada peringkat

- 7500 HP Speed Increaser Gearbox Case History Bearing Problem-1Dokumen4 halaman7500 HP Speed Increaser Gearbox Case History Bearing Problem-1Abdulrahman AlkhowaiterBelum ada peringkat

- Fundamentals of Reliability Fundamentals of Reliability Engineering and Applications Part 1 of 3Dokumen36 halamanFundamentals of Reliability Fundamentals of Reliability Engineering and Applications Part 1 of 3Abdulrahman AlkhowaiterBelum ada peringkat

- Burgmann iTDGS Product PresentationDokumen16 halamanBurgmann iTDGS Product PresentationAbdulrahman AlkhowaiterBelum ada peringkat

- PDFDokumen163 halamanPDFAmin NziBelum ada peringkat

- Of Spares and Equipment in Storage: Preserving The ReliabilityDokumen11 halamanOf Spares and Equipment in Storage: Preserving The ReliabilityAbdulrahman AlkhowaiterBelum ada peringkat

- Through The Design Process: Guide On Achieving ReliabilityDokumen19 halamanThrough The Design Process: Guide On Achieving ReliabilityAbdulrahman AlkhowaiterBelum ada peringkat

- Failure Analysis: Integrally Geared Compressor Cracked ImpellerDokumen35 halamanFailure Analysis: Integrally Geared Compressor Cracked ImpellerAbdulrahman AlkhowaiterBelum ada peringkat

- Root Cause AnalysisDokumen28 halamanRoot Cause AnalysisRashid Saleem100% (2)

- Belt Preventive Maintenance ManualDokumen67 halamanBelt Preventive Maintenance ManualAbdulrahman AlkhowaiterBelum ada peringkat

- Investigating Roller Bearing Failures by Physics of Failure Analysis-1Dokumen10 halamanInvestigating Roller Bearing Failures by Physics of Failure Analysis-1Abdulrahman AlkhowaiterBelum ada peringkat

- Case Study: Detection of High-Speed Coupling LoosenessDokumen4 halamanCase Study: Detection of High-Speed Coupling LoosenessAbdulrahman AlkhowaiterBelum ada peringkat

- BAN0006EN11 CS Huntly - Power - StationDokumen4 halamanBAN0006EN11 CS Huntly - Power - StationLong NguyenBelum ada peringkat

- Minimum Maintenance Strategy by Physics of Failure AnalysisDokumen8 halamanMinimum Maintenance Strategy by Physics of Failure AnalysisAbdulrahman Alkhowaiter100% (1)

- Centrifugal Pumps and SealDokumen32 halamanCentrifugal Pumps and SealAnatoli KarpobBelum ada peringkat

- Risk-Based Approach To Centrifugal Pump Seal Selection: DisclaimerDokumen7 halamanRisk-Based Approach To Centrifugal Pump Seal Selection: DisclaimerAbdulrahman AlkhowaiterBelum ada peringkat

- Rolling BearingTechnical Information-FAGDokumen55 halamanRolling BearingTechnical Information-FAGAbdulrahman AlkhowaiterBelum ada peringkat

- The James Reason Swiss Cheese Failure Model in 300 Seconds-1Dokumen5 halamanThe James Reason Swiss Cheese Failure Model in 300 Seconds-1Abdulrahman AlkhowaiterBelum ada peringkat

- IA Report Maintanence WorksDokumen19 halamanIA Report Maintanence WorkshossainmzBelum ada peringkat

- Mechanical Seals Optimization DesignDokumen8 halamanMechanical Seals Optimization DesigneduardogcarvalhoBelum ada peringkat

- Bearing Mounting DesignDokumen42 halamanBearing Mounting Designraghunath.psBelum ada peringkat

- Large Centrifugal Compression Trains Reliability and Performance StudyDokumen20 halamanLarge Centrifugal Compression Trains Reliability and Performance StudyAbdulrahman AlkhowaiterBelum ada peringkat

- Stability Analysis and Testing of A Train of Centrifugal Compressor For High Pressure Gas Injection PDFDokumen14 halamanStability Analysis and Testing of A Train of Centrifugal Compressor For High Pressure Gas Injection PDFVILLANUEVA_DANIEL2064Belum ada peringkat

- Water Pump Modifications-Propump Services-1Dokumen12 halamanWater Pump Modifications-Propump Services-1Abdulrahman AlkhowaiterBelum ada peringkat

- Bearing Failure On A Boiler Feed Water PumpDokumen16 halamanBearing Failure On A Boiler Feed Water PumpSuruttaiyan SuruBelum ada peringkat

- Centrifugal Carbamate Pump Failures-Improvement PDFDokumen21 halamanCentrifugal Carbamate Pump Failures-Improvement PDFAbdulrahman Alkhowaiter100% (1)

- Plain English Part 2Dokumen18 halamanPlain English Part 2ابو ريمBelum ada peringkat

- Vocabulary FceDokumen17 halamanVocabulary Fceivaan94Belum ada peringkat

- Liquitex Soft Body BookletDokumen12 halamanLiquitex Soft Body Booklethello belloBelum ada peringkat

- An Eastern Orthodox Understanding of The Dangers of Modernity and TechnologyDokumen10 halamanAn Eastern Orthodox Understanding of The Dangers of Modernity and TechnologyTimothy ZelinskiBelum ada peringkat

- Cipet Bhubaneswar Skill Development CoursesDokumen1 halamanCipet Bhubaneswar Skill Development CoursesDivakar PanigrahiBelum ada peringkat

- The Time Machine Was First Published in 1984 As A Story Under The Name The Time Traveller in The National ObserverDokumen1 halamanThe Time Machine Was First Published in 1984 As A Story Under The Name The Time Traveller in The National ObservermarceBelum ada peringkat

- Ti05001 PDFDokumen1 halamanTi05001 PDFanggieBelum ada peringkat

- 35 Electrical Safety SamanDokumen32 halaman35 Electrical Safety SamanSaman Sri Ananda RajapaksaBelum ada peringkat

- Concrete Specification (BS8500)Dokumen3 halamanConcrete Specification (BS8500)teh100% (1)

- March For Our LivesDokumen22 halamanMarch For Our LivesLucy HanBelum ada peringkat

- Marketing Micro and Macro EnvironmentDokumen8 halamanMarketing Micro and Macro EnvironmentSumit Acharya100% (1)

- Duo Interpretation Class PresentationDokumen31 halamanDuo Interpretation Class PresentationPlanetSparkBelum ada peringkat

- Introduction To Password Cracking Part 1Dokumen8 halamanIntroduction To Password Cracking Part 1Tibyan MuhammedBelum ada peringkat

- Galman V PamaranDokumen7 halamanGalman V PamaranChow Momville EstimoBelum ada peringkat

- Brosur YSIO X.preeDokumen20 halamanBrosur YSIO X.preeRadiologi RSUD KilisuciBelum ada peringkat

- Low Speed Aerators PDFDokumen13 halamanLow Speed Aerators PDFDgk RajuBelum ada peringkat

- PetrifiedDokumen13 halamanPetrifiedMarta GortBelum ada peringkat

- Current Trends and Issues in Nursing ManagementDokumen8 halamanCurrent Trends and Issues in Nursing ManagementMadhu Bala81% (21)

- Changed Report 2015 PDFDokumen298 halamanChanged Report 2015 PDFAnonymous FKjeRG6AFnBelum ada peringkat

- Rotating Equipment & ServiceDokumen12 halamanRotating Equipment & Servicenurkasih119Belum ada peringkat

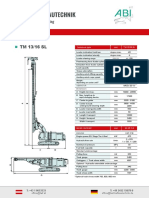

- ABI TM 13 16 SL - EngDokumen1 halamanABI TM 13 16 SL - EngJuan Carlos Benitez MartinezBelum ada peringkat

- Directorate of Technical Education, Admission Committee For Professional Courses (ACPC), GujaratDokumen2 halamanDirectorate of Technical Education, Admission Committee For Professional Courses (ACPC), GujaratgamailkabaaaapBelum ada peringkat

- Preparing For CPHQ .. An Overview of Concepts: Ghada Al-BarakatiDokumen109 halamanPreparing For CPHQ .. An Overview of Concepts: Ghada Al-BarakatiBilal SalamehBelum ada peringkat

- Calculus For The Life Sciences 2nd Edition Greenwell Solutions ManualDokumen26 halamanCalculus For The Life Sciences 2nd Edition Greenwell Solutions ManualSharonPerezozqy100% (56)

- Philhis 1blm Group 6 ReportDokumen19 halamanPhilhis 1blm Group 6 Reporttaehyung trashBelum ada peringkat

- Rishika Reddy Art Integrated ActivityDokumen11 halamanRishika Reddy Art Integrated ActivityRishika ReddyBelum ada peringkat

- KundaliniDokumen3 halamanKundaliniAlfred IDunnoBelum ada peringkat

- Seizure Control Status and Associated Factors Among Patients With Epilepsy. North-West Ethiopia'Dokumen14 halamanSeizure Control Status and Associated Factors Among Patients With Epilepsy. North-West Ethiopia'Sulaman AbdelaBelum ada peringkat

- Crafer. The Apocriticus of Macarius Magnes (S.P.C.K. Edition) - 1919.Dokumen188 halamanCrafer. The Apocriticus of Macarius Magnes (S.P.C.K. Edition) - 1919.Patrologia Latina, Graeca et OrientalisBelum ada peringkat

- Embedded Systems Online TestingDokumen6 halamanEmbedded Systems Online TestingPuspala ManojkumarBelum ada peringkat

- Summary of Neil Postman's Amusing Ourselves to DeathDari EverandSummary of Neil Postman's Amusing Ourselves to DeathPenilaian: 4 dari 5 bintang4/5 (2)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDari EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansBelum ada peringkat

- To Engineer Is Human: The Role of Failure in Successful DesignDari EverandTo Engineer Is Human: The Role of Failure in Successful DesignPenilaian: 4 dari 5 bintang4/5 (137)

- Cable Supported Bridges: Concept and DesignDari EverandCable Supported Bridges: Concept and DesignPenilaian: 5 dari 5 bintang5/5 (1)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDari EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Troubleshooting and Repair of Diesel EnginesDari EverandTroubleshooting and Repair of Diesel EnginesPenilaian: 1.5 dari 5 bintang1.5/5 (2)

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisDari EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisPenilaian: 5 dari 5 bintang5/5 (3)

- Structural Analysis 1: Statically Determinate StructuresDari EverandStructural Analysis 1: Statically Determinate StructuresBelum ada peringkat

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDari EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansPenilaian: 4.5 dari 5 bintang4.5/5 (21)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeDari EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgePenilaian: 4.5 dari 5 bintang4.5/5 (59)

- CAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementDari EverandCAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementBelum ada peringkat

- Structural Cross Sections: Analysis and DesignDari EverandStructural Cross Sections: Analysis and DesignPenilaian: 4.5 dari 5 bintang4.5/5 (19)

- Pile Design and Construction Rules of ThumbDari EverandPile Design and Construction Rules of ThumbPenilaian: 4.5 dari 5 bintang4.5/5 (15)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDari EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationPenilaian: 4 dari 5 bintang4/5 (18)

- Construction Innovation and Process ImprovementDari EverandConstruction Innovation and Process ImprovementAkintola AkintoyeBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesDari EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesBelum ada peringkat

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyDari EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyPenilaian: 4.5 dari 5 bintang4.5/5 (5)

- Engineering Rock Mass Classification: Tunnelling, Foundations and LandslidesDari EverandEngineering Rock Mass Classification: Tunnelling, Foundations and LandslidesPenilaian: 4 dari 5 bintang4/5 (5)

- Up and Running with AutoCAD 2020: 2D Drafting and DesignDari EverandUp and Running with AutoCAD 2020: 2D Drafting and DesignBelum ada peringkat

- Skyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownDari EverandSkyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownBelum ada peringkat

- Transportation Decision Making: Principles of Project Evaluation and ProgrammingDari EverandTransportation Decision Making: Principles of Project Evaluation and ProgrammingBelum ada peringkat