Safety Valve Laser

Diunggah oleh

sajjad_naghdi2410 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

158 tayangan15 halamanThis document discusses LESER's pilot operated safety valves. It describes their two main series - Series 810 which opens rapidly and Series 820 which opens proportionally to pressure. Pilot operated safety valves maintain tightness closer to the set pressure than spring valves and have smaller pressure differences on opening and closing. They can be used worldwide and are approved according to international standards. Typical applications include gas pipelines, refineries, offshore platforms, and pulp/paper industries.

Deskripsi Asli:

catalog from laser company for safety valve

Judul Asli

safety valve laser

Hak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThis document discusses LESER's pilot operated safety valves. It describes their two main series - Series 810 which opens rapidly and Series 820 which opens proportionally to pressure. Pilot operated safety valves maintain tightness closer to the set pressure than spring valves and have smaller pressure differences on opening and closing. They can be used worldwide and are approved according to international standards. Typical applications include gas pipelines, refineries, offshore platforms, and pulp/paper industries.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

158 tayangan15 halamanSafety Valve Laser

Diunggah oleh

sajjad_naghdi241This document discusses LESER's pilot operated safety valves. It describes their two main series - Series 810 which opens rapidly and Series 820 which opens proportionally to pressure. Pilot operated safety valves maintain tightness closer to the set pressure than spring valves and have smaller pressure differences on opening and closing. They can be used worldwide and are approved according to international standards. Typical applications include gas pipelines, refineries, offshore platforms, and pulp/paper industries.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 15

Pilot Operated Safety Valve

Series 810 Pop Action

Series 820 Modulate Action

The-Safety-Valve.com

High

Efficiency

High

Efficiency

LESERs High Efficiency Product Group

LESERs High Efficiency Product Group consists of products

that increase the efficiency and productivity of the protected

plant.

These products are:

Pilot Operated Safety Valves

Safety Valves with Supplementary Loading System

Highlights

LESERs pilot operated safety valves are characterized by

maintaining seat tightness closer to the set pressure.

LESERs pilot operated safety valves are distinguished by

small opening and closing pressure differences.

A solution that can be used worldwide in the market for

pilot operated safety valves.

Approvals

LESERs pilot operated safety valves can be used worldwide,

as they are approved according to the following international

codes and standards:

European Community: CE marking as per Pressure

Equipment Directive 97/23/EC and EN ISO 4126-4

USA: UV-Stamp acc. to ASME Section VIII Division 1,

National Board certified capacities

Germany: VdTV approval as per Pressure Equipment

Directive, EN ISO 4126-4, VdTV Merkblatt SV 100/1

Regarding the design, manufacture and marking of LESERs

pilot operated safety valves, LESER also complies with the

following regulations:

EN ISO 4126-7, EN 12266-1/-2, EN 1092 Part I and II, ASME

PTC 25, ASME-Code Sec. II, ASME B16.34 and ASME B16.5,

API Std. 527, API RP 576

Applications

Gas compressor stations

Refineries

Petrochemical industry

Oil / gas Onshore and Offshore

Tank farms / tanker ships (LNG / LPG)

Pulp and Paper industry

Pumps

General Information General Information

LWN 487.61-E 2

General Information General Information

LWN 487.61-E 3

Product Profile

LESERs Pilot Operated Safety Valves

LESERs series 810 and series 820 safety valves cover a wide

spectrum of models, materials, and design features for any

application:

Design in compliance with API 526 for easy replacement.

Complete API 526 product range with valve sizes from

1" to 8", orifice D to T.

Body materials WCB, CF8M, LCB, 1.0619, 1.4408 and a

diversity of custom materials for an extended range of

applications.

One design and spring (single trim) for steam, gas and

liquid applications reduces the number of spare parts

and ensures low cost maintenance management.

Back pressure independent construction allows for external

back pressure > 50% of set pressure.

Flange connections according to ASME, EN and JIS

guarantee worldwide suitability.

LESERs pilot operated safety valves offer a simple, safe

solution for applications with

high operating pressures in relation to the set pressure

high back pressure

high set pressures with large nominal diameters

high capacities relating to the nominal diameter

high seat tightness requirements with operating pressures

that are close to the set pressure

Series 810 and Series 820

Depending on the design principle, LESERs pilot operated

safety valves open rapidly (Pop Action) or in proportion to the

system pressure (Modulate Action). Pop Action pilot valves

make up LESERs Series 810 and the Modulate Action pilot

valves make up LESERs Series 820.

Series 810 Pop Action

LESERs Series 810 pop action pilot operated safety valves:

are used mainly for vapour and gas applications where the

maximum discharge capacity needs to be reached quickly.

open completely within approx. 1% opening pressure

difference and close within an adjustable blowdown

of 2 7%.

blowdown can be adjusted to 7% to 15% during plant oper-

ation in order to guarantee safe functioning of the safety

valve in cases of high pressure losses in the inlet line.

have an adjustable blowdown of 2 7% conforming to

ASME VIII with an optical marking feature.

allow spring replacement in the pilot without complete

disassembly of the pilot. This eliminates the need to remove

the valve from service to change the set pressure.

Series 820 Modulate Action

LESERs Series 820 modulate action pilot operated safety

valves:

open in proportion to the overpressure to ensure that only

as much mass flow as necessary is discharged from the

safety valve to prevent further pressure increase.

minimize medium losses.

open completely at an approximate 5 10% overpressure

and close within a blowdown of 2 7% for steam and

gas applications.

LWN 487.61-E 4

The three designs of safety valves each have specific feature profiles and benefits in their applications.

The benefits of LESERs pilot operated safety valves compared to spring loaded safety valves and spring loaded

safety valves with supplementary loading are shown in table below.

Closing forces for the three safety valve designs

With a pilot operated safety valve, in contrast to a spring loaded safety valve, the increasing system pressure leads to

an increasing closing force and hence to better seat tightness closer to the set pressure. A comparably secure clamping

force can otherwise only be achieved with spring loaded safety valves with supplementary loading.

Safety valve designs Safety valve designs

Benets of

compared to

Spring loaded

safety valve

Spring loaded SV with

supplementary loading

Pilot operated

safety valve

Spring loaded safety valve

seat tightness up to

set pressure

higher operating to

set pressure ratios

small overpressure

and blowdown

fast and complete valve

opening

low medium loss

small structural size,

low weight

higher seat tightness

small overpressure and

blowdown

higher set pressures

higher operating to

set pressure ratios

higher back pressures

adjustable blowdown

Spring loaded Safety valve

with supplementary loading

technically simpler

lower investment costs

no supplemental energy

needed

small structural size,

low weight

suitable for larger operating

pressure ranges

lower investment costs

lower installation effort

no supplemental energy

needed

Pilot operated safety valve

less sensitive

does not require clean

medium

very good for high

temperatures (hot steam)

individual control of multiple

safety valves possible with

one control unit

excellent for high

temperatures (hot steam)

triple redundancy for

control lines for high

operating safety

retrotting of competitors

valves

3. Pilot operated safety valve

Seat tightness up to set pressure

F [N]

C

l

o

s

i

n

g

f

o

r

c

e

P

set

p [bar/psig]

F [N]

C

l

o

s

i

n

g

f

o

r

c

e

P

set

p [bar/psig]

1. Spring loaded safety valve

Untightness close to set pressure

F [N]

C

l

o

s

i

n

g

f

o

r

c

e

P

set

p [bar/psig]

2. Spring loaded SV with

supplementary loading

Tight up to set pressure with active

supplementary loading

LWN 487.61-E 5

Compressors in Gas Main Systems

Pilot operated safety valves are frequently used for gas

transport in pipelines. The reasons are:

highest possible operating pressure to set pressure

ratios facilitates maximum energy density of transport

medium

vibrations from compressors lead to leakage with

spring loaded safety valves

The Pop Action pilot valve is frequently used for gas

applications.

Refineries and Gas Conditioning Plants

Pilot operated safety valves acc. to API 526 are fre-

quently used in refineries. The reasons are:

backpressure greater than 50% of set pressure

because blow-down systems often include long pipe

systems

high absolute backpressures that cannot be handled

with spring loaded safety valves with stainless steel

bellows

In these applications, the backpressure-independent

opening characteristic of LESER pilot valves guaran-

tees reliable protection of the equipment.

Offshore Applications

On offshore platforms, more pilot operated safety

valves than spring loaded safety valves are used. The

reasons are:

lower weight and lower overall height because,

compared to a spring loaded safety valve, there is no

bonnet

high set pressures with larger orifices reduce the

number of valves required

no leakage with pilot operated safety valves means

a low risk of fire

Pulp and Paper Industry

Pilot operated safety valves are used with steam-

heated dryer drums, for example the Yankee Cylinder.

The reasons are:

operating pressures of the dryer drums should be as

close as possible to the MAWP (Maximum Allowable

Working Pressure) in order to increase plant productivity

minimized overpressure and blowdown in order to

avoid a paper tear caused by fluctuating saturated

steam temperatures

usability of LESER's pilot operated safety valves as

an alternative to LESER supplementary loading

Pilot operated safety valves are used in a large variety of applications.

Typical applications are:

Applications Applications

6 LWN 487.61-E

Pilot Operated Safety Valve

Components Components

Overview

LESERs pilot operated safety valves facilitate seat

tightness of the main valve up to the set pressure as

well as opening and closing operation within very small

overpressure and blowdown.

LESERs pilot operated safety valves are controlled by

process medium.

1 Pilot

Pipeline

Cover with integrated control pipe

3 Dome

Piston guide

4 Main valve Piston 2 Pressure pickup Seat

7 LWN 487.61-E

Pilot Operated Safety Valve

Function Function

LESERs pilot operated safety valve is controlled by

process medium. The system pressure is applied to the

pilot 1 (= control component for the main valve) via the

pressure pickup 2.

1. Normal Operation

Filling of the dome (as per diagram: Operating condi-

tions of the pilot operated safety valve).

In the normal operating cyle, the system pressure is

taken from the main valve inlet and channelled to the

dome 3 of the main valve 4. Since the dome area is

larger than the area of the valve seat, there is always a

greater force on the dome due to the hydraulic princi-

ple. This keeps the main valve tightly closed.

2. Set pressure reached

The pilot actuates when the set pressure is reached:

The medium is no longer channelled to the dome 3.

Instead, the pressure in the dome 3 is released. The

main valve opens. According to the design principle of

the pilot, either rapidly and completely (Pop Action) or

gradually and partially depending on the system pres-

sure (Modulate Action).

3. System pressure drops below the closing pressure

If the system pressure drops below the closing pres-

sure, the pilot actuates and channels the medium to

the dome of the main valve again. The pressure in

the dome 3 builds up and the main valve 4 recloses.

The closing is in accordance to the design principle

of the pilot, either rapidly and completely (Pop Action)

or gradually and partially depending on the system

pressure (Modulate Action).

Features and benefits:

The piping of the pilot is integrated into the cover,

which minimises the danger of leakage points, pipe

damage, and leads to fewer faults in the system.

Integrated support brackets on the body for easy

handling and safe installation

The self-draining angle type body prevents residue

and reduces corrosion.

The pilot is not sensitive to vibrations due to its direct

and robust connection to the main valve.

Discs with soft seal (O-ring) fulfil increased demands

of functional tightness.

1

3 2

1 = Normal state

2 = Set pressure reached

3 = Closing pressure

Diagram: Operating conditions of the pilot operated safety valve

Set pressure Pressure

Lift

8 LWN 487.61-E

Function

The Series 810 Pop Action pilot safety valve is char-

acterized by rapid opening or pop action. Another

typical terminology to characterize the function is snap

action. The dome of the main valve is vented quickly

and completely when the set pressure is reached; the

main valve opens just as quickly and completely. The

medium from the dome is discharged into the atmos-

phere.

The Pop Action pilot safety valve is mainly used for

vapour and gas applications.

Features and benefits

Robust and insensitive to vibrations. The robust con-

nection of the pilot to the main valve and the reduced

exposed piping guarantees safe operating even if there

are vibrations in the system.

The spring is easily accessible by removing the top

section of the bonnet only. This allows easy replace-

ment of the spring and saves time and costs. Other

functional parts or seals do not have to be disassem-

bled and therefore do not need to be replaced.

Blowdown failsafe. Depending on the construction,

the blowdown can only be adjusted in such a way that

safe functioning of the pilot remains guaranteed. Even a

maximum adjustment does not lead to the pilot having

unstable behavior (e.g. fluttering).

Easy blowdown setting within the requirements of

codes and standards. The blowdown range of 2 7%,

which conforms to codes and standards, can easily be

adjusted with the help of an optical marking feature on

the pilot. Other test devices are not necessary.

A large pressure range of 2.5 63 bar (36 1480

psig) ensures that the Series 810 Pop Action pilot safety

valve can be used for a multitude of applications.

Easy material replacement. The complete pilot is

machined from bar material in 1.4404/316L. Hence, all

parts can also be made of custom materials.

Series 810 Pop Action Pilot Series 810 Pop Action Pilot

Lift

Functional characteristics of Series 810 with Pop Action pilots

Set pressure

min. 3%

max. 15%

Adjustable blowdown

93% 100% 110% Pressure

Pilot-operated

safety valve

Series 810

LESER spring-

loaded safety valve

for comparison only

9 LWN 487.61-E

Function

The Series 820 Modulate Action pilot safety valve

opens gradually and possibly only partly depending on

the system overpressure. For pressures above the set

pressure, this means that when the pressure increases,

only as much mass flow is discharged as is needed to

prevent a further pressure increase. In contrast to the

Pop Action opening characteristic, the pressure drop

in the system is limited and an unnecessary loss of

medium is avoided.

The Modulate Action pilot safety valve is used for liquid

as well as for steam and gas applications.

Features and benefits

The Modulate Action pilot safety valve has the same

construction related benefits as the Pop Action pilot

safety valve with regard to easy manufacture, deliv-

ery in custom materials, the robustness, easy spring

replacement, and large pressure range of 2.5 63 bar

(36 1480 psig). Furthermore, it has the following spe-

cific benefits:

Suitability for media that are harmful to health/

environment. The Modulate Action pilot safety valve

releases the medium from the dome into the main valve

outlet and not into the atmosphere like the Pop Action

pilot safety valve. Since back pressure can occur here,

the Modulate Action pilot has a back pressure compen-

sating design.

Same performance, full lift. The Modulate Action pilot

safety valve has the same discharge capacity and the

same lift when completely open as the Pop Action pilot

valve.

Series 820 Modulate Action Pilot Series 820 Modulate Action Pilot

Functional characteristics of Series 820 with Modulate Action pilots

LESER spring-

loaded safety valve

for comparison only

Pilot-operated

safety valve

Series 820

Lift

Set pressure

Blowdown

2 % 7%

93% 100% 98% 110% Pressure

10 LWN 487.61-E

The following options for LESERs pilot operated safety valves (810 and 820 series) facilitate further adaptations

to specific operating conditions.

Solutions with Options Solutions with Options

Problem Solution with Option

Backow preventer

Unwanted opening of the main valve from excess

pressure in the discharge side (or low pressure at

the pressure pickup)

Prevents unwanted opening of the main valve and

hence a return flow of the medium from the discharge

side into the system to be secured

Remote sensing

Chattering safety valve due to high pressure loss

in the inlet line

Pressure pickup is relocated from the main valve

to the pipeline or the vessel

The pilot safety valve works independently

of pressure loss in the inlet line. That way,

chattering of the safety valve is prevented

Field test connection

The set pressure is to be tested in the plant

Facilitates quick and easy checking of the set

pressure while the plant is in operation

Pilot supply lter

Dirty service

Filters out solids in the process media,

guarantees defined purity

For liquid and gaseous media

Integrated into the inlet piping

Manual blowdown

Opening of the main valve is to be tested

The function of the main valve is tested without

the pilot having to execute a switching operation

The dome pressure is released directly into the

atmosphere

Pulsation damper

Unwanted opening of the main valve due

to pulsations or pressure peaks

Is integrated into the pressure sensing line between

the pressure pickup and the inlet of the pilot with

the medium flowing through it

Dampens sudden pressure increases

Pilot lifting device H4

Because of codes and standards or customer

requests, the function of the pilot and the main

valve must be tested manually

The main valve can be lifted manually with pilot lifting

device H4

Note: The set pressure is not tested by manual lifting.

100 LWN 493.10-E

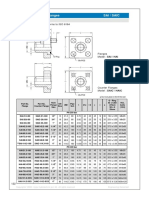

Dimensions and weights

D

i

m

e

n

s

i

o

n

s

a

n

d

w

e

i

g

h

t

s

High Efficiency High Efficiency

Valve size 1 x 2 1 x 2 1 x 3 2 x 3

Orifice D E F D E F G H G H J

Extra Orifice G H J K+

d

0

11 14,7 18,4 23 11 14,7 18,4 29 23,6 29,4 35,7 23,6 29,4 38 48

A

0

95 170 266 415 95 170 266 661 437 679 1001 437 679 1134 1810

Flange rating class 150 x 150

a 105 105 105 105 124 124 124 124 130 130 130 137 137 137 137

b 114 114 114 114 121 121 121 121 124 124 124 124 124 124 124

H Series 810 330 330 330 330 359 359 359 359 370 370 370 386 386 386 386

H Series 820 456 456 456 456 485 485 485 485 496 496 496 512 512 512 512

S

1

20 20 20 20 31 31 31 31 31 31 31 36 36 36 36

S

2

24 24 24 24 24 24 24 24 29 29 29 29 29 29 29

A 143 143 143 143 152 152 152 152 160 160 160 179 179 179 179

B

C 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14

D 182 182 182 182 186 186 186 186 200 200 200 209 209 209 209

E 271 271 271 271 284 284 284 284 292 292 292 299 299 299 299

m 19,5 19,5 19,5 19,5 24 24 24 24 28 28 28 34 34 34 34

Flange rating class 300 x 150

a 111 111 111 111 124 124 124 124 130 130 130 137 137 137 137

b 114 114 114 114 121 121 121 121 124 124 124 124 124 124 124

H Series 810 336 336 336 336 359 359 359 359 370 370 370 386 386 386 386

H Series 820 462 462 462 462 485 485 485 485 496 496 496 512 512 512 512

S

1

26 26 26 26 31 31 31 31 31 31 31 36 36 36 36

S

2

24 24 24 24 24 24 24 24 29 29 29 29 29 29 29

A 143 143 143 143 152 152 152 152 160 160 160 179 179 179 179

B

C 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14

D 182 182 182 182 186 186 186 186 200 200 200 209 209 209 209

E 271 271 271 271 284 284 284 284 292 292 292 299 299 299 299

m 19,5 19,5 19,5 19,5 24 24 24 24 28 28 28 34 34 34 34

Flange rating class 600 x 150

a 111 111 111 111 124 124 124 124 130 130 130 137 137 137 137

b 114 114 114 114 121 121 121 121 124 124 124 124 124 124 124

H Series 810 336 336 336 336 359 359 359 359 370 370 370 386 386 386 386

H Series 820 462 462 462 462 485 485 485 485 496 496 496 512 512 512 512

S

1

26 26 26 26 31 31 31 31 31 31 31 36 36 36 36

S

2

24 24 24 24 24 24 24 24 29 29 29 29 29 29 29

A 143 143 143 143 152 152 152 152 160 160 160 179 179 179 179

B

C 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14

D 182 182 182 182 186 186 186 186 200 200 200 209 209 209 209

E 271 271 271 271 284 284 284 284 292 292 292 299 299 299 299

m 19,5 19,5 19,5 19,5 24 24 24 24 28 28 28 34 34 34 34

Metric Units

d

0

= Actual discharge diameter [mm]

A

0

= Actual discharge area [mm

2

]

a = Center to face [mm]

b = Center to face [mm]

H = Heights [mm]

S

1

= Inlet flange thicknes [mm]

S

2

= Outlet flange thickness [mm]

A = Bracket [mm]

B = Bracket [mm]

C = Hole diameter [mm]

D = Total width [mm]

E = Total length [mm]

m = Weight [kg]

101 LWN 493.10-E

Dimensions and weights

D

i

m

e

n

s

i

o

n

s

a

n

d

w

e

i

g

h

t

s

High Efficiency High Efficiency

Valve size 3 x 4 4 x 6 6 x 8 8 x 10

Orifice J K L L M N P Q R T

Extra Orifice N+ P+ R+ T+

d

0

38 45 56 75 56 63 69 83 95 110 133 142 168 180

A

0

1134 1590 2463 4418 2463 3117 3739 5411 7088 9503 13893 15837 22167 25447

Flange rating class 150 x 150

a 156 156 156 156 197 197 197 197 197 240 240 240 276 276

b 162 162 162 162 210 210 210 210 210 241 241 241 279 279

H Series 810 428 428 428 428 481 481 481 481 481 580 580 580 668 668

H Series 820 554 554 554 554 607 607 607 607 607 706 706 706 794 794

S

1

36 36 36 36 49 49 49 49 49 52 52 52 45 45

S

2

29 29 29 29 30 30 30 30 30 47 47 47 35 35

A 223 223 223 223 249 249 249 249 249 320 320 320 356 356

B 110 110 110 110 110 110 110 110 110 160 160 160 160 160

C 18 18 18 18 18 18 18 18 18 18 18 18 18 18

D 259 259 259 259 305 305 305 305 305 381 381 381 430 430

E 358 358 358 358 420 420 420 420 420 516 516 516 549 549

m 56 56 56 56 86 86 86 86 86 192 192 192 260 260

Flange rating class 300 x 150

a 156 156 156 156 197 197 197 197 197 240 240 240 276 276

b 162 162 162 162 210 210 210 210 210 241 241 241 279 279

H Series 810 428 428 428 428 481 481 481 481 481 580 580 580 668 668

H Series 820 554 554 554 554 607 607 607 607 607 706 706 706 794 794

S

1

36 36 36 36 49 49 49 49 49 52 52 52 45 45

S

2

29 29 29 29 30 30 30 30 30 47 47 47 35 35

A 223 223 223 223 249 249 249 249 249 320 320 320 356 356

B 110 110 110 110 110 110 110 110 110 160 160 160 160 160

C 18 18 18 18 18 18 18 18 18 18 18 18 18 18

D 259 259 259 259 305 305 305 305 305 381 381 381 430 430

E 358 358 358 358 420 420 420 420 420 516 516 516 549 549

m 56 56 56 56 86 86 86 86 86 192 192 192 260 260

Flange rating class 600 x 150

a 162 162 162 162 197 197 197 197 197 246 246 246 297 297

b 162 162 162 162 210 210 210 210 210 241 241 241 279 279

H Series 810 434 434 434 434 481 481 481 481 481 586 586 586 689 689

H Series 820 560 560 560 560 607 607 607 607 607 712 712 712 815 815

S

1

42 42 42 42 49 49 49 49 49 58 58 58 66 66

S

2

29 29 29 29 30 30 30 30 30 47 47 47 35 35

A 223 223 223 223 249 249 249 249 249 320 320 320 356 356

B 110 110 110 110 110 110 110 110 110 160 160 160 160 160

C 18 18 18 18 18 18 18 18 18 18 18 18 18 18

D 259 259 259 259 305 305 305 305 305 381 381 381 430 430

E 358 358 358 358 420 420 420 420 420 516 516 516 549 549

m 56 56 56 56 86 86 86 86 86 192 192 192 260 260

Metric Units

A D

B

C

H

a

b

E

S

1

S

2

15 LWN487.61-E

Howtoorder-Art|c|enumbers

D E F D E F G H G H J J K L L M N P Q R T

G H J K+ N+ P+ R+ T+

Body materiaI: WCB (1.0619)

Pressure range ArticIe-No

8112. 0010 0020 0030 1820 0040 0050 0060 1830 0070 0080 1840 0090 0100 0110 1850 0120 0130 0140 1860 0150 0160 0170 0180 1870 0190 0200 1880 0210 1890

8112. 0220 0230 0240 1900 0250 0260 0270 1910 0280 0290 1920 0300 0310 0320 1930 0330 0340 0350 1940 0360 0370 0380 0390 1950 0400 0410 1960 0420 1970

8112. 0640 0650 0660 2060 0670 0680 0690 2070 0700 0710 2080 0720 0730 0740 2090 0750 0760 0770 2100 0780 0790 0800 0810 2110 0820 0830 2120 0840 2130

D E F D E F G H G H J J K L L M N P Q R T

G H J K+ N+ P+ R+ T+

Body materiaI: CF8M (1.4408)

Pressure range ArticIe-No

8114. 0010 0020 0030 1820 0040 0050 0060 1830 0070 0080 1840 0090 0100 0110 1850 0120 0130 0140 1860 0150 0160 0170 0180 1870 0190 0200 1880 0210 1890

8114. 0220 0230 0240 1900 0250 0260 0270 1910 0280 0290 1920 0300 0310 0320 1930 0330 0340 0350 1940 0360 0370 0380 0390 1950 0400 0410 1960 0420 1970

8114. 0640 0650 0660 2060 0670 0680 0690 2070 0700 0710 2080 0720 0730 0740 2090 0750 0760 0770 2100 0780 0790 0800 0810 2110 0820 0830 2120 0840 2130

D E F D E F G H G H J J K L L M N P Q R T

G H J K+ N+ P+ R+ T+

Body materiaI: LCB

Pressure range ArticIe-No

8113. 0010 0020 0030 1820 0040 0050 0060 1830 0070 0080 1840 0090 0100 0110 1850 0120 0130 0140 1860 0150 0160 0170 0180 1870 0190 0200 1880 0210 1890

8113. 0220 0230 0240 1900 0250 0260 0270 1910 0280 0290 1920 0300 0310 0320 1930 0330 0340 0350 1940 0360 0370 0380 0390 1950 0400 0410 1960 0420 1970

8113. 0640 0650 0660 2060 0670 0680 0690 2070 0700 0710 2080 0720 0730 0740 2090 0750 0760 0770 2100 0780 0790 0800 0810 2110 0820 0830 2120 0840 2130

Orifice

Orifice

Orifice

ArticIe numbers

150 x 150

300 x 150

600 x 150

ArticIe numbers

ArticIe numbers

150 x 150

300 x 150

600 x 150

600 x 150

4 x 6 6 x 8 8 x 10

Extra Orifice

1 x 3 2 x 3 3 x 4

Size

1 x 2 1 x 2

Extra Orifice

150 x 150

300 x 150

2 x 3

Size

1 x 2

Extra Orifice

1 x 2 1 x 3 2 x 3

Size

1 x 2

1 x 2 1 x 3

6 x 8 8 x 10 3 x 4 4 x 6

8 x 10 3 x 4 4 x 6 6 x 8

16 LWN487.61-E

Howtoorder-Art|c|enumbers

D E F D E F G H G H J J K L L M N P Q R FB T

G H J K+ N+ P+ R+ T+

Body materiaI: WCB (1.0619)

Pressure range ArticIe-No

8212. 0010 0020 0030 1820 0040 0050 0060 1830 0070 0080 1840 0090 0100 0110 1850 0120 0130 0140 1860 0150 0160 0170 0180 1870 0190 0200 1880 0210 1890

8212. 0220 0230 0240 1900 0250 0260 0270 1910 0280 0290 1920 0300 0310 0320 1930 0330 0340 0350 1940 0360 0370 0380 0390 1950 0400 0410 1960 0420 1970

8212. 0640 0650 0660 2060 0670 0680 0690 2070 0700 0710 2080 0720 0730 0740 2090 0750 0760 0770 2100 0780 0790 0800 0810 2110 0820 0830 2120 0840 2130

D E F D E F G H G H J J K L L M N P Q R FB T

G H J K+ N+ P+ R+ T+

Body materiaI: CF8M (1.4408)

Pressure range ArticIe-No

8214. 0010 0020 0030 1820 0040 0050 0060 1830 0070 0080 1840 0090 0100 0110 1850 0120 0130 0140 1860 0150 0160 0170 0180 1870 0190 0200 1880 0210 1890

8214. 0220 0230 0240 1900 0250 0260 0270 1910 0280 0290 1920 0300 0310 0320 1930 0330 0340 0350 1940 0360 0370 0380 0390 1950 0400 0410 1960 0420 1970

8214. 0640 0650 0660 2060 0670 0680 0690 2070 0700 0710 2080 0720 0730 0740 2090 0750 0760 0770 2100 0780 0790 0800 0810 2110 0820 0830 2120 0840 2130

D E F D E F G H G H J J K L L M N P Q R FB T

G H J K+ N+ P+ R+ T+

Body materiaI: LCB

Pressure range ArticIe-No

8213. 0010 0020 0030 1820 0040 0050 0060 1830 0070 0080 1840 0090 0100 0110 1850 0120 0130 0140 1860 0150 0160 0170 0180 1870 0190 0200 1880 0210 1890

8213. 0220 0230 0240 1900 0250 0260 0270 1910 0280 0290 1920 0300 0310 0320 1930 0330 0340 0350 1940 0360 0370 0380 0390 1950 0400 0410 1960 0420 1970

8213 0640 0650 0660 2060 0670 0680 0690 2070 0700 0710 2080 0720 0730 0740 2090 0750 0760 0770 2100 0780 0790 0800 0810 2110 0820 0830 2120 0840 2130

150 x 150

300 x 150

600 x 150

ArticIe numbers

Size

Orifice

Extra Orifice

ArticIe numbers

Size

Orifice

Extra Orifice

ArticIe numbers

Size

Orifice

Extra Orifice

300 x 150

600 x 150

150 x 150

300 x 150

600 x 150

150 x 150

4 x 6

1 x 2 1 x 3

6 x 8 8 x 10 1 x 2 1 x 3 2 x 3 3 x 4 1 x 2

8 x 10 2 x 3 3 x 4 4 x 6 6 x 8 1 x 2

4 x 6 6 x 8 8 x 10 1 x 3 2 x 3 3 x 4 1 x 2 1 x 2

Pilot Operated Safety Valve

Edition April 2009

LWN 487.61-E / 04.2009 / 3000

20537 Hamburg, Wendenstr. 133-135

20506 Hamburg, P.O. Box 26 16 51

Fon +49 (40) 251 65-100

Fax +49 (40) 251 65-500

LESER GmbH & Co. KG E-Mail: sales@leser.com

www.leser.com

The-Safety-Valve.com

Anda mungkin juga menyukai

- Hydraulic System Troubleshooting GuideDokumen27 halamanHydraulic System Troubleshooting Guidekhumiso100% (1)

- Troubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreDari EverandTroubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreBelum ada peringkat

- Screw Compressors: Damian Vogt Course MJ2429Dokumen12 halamanScrew Compressors: Damian Vogt Course MJ2429Aneeq RaheemBelum ada peringkat

- 1final Project - Design of A Concrete Vibrating TableDokumen50 halaman1final Project - Design of A Concrete Vibrating Tablesajjad_naghdi241100% (2)

- 1final Project - Design of A Concrete Vibrating TableDokumen50 halaman1final Project - Design of A Concrete Vibrating Tablesajjad_naghdi241100% (2)

- Presentation Centrifugal 02.ppsxDokumen97 halamanPresentation Centrifugal 02.ppsxEslam Elmadboly100% (1)

- Pressure Relief Safety Valves (SNR)Dokumen43 halamanPressure Relief Safety Valves (SNR)Syed Naveed Raza100% (1)

- Pressure Vessels Field Manual: Common Operating Problems and Practical SolutionsDari EverandPressure Vessels Field Manual: Common Operating Problems and Practical SolutionsPenilaian: 4 dari 5 bintang4/5 (12)

- Process Industry Practices Machinery: Pip Reec001 General Guidelines For Compressor SelectionDokumen62 halamanProcess Industry Practices Machinery: Pip Reec001 General Guidelines For Compressor SelectionalainBelum ada peringkat

- Failure Analysis of Fire Tube Liner (Sleeve)Dokumen6 halamanFailure Analysis of Fire Tube Liner (Sleeve)Mahmoud AbdullahBelum ada peringkat

- BORSIG ZM Compression - Innovative Solutions for Process Gas CompressionDokumen16 halamanBORSIG ZM Compression - Innovative Solutions for Process Gas CompressionMachineryengBelum ada peringkat

- Gas LiftDokumen66 halamanGas LiftWahyu NugrahaBelum ada peringkat

- Heat ExchangersDokumen62 halamanHeat ExchangersMahmoud Abdelaal100% (2)

- Presentation On Heat ExchangersDokumen54 halamanPresentation On Heat ExchangersNagendrababu Mahapatruni100% (1)

- Ondition Onitoring: P - H N.SDokumen39 halamanOndition Onitoring: P - H N.Sकृष्णकुमार दत्तात्रेय जोशीBelum ada peringkat

- Constant Level Oiler - Vented or NonventedDokumen7 halamanConstant Level Oiler - Vented or Nonventedpeach5Belum ada peringkat

- Safety ValveDokumen56 halamanSafety ValveAbhishek KumarBelum ada peringkat

- Plant Engineering and Design The Ultimate Step-By-Step GuideDari EverandPlant Engineering and Design The Ultimate Step-By-Step GuideBelum ada peringkat

- Valves: Training Centre Wednesday, December 7, 2 016Dokumen77 halamanValves: Training Centre Wednesday, December 7, 2 016Hoang DucBelum ada peringkat

- Shell Corrosion Under InsulationDokumen16 halamanShell Corrosion Under InsulationDavide CongiuBelum ada peringkat

- Oil and Gas Static Equipment OperationsDokumen93 halamanOil and Gas Static Equipment OperationssajiBelum ada peringkat

- John CraneDokumen83 halamanJohn CraneVj KrshkumrBelum ada peringkat

- Question and Answer On Steam TurbinesDokumen33 halamanQuestion and Answer On Steam TurbineschunkyBelum ada peringkat

- Stress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsDari EverandStress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsBelum ada peringkat

- Relief ValvesDokumen59 halamanRelief ValvesAli Naveed Farooki100% (2)

- 01 220043enc Routine Turbine MaintenanceDokumen8 halaman01 220043enc Routine Turbine Maintenanceajipramudio100% (1)

- Equipment DetailsDokumen33 halamanEquipment DetailsSaif Siddiqui100% (1)

- Basics Steam Boilers Section B 2Dokumen31 halamanBasics Steam Boilers Section B 2Jagdeep ArryBelum ada peringkat

- Compressors - Written ReportDokumen17 halamanCompressors - Written ReportJenina Rosa P. LlanesBelum ada peringkat

- Valves Guide: Types, Parts, Standards & SpecificationsDokumen141 halamanValves Guide: Types, Parts, Standards & SpecificationsrichardBelum ada peringkat

- Steam CondenserDokumen20 halamanSteam CondensernitinBelum ada peringkat

- Turbomachinery Selection Exploitation and MaintenanceDokumen9 halamanTurbomachinery Selection Exploitation and MaintenanceMichael Chikwendu100% (1)

- FURNACEDokumen74 halamanFURNACESonam Bijaya100% (2)

- Why A Shell and Tube Heat Exchanger?Dokumen17 halamanWhy A Shell and Tube Heat Exchanger?Avishek KumarBelum ada peringkat

- Centrifugal Pumps and SealDokumen32 halamanCentrifugal Pumps and SealAnatoli KarpobBelum ada peringkat

- Relief valve leak tightness testing at 90% CDTPDokumen5 halamanRelief valve leak tightness testing at 90% CDTPabdoBelum ada peringkat

- Floating Head Heat Exchangers: Maintenance & PartsDokumen44 halamanFloating Head Heat Exchangers: Maintenance & PartsskgbondBelum ada peringkat

- TutoDokumen2 halamanTutoFfmohamad NAdBelum ada peringkat

- 4.10 Shaft SealingDokumen11 halaman4.10 Shaft SealingSandi AslanBelum ada peringkat

- Air Heaters: Requirement, Types ConstructionDokumen20 halamanAir Heaters: Requirement, Types ConstructionArvind ShuklaBelum ada peringkat

- Turbine Auxiliaries - Arrangement of Turbine Auxiliaries - ALL ABOUT POWER PLANTDokumen14 halamanTurbine Auxiliaries - Arrangement of Turbine Auxiliaries - ALL ABOUT POWER PLANTKolahalam RakeshrajuBelum ada peringkat

- Troubleshooting Shell-And-Tube Heat ExchangersDokumen2 halamanTroubleshooting Shell-And-Tube Heat ExchangersForcus onBelum ada peringkat

- HRSG Final InspectionDokumen8 halamanHRSG Final Inspectionmkarahan100% (1)

- Lect 3Dokumen43 halamanLect 3Mahesh KumarBelum ada peringkat

- Troubleshooting of Rotating EquipmentsDokumen4 halamanTroubleshooting of Rotating Equipmentss33d_2010Belum ada peringkat

- Let's Talk About How They Compress AirDokumen6 halamanLet's Talk About How They Compress AirrahulBelum ada peringkat

- Fire Fighting Course Outline NWDokumen5 halamanFire Fighting Course Outline NWMuhammadBelum ada peringkat

- AFT XStream Data SheetDokumen2 halamanAFT XStream Data SheetdelitesoftBelum ada peringkat

- Draft Boiler and FurnaceDokumen8 halamanDraft Boiler and FurnaceJayandi FitraBelum ada peringkat

- PSVDokumen32 halamanPSVAhtsham Ahmad100% (2)

- Pap 2Dokumen68 halamanPap 2Aziz SyahrizalBelum ada peringkat

- Bomba A10vso Bosch RexrothDokumen5 halamanBomba A10vso Bosch RexrothHIDRAFLUIDBelum ada peringkat

- Steam Turbine Design GuideDokumen27 halamanSteam Turbine Design GuideEkta Gupta50% (2)

- Understanding Tube Failures in High Pressure Boilers PDFDokumen2 halamanUnderstanding Tube Failures in High Pressure Boilers PDFPravin KumarBelum ada peringkat

- Project PPT of Heat ExchangerDokumen18 halamanProject PPT of Heat ExchangerGaurav Thakkar50% (2)

- Power Plant Engineering Final Exam 2013-2014:) ططخم و راخبلا لودج مادختساب حمسي s - h (Answer Five Questions OnlyDokumen7 halamanPower Plant Engineering Final Exam 2013-2014:) ططخم و راخبلا لودج مادختساب حمسي s - h (Answer Five Questions Onlyxan pitchuBelum ada peringkat

- Group#02Dokumen29 halamanGroup#02amir zia100% (1)

- Safety Valves and Relief Valves.Dokumen17 halamanSafety Valves and Relief Valves.Shikhar SwaroopBelum ada peringkat

- Faisal Khan - CV PDFDokumen4 halamanFaisal Khan - CV PDFHENRY LAPACABelum ada peringkat

- FM Safety Relief Valve Folder Vsr1n2colour Nov05Dokumen4 halamanFM Safety Relief Valve Folder Vsr1n2colour Nov05jabalpuramit100% (1)

- Industrial Valves Module 1 Functions TypesDokumen66 halamanIndustrial Valves Module 1 Functions TypesUmar DrazBelum ada peringkat

- Compressor Turbo-Air API a4-IRDokumen12 halamanCompressor Turbo-Air API a4-IRMachineryengBelum ada peringkat

- Bearing Life TimeDokumen83 halamanBearing Life TimeFadoooll100% (1)

- Mechanical Interview QuestionsDokumen3 halamanMechanical Interview Questionsz_sheerazBelum ada peringkat

- Asset Integrity Management A Complete Guide - 2020 EditionDari EverandAsset Integrity Management A Complete Guide - 2020 EditionBelum ada peringkat

- Corrosion Failures: Theory, Case Studies, and SolutionsDari EverandCorrosion Failures: Theory, Case Studies, and SolutionsBelum ada peringkat

- A. Hot Air Oven Specification: Inner Chamber Load Shelves (WXDXH) (Liters) (KW) (No'S) Model NoDokumen1 halamanA. Hot Air Oven Specification: Inner Chamber Load Shelves (WXDXH) (Liters) (KW) (No'S) Model Nosajjad_naghdi241Belum ada peringkat

- Final Data Flow: Sensor Arduino Raspberry PiDokumen1 halamanFinal Data Flow: Sensor Arduino Raspberry Pisajjad_naghdi241Belum ada peringkat

- Video 5 - States of The MarketsDokumen1 halamanVideo 5 - States of The Marketssajjad_naghdi241Belum ada peringkat

- Iot-Shm: Internet of Things: Structural Health Monitor: Reinaldo422@Gatech - EduDokumen38 halamanIot-Shm: Internet of Things: Structural Health Monitor: Reinaldo422@Gatech - Edusajjad_naghdi241Belum ada peringkat

- How Big Players Impact TradersDokumen1 halamanHow Big Players Impact TradersCristian MangoBelum ada peringkat

- 02Dokumen276 halaman02sajjad_naghdi241Belum ada peringkat

- Video 2 - Logic of Trading On ChartsDokumen1 halamanVideo 2 - Logic of Trading On Chartssajjad_naghdi241Belum ada peringkat

- Video 3 - Intro To Big BoysDokumen1 halamanVideo 3 - Intro To Big Boyssajjad_naghdi241Belum ada peringkat

- Kaleydar - Jelde 1Dokumen390 halamanKaleydar - Jelde 1civilgirl66Belum ada peringkat

- How Big Players Impact TradersDokumen1 halamanHow Big Players Impact TradersCristian MangoBelum ada peringkat

- Structural Health MonitoringDokumen14 halamanStructural Health Monitoringsajjad_naghdi241Belum ada peringkat

- ANSI Safety Relief Valve GuideDokumen22 halamanANSI Safety Relief Valve Guidesajjad_naghdi241Belum ada peringkat

- Guage Thickness in MM Weight Per Sq. Ft. Weight Per Pc. Kgs. Pc. IN M/TonDokumen3 halamanGuage Thickness in MM Weight Per Sq. Ft. Weight Per Pc. Kgs. Pc. IN M/Tonsajjad_naghdi241Belum ada peringkat

- Sulzer Sense Wireless Iot Condition Monitoring: Save Time and MoneyDokumen2 halamanSulzer Sense Wireless Iot Condition Monitoring: Save Time and Moneysajjad_naghdi241Belum ada peringkat

- Gas Turbine Order Data SampleDokumen13 halamanGas Turbine Order Data Samplesajjad_naghdi241Belum ada peringkat

- Arizona Public Service Scales Investment in Iiot Based PDM With PetasenseDokumen2 halamanArizona Public Service Scales Investment in Iiot Based PDM With Petasensesajjad_naghdi241Belum ada peringkat

- Gekko TutorialDokumen55 halamanGekko Tutorialsajjad_naghdi2410% (1)

- Pipe On SupportsDokumen8 halamanPipe On SupportsMahesh KoiladaBelum ada peringkat

- 1final Project - Design of A Concrete Vibrating TableDokumen28 halaman1final Project - Design of A Concrete Vibrating Tablesajjad_naghdi241Belum ada peringkat

- PDM vs. PLM: It All Starts With PDM: White PaperDokumen7 halamanPDM vs. PLM: It All Starts With PDM: White Papersajjad_naghdi241Belum ada peringkat

- 0105smit PDFDokumen4 halaman0105smit PDFsajjad_naghdi241Belum ada peringkat

- Dynamics of CranesDokumen46 halamanDynamics of CranesGogyBelum ada peringkat

- dSPACE Tutorial PDFDokumen22 halamandSPACE Tutorial PDFHichem HamdiBelum ada peringkat

- 2Dokumen26 halaman2dongheep811Belum ada peringkat

- Vibration MachineDokumen7 halamanVibration Machinesajjad_naghdi241Belum ada peringkat

- PHD RegulationsDokumen25 halamanPHD Regulationssajjad_naghdi241Belum ada peringkat

- 2 - Kinematics of Mechanisms - Instantaneous Center MethodDokumen4 halaman2 - Kinematics of Mechanisms - Instantaneous Center MethodGaurav GuptaBelum ada peringkat

- ME321 Notes 1Dokumen10 halamanME321 Notes 1SamuelHericBelum ada peringkat

- Installation Guide SummaryDokumen6 halamanInstallation Guide SummaryLuis Meza ArevaloBelum ada peringkat

- JISKOOT Hybrid Cell Sampler ManualDokumen46 halamanJISKOOT Hybrid Cell Sampler ManualJuancho GuzmanBelum ada peringkat

- Bermad Waterworks ValvulasDokumen170 halamanBermad Waterworks ValvulasJoséBelum ada peringkat

- Design Guide For Multi-Stage Restriction Orifices (Ros) Plates With 1 Hole and N 3 HolesDokumen38 halamanDesign Guide For Multi-Stage Restriction Orifices (Ros) Plates With 1 Hole and N 3 HolesEnrique Riera100% (1)

- Aircraft Pneumatic Systems ExplainedDokumen8 halamanAircraft Pneumatic Systems ExplainedRam KumarBelum ada peringkat

- Aerodinámica de OjivasDokumen154 halamanAerodinámica de OjivasEsteban MoccagattaBelum ada peringkat

- PSV - General GuidelinesDokumen60 halamanPSV - General GuidelinesamrazamBelum ada peringkat

- Flow Separation or Boundary Layer Separation IsDokumen4 halamanFlow Separation or Boundary Layer Separation Isengineer bilalBelum ada peringkat

- Parts Available For: E-1 (Water Pump /cooling Fan) : Ref No. Part Number Description Reqd. No MOQ MRP (RS.)Dokumen1 halamanParts Available For: E-1 (Water Pump /cooling Fan) : Ref No. Part Number Description Reqd. No MOQ MRP (RS.)senthilnaveenBelum ada peringkat

- SDV40 & SDV70: Sectional Directional Control ValveDokumen35 halamanSDV40 & SDV70: Sectional Directional Control ValveJeisson RodriguezBelum ada peringkat

- Bernoulli Equation GuideDokumen33 halamanBernoulli Equation Guidenaru_saBelum ada peringkat

- Dual Element 9100-9202 Info SheetDokumen3 halamanDual Element 9100-9202 Info Sheetapi-449237312Belum ada peringkat

- Spare Part List - Brewhouse & Cellar FinalDokumen26 halamanSpare Part List - Brewhouse & Cellar FinalYen NguyenBelum ada peringkat

- Tutorial 3Dokumen3 halamanTutorial 3Andrew0% (1)

- ButtWeld Swivel Flange - ISO 6164Dokumen1 halamanButtWeld Swivel Flange - ISO 6164nemi90Belum ada peringkat

- Ex KodlariDokumen1 halamanEx KodlaridhnsekaranBelum ada peringkat

- Reinforcing Saddle Dimensions ChartDokumen1 halamanReinforcing Saddle Dimensions ChartRyan DuhonBelum ada peringkat

- Test Bank For Equipment Theory For Respiratory Care 5th Edition by WhiteDokumen28 halamanTest Bank For Equipment Theory For Respiratory Care 5th Edition by WhiteJohn Smoldt100% (28)

- Nov Dec 208-6Dokumen4 halamanNov Dec 208-6Deshmukh DattaBelum ada peringkat

- TD Series Data Sheet: "H" VersionDokumen4 halamanTD Series Data Sheet: "H" VersionCapacitacion TodocatBelum ada peringkat

- VZ Series: Operating InstructionsDokumen42 halamanVZ Series: Operating InstructionsЮрий ДмитриевBelum ada peringkat

- Safety Meo Class 4 CocDokumen16 halamanSafety Meo Class 4 CocROSHANBelum ada peringkat

- Chapter 7 - Work Study (Time and Motion Study)Dokumen8 halamanChapter 7 - Work Study (Time and Motion Study)Pankaj KanatheBelum ada peringkat