Software Verification: Example 17

Diunggah oleh

sancloudJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Software Verification: Example 17

Diunggah oleh

sancloudHak Cipta:

Format Tersedia

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

EXAMPLE 17 - 1

EXAMPLE 17

Crack Width Analysis

The crack width, w

k

, is calculated using the methodology described in the

Eurocode EN 1992-1-1:2004, Section 7.3.4, which makes use of the following

expressions:

(1)

,max

( )

k r sm cm

w s = c c (eq. 7.8)

where

s

r,max

is the maximum crack spacing

c

sm

is the mean strain in the reinforcement under the relevant combination

of loads, including the effect of imposed deformations and taking into

account the effects of tension stiffening. Only the additional tensile

strain beyond the state of zero strain of the concrete at the same level

is considered.

c

cm

is the mean strain in the concrete between cracks

(2) c

sm

c

cm

may be calculated from the expression

( )

,eff

.eff

,eff

1

0.6

ct

s t e p

p

s

sm cm

s s

f

k

E

E E

o + o

o

c c = > (eq. 7.9)

where

o

s

is the stress in the tension reinforcement assuming a cracked section.

For pretensioned members, o

s

may be replaced by Ao

s

, the stress

variation in prestressing tendons from the state of zero strain of the

concrete at the same level.

o

e

is the ratio E

c

/E

cm

p,eff

is A

s

/ A

c,eff

A

p

' and A

c,eff

; A

p

' is the area of tendons within A

c,eff

, and A

c,eff

is the area of

tension concrete surrounding the reinforcing.

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

EXAMPLE 17 - 2

k

t

is a factor dependent on the duration of the load

k

t

= 0.6 for short term loading

k

t

= 0.4 for long-term loading

(3) In situations where bonded reinforcement is fixed at reasonably close

centers within the tension zone [spacing s 5(c + | / 2)], the maximum final

crack spacing may be calculated from

s

r,max

= k

3

c +k

1

k

2

k

4

| /

p,eff

(eq. 7.11)

where

| is the bar diameter. Where a mixture of bar diameters is used in a

section, an equivalent diameter, |

eq

, should be used. For a section with

n

1

bars of diameter |

1

and n

2

bars of diameter |

2

, the following equation

should be used:

2 2

1 1 2 2

1 1 2 2

eq

n n

n n

| + |

| =

| + |

(eq. 7.12)

where

c is the cover to the longitudinal reinforcement

k

1

is a coefficient that takes into account the bond properties of the bonded

reinforcement:

= 0.8 for high bond bars

= 1.6 for bars with an effectively plain surface (e.g., prestressing

tendons)

k

2

is a coefficient that takes into account the distribution of strain:

= 0.5 for bending

= 1.0 for pure tension

k

3

and k

4

are recommended as 3.4 and 0.425 respectively. See the

National Annex for more information.

For cases of eccentric tension or for local areas, intermediate values of k

2

should be used that may be calculated from the relation:

k

2

=(c

1

+c

2

) / 2c

1

(eq. 7.13)

where c

1

is the greater and c

2

is the lesser tensile strain at the boundaries of

the section considered, assessed on the basis of a cracked section.

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

EXAMPLE 17 - 3

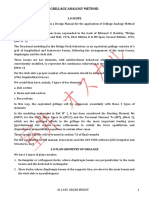

PROBLEM DESCRIPTION

The purpose of this example is to verify that the crack width calculation

performed by SAFE is consistent with the methodology described above. Hand

calculations using the Eurocode EN 1992-1-1:2004, Section 7.3.4 are shown

below as well as a comparison of the SAFE and hand calculated results.

A one-way, simply supported slab is modeled in SAFE. The modeled slab is 254

mm thick by 914 mm wide and spans 9,754 mm, as shown in Figure 17-1, and is

the same slab used to validate the Eurocode PT design (see design verification

example Eurocode 2-04 PT-SL-001). To test the crack width calculation, seven

#5 longitudinal bars have been added to the slab. The total area of mild steel

reinforcement is 1,400mm

2

. Currently, SAFE will account for some of the PT

effects. SAFE accounts for the PT effects on the moments and reinforcing

stresses but the tendon areas are not considered effective to resist cracking.

Length, L = 9754 mm

Elevation Section

Prestressing tendon, Ap

Mild Steel, As

914 mm

25 mm

229 mm

254 mm

Length, L = 9754 mm

Elevation Section

Prestressing tendon, Ap

Mild Steel, As

914 mm

25 mm

229 mm

254 mm

Figure 17-1 One-Way Slab

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

EXAMPLE 17 - 4

A 254-mm-wide design strip is centered along the length of the slab and has been

defined as an A-Strip. B-strips have been placed at each end of the span,

perpendicular to Strip-A (the B-Strips are necessary to define the tendon profile).

A tendon with two strands, each having an area of 99 mm

2

, was added to the A-

Strip. The loads are as follows:

Loads: Dead = self weight

GEOMETRY, PROPERTIES AND LOADING

Thickness T, h = 254 mm

Effective depth d = 229 mm

Clear span L = 9754 mm

Concrete strength f '

c

= 30 MPa

Yield strength of steel f

y

= 400 MPa

Prestressing, ultimate f

pu

= 1862 MPa

Prestressing, effective f

e

= 1210 MPa

Area of Prestress (single strand) A

p

= 198 mm

2

Concrete unit weight w

c

= 23.56 KN/m

3

Modulus of elasticity E

c

= 25000 N/mm

3

Modulus of elasticity E

s

= 200,000 N/mm

3

Poissons ratio v = 0

Dead load w

d

= self KN/m

2

TECHNICAL FEATURES OF SAFE TESTED

Calculation of the reported crack widths.

RESULTS COMPARISON

Table 1 shows the comparison of the SAFE crack widths to those calculated by

hand.

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

EXAMPLE 17 - 5

Table 1 Comparison of Results

FEATURE TESTED

INDEPENDENT

RESULTS

SAFE

RESULTS

DIFFERENCE

Crack Widths (mm) 0.151mm 0.147mm 2.60%

COMPUTER FILE: S17.FDB

CONCLUSION

The SAFE results show an acceptable comparison with the independent results.

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

EXAMPLE 17 - 6

HAND CALCULATIONS:

Design Parameters:

Mild Steel Reinforcing Post-Tensioning

fc =30MPa f

pu

=1862 MPa

fy =400MPa f

py

=1675 MPa

Stressing Loss = 186 MPa

Long-Term Loss = 94 MPa

f

i

=1490 MPa

f

e

=1210 MPa

Length, L = 9754 mm

Elevation Section

Prestressing tendon, Ap

Mild Steel, As

914 mm

25 mm

229 mm

254 mm

Length, L = 9754 mm

Elevation Section

Prestressing tendon, Ap

Mild Steel, As

914 mm

25 mm

229 mm

254 mm

Loads:

Dead, self-wt =0.254 m x 23.56 kN/m

3

= 5.984 kN/m

2

(D)

e =5.984 kN/m

2

x 0.914 m =5.469 kN/m

Ultimate Moment,

2

1

8

U

wl

M = = 5.469 x (9.754)

2

/8 =65.0 kN-m

Reinforcing steel stress,

2

207N / mm o = (calculated but not reported by SAFE)

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

EXAMPLE 17 - 7

Check of Concrete Stresses at Midspan:

Figure 17-1 Settings used for this example

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

EXAMPLE 17 - 8

Calculation of Crack Width:

,max

( ) = c c

k r sm cm

w s

where

( )

,eff

,eff

,eff

1

0.6

o + o

o

c c = >

ct

s t e p

p

s

sm cm

s s

f

k

E E

, where

( )

2 2

,eff .eff

/ 1.53mm / mm/ 60mm / mm = =

p c

As A

0026

p,eff

. =

( ) ( )

2

2

1.744 / mm

206 / mm 0.4 1 8 0.026

206

0.026

0.6

199948 199948

+

c c = >

sm cm

N

N

00009 00006 c c = >

sm cm

. .

,max 3 1 2 4 ,eff

/ = + |

r p

s k c k k k ( ) ( )( ) 3.4 19.0mm 0.8 0.5 0.425 15.8mm/ 0.026 = +

168mm =

Total crack width,

k r ,max sm cm

w s ( ) c c = = ( ) 168mm 0.0009 0.151mm =

Anda mungkin juga menyukai

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDari EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionBelum ada peringkat

- Vertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisDokumen10 halamanVertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisNeven Ahmed HassanBelum ada peringkat

- Huong Dan MegafloorDokumen11 halamanHuong Dan Megafloortrung1983Belum ada peringkat

- Seismic Design of Concrete StructuresDokumen56 halamanSeismic Design of Concrete Structuresclarkgagui100% (1)

- Building Story Drift in ETABS PDFDokumen10 halamanBuilding Story Drift in ETABS PDFntirugiribambeBelum ada peringkat

- RC Beam Design Procedure SummaryDokumen4 halamanRC Beam Design Procedure SummaryRohana Illukkumbura100% (1)

- Tubular Profiles For Telecom Structures PDFDokumen8 halamanTubular Profiles For Telecom Structures PDFJitendraBelum ada peringkat

- Punching Shear design and reinforcement calculationDokumen4 halamanPunching Shear design and reinforcement calculationMohafisto SofistoBelum ada peringkat

- Moment Connection Using Mathcad PDFDokumen11 halamanMoment Connection Using Mathcad PDFbong2rmBelum ada peringkat

- Strut and tie modeling, yield line analysis, and plastic analysis of concrete and steel structuresDokumen9 halamanStrut and tie modeling, yield line analysis, and plastic analysis of concrete and steel structuresmalumius100% (2)

- Daniel Tian Li: Plain Concrete Footing Design Based On ACI 318-05Dokumen2 halamanDaniel Tian Li: Plain Concrete Footing Design Based On ACI 318-05Wintun73Belum ada peringkat

- Wind Load On The RoofDokumen14 halamanWind Load On The RoofHussein HasenBelum ada peringkat

- Sway Frame Steel Column DesignDokumen1 halamanSway Frame Steel Column DesignChirianu MarianBelum ada peringkat

- Openwell StaircaseDokumen8 halamanOpenwell StaircaseAbdul AzeemBelum ada peringkat

- Base Shear ComputationDokumen5 halamanBase Shear ComputationAmante MorenoBelum ada peringkat

- Design of Tall Structures Unit - 2: Wind Load and Earthquake LoadingDokumen12 halamanDesign of Tall Structures Unit - 2: Wind Load and Earthquake LoadingDarshanBelum ada peringkat

- Cantilever FrameDokumen3 halamanCantilever FrameNikki RobertsBelum ada peringkat

- Retaining Wall Analysis & Design (BS8002 - 1994)Dokumen10 halamanRetaining Wall Analysis & Design (BS8002 - 1994)IKBelum ada peringkat

- Beam On Elastic Foundation AnalysisDokumen5 halamanBeam On Elastic Foundation AnalysisMagdy BakryBelum ada peringkat

- Base Plate DesignDokumen1 halamanBase Plate DesignmadodandembeBelum ada peringkat

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Dokumen7 halaman1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12asuncionBelum ada peringkat

- تصميم الكمرات بطريقة ultimate PDFDokumen42 halamanتصميم الكمرات بطريقة ultimate PDFqaisalkurdyBelum ada peringkat

- Member resistance under combined bi-axial bending and axial compressionDokumen12 halamanMember resistance under combined bi-axial bending and axial compressionrd radenBelum ada peringkat

- ASCE7 Wind For Cladding CN8 Block BDokumen4 halamanASCE7 Wind For Cladding CN8 Block BCheng KoBelum ada peringkat

- Portal Method: For Transversal/Longitudinal SectionDokumen70 halamanPortal Method: For Transversal/Longitudinal SectionJoseph Tan LantoBelum ada peringkat

- Earthquake Resistant Design of Steel StructuresDokumen12 halamanEarthquake Resistant Design of Steel StructuresFranklin GarciaBelum ada peringkat

- Dynamic Analysis of Steel Structure With Bracings and Dampers Under Wind and Earthquake LoadsDokumen5 halamanDynamic Analysis of Steel Structure With Bracings and Dampers Under Wind and Earthquake LoadsEditor IJTSRDBelum ada peringkat

- Welds of A Fin Plate ConnectionDokumen2 halamanWelds of A Fin Plate Connectioncretz2Belum ada peringkat

- RCC Beams: Doubly Reinforced BeamDokumen2 halamanRCC Beams: Doubly Reinforced BeamSandeep ChavanBelum ada peringkat

- Mechanical Columns Buckling FailureDokumen19 halamanMechanical Columns Buckling FailurePraful Patil100% (1)

- 03 1 Weynand Moment Resistant JointsDokumen71 halaman03 1 Weynand Moment Resistant Jointsdeepak_dce_meBelum ada peringkat

- DBR How To MakeDokumen15 halamanDBR How To Maketanmay271100% (1)

- Wind Load IS875Dokumen30 halamanWind Load IS875Pranjal Pareek100% (2)

- Shear Lug Verification Example 2Dokumen1 halamanShear Lug Verification Example 2Nasrul AdliBelum ada peringkat

- Beam DesignDokumen7 halamanBeam DesignKasi ViswanathanBelum ada peringkat

- Geometrical Properties Material Properties: Design of Helicoidal StairDokumen5 halamanGeometrical Properties Material Properties: Design of Helicoidal StairPrashant Verma100% (1)

- Masonry Wall Design - 2Dokumen3 halamanMasonry Wall Design - 2Michael AbandeBelum ada peringkat

- RCFootingDesignWebDokumen3 halamanRCFootingDesignWebjudeBelum ada peringkat

- Description: Welded Lifting LugDokumen2 halamanDescription: Welded Lifting LugHomer SilvaBelum ada peringkat

- Member Stability CheckDokumen3 halamanMember Stability CheckdamindaBelum ada peringkat

- PDS STAAD Foundation Advanced LTR EN LR PDFDokumen2 halamanPDS STAAD Foundation Advanced LTR EN LR PDFAndres Felipe Forero GacharnáBelum ada peringkat

- SikaTack Panel System - Sheet 1 Cert 05 - 4218Dokumen10 halamanSikaTack Panel System - Sheet 1 Cert 05 - 4218Peter DudasBelum ada peringkat

- Steady Flow in Pipes: BTB 323/ Cse 352 Hydraulics Edwin K. Kanda, PHDDokumen19 halamanSteady Flow in Pipes: BTB 323/ Cse 352 Hydraulics Edwin K. Kanda, PHDErick WanduBelum ada peringkat

- Structural Design and Analysis Proposed Three Storey Commercial ResidenceDokumen79 halamanStructural Design and Analysis Proposed Three Storey Commercial ResidenceGEREMY SANTIAGOBelum ada peringkat

- Ch.5 Structural Design of Foundations: Q P L BDokumen8 halamanCh.5 Structural Design of Foundations: Q P L BHusam A. Al-HaidriBelum ada peringkat

- International Lateral LoadsDokumen38 halamanInternational Lateral LoadsRamilArtates100% (1)

- Insight Into Wind Loading of Tall Buildings As Per IS 875 Part 3 (2015)Dokumen10 halamanInsight Into Wind Loading of Tall Buildings As Per IS 875 Part 3 (2015)vatsalgokaniBelum ada peringkat

- Analytical Behavior of Concrete-Encased CFST Columns Under Cyclic Lateral Loading, 2016 (Wei-Wu Qian)Dokumen15 halamanAnalytical Behavior of Concrete-Encased CFST Columns Under Cyclic Lateral Loading, 2016 (Wei-Wu Qian)Phan Đào Hoàng Hiệp100% (1)

- Earthquake Resistant StructuresDokumen6 halamanEarthquake Resistant StructuresAmith KeshvtakarBelum ada peringkat

- CMRL Nehru Park Station column coupler calculationsDokumen6 halamanCMRL Nehru Park Station column coupler calculationsvineetukBelum ada peringkat

- Actual Base Plate Design-V1.2-42-210Dokumen6 halamanActual Base Plate Design-V1.2-42-210Livian TeddyBelum ada peringkat

- RV Design of Column Base PlateDokumen2 halamanRV Design of Column Base Plateapi-190618655Belum ada peringkat

- BS 8110-97 PT-SL-001Dokumen6 halamanBS 8110-97 PT-SL-001riprap100% (1)

- Spreader Beam BLOCK EDokumen23 halamanSpreader Beam BLOCK Evaminos85% (13)

- As 3600-01 RC-BM-001Dokumen7 halamanAs 3600-01 RC-BM-001VinnieTranBelum ada peringkat

- SAFE VerificationDokumen7 halamanSAFE VerificationRahul AggarwalBelum ada peringkat

- Design For 11early Thermal CrackingDokumen9 halamanDesign For 11early Thermal CrackingdhruvgokuBelum ada peringkat

- ENGI 8673 Subsea Pipeline Engineering Lecture 17 ExampleDokumen3 halamanENGI 8673 Subsea Pipeline Engineering Lecture 17 ExampleThyago de LellysBelum ada peringkat

- Linear InterpolationDokumen2 halamanLinear InterpolationsancloudBelum ada peringkat

- 0435Dokumen8 halaman0435sancloudBelum ada peringkat

- ASCE Resources For Steel DesignDokumen8 halamanASCE Resources For Steel DesignTimbo6808100% (1)

- 1Dokumen354 halaman1sancloudBelum ada peringkat

- Example Problem 4.1 Given:: Results SummaryDokumen32 halamanExample Problem 4.1 Given:: Results SummarynguyenduccuongactBelum ada peringkat

- MRFDokumen22 halamanMRFsancloud100% (1)

- Performance-Based Analysis of A Reinforced Concrete Shear Wall BuDokumen126 halamanPerformance-Based Analysis of A Reinforced Concrete Shear Wall BusancloudBelum ada peringkat

- Analysis and Design of A 47-Story Reinforced Concrete Structure PDFDokumen14 halamanAnalysis and Design of A 47-Story Reinforced Concrete Structure PDFovikbasuBelum ada peringkat

- JL 06 May June 5Dokumen3 halamanJL 06 May June 5sancloudBelum ada peringkat

- DesignExample 2Dokumen9 halamanDesignExample 2sancloudBelum ada peringkat

- SEISMIC DESIGN OF NEW RBS MOMENT CONNECTION WITH CORRUGATED WEBDokumen9 halamanSEISMIC DESIGN OF NEW RBS MOMENT CONNECTION WITH CORRUGATED WEBt7acarraBelum ada peringkat

- The Beginner's Guide to Studying ArabicDokumen30 halamanThe Beginner's Guide to Studying ArabicamitBelum ada peringkat

- LRFD 05seminarDokumen3 halamanLRFD 05seminarsancloudBelum ada peringkat

- Two Way Slab: Check For ShearDokumen3 halamanTwo Way Slab: Check For ShearsancloudBelum ada peringkat

- Analysis of Torsion in Prestressed Concrete StructuresDokumen11 halamanAnalysis of Torsion in Prestressed Concrete StructuresNeil DuldulaoBelum ada peringkat

- May 2012 ConveyorDokumen13 halamanMay 2012 ConveyorsancloudBelum ada peringkat

- IBAU HAMBURG Central Cone Silos structural designDokumen28 halamanIBAU HAMBURG Central Cone Silos structural designdox4use100% (1)

- Tech Data 12Dokumen34 halamanTech Data 12sancloudBelum ada peringkat

- NISTIR 5634 Prediction of Cracking in Reinforced Concrete StructuresDokumen51 halamanNISTIR 5634 Prediction of Cracking in Reinforced Concrete Structurespmc_lbm4440Belum ada peringkat

- Etabs To SapDokumen3 halamanEtabs To SapKuber BogatiBelum ada peringkat

- Pratical Guidance For Design of Buildings1 Compatibility Mode 653Dokumen67 halamanPratical Guidance For Design of Buildings1 Compatibility Mode 653Satya Yugandhar GannamaniBelum ada peringkat

- 2 Way SlabDokumen22 halaman2 Way SlabAhmed Al-AmriBelum ada peringkat

- Draft: Finite Element IDokumen73 halamanDraft: Finite Element ISiavash KhademBelum ada peringkat

- Control of Cracking Mohammed Telbani PDFDokumen29 halamanControl of Cracking Mohammed Telbani PDFRaeghoBelum ada peringkat

- RC16 Torsion2Dokumen11 halamanRC16 Torsion2sancloudBelum ada peringkat

- Design of Pile Cap - Strut and Tie MethodDokumen7 halamanDesign of Pile Cap - Strut and Tie MethodHong VeasnaBelum ada peringkat

- Tabla 137 C0016Dokumen22 halamanTabla 137 C0016andradeinsuaBelum ada peringkat

- Indian Standard: Criteria For Design of Steel Bins For Storage of Bulk MaterialsDokumen27 halamanIndian Standard: Criteria For Design of Steel Bins For Storage of Bulk MaterialsajayaghimireBelum ada peringkat

- Solids Notes 10 Hopper DesignDokumen26 halamanSolids Notes 10 Hopper Designellantidinesh100% (1)

- Nemo Handy-A 2.00 ManualDokumen160 halamanNemo Handy-A 2.00 ManualakkarapatBelum ada peringkat

- FortiClient EMS 6.2 Course Description-OnlineDokumen2 halamanFortiClient EMS 6.2 Course Description-OnlineyoubpBelum ada peringkat

- A New Approach: Data Segregation ModelDokumen3 halamanA New Approach: Data Segregation ModelEditor IJRITCCBelum ada peringkat

- 3022Dokumen2 halaman3022markjparrBelum ada peringkat

- Develop Web Services using WSDL and UDDIDokumen13 halamanDevelop Web Services using WSDL and UDDIMahamud elmogeBelum ada peringkat

- IBM OpenPages Admin Guide 7.0 PDFDokumen822 halamanIBM OpenPages Admin Guide 7.0 PDFMba NaniBelum ada peringkat

- 02 18 03 B2B RF Spectrum Analysis Thomas Holmes Hightower 839Dokumen59 halaman02 18 03 B2B RF Spectrum Analysis Thomas Holmes Hightower 839Hatem OdatAllahBelum ada peringkat

- How to Start a Software Company in 3 StepsDokumen3 halamanHow to Start a Software Company in 3 Stepshigh2Belum ada peringkat

- Design, Prototyping and Construction: by Anupa Mogili Arun MuralidharanDokumen51 halamanDesign, Prototyping and Construction: by Anupa Mogili Arun MuralidharanTobi MMBelum ada peringkat

- Sitecore Experience Platform 8.0Dokumen456 halamanSitecore Experience Platform 8.0Pushpaganan NBelum ada peringkat

- Tokyo sales reportDokumen5 halamanTokyo sales reportMariam OkropiridzeBelum ada peringkat

- Grillage Analogy MethodDokumen43 halamanGrillage Analogy Methodkhx2Belum ada peringkat

- Advanced Geometrical Optics by P D Lin Scope TextbDokumen3 halamanAdvanced Geometrical Optics by P D Lin Scope TextbShrey badoniBelum ada peringkat

- HTTP Boot Console LogDokumen31 halamanHTTP Boot Console Logdhiraj.testingBelum ada peringkat

- Computer Network Q - A Part-1Dokumen7 halamanComputer Network Q - A Part-1Avi DahiyaBelum ada peringkat

- Setting Up DB2 With TSMDokumen5 halamanSetting Up DB2 With TSMprakash_6849Belum ada peringkat

- CISSP Cheat Sheet Domain 3Dokumen1 halamanCISSP Cheat Sheet Domain 3Zainulabdin100% (4)

- Datasheet MX 880Dokumen3 halamanDatasheet MX 880jorge_chavez01Belum ada peringkat

- Internet of ThingsDokumen23 halamanInternet of Thingssarada rajBelum ada peringkat

- Computer Notes - Networking and Internet For IBPS Bank ExamDokumen4 halamanComputer Notes - Networking and Internet For IBPS Bank ExamakshitaBelum ada peringkat

- Design and Implementation of Convolutional Neural Network Accelerator Based On RISCVDokumen6 halamanDesign and Implementation of Convolutional Neural Network Accelerator Based On RISCVmadupiz@gmailBelum ada peringkat

- DMC Card 00180020430723Dokumen2 halamanDMC Card 00180020430723jotu sheelaBelum ada peringkat

- VACON-ADP-MCAA adapter guideDokumen10 halamanVACON-ADP-MCAA adapter guideSharad Soni0% (1)

- Online ClassDokumen5 halamanOnline ClassLokendra RathoreBelum ada peringkat

- PHP Interview Questions & AnswersDokumen113 halamanPHP Interview Questions & Answersmudrika100% (1)

- 11.2.3.11 Packet TR Logging From Multiple Sources InstructionsDokumen4 halaman11.2.3.11 Packet TR Logging From Multiple Sources InstructionsNBelum ada peringkat

- CV Software Tester Nguyen Thi Ngoc ThuyDokumen5 halamanCV Software Tester Nguyen Thi Ngoc ThuyNguyễn ThiệnBelum ada peringkat

- Qwikimd TutorialDokumen22 halamanQwikimd TutorialVenkata Suryanarayana GorleBelum ada peringkat

- Script MafiaDokumen2 halamanScript MafiaHassan FethiBelum ada peringkat

- Programming Assignment: Simple TCP / IP Client - Performance TestDokumen3 halamanProgramming Assignment: Simple TCP / IP Client - Performance TestAdis HodzicBelum ada peringkat