6708-EX PUFAS Pufatherm Isolation Panels TI Engl

Diunggah oleh

richashyampatilHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

6708-EX PUFAS Pufatherm Isolation Panels TI Engl

Diunggah oleh

richashyampatilHak Cipta:

Format Tersedia

Technical Information Sheet

pufatherm isolation panels

Extruded rigid polystyrene in the form of a panel with coating facilitating bonding with other materials.

Field of application: Pufatherm are thermal Isolation panels for interior use. The special white bonding bridge makes the panels ready to wallpaper and paint. Reduce the moisture vapour permeability. Mould formation gets avoided and this also improves the indoor climate, due to the effective humidity protection for walls and ceilings. Slight unevenness can be compensated thanks to the panels. The thermal bridges will be reduced. Up to 30 % less heat loss compared to uninsulated brick masonries. - accelerates heating of the air in premises and maintains a given temperature regime - does not absorb water, does not get wet, has no odour - reduces penetration of steam, protects walls and ceilings against moisture - resistant to cement, lime, plaster, alkali, to the release of salts and to nearly all watery substances (not resistant to organic solvents) - does not rot; does not create a nutritive medium for fungal mould - for sanitation of surfaces damaged by condensation and mould Form of the material: Thickness: Density: Format: extruded rigid polystyrene 7 mm 35 kg/m 1.00 m 0.50 m

Distinguishing features:

Technical data:

Preparation of the support:

Old wallpaper and layers of paint which remain and are decomposing due to exposure to water should be removed using PUFAS material for removing wallpaper and glue paints. With the help of PUFAS Fill and Finish filler eliminate surface cracks, holes and dents. After smoothing out and polishing the putty filled surface (if this was necessary), clean away dust on the surface and apply a primer, for example. PUFAS Primer. Rough/structural plasterwork: remove protruding grain, clean away dust, level out using, for example, PUFAS fill and Finish filler. Apply a primer to a highly absorbent support and also to sandy and chalky plasterwork. When using primers containing solvents (for example, for supports made of wooden panels) you must ensure that the odour has completely been driven off by ventilation. Moist areas, sections of the surface infected with mould or affected by release of salts should be carefully cleaned and allowed to dry, ensuring that pre-existing moisture is eliminated.

Handling:

To glue down the pufatherm isolation panels to an absorbent support it is recommended that you apply ready to use dispersion glues such as PUFAS Styrofoam Adhesive. To glue to a support which does not have absorbent qualities, we recommend applying contact glues such as PUFAS Contact Adhesive K12. Use only glues without solvents. 16 m per box (4 VE x 4 m) 6708 - EX Store in a dry and cool place. Unlimited shelf life.

Packaging: Article number: Storage:

PUFAS Werk KG, Im Schedetal 1, D-34346 Hann. Muenden Phone: +49 5541 70 03 -01 Fax: +49 5541 70 03 -08 Internet: www.pufas.com

As of 2012-01-01 Page 1 of 2

Technical Information Sheet pufatherm 7 mm isolation panels

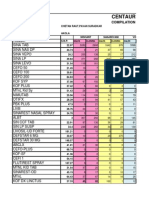

Type of material: Colour: extruded rigid polystyrene grey Heat insulation panel Unit of measurement

Indicator

Symbol

Test method

Dimensions / Dimension Eigenschaften: Thickness/ Schaumdicke Format (l w)/ Format (LxB) Density/ Dichte Weight / Gewicht

s

7 1000 500 35 245

mm mm kg/m

3

EN 22286 --EN ISO 845

g/m

hermal characteristics/

Thermische Eigenschaften:

Heat conductivity (measured)

Wrmeleitfhigkeit (gemessen)

0.035 R (or 1/ ) b

W/m m/W

m2K/W

2 0.5

DIN 52612

Coefficient of thermal insulation/

Wrmedurchlawiderstand

0.2

Heat absorption

Wrmeeindringzahl

2.4 - 60/ + 100

kJ/m h K

Field of temperature application

Anwendungs-Temperaturbereich

Melting temperature

Schmelztemperatur

>160

Thermal decomposition

Thermische Zersetzung

>250

Ignition temperature

Entzndungstemperatur

- when under flame/mit Flammeneinwirkung - without flame/ohne Flammeneinwirkung Flammability class

Brandnorm Baustoffklasse

350-400 450-500 B2

DIN 4102

Other characteristics /

Sonstige Eigenschaften:

Hydroscopic qualities (in combination with the gripping layer

Wasseraufnahme (in Kombination mit HB)

WAV

< 0.1

% by volume --m

DIN 53434

Resistance to diffusion of water steam

Wasserdampfdiffusionswiderstandsfaktor

450 Sd 2.7

DIN 52615 DIN 52615

Coefficient of steam penetrability ( x s / 1000)

Wasserdampfbremswert

Surface tension

Oberflchenspannung

> 42

mN/m

DIN ISO 8296

PUFAS Werk KG, Im Schedetal 1, D-34346 Hann. Muenden Phone: +49 5541 70 03 -01 Fax: +49 5541 70 03 -08 Internet: www.pufas.com

As of 2012-01-01 Page 2 of 2

Anda mungkin juga menyukai

- UP210 Lime/cement Basecoat Render: Data Sheet Sept 2014Dokumen3 halamanUP210 Lime/cement Basecoat Render: Data Sheet Sept 2014Francesco FanaraBelum ada peringkat

- Uzin PE 260Dokumen2 halamanUzin PE 260FloorkitBelum ada peringkat

- Moisture damage prevention and removal with insulation boardsDokumen2 halamanMoisture damage prevention and removal with insulation boardsrichashyampatilBelum ada peringkat

- Baumit Facade Insulating Board EPS-F: ProductDokumen6 halamanBaumit Facade Insulating Board EPS-F: ProductIbrahim SahinBelum ada peringkat

- Uzin PE 360Dokumen2 halamanUzin PE 360FloorkitBelum ada peringkat

- Polyurethane / Polyisocyanurate For: Cryogenic InsulationDokumen28 halamanPolyurethane / Polyisocyanurate For: Cryogenic InsulationhacenescribdBelum ada peringkat

- IZOFLEXDokumen2 halamanIZOFLEXmikivukBelum ada peringkat

- (PDS) Nitoproof 30Dokumen4 halaman(PDS) Nitoproof 30ari_prasBelum ada peringkat

- Fevicol PurDokumen3 halamanFevicol PurVenkata ChadaBelum ada peringkat

- CRETEX PU SealantDokumen3 halamanCRETEX PU Sealantislam mohamedBelum ada peringkat

- 2020insulation (1)Dokumen33 halaman2020insulation (1)felipe.moliveira18Belum ada peringkat

- Disc Diffuser BIBUSDokumen4 halamanDisc Diffuser BIBUSAnonymous RW6ce9hFBelum ada peringkat

- Styrofoam BasfDokumen10 halamanStyrofoam Basfkunalji_jainBelum ada peringkat

- Boscoseal Torch OnDokumen3 halamanBoscoseal Torch OnjbonvierBelum ada peringkat

- Wood Cement BoardDokumen15 halamanWood Cement BoardpiangphetBelum ada peringkat

- Lloyd Insulations Supertherm Pipe SupportsDokumen2 halamanLloyd Insulations Supertherm Pipe SupportsJoshua FernandezBelum ada peringkat

- Unit 4 NotesDokumen6 halamanUnit 4 Notesmayurcshetty2007Belum ada peringkat

- Bostik Boscoseal Puxrev 1Dokumen4 halamanBostik Boscoseal Puxrev 1Yayat Syam HidayatBelum ada peringkat

- Types of PlasticsDokumen13 halamanTypes of PlasticsSander100% (1)

- PETg Data SheetDokumen4 halamanPETg Data SheetVikram BorkhediyaBelum ada peringkat

- Waterproofing MethodologyDokumen16 halamanWaterproofing MethodologyGaurav Nijhawan100% (1)

- 2608 Planitop Fast 330 Uk NoRestrictionDokumen4 halaman2608 Planitop Fast 330 Uk NoRestrictionFloorkitBelum ada peringkat

- Technical Data Sheet for ORAJET 3105 HT Outdoor Vinyl FilmDokumen2 halamanTechnical Data Sheet for ORAJET 3105 HT Outdoor Vinyl FilmReclame AradBelum ada peringkat

- Cat Epoxy TD MULTIPOX MX-99 (Rev.02)Dokumen2 halamanCat Epoxy TD MULTIPOX MX-99 (Rev.02)yesitamaBelum ada peringkat

- Brushbond TI Flexicoat PDFDokumen2 halamanBrushbond TI Flexicoat PDFhelloitskalaiBelum ada peringkat

- Eu Co Rub Bit EmulsionDokumen2 halamanEu Co Rub Bit Emulsionpravi3434Belum ada peringkat

- Uzin KE 603Dokumen2 halamanUzin KE 603FloorkitBelum ada peringkat

- Fenomastic EnamelDokumen9 halamanFenomastic EnamelhemajsuryaBelum ada peringkat

- ConcreteDokumen3 halamanConcreteTran DtrungBelum ada peringkat

- Ultrabond P902 2K Ultrabond P902 2K: Two-Component Epoxy-Polyurethane Adhesive For Wooden FlooringDokumen4 halamanUltrabond P902 2K Ultrabond P902 2K: Two-Component Epoxy-Polyurethane Adhesive For Wooden FlooringFloorkitBelum ada peringkat

- Aluminum Composite Panel For AdvertisingDokumen6 halamanAluminum Composite Panel For Advertisingmcwong_98Belum ada peringkat

- Epoxy Flooring TDSDokumen7 halamanEpoxy Flooring TDSMohamed MagdiBelum ada peringkat

- L3 Gold System Primer GB 01Dokumen2 halamanL3 Gold System Primer GB 01FloorkitBelum ada peringkat

- Bih Ceresit cp30 Silikonski Hidroizolacioni Premaz Tds BihDokumen2 halamanBih Ceresit cp30 Silikonski Hidroizolacioni Premaz Tds BihPuppala Laxmana PrasadBelum ada peringkat

- WaterproofingDokumen23 halamanWaterproofingKenneth Ituralde BesmonteBelum ada peringkat

- Condensation in Metal BuildingDokumen7 halamanCondensation in Metal BuildingMegha JJBelum ada peringkat

- Uzin NC 110Dokumen4 halamanUzin NC 110FloorkitBelum ada peringkat

- MASTERSEAL 550 EL v3 PDFDokumen2 halamanMASTERSEAL 550 EL v3 PDFRajesh KumarBelum ada peringkat

- TDS DR - Fixit Hydrolastic PU Seal Eng 2018 Rev.12Dokumen6 halamanTDS DR - Fixit Hydrolastic PU Seal Eng 2018 Rev.12kiranmisale7Belum ada peringkat

- Product Info GuideDokumen11 halamanProduct Info GuideniroBelum ada peringkat

- B Tech FLOOR FINISHSDokumen13 halamanB Tech FLOOR FINISHSGabby ChebetBelum ada peringkat

- PMT Module 1Dokumen73 halamanPMT Module 1Palliyil UjwalBelum ada peringkat

- Hyper Coat PU - 40Dokumen6 halamanHyper Coat PU - 40Nimra EmanBelum ada peringkat

- Instructions and Guidelines To The Contractor For Painting of Exterior Wall of IEDokumen8 halamanInstructions and Guidelines To The Contractor For Painting of Exterior Wall of IEhbgdiatmBelum ada peringkat

- Exterior Finishes To WoodDokumen59 halamanExterior Finishes To WoodSureshPothyBelum ada peringkat

- Tds en DesmopolDokumen9 halamanTds en Desmopolankhan29327Belum ada peringkat

- Lunawood Vanjski PodoviDokumen2 halamanLunawood Vanjski PodovigagomatBelum ada peringkat

- Uzin NC 152Dokumen2 halamanUzin NC 152FloorkitBelum ada peringkat

- BMC V - Unit-2 - PlasticsDokumen12 halamanBMC V - Unit-2 - PlasticsniviBelum ada peringkat

- Uzin L 3 Gold: Product Data SheetDokumen2 halamanUzin L 3 Gold: Product Data SheetFloorkitBelum ada peringkat

- EGGER wood panels for constructionDokumen28 halamanEGGER wood panels for constructionstefan hergheligiuBelum ada peringkat

- Multi Purpose Floor Coating - Nippon PaintDokumen2 halamanMulti Purpose Floor Coating - Nippon PaintNippon Paint Total Coating and Construction SolutionsBelum ada peringkat

- TDS Pattex BondsealfillDokumen5 halamanTDS Pattex BondsealfilldknisBelum ada peringkat

- HayparoofDokumen2 halamanHayparoofHisham BerrasaliBelum ada peringkat

- Plastic ProcessesDokumen27 halamanPlastic Processesnitouch3564Belum ada peringkat

- Waterproofing of Cut and Cover Tunnels-V8Dokumen16 halamanWaterproofing of Cut and Cover Tunnels-V8ahmedmido14Belum ada peringkat

- Alumino Silicate Fibre Mesh Product DataDokumen2 halamanAlumino Silicate Fibre Mesh Product DataKesavan DhuraiBelum ada peringkat

- Transportation Quotation for Various DestinationsDokumen2 halamanTransportation Quotation for Various DestinationsrichashyampatilBelum ada peringkat

- Curriculum Vitae Rohit Shinde: Mob-9096400444 Job ObjectiveDokumen4 halamanCurriculum Vitae Rohit Shinde: Mob-9096400444 Job ObjectiverichashyampatilBelum ada peringkat

- NPAV LicenseDokumen1 halamanNPAV LicenserichashyampatilBelum ada peringkat

- InternetDokumen1 halamanInternetrichashyampatilBelum ada peringkat

- Curriculum Vitae Rohit Shinde: Mob-9096400444 Job ObjectiveDokumen4 halamanCurriculum Vitae Rohit Shinde: Mob-9096400444 Job ObjectiverichashyampatilBelum ada peringkat

- +C +B +K +Dokumen2 halaman+C +B +K +richashyampatilBelum ada peringkat

- Anil ResumDokumen2 halamanAnil ResumrichashyampatilBelum ada peringkat

- Poonam Cargo ServicesDokumen5 halamanPoonam Cargo ServicesrichashyampatilBelum ada peringkat

- EiffelDokumen2 halamanEiffelrichashyampatilBelum ada peringkat

- Curriculam Vitae/Resume: Miraj Mahmud MazumderDokumen2 halamanCurriculam Vitae/Resume: Miraj Mahmud MazumderrichashyampatilBelum ada peringkat

- Micro Slitter For Small Tape DomDokumen1 halamanMicro Slitter For Small Tape DomrichashyampatilBelum ada peringkat

- Resume: Sachin Bapuso Kumbhar Contact:, Email: ObjectiveDokumen3 halamanResume: Sachin Bapuso Kumbhar Contact:, Email: ObjectiverichashyampatilBelum ada peringkat

- Financial AccountingDokumen50 halamanFinancial AccountingrichashyampatilBelum ada peringkat

- C 114920Dokumen1 halamanC 114920sarvesh.bhartiBelum ada peringkat

- Niroj CV NEWDokumen4 halamanNiroj CV NEWrichashyampatilBelum ada peringkat

- Curriculum Vitae: Zeeshan.M.MullaDokumen3 halamanCurriculum Vitae: Zeeshan.M.MullarichashyampatilBelum ada peringkat

- Dijin R - ResumeDokumen3 halamanDijin R - ResumerichashyampatilBelum ada peringkat

- NraDokumen3 halamanNrarichashyampatilBelum ada peringkat

- CPLDokumen1 halamanCPLrichashyampatilBelum ada peringkat

- Dijin R - ResumeDokumen3 halamanDijin R - ResumerichashyampatilBelum ada peringkat

- PRASHANT S BIJJARAGI MECHANICAL ENGINEER RESUMEDokumen2 halamanPRASHANT S BIJJARAGI MECHANICAL ENGINEER RESUMErichashyampatilBelum ada peringkat

- Electrical Engineer CVDokumen2 halamanElectrical Engineer CVrichashyampatilBelum ada peringkat

- R 2 RDokumen1 halamanR 2 RrichashyampatilBelum ada peringkat

- The Moon Is EarthDokumen5 halamanThe Moon Is EarthrichashyampatilBelum ada peringkat

- Near Grampanchayat: ObjectiveDokumen2 halamanNear Grampanchayat: ObjectiverichashyampatilBelum ada peringkat

- TrixieDokumen1 halamanTrixierichashyampatilBelum ada peringkat

- Ge Energy Application FormDokumen3 halamanGe Energy Application FormrichashyampatilBelum ada peringkat

- Akl HQ Aug 13Dokumen6 halamanAkl HQ Aug 13richashyampatilBelum ada peringkat

- Akola OctoberinputfeedbackDokumen14 halamanAkola OctoberinputfeedbackrichashyampatilBelum ada peringkat

- LogDokumen16 halamanLogrichashyampatilBelum ada peringkat