Heat Pump Calculation (Train)

Diunggah oleh

gopaltryJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Heat Pump Calculation (Train)

Diunggah oleh

gopaltryHak Cipta:

Format Tersedia

Project: Subject:

Date: Rev:

DESIGN CALCULATION

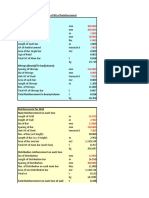

1. HOT WATER LOAD INFORMATION:

2. DESIGN CONDITION: 2.1) Make up water temperature (T1) 2.2) Design hot water temperature (T2) 2.3) Design run time 3. HOT WATER DEMAND CALCULATION (60 DEG C) 3.1) Design from Number of Guest and Activities a) at Guestroom Average guest per room Hot water demand per guest (60 C) - 2 x Shower (10 mins shower) - 1 x Bath Tub - 5 x Lavatory (2 litre ea.) Total HW Demand per guest Total Hot Water demand for Guestrooms b) at Kitchens Estimated No. of Meals Total Hot Water demand for Kitchens c) at SPA No. of Treatment room Operating hour Utilisation times (1.5 hous per guest) Total guest at 100% occupied Hot Water Demand per guest - 1 x Shower (10 min Shower) - 1 x Bath Tub - 2 x Washbasins Total demand per guest per day Total Hot Water demand for SPA d) Others Total Hot Water demand for Others Total Hot Water Demand % Occupancy therefore; Total Hot Water Damand = 291 = 2.0 = = = = = 180 60 10 250 145,500 Rooms Person Litre/day Litre/day Litre/day Litre/day Litre/day Flow rate = 0.5 l/s (hot + cold water) = = = 30 60 10.28 C C hours

Fill in required

= Total Guest x avg. meal per person = 1,164 meals = 10,592 Litre/day (@ 9.1 litre per meal) = = = = = = = = = 0 12 8 0 28 80 4 112 0 rooms hour times person Litre/day Litre/day Litre/day Litre/day Litre/day Litre/day Litre/day Litre/day (@ 100% Occupancy)

= 0 = 156,092 = 80% = 124,874

Page 1 of 3

Project: Subject:

Date: Rev:

DESIGN CALCULATION

4. OPTIMUM SYSTEM DESIGN CALCULATION FOR HEAT PUMP WATER HEATER 4.1) Peak Load Calculation Hourly Peak Demand Peak Duration Total Peak Demand for entire peak Number of Building HW Demand During Peak / Building Storage Tank Size Storage Tank Size Storage Tank from COMPACT HP Total Effective Volume (80% usable) Actual HW Demand during peak Actual Hourly HW Demand during peak Required Heating Capacity (HPC) **40% loss factor for standard model Adjusted Heating Capacity (HPC) 18,731 3 56,193 1 56,193 124,874 30,000 0 24,000 32,193 10,731 373 N 373 Litre/hr hr Litre litre/ total peak period x 0.20 = 24,975 Litre Litre Litre Litre Litre (total peak period) litre/hr kW ( Y / N ) ; Y for standard / N for Advanced kW

= = = = = = = = = = = = =

5. EQUIPMENT SELECTION 5.1) AWHP System Solution Alternative 1: HEAT PUMP Power output(30 C ambient) Cooling Capacity Power Input (kW) Coefficient of Performance (COP) Built-in storage size Unit of Heat Pump

Minimum running unit Recommended: Recovery rate (L/hr) Alternative 1: STORAGE TANK Recommended: 6. OPERATING HOUR Morning peak running hour Filled up tank (day time) running hour Evening peak running hour Filled up tank (night time) running hour TOTAL RUNNING HOUR = = = = 56,193 24,000 56,193 24,000 = = = = =

= = = = = = = = = = = =

65.00 55.70 14.50 4.48 0 HPC 373 5.75 6.00 6.00 11,207

kW/unit kW/unit kW Litre / Heating Capacity / 65.00 kW Unit Unit Unit L/hr (from operating unit) L

2.00 X 15,000

3 hr 2.14 hr 3 hr 2.14 hr 10.28 hr

Page 2 of 3

Project: Subject:

Date: Rev:

DESIGN CALCULATION

7. ENERGY CONSUMPTION COMPARISON 7.1) Heat Pump Week Day Operating kWh/day - On Peak = = kWh/day - Off Peak = = Sat-Sun Day Operating kWh/day - On Peak = = kWh/day - Off Peak = = 8. UTILITY & FUEL RATE 8.1) Electricity Cost On Peak = Off Peak = Demand Charge = Ft Rate = 9. ENERGY COST SAVING 9.1) Operating Cost - Heat Pump Unit Rate Yearly Expense = Demand Charge Expense = Ft Charge Yearly Expense = Total Yearly Expense for Heat Pump = 593,668 138,779 247,615 980,061 Baht/year Baht/year Baht/year Baht/year 2.6950 1.1914 132.93 0.7583 Baht/kW-Hr (Mon - Fri: 9:00 - 22:00, 13 hr) Baht/kW-Hr (Mon - Fri: 22:00 - 9:00, 11 hr) (Sat - Sun: 0:00 - 24:00, 24 hr) Baht/kW Baht/kW-Hr 0.00 0 10.28 895 hr kWh/day hr kWh/day 6.00 522 4.28 372.63 hr kWh/day hr kWh/day

Page 3 of 3

Anda mungkin juga menyukai

- Energy Management Tutorial SolutionsDokumen9 halamanEnergy Management Tutorial SolutionsLucas LentzBelum ada peringkat

- Heat Pump CalculationDokumen19 halamanHeat Pump CalculationClement Chong100% (2)

- Exhaust and Jacket Water Heat Recovery From GeneratorDokumen8 halamanExhaust and Jacket Water Heat Recovery From GeneratorMuhammad Abdul Samad50% (2)

- Removing of Heat From Room Air: HE B/W PR & Room Air at Eavap Side Is Known As DX SystemDokumen20 halamanRemoving of Heat From Room Air: HE B/W PR & Room Air at Eavap Side Is Known As DX SystemMohammed Majeed AliBelum ada peringkat

- Heat Load CalculationsDokumen6 halamanHeat Load CalculationsHoney Tiwari0% (1)

- Cooling Load EstimationDokumen69 halamanCooling Load EstimationkarimBelum ada peringkat

- Header & Piping SizingDokumen9 halamanHeader & Piping Sizingmedicbest0% (1)

- Plate Heat Exchanger CalculationDokumen6 halamanPlate Heat Exchanger CalculationNgoVietCuongBelum ada peringkat

- Pumps Best Practice ToolsDokumen9 halamanPumps Best Practice Toolspm2013100% (1)

- Shell Tube Heat Exchanger DesignDokumen7 halamanShell Tube Heat Exchanger DesignAbhijeet JhaBelum ada peringkat

- Cooling Tower-CalculatorDokumen7 halamanCooling Tower-CalculatorparykoochakBelum ada peringkat

- Heat LoadDokumen53 halamanHeat Loadabdul azizBelum ada peringkat

- HVAC CalculationDokumen6 halamanHVAC CalculationvijayananthBelum ada peringkat

- Cooling Load Calculations: Sample Project Date: Cabin 150 (SQFT) 10 (FT) 1500Dokumen3 halamanCooling Load Calculations: Sample Project Date: Cabin 150 (SQFT) 10 (FT) 1500HARISH VERMABelum ada peringkat

- Chillers Calculation 2Dokumen6 halamanChillers Calculation 2hamid vahedil larijani100% (1)

- Calculation For Thermal Storage Tank DiffusersDokumen2 halamanCalculation For Thermal Storage Tank DiffusersYamen SleimanBelum ada peringkat

- VSD Calculator For PumpsDokumen13 halamanVSD Calculator For PumpsG_J_C_CBelum ada peringkat

- Tube Ice Machine TB30TDokumen5 halamanTube Ice Machine TB30TWisermenBelum ada peringkat

- Chiller Estimator 4.0Dokumen25 halamanChiller Estimator 4.0Dee RajaBelum ada peringkat

- Calculation of Scrubber DiameterDokumen44 halamanCalculation of Scrubber DiameterRamakrishna SomuBelum ada peringkat

- Boiler Draft CalculationDokumen25 halamanBoiler Draft Calculationsehono100% (1)

- A. Process Inputs Fluid Flow Rate (Kg/hr) Density (gm/cc) Sp.Heat (Kcal/kg.°C) λ (Kcal/kg) Inlet Temperature °CDokumen12 halamanA. Process Inputs Fluid Flow Rate (Kg/hr) Density (gm/cc) Sp.Heat (Kcal/kg.°C) λ (Kcal/kg) Inlet Temperature °CPrad1979100% (1)

- Pump Sizing SpreadsheetDokumen2 halamanPump Sizing Spreadsheetsyamsudin200683% (6)

- CW Pump CalculationDokumen22 halamanCW Pump Calculationzamijaka100% (1)

- Calorifier - Heat Recovery Time EtcDokumen5 halamanCalorifier - Heat Recovery Time Etcmahmed111Belum ada peringkat

- Engine Room Calc Air 2Dokumen1 halamanEngine Room Calc Air 2jack macBelum ada peringkat

- Pressuredrop Calculations by Kern Method SRRDokumen18 halamanPressuredrop Calculations by Kern Method SRRrajeev50588Belum ada peringkat

- Gasifier Design Spreadsheet (Rice Husk) : CalculationsDokumen4 halamanGasifier Design Spreadsheet (Rice Husk) : CalculationsJarus Ydenap0% (1)

- Chiller Size CalculatorDokumen4 halamanChiller Size CalculatormpokeBelum ada peringkat

- HVAC Cooling Load Estimate SheetDokumen1 halamanHVAC Cooling Load Estimate SheetideepujBelum ada peringkat

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterDokumen3 halamanDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaBelum ada peringkat

- Economizer Design CalculationsDokumen4 halamanEconomizer Design CalculationsDaniyal HashmiBelum ada peringkat

- P&F HX - Counter Flow: Plate & Frame Heat Exchanger Sizing Waterside Economizer (Wse) FormulasDokumen4 halamanP&F HX - Counter Flow: Plate & Frame Heat Exchanger Sizing Waterside Economizer (Wse) Formulasjnmanivannan100% (1)

- RTS Heating and Cooling Loads GDS - SI Units Rev 2010-01-20Dokumen1 halamanRTS Heating and Cooling Loads GDS - SI Units Rev 2010-01-20alvinchuanBelum ada peringkat

- Chiller Plant Calculation & Raw Data RequiredDokumen1 halamanChiller Plant Calculation & Raw Data RequiredBudi IswahyudiBelum ada peringkat

- Solar Angle CalculatorDokumen51 halamanSolar Angle CalculatorJeff FainBelum ada peringkat

- Thermopack Heat Generation CalculationDokumen8 halamanThermopack Heat Generation CalculationAyush AgrawalBelum ada peringkat

- Radiator CalculationDokumen24 halamanRadiator Calculationmohammed sallem100% (1)

- Elec Floor Heating HandbookDokumen60 halamanElec Floor Heating HandbookNavanee KrishnanBelum ada peringkat

- Calculations: Specimen Calculations For Test 1Dokumen8 halamanCalculations: Specimen Calculations For Test 1Saman KumaraBelum ada peringkat

- Steam Viscosity D - 770 PDFDokumen5 halamanSteam Viscosity D - 770 PDFATUL SONAWANEBelum ada peringkat

- VSD Calculator For FansDokumen10 halamanVSD Calculator For FansCésar Christian JankoBelum ada peringkat

- Calorifier ManualDokumen27 halamanCalorifier ManualPaul KwongBelum ada peringkat

- Heat Load CalculationsDokumen18 halamanHeat Load Calculationssiruslara6491Belum ada peringkat

- Design Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectDokumen1 halamanDesign Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectAbdelfatah NewishyBelum ada peringkat

- Water Consumption For Coolig TowerDokumen19 halamanWater Consumption For Coolig TowerMyungkwan Ha100% (1)

- Static Pressure Calculator r3Dokumen3 halamanStatic Pressure Calculator r3arshi_yusufBelum ada peringkat

- Water Tank DesignDokumen2 halamanWater Tank DesignEdgardo Dejaño Dultra Jr100% (2)

- Instituto Tecnológico Superior Progreso Ingeniería en Energías RenovablesDokumen11 halamanInstituto Tecnológico Superior Progreso Ingeniería en Energías RenovablesFidelina QuijanoBelum ada peringkat

- PP Lab Manual 2015Dokumen20 halamanPP Lab Manual 2015Abdul Fatir Khan100% (1)

- Ash Handling System CalculationDokumen4 halamanAsh Handling System CalculationAndi HarsoBelum ada peringkat

- Tips and Tricks For Estimating Energy SavingsDokumen38 halamanTips and Tricks For Estimating Energy SavingsShujath Ali SyedBelum ada peringkat

- National Certification Examination 2008 FOR Energy AuditorsDokumen10 halamanNational Certification Examination 2008 FOR Energy AuditorsMukesh KumarBelum ada peringkat

- Heat Pump CalculationDokumen14 halamanHeat Pump Calculationrahul8595shindeBelum ada peringkat

- Assignment 3 of Casein Plant Design2Dokumen15 halamanAssignment 3 of Casein Plant Design2Latifani Ayu ChaerunnisaBelum ada peringkat

- Intro To Energy ManagementDokumen39 halamanIntro To Energy ManagementchandumistryBelum ada peringkat

- DHW Calc MincomDokumen20 halamanDHW Calc MincomZaid Al RayesBelum ada peringkat

- Paper 4 - Set A Key 14 National Certification Examination FOR Energy Auditors - August, 2013Dokumen14 halamanPaper 4 - Set A Key 14 National Certification Examination FOR Energy Auditors - August, 2013Muthiah Chidambaram MuthiahBelum ada peringkat

- Estimating Methods For Determining EndDokumen9 halamanEstimating Methods For Determining EndReza KhajeBelum ada peringkat

- Section 8 Ship PipelineDokumen4 halamanSection 8 Ship PipelinegopaltryBelum ada peringkat

- Notes:: Type IBL: Base Supports For Cold LinesDokumen6 halamanNotes:: Type IBL: Base Supports For Cold LinesgopaltryBelum ada peringkat

- Architectural SymbolsDokumen34 halamanArchitectural SymbolsNiallburke100% (4)

- Multi Fuel Fired Boiler-Design Improvement: Phase-IDokumen8 halamanMulti Fuel Fired Boiler-Design Improvement: Phase-IgopaltryBelum ada peringkat

- Architectural SymbolsDokumen34 halamanArchitectural SymbolsNiallburke100% (4)

- TNEB Online Payment For May, JuneDokumen1 halamanTNEB Online Payment For May, JunegopaltryBelum ada peringkat

- 632 - Rev.01 - Top Suspension-Bearing Plate ManuDokumen1 halaman632 - Rev.01 - Top Suspension-Bearing Plate ManugopaltryBelum ada peringkat

- Standards For Pipe LineDokumen57 halamanStandards For Pipe Linegopaltry33% (3)

- SPEC of Pipes For ShipbuildingDokumen13 halamanSPEC of Pipes For ShipbuildinggopaltryBelum ada peringkat

- GD TDokumen17 halamanGD TSuraj KrishnanBelum ada peringkat

- Ships PipingDokumen25 halamanShips Pipinggopaltry100% (1)

- I B R CalculationDokumen10 halamanI B R CalculationgopaltryBelum ada peringkat

- Ship Piping SystemsDokumen32 halamanShip Piping Systemsvivek_rec100% (9)

- Esp ModellingDokumen7 halamanEsp ModellinggopaltryBelum ada peringkat

- Calculation of WT of RCCDokumen2 halamanCalculation of WT of RCCankurbgaurBelum ada peringkat

- ArcweldingbasicsDokumen61 halamanArcweldingbasicsapi-302554558Belum ada peringkat

- 24 Piping PDFDokumen11 halaman24 Piping PDFgopaltryBelum ada peringkat

- Maintenance Monthly1 (Boiler, CA, N2)Dokumen1 halamanMaintenance Monthly1 (Boiler, CA, N2)gopaltryBelum ada peringkat

- 01 - SNFAIL Total MetricDokumen11 halaman01 - SNFAIL Total MetricBùi Văn HợpBelum ada peringkat

- SNFAIL Freq ContentDokumen7 halamanSNFAIL Freq ContentBùi Văn HợpBelum ada peringkat

- Boq For BeamsDokumen22 halamanBoq For BeamsgopaltryBelum ada peringkat

- Boq For BeamsDokumen22 halamanBoq For BeamsgopaltryBelum ada peringkat

- Mat CodesDokumen64 halamanMat CodesgopaltryBelum ada peringkat

- IS 1239 (Part 1) 1969Dokumen21 halamanIS 1239 (Part 1) 1969gopaltryBelum ada peringkat

- BouilerDokumen6 halamanBouilerAssem ElhajjBelum ada peringkat

- Cold Formed SteelDokumen149 halamanCold Formed SteelgopaltryBelum ada peringkat

- Aisi 2001Dokumen149 halamanAisi 2001crnewsomBelum ada peringkat

- Analysis Comparison FinalDokumen1 halamanAnalysis Comparison FinalgopaltryBelum ada peringkat

- BoilersDokumen59 halamanBoilersgopaltryBelum ada peringkat

- Engineering DictionaryDokumen138 halamanEngineering DictionaryAbdul Majjid KhanBelum ada peringkat

- Guide B2 2016 B PDFDokumen157 halamanGuide B2 2016 B PDFTanveer100% (4)

- HP-CurrentPriceListZero Normal PDFDokumen50 halamanHP-CurrentPriceListZero Normal PDFbilal mustafa100% (1)

- AC Products Introduction - EngDokumen50 halamanAC Products Introduction - EngMICAH JEDAHBelum ada peringkat

- Section 1: Theory of Heat Unit 3: Refrigeration and RefrigerantsDokumen43 halamanSection 1: Theory of Heat Unit 3: Refrigeration and Refrigerantslemuel ramirezBelum ada peringkat

- Smartcool PDFDokumen16 halamanSmartcool PDFJack BedjoBelum ada peringkat

- COP of Refrigerator by Using PH ChartDokumen16 halamanCOP of Refrigerator by Using PH ChartMuhammad MashamBelum ada peringkat

- 609Dokumen64 halaman609hipcov2Belum ada peringkat

- 5 Tons Tube Ice PDFDokumen7 halaman5 Tons Tube Ice PDFARISBelum ada peringkat

- Cooling SystemDokumen33 halamanCooling SystemJayson B. CadelinaBelum ada peringkat

- HVAC System Design and Installation ProceduresDokumen24 halamanHVAC System Design and Installation ProceduresMiguelAzucena100% (5)

- Ac BoqDokumen6 halamanAc BoqRaghunatha Gowda100% (1)

- Plant RoomDokumen1 halamanPlant RoomShafi AshrafBelum ada peringkat

- Mechanical Overview-HVAC 101Dokumen49 halamanMechanical Overview-HVAC 101Anwar PariyarathBelum ada peringkat

- DHC in Helsinki - The Ultimate Heating and Cooling Solution For A Large Urban AreaDokumen18 halamanDHC in Helsinki - The Ultimate Heating and Cooling Solution For A Large Urban AreasmmrifaiBelum ada peringkat

- Catalogo GS 2018 PDFDokumen116 halamanCatalogo GS 2018 PDFOcma MallidaBelum ada peringkat

- Air Changes Per HourDokumen2 halamanAir Changes Per HourjjzoranBelum ada peringkat

- Hot & Cold Chamber: ConstructionDokumen2 halamanHot & Cold Chamber: ConstructionSayyadh Rahamath BabaBelum ada peringkat

- The GOLD Air Handling System Project Design GuideDokumen26 halamanThe GOLD Air Handling System Project Design GuidepcvietBelum ada peringkat

- Mont Vs HRE UKDokumen89 halamanMont Vs HRE UKbibicualinBelum ada peringkat

- Sohail Villa Equip ScheduleDokumen6 halamanSohail Villa Equip ScheduleAslamBelum ada peringkat

- Machine Load - KCLDokumen3 halamanMachine Load - KCLMd HossainBelum ada peringkat

- Boiler Documentation Air Flue Gas Path Ducts EJ Gates Dampers 1 5 Hrs PDFDokumen90 halamanBoiler Documentation Air Flue Gas Path Ducts EJ Gates Dampers 1 5 Hrs PDFaruntpeBelum ada peringkat

- Emerging Trends in Mechanical Engineering: Course Code - 22652 (AE/PG/PT/ME) Unit 2 - Process EngineeringDokumen12 halamanEmerging Trends in Mechanical Engineering: Course Code - 22652 (AE/PG/PT/ME) Unit 2 - Process EngineeringKunal AhiwaleBelum ada peringkat

- Airstage J-IIDokumen6 halamanAirstage J-IIBulclimaBelum ada peringkat

- Ed24-631a (Sky Air Standard - r22)Dokumen149 halamanEd24-631a (Sky Air Standard - r22)Rizky Riva'iBelum ada peringkat

- Rocket Stove Mass HeaterDokumen14 halamanRocket Stove Mass Heaterdanut_doc100% (1)

- Cooling Systems AssignmentDokumen14 halamanCooling Systems AssignmentBecky DavisBelum ada peringkat

- Copeland ZP SeriesDokumen4 halamanCopeland ZP Seriesakram rasheed shaikBelum ada peringkat

- HVAC System PDFDokumen79 halamanHVAC System PDFBülent KabadayiBelum ada peringkat

- Technical Data Manual: M-Thermal SplitDokumen63 halamanTechnical Data Manual: M-Thermal SplitZoltán BartókBelum ada peringkat