Compostare PDF

Diunggah oleh

Alexandru GhergheDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Compostare PDF

Diunggah oleh

Alexandru GhergheHak Cipta:

Format Tersedia

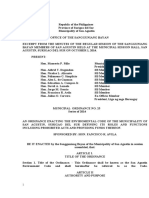

Biosystems Engineering (2002) 81 (4), 433441 doi:10.1006/bioe.2001.0047, available online at http://www.idealibrary.

com on SE}Structures and Environment

Compost Airow Resistance

" re; Maher Trigui; William Knight Suzelle Barrington; Denis Choinie

Department of Agricultural and Biosystems Engineering, Macdonald Campus of McGill University, 21 111 Lakeshore, Ste Anne de Bellevue, ! bec, Canada H9X 3V9; e-mail of corresponding author: barrington@macdonald.mcgill.ca Que (Received 13 March 1999; accepted in revised form 9 January 2002)

Four bulking agents, pine shavings, mixed (long and chopped) grass hay, chopped grass hay and long (whole) wheat straw, were each mixed with pig slurry and tap water to obtain three moisture contents (MC) of 60, 65 and 70%. Quadruplets of each treatment were placed in laboratory composting vessels with a capacity of 105 l and a composting depth of 095 m. Using the air plenum at the bottom of each vessel, air was forced at apparent velocities of 00002 m s1 through each compost mass to measure the air static pressure drop across the compost mass as a function of apparent air velocity. Airow resistance values were measured for compost depths ranging from 055 to 085 m. Following this test, all mixtures were aerated for 21 days of composting without overturning. The static pressure measurement procedure was then repeated on all quadruplet mixtures. The air static pressure drop was found with respect to a packed bed under laminar ow, dened using the particle size distribution, porosity, depth and airow channel characteristics of the compost material. Although MC aected the value of the airow channel characteristics of the compost material, both the hay and straw demonstrated similar values, while shavings demonstrated values more variable and wider values for MC between 60 and 70%. There was a signicant increase in airow resistance after 21 days of composting, which supports the need for compost overturning to reestablish the materials structure and to restore the airow channels or pores. # 2002 Silsoe Research Institute. Published by Elsevier Science Ltd. All rights reserved 1. Introduction Aeration is a key element in controlling the temperature regime and thus, the performance of any composting operation. Under aerobic conditions, microbes can rapidly degrade the available hydrocarbons releasing large amounts of energy to elevate the compost temperature to the thermophilic range. Aeration is further used to maintain the temperature for several days, between 55 and 658C. Higher temperatures will destroy the microbes composting the waste material, while lower temperatures will not stabilize the waste material. Waste stabilization is the most signicant objective of composting because it reduces the incidence of parasites, pathogens and viruses. Aerobic conditions also reduce the amount of putrefactive odours released from the waste during its treatment. Furthermore, composting generally dries the waste material below 50% and eliminates the readily degradable hydrocarbons, thus producing a waste material unattractive to

1537-5110/02/$35.00

insects. Finally, aerobic conditions allow for a rapid treatment reducing the size and improving the eciency of the composting unit. The ventilation system used in the compost plant is, therefore, an important design element, and represents a signicant cost. Airow resistance parameters are required to design a composting ventilation system with sucient capacity without being oversized. Relating air static pressure drop to airow through the compost mass allows for the ecient design of the ventilation system whether it be passive (oor ducts) or active (ducts and fan system). The objectives of this research were to measure and describe, using laboratory vessels, the static pressure drop of air owing through compost materials. Four bulking agents were used as compost materials, pine shavings, a mixture of long and chopped grass hay, chopped grass hay and long (whole) wheat straw. These bulking agents were each mixed with enough pig slurry to obtain a C/N ratio of 20. Furthermore, each compost

433 # 2002 Silsoe Research Institute. Published by Elsevier Science Ltd. All rights reserved

434

S. BARRINGTON ET AL.

Notation Cd Cl Cp Ct Dp f H j; n L M discharge coecient of the compost vessel cap orice pore length correction factor for laminar ow pressure drop coecient related to the physical properties of the compost material pore length correction factor for turbulent ow average diameter of the compost particles, m friction factor depth of compost material opposing airow, m respective empirical exponential coecients for H and V coecient characterizing airow channels of the composting material compost moisture content, decimal P Pc Pl Pp Pt Sp V Vo pressure drop across the compost, Pa static air pressure under the vessel cap, Pa pressure drop across the compost depth under laminar ow, Pa static air pressure in the plenum, Pa pressure drop across the compost depth under turbulent ow, Pa particle shape correction factor apparent velocity of the air across the face of the compost material, m s1 air velocity across the face orice, m s1

Greek letters r m e air density, kg m3 viscosity of air, Pa s void ratio of the compost

material was tested at three moisture contents, namely 60, 65 and 70%. The depth of the aerated compost ranged between 055 and 085 m. All mixtures (four bulking agents at three moisture levels) were tested in quadruplets for airow resistance. Measurements were conducted on the fresh (2 h old) compost mixtures and after 21 days of composting.

2. Theoretical analysis The pressure drop P through compost material has been expressed using an empirical equation with terms related to the physical properties of the material Cp , its depth H and the apparent air velocity across its face V (Higgins et al., 1982): P Cp H j V n 1

maize cob compost, the value for Cp ranged between 0556 and 2554, while j was 10 and n ranged between 123 and 182 (Keener et al., 1987). For cattle manure, values of 031041 were measured for Cp H j and 083 215 were measured for n (Saint-Joly et al., 1989). The value of Cp H j increased as n increased (Keener et al., 1987; Saint-Joly et al., 1989). Pressure drop across a layer of compost can also be expressed according to the HagenPoiseuille equation (Geankoplis, 1978), describing the airow across a packed bed under conditions of laminar ow:

2 2 3 Pl 72Cl H mV 1 e2=Sp Dp e

where apparent air velocity, V , is dened as the volumetric airow rate divided by the cross-sectional area of the compost bed perpendicular to this airow. Thus, Cp is aected by the mixing regime, degradation and ageing of the compost (Higgins et al., 1982). The coecient j , exponent of H , was found to be 10, for compost with over 40% dry matter and to be more than 10 otherwise (Keener et al., 1987). The coecient n, exponent of V , is directly related to the porosity of the compost material (Saint-Joly et al., 1989). The coecients Cp , j and n have been measured for various compost materials (Table 1). The coecient Cp was found to vary between 4 and 60 for sewage sludge and wood chip compost, while j and n ranged between 105 and 147 and between 148 and 174 (Higgins et al., 1987; Keener et al., 1987). For cage layer and sawdust or

where Pl is the pressure drop across the bed depth under laminar ow in Pa, Cl is a dimensionless laminar airow channel or pore length correction factor applied to H , and having a value of 2 for a packed sand bed with a porosity of less than 05, m is the viscosity of air in Pa s, e is the dimensionless void ratio of the bed, Sp is a dimensionless particle shape correction factor, and Dp is the average diameter of the particles in the packed or compost bed in m. When the ow is turbulent, the pressure drop Pt expression (Geankoplis, 1978) changes to Pt 3f Ct H rV 2 1 e=Sp Dp e3 3

where f is a dimensionless friction factor, Ct is a dimensionless turbulent airow channel or pore length correction factor and r is the density of the air in kg m3. In packed beds, both laminar and turbulent ow can occur (Geankoplis, 1978): Pt 3f Ct H rV 2 1 e=Sp Dp e3

2 2 3 DP e 72Cl H mV 1 e2=Sp

COMPOST AIRFLOW RESISTANCE

435

Table 1 Airow resistance coecients for various fresh compost mixtures Compost Compost material Bulking agent Sewage sludge Wood chip Ratio 1:0 1:3 1:75 1:11 1:22 1:2 1:2 1:5:7 5:1:10 3:5:7 1:0:17 1:33 1:17 1:11 1:7 1:22 Wet bulk density, kg m3 90 485 680 750 850 670 400 325 515 320 400 960 880 510 430 170 Dry matter, % 95 31 20 17 14 40 40 50 51 51 48 133 147 153 172 232 Pressure drop coe. (Cp), MPa 381 730 1234 2028 6007 0556 2554 1109 1694 2473 1181 937 448 24 24 27 Exponent j 108 105 130 147 141 100 100 100 100 100 100 } } } } } n 174 161 163 147 148 173 160 173 182 202 123 215 201 169 169 083 Higgins et al. (1982) Reference

Cage layer manure Sludge

Sawdust Maize cobs Wood chips and leaves

Keener et al. (1993) Keener et al. (1993)

Cattle manure

Straw

Saint-Joly et al. (1987)

Note: The ratio is expressed in terms of bulking agent mass over wet sludge or manure mass; the coecient and exponents apply to Eqn (1).

where the rst term applies to turbulent airow in small pores (high Reynolds number) and the second term applies to laminar airow in the large pores (small Reynolds number). Thus, pressure drop across a depth of compost can be expressed using either Eqns. (2) or (4), whether the ow is laminar or mixed (laminar and turbulent). Generally, the ow should be laminar, considering the relatively low airow required. Barrington et al. (1997) successfully obtained compost temperatures of 658C, using a maximum value for V of 00002 m s1. Similarly, the aeration of grain beds, demonstrates laminar ow (exponent for V of 10) under aeration velocities of up to 002 m s1 (ASAE, 2000). The parameter V demonstrates an exponent of 20 only for beds of large particles (ear maize) exposed to velocities over 010 m s1. For small grains (wheat and maize) exposed to apparent aeration velocities above 002 m s1, the parameter V has an exponent between 10 and 20, indicating that some pores are under laminar ow while others are under turbulent ow. Furthermore, the parameters Ct and Cl vary with the type of material. The empirical expression, Eqn (1), is similar to Eqns (2) and (4), when considering the value of the exponent n (Table 1). A value of 2 indicates a completely turbulent ow, while a value between 1 and 2 indicates laminar and turbulent ow, and a value of 1 indicates laminar

ow. As it may be dicult to separately and experi2 , Eqn (2) can be redened mentally design both Cl and Sp using

2 L Cl =Sp

5 6

giving

3 Pl 72LH mV 1 e2 =D2 pe

where L is a dimensionless coecient characterizing the airow channels of the composting material.

3. Materials and methods

3.1. The experimental material The bulking agents used were a mixture of 33% long (unchopped) grass hay and 67% chopped grass hay, 100% chopped grass hay, long (unchopped) wheat straw and pine shavings. The pig slurry used to adjust the C/N ratio of the bulking agents was obtained from the pig fattening house of the Macdonald Campus farm of McGill University (Table 2). Soya beans were added to the pine shavings for a C/N of 20. Urea was initially tested as nitrogen supplement, but was not used as it would increase the pH of the mixture above 90. The pH,

436

S. BARRINGTON ET AL.

Table 2 Compost composition for the experimental tests Item Units 1 Bulking agent type Pig slurry N complement type Total Moisture content C/N ratio Note: d.b., dry weight basis. % d.b. % d.b. % d.b. % d.b. % d.b. Wheat straw 74 26 } 100 63 67 72 18 2 Mixed hay 76 24 } 100 60 67 75 23 Trial 3 Chopped hay 77 15 } 100 60 65 70 21 4 Wood shavings 77 15 Soya beans 8 100 59 64 69 20

moisture content (MC), total nitrogen (TN), total carbon (C) and dry particle density of the experimental materials were measured prior to starting the tests (Table 3). The particle size distribution for all the experimental materials is illustrated in Fig. 1. The three moisture contents, 60, 65 and 70%, were tested in quadruplets for each bulking agent and one bulking agent was tested at any one time. Tap water was used to obtain the desired MC for all compost mixtures, and its quantity varied among bulking agent tests, to obtain the required moisture content. The 70% MC corresponded to the maximum amount of humidity capable of being held by the bulking agent while the 60% MC corresponded to the minimum MC at which composting can be carried out eectively. 3.2. The equipment The tests were conducted using 12 identical 105 l cylindrical plastic vessels, 095 m high and 040 m in diameter (Fig. 2). Each container was insulated with 100 mm of mineral wool for a thermal resistance value of 25 m28C W1. An air plenum, 100 mm in height, was created at the bottom of each container using a supporting metal wire mesh. Before conducting the test,

the volumetric capacity of the experimental vessels was determined as a function of depth by gradually lling with a known volume of water. The air plenum under the compost had two perforations, each equipped with a tube. One perforation was used to inject air and the other was connected to a manometer tube to measure the static air pressure. Caulking was used around each connection for air tightness. Air was supplied by a pressurized air tank connected to a compressor unit. All static pressure readings were conducted with a vertical Dwyer micromanometer with an accuracy of 0062 Pa. 3.3. The method One test was conducted for each of the four bulking agents. For each test, 12 compost vessels were lled to give three levels of moisture tested in quadruplets (Table 2). The bulking agent was sampled and analysed before each test. The pig slurry could not be analysed ahead of time because of the signicant loss in TN content during the 24 h required to carry out the analytical procedures. However, its composition changes only slightly from one test to another and an average MC, TN and C content could be assumed.

Table 3 Characteristics of the experimental materials Material Wheat straw Hay Pine shavings Pig slurry Soya beans Dry matter, % 869 872 924 168 900 (05) (11) (03) (09) (05) Total N, g kg1 979 (025) 110 (18) 064 (04) 751 (55) 68 (03) 63 52 44 72 pH (060) (010) (013) (016) } Ash, % 90 (04) 65 (03) 038 (013) 198 (14) 23 (02) C, % 498 511 544 438 534 Density, g ml1 050 (004) 066 (009) 078 (010) 130 (013) }

Note: All analyses are reported on a dry weight (d.w.) basis; the value for the pig slurry is typical of the six tests; the C content was calculated from {(100% ash (%))/183}; the values in parentheses are the standard deviations.

COMPOST AIRFLOW RESISTANCE

437

Fig. 1. Particle size distribution of the experimental materials item;

, wood shavings; , pig slurry

, long hay;

, chopped hay;

, long

the same amount of bulking agent and swine liquid manure, but with dierent amounts of tap water. The depth of compost in each vessel was recorded, and the volume, bulk density and air porosity of the fresh compost were determined. Air pressure dierentials with air velocity across the compost was measured 12 h after lling the experimental vessels. The top of the vessel was closed using an air-tight cap with a 5 mm orice. Air was introduced into the plenum at dierent ow rates, while the air static pressure of the plenum Pp and the top orice velocity Vo were measured. The pressure dierential was calculated from the air static pressure in the plenum less that created under the cap, calculated from the orice air velocity, using Bernoullis principle:

2 Pc rVo =2

Fig. 2. The experimental composting vessel

A 15 kg mass (d. b.) of bulking agent was mixed with the required amounts of pig slurry, water and amendment (soybeans for the pine shavings) to obtain a C/N ratio of 20 and a moisture content of either 60, 65 or 70%. The batches were prepared by weighing all ingredients on a scale with an accuracy of 01 kg, dumping the ingredients in a 400 l container and thoroughly mixing all ingredients manually. Then, the mixture was used to ll two experimental vessels. The procedure was repeated for all other treatments using

where Pc is the static air pressure under the vessel cap in Pa, r is the air density in kg m3 and Vo is the air velocity across the face orice in m s1. The pressure dierential across the compost mass was therefore calculated as

2 P Pp rVo =2

The orice air velocity Vo was measured using a hot wire anemometer glued to the centre of this orice. The airow rate across the compost was determined from the air velocity and the discharge coecient Cd of the vessel cap orice. The value for Cd was determined before the test, using an empty vessel. An airow rate measured using a ow meter (01201 l min1) was introduced at

438

S. BARRINGTON ET AL.

the bottom of the vessel while measuring the central velocity of the air jet escaping the cap orice. The discharge coecient Cd of this orice for an airow Vo below 275 m s1 was found to be Cd e01547Vo and for Vo above 275 m s1: Cd 0 64 10 After measuring initial airow resistances, the mixtures were aerated at a rate of 2 l min1 and composted for 21 days. The mixtures composted adequately, reached a temperature of 658C after 2472 h and maintained this temperature for at least 3 days (Barrington et al., 1997). After 21 days of composting, the temperature of the mixtures dropped below 358C. Using the procedure described earlier, the air static pressure test was repeated for all vessels except that for the shavings, because of technical diculties. 3.4. Analytical procedures All compost materials were analysed using standard methods (APHA et al., 1995). The moisture content was determined by drying at 1038C for 24 h. The pH was determined with a probe on 5 g of material soaked in 50 ml of distilled water for 24 h. The total Kjeldahl nitrogen (TKN) was determined by digesting the material with sulphuric acid at 5008C and measuring the NH3-N content at a sample pH of 13, using an NH 3 sensitive electrode. The NO3-N content was determined by soaking a 5 g sample in 50 ml of distilled water for 24 h and measuring the level of NO3-N using an NO 3 sensitive electrode. The ash content was obtained by burning each dried sample at 5008C for 4 h. The organic matter content was equated to the volatile portion of the burned samples and converted to C using a factor of 183 (Castellanos & Pratt, 1981). The particle dry density was measured by soaking in commercial grade kerosene and measuring the volume against the weight of the particles. 3.5. Statistical analysis The air static pressure drop P in Pa for each test was related to the apparent air velocity V in m s1 across the compost by applying the procedure of linear regression (Steel & Torrie, 1986). Averaged from the quadruplets, 3 the slope gave the value of H m1 e2 =D2 p e in Eqn (2), while the intercept represents the amount of pressure required before any airow can occur through the compost. The value for L was calculated from the 9

known value of m, H , Dp and e. The true value of Dp was assumed to remain the same throughout the composting period (Geankoplis, 1978). The procedure for the analysis of variance with blocks representing the moisture levels was used to determine whether or not there was a signicant dierence between the values for the coecient L obtained before and after composting and among the three MCs. Duncans New Multiple Range Test was used to establish which treatment was signicantly dierent (Steel & Torrie, 1986).

4. Results and discussion The air pressure dierentials measured across the compost material for all four bulking agents and the three MCs are summarized in Tables 47. The pine shavings compost oered the least resistance to airow despite its higher wet and dry bulk density. The chopped grass hay oered less resistance to airow than the mixed grass hay. The long wheat straw compost oered the most resistance to airow, especially at a moisture content under 67%. The air static pressure drop for all fresh compost generally increased with MC, air velocity across the compost and age of the compost. For apparent air velocities under 0002 m s1, the pressure drop regression equations respected the laminar ow model [Eqn (2)] with coecients of determination R2 ranging from 085 to 097. The slope of the regression equation increased slightly with apparent air velocity, thus lowering the value of R2 . This increase in slope value indicates that higher airows were likely to change the size and geometry of the airow pores, or that some pores were starting to experience turbulent air ow. All regression equations gave a zero Y-axis intercept.

4.1. The hay compost The air static pressure drop for the chopped and mixed hay are summarized in Tables 4 and 5. The value for L for the fresh low, medium and high MC compost was 10 500, 1800 and 900, while that for the 21-day compost was 10 000, 9000 and 11 400. As expected, the value for L was the same for the chopped and the mixed hay, for all MC and compost age, because both bulking agents had the same shape and created the same pore tortuosity. Therefore, L for fresh hay compost can be expressed as L 25 M 16 11

COMPOST AIRFLOW RESISTANCE

439

Table 4 Pressure losses with aeration of the chopped hay Moisture content, % Bulk density, kg m3 Wet Fresh compost 60 250 65 295 70 325 Compost, 21 day old 62 185 53 225 67 245 Dry 100 103 98 70 106 80 071 067 062 079 075 073 063 062 062 062 049 047 24 100V 56 200V 51 100V 33 200V 43 600V 40 500V 084 093 094 088 086 083 10 500 1 800 900 10 000 9000 11 400 Void ratio (e) Depth of compost (H), m Pressure drop (P), Pa Coe. of determination (R2) Airow channel coe. (L)

Note: R2 is for linear regression describing P; the regression equation for P is valid for the apparent airow velocity V of 500015 m1 s; average compost diameter Dp is 20 mm.

Table 5 Pressure losses with aeration of the mixed hay Moisture content, % Bulk density, kg m3 Wet Fresh compost 60 195 67 245 75 380 Compost, 21 day old 52 156 59 174 67 245 Dry 78 51 98 75 71 81 076 071 057 080 076 073 066 064 061 054 049 047 95 700V 54 700V 74 100V 56700V 77 200V 134 200V 089 087 093 085 082 087 10 600 1800 900 10 000 9000 11 400 Void ratio (e) Depth of compost (H), m Pressure drop (P), Pa Coe. of determination (R2) Airow channel coe. (L)

Note: R2 is for linear regression describing P; the regression equation for P is valid for the apparent airow velocity V of 50002 m s1; average compost diameter Dp is 32 mm.

Table 6 Pressure losses with aeration of the wheat straw Moisture content, % Bulk density, kg m3 Wet Fresh compost 63 175 67 205 72 235 Compost, 21 day old 64 175 69 185 75 200 Dry 65 69 70 63 57 50 075 071 065 079 078 076 085 085 085 075 075 075 48 200V 30 000V 22 600V 77 500V 56 500V 26 100V 087 094 088 084 090 085 5500 2200 900 16 700 10 600 3800 Void ratio (e) Depth of compost (H), m Pressure drop (P), Pa Coe. of determination (R2) Airow channel coe. (L)

Note: R2 is for linear regression describing P; the regression equation for P is valid for the apparent airow velocity V of 50002 m s1; average compost diameter Dp is 35 mm.

440

S. BARRINGTON ET AL.

Table 7 Pressure losses with aeration of the fresh wood shavings compost Moisture content, % 59 64 69 Bulk density, kg m3 Wet 300 326 412 Dry 123 117 128 076 071 057 054 052 051 192V 124V 176V 096 097 094 2030 760 260 Void ratio (e) Depth of compost (H), m Pressure drop (P), Pa Coe. of determination (R2) Airow channel coe. (L)

Note: R2 is for linear regression describing P; the regression equation for P is valid for the apparent airow velocity V of 50002 m s1; average compost diameter Dp is 24 mm.

with a value for R2 of 097, and for unturned 21-day-old compost from hay by L 10 0001000 12

where M is the moisture content of the compost expressed as a decimal. For the fresh compost, the initial MC had a signicant eect on P, whereas after 21 days of composting, the MC had dropped and no longer exerted any signicant eect (95% condence level). Thus, overturning the compost during its fermentation stage is likely to reduce in pore clogging. 4.2. The whole wheat straw compost The value of L, for the fresh low, medium and high MC straw compost was 5500, 2200 and 900, while that for the 21-day compost was 16 700, 10 600 and 3800. The value of L was in the same range as that for the hay, except that MC had a signicant eect on the value of L after 21 days of composting. These higher values resulted from the more extensive decomposition and collapsing of the straw stems, as opposed to the hay stem which remained hollow after 21 days. Thus, the straw composted oered more airow resistance after 21 days of composting, as compared to the hay compost. Therefore, L for fresh straw compost can be expressed as L 10 M 155 L 91 600 117 000 M with a value for R2 of 10 in both cases. 4.3. The pine shaving compost The value of L, for the fresh low, medium and high MC shavings compost was 2030, 760 and 260. The value 13 14

for L was generally lower than that for the hay and the straw, likely because the shaving particles are more spherical in shape than the long tubular shape of the hay and straw. Thus, the airow pores of the shaving compost are more regular in geometry. As for the hay and straw compost, the shavings compost demonstrated a value for L decreasing with increasing MC. Therefore, L for fresh shavings compost can be expressed as L 12 355 17 720 M with a value for R2 of 094. 15

5. Conclusions For apparent air velocities Vo under 0002 m s1, the static air pressure drop P occurring in compost of hay, wheat and shavings can be described using a laminar airow equation based on porosity, particle size distributution, depth and airow channel characteristics of the compost material. These equations can be solved if the airow channel coecient L is known. This coecient corrects the eective length of the airow paths, based on the compost depth H , and the eective shape of the compost particles, based on an average particle diameter measured by sieving D2 p . Although there were some variations in the value of L with MC, both the hay and straw demonstrated values of 1000 and 15 000, while shavings demonstrated values of 2602030 for MC of 7060%. Ageing increased the value of L for all composts. The loss of compost structure resulted from the blocking of pores and in the increase in the value of L. Overturning can help reestablish the materials structure and unclog the air pore channels. Compost material oers a value of L much higher than that experienced with the bed of packed granular material, as compost contains particles of an irregular shape, resulting in tortuous airow channels.

and for unturned 21-day-old compost from straw by

COMPOST AIRFLOW RESISTANCE

441

Acknowledgements This project was nancially supported by the Natural Sciences and Engineering Research Council of Canada.

References

APHA; WPCF; AWWA (1990). Standard analysis for water and waste water. American Public Health Association, American Waster Works Association and Water Pollution Control Federation, Washington, DC ASAE (2000). Resistance to airow of grains, seeds, other agricultural products, and performance of metal sheets. In: ASAE Standards, D272.2. American Society of Agricultural Engineering, St Joseph, MI, USA " re D; Trigui M; Knight W (1997). Barrington S F; Choinie Passive versus active aeration for composting. In: Proceedings of the CSAE Technical Sessions, pp. 514523.

Canadian Society of Agricultural Engineering, Saskatoon, Saskatchewan, Canada Castellanos J Z; Pratt P F (1981). Mineralization of manure nitrogen}correlation with laboratory indexes. Soil Science Society of American Journal, 45, 354357 Geankoplis C J (1978). Transport Processes and Unit Operations. pp. 129132. Allyn and Bacon Inc. Boston, USA Higgins A J; Chen S; Singley M E (1982). Airow resistance in sewage sludge composting aeration systems. Transactions of the ASAE , 24(4), 10101014, 1018 Keener H M; Hansen R C; Elwell D L (1987). Airow through compost: design and cost implications. Applied Engineering in Agriculture, 13(3), 377384 Saint-Joly C; Peyre A; Bochu J L; NDao O (1989). Pressure losses during ventilation of manure. Biological Wastes, 30, 123132 Steel R D G; Torrie J H (1986). Principles and procedures of Statistics, a Biometrical Approach. (2nd edn.). McGraw Hill Inc., New York, USA

Anda mungkin juga menyukai

- Leaflet FAN COIL RANGE PDFDokumen44 halamanLeaflet FAN COIL RANGE PDFAlexandru GhergheBelum ada peringkat

- Leaflet FAN COIL RANGE PDFDokumen44 halamanLeaflet FAN COIL RANGE PDFAlexandru GhergheBelum ada peringkat

- CA/LINE-15: Characteristic Curve and Acoustics at 1.2Kg/MDokumen2 halamanCA/LINE-15: Characteristic Curve and Acoustics at 1.2Kg/MAlexandru GhergheBelum ada peringkat

- PalanDokumen5 halamanPalanAlexandru GhergheBelum ada peringkat

- Road Bike Size Sheet - EBicyclesDokumen2 halamanRoad Bike Size Sheet - EBicyclesAlexandru GhergheBelum ada peringkat

- CAM-752-2T-10: Centrifugal High-Pressure Fans Made From Sheet SteelDokumen3 halamanCAM-752-2T-10: Centrifugal High-Pressure Fans Made From Sheet SteelAlexandru GhergheBelum ada peringkat

- The Introduction of Gypsum Board Production LineDokumen29 halamanThe Introduction of Gypsum Board Production LineAlexandru GhergheBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- PA-EAD 200x100 50 L/s PA-EAD 300x200 144 L/S: Biohazard Waste HoldingDokumen13 halamanPA-EAD 200x100 50 L/s PA-EAD 300x200 144 L/S: Biohazard Waste HoldingAyman Gamal eldeenBelum ada peringkat

- Rssay: EssayDokumen50 halamanRssay: EssayJack HarresBelum ada peringkat

- Msds - Hfo Heavy Fuel OilDokumen9 halamanMsds - Hfo Heavy Fuel OilKrishnan RajappanBelum ada peringkat

- List of E-Waste RecyclerDokumen29 halamanList of E-Waste RecyclerTanya VermaBelum ada peringkat

- Best Practices of RAP&RAS Management PDFDokumen44 halamanBest Practices of RAP&RAS Management PDFSinan İcikBelum ada peringkat

- Coal Gasification - EastmanDokumen44 halamanCoal Gasification - Eastmanstavros7Belum ada peringkat

- 0 B4 GU13 C 4 Z Cu 1 VUx Ed 2 X 1 Un ZP TK UDokumen16 halaman0 B4 GU13 C 4 Z Cu 1 VUx Ed 2 X 1 Un ZP TK ULarizza Delos SantosBelum ada peringkat

- De 22-HSDokumen6 halamanDe 22-HSthungungo299Belum ada peringkat

- Lecture 28Dokumen11 halamanLecture 28Tejas MhaiskarBelum ada peringkat

- Unit 10Dokumen10 halamanUnit 10ESC Vietnam fanBelum ada peringkat

- ZenTreat D 302 (SDS)Dokumen3 halamanZenTreat D 302 (SDS)Abhay BhoirBelum ada peringkat

- Mixed-Use High-Rise Building - OfficeDokumen2 halamanMixed-Use High-Rise Building - Officewilmar batalunaBelum ada peringkat

- Sukuma Afrika MDGs AwardsDokumen5 halamanSukuma Afrika MDGs AwardsJerome JT OrangaBelum ada peringkat

- Environemntal Code From DenrDokumen14 halamanEnvironemntal Code From DenrChinggay Aliva100% (1)

- Mahmoud 2017Dokumen9 halamanMahmoud 2017Thulasirajan KrishnanBelum ada peringkat

- Best Practices in MiningDokumen90 halamanBest Practices in MiningUriel Placido Jacho Pacha100% (1)

- Quality Improvement Techniques For Recycled Concrete AggregateDokumen18 halamanQuality Improvement Techniques For Recycled Concrete AggregatejuigaykeBelum ada peringkat

- 02 QHSE Module Admin ManualDokumen74 halaman02 QHSE Module Admin ManualharounBelum ada peringkat

- 6 Opalxtraboost Opaldam PDFDokumen10 halaman6 Opalxtraboost Opaldam PDFlucserpBelum ada peringkat

- Anis Nurul Shofriyyah - f44160092 - Analisis Timbulan Sampah Dan Desain Dari Instalasi Kompos Di Kampus Ipb Dramaga, Bogor, Jawa BaratDokumen20 halamanAnis Nurul Shofriyyah - f44160092 - Analisis Timbulan Sampah Dan Desain Dari Instalasi Kompos Di Kampus Ipb Dramaga, Bogor, Jawa BaratAnis Nurul ShofriyyahBelum ada peringkat

- Nagpur Smart CityDokumen10 halamanNagpur Smart CityBK NGPRBelum ada peringkat

- SDS - All Purpose Marine Wood Primer - Marine - Protective - English (Uk) - Australia - 27580 - 29.11.2013Dokumen9 halamanSDS - All Purpose Marine Wood Primer - Marine - Protective - English (Uk) - Australia - 27580 - 29.11.2013DonBelum ada peringkat

- GB 2H TUBEdek TubeSettlersDokumen2 halamanGB 2H TUBEdek TubeSettlersPhạm BắcBelum ada peringkat

- Lab Handbook - GuidelineDokumen16 halamanLab Handbook - GuidelineteahockBelum ada peringkat

- Air Cooler Cleaner (Acc) Is A Liquid Blend of Highly Active CleaningDokumen5 halamanAir Cooler Cleaner (Acc) Is A Liquid Blend of Highly Active CleaningAbdul AnisBelum ada peringkat

- Ecosystems. Aneatsketch. I: AMIE Study Material & Admission Packages AMIE (I) Study Circle, RoorkeeDokumen27 halamanEcosystems. Aneatsketch. I: AMIE Study Material & Admission Packages AMIE (I) Study Circle, RoorkeeSharadBelum ada peringkat

- Digital Profile of Godawari ReportDokumen106 halamanDigital Profile of Godawari ReportYuzvi SolutionsBelum ada peringkat

- Methods: 1.use of Control RodsDokumen8 halamanMethods: 1.use of Control RodsonikBelum ada peringkat

- Crossconnect Multiplexer CMXC User ManualDokumen156 halamanCrossconnect Multiplexer CMXC User ManualrzhevskiyBelum ada peringkat