A - P Airframe 1-3

Diunggah oleh

Abu Bakar SiddiqueJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

A - P Airframe 1-3

Diunggah oleh

Abu Bakar SiddiqueHak Cipta:

Format Tersedia

A&P Airframe 1-3

Study online at quizlet.com/_cu2om

1.

What is the function of a vortex generator: It is designed to delay or percent separation of the boundary layer What are the three axes of an airplane: Longitudinal, lateral, and vertical. What are the three primary flight controls of a aircraft: Ailerons, elevator, and rudder Name several secondary flight controls and describe their general purpose: Secondary flight controls consist of various types of trim tabs such as balance tabs, anti-servo and servo tabs, and spring tabs. Their function is to assist the pilot in moving the controls and to trim the aircraft to fly hands-off.

17.

Describe the function of a rotorcraft cyclic pitch control: The cyclic control tilts the main rotor disc by by changing the pitch angle of each rotor blade during its cycle of rotation, which causes the helicopter to move in the direction the rotor tilts.

2.

3.

18.

What mechanism is most commonly used to compensate for the torque produced by the main rotor of a helicopter: Tail ( or anti-torque ) rotor

4.

19.

How is the amount of thrust produced by the tail rotor controlled: By moving the foot pedals Why should control surfaces be locked when an aircraft is parked: To prevent damage from the wind. What is the major type of damage to aluminum structures that is caused by exposure to the weather: Corrosion

20.

5.

Name several types of auxiliary flight controls and describe their general purpose: The auxiliary flight controls consist of the various high-lift devices used during low-speed flight such as leading and trailing edge flaps, slats, slots, speed brakes, etc.

21.

22.

Name several methods for forming sheet metal: Bending or folding, stretching, shrinking, bumping, and crimping. What are the dimensions of a properly formed rivet head: The head should be 1 1/2 times the shank diameter in width and 1/2 the shank diameter in height

6.

What is a servo trim tab: It is an auxiliary control, positioned by the movement of a cockpit control and designed to create aerodynamic forces to assist in moving a control surface.

23.

7.

What is a spring tab: It is an auxiliary control designed to aid the movement of a primary control at high speeds when control forces become too high

24.

Describe the markings found on the heads of A, B, D, AD, and DD rivets: A rivets are plain, B rivets have a cross, D rivets have a raised dot, AD rivets have a dimple, and DD rivets have a double dash.

8.

What is a balance tab: It is an auxiliary control designed to create aerodynamic forces to assist in moving a control surface. The tab is positioned by a control rod connected to the fixed surface on the same side as the horn on the tab. (when the primary control surface is moved in any direction, the tab automatically moves in the opposite direction, helping pilot move the control surface)

25.

What happens to the stem of a self-plugging (friction lock) rivet when the rivet is installed: The stem is pulled until it snaps off and the remaining projecting part is trimmed flush with the head.

26.

Name at least three types of self-plugging mechanical lock rivets: CherryMAX, CherryLOCK, OLYMPIC-LOK, and HuckLok.

9.

What are four most common types of high lift devices: Leading and trailing edge flaps, slats, and slots. Describe some of the tools used to check control surface travel: Universal propeller protractor or special control surface protractor

27.

What is the difference between the tools required to pull a CherryLOCK rivet and a CherryMAX rivet: CherryLOCK rivets require a tool for each different size and head shape, while one pulling tool will set any size CherryMAX rivet

10.

11.

Name three mechanical methods by which flight control systems may be actuated: Cables, push-pull rods, and torque tubes.

28.

Which of the five stresses is the most common cause of rivet failure: Shear If a 2024 rivet must be replaced with a 2117 rivet, how do you determine the size to be used: For 5/32" or smaller diameter, use the next larger size 2117 rivet, assuming that the edge distance and spacing meet the minimum requirements.

12.

What is a fairlead: It is a device to prevent a cable from rubbing on the aircraft structure. What are the most likely places for a control cable to wear or break: Where the cables pass over pulleys or through fairleads

29.

13.

30.

Describe the process for determining the total length of a solid rivet for a particular installation: Add the grip length ( thickness of the materials being joined) plus 1 1/2 times the rivet diameter

14.

What information is required before a cable rigging chart can be used: The ambient temperature and cable size What is the function of a cable tension regulator: It automatically adjusts the cable tension to compensate for expansion and contraction in the aircraft structure.

31.

15.

What minimum edge distance and spacing should be used for a single row of protruding head rivets: Not less than two rivet diameters from the edge and not less than three river diameters apart.

16.

Describe the function of a rotorcraft collective pitch control: The collective control causes each rotor blade to change its pitch angle by the same amount, thus increasing or decreasing the lift produced by the rotor

32.

How can a mechanic determine whether the countersink for a flush rivet should be dimpled of drilled: By the thickness of the top sheet; thin sheets are dimpled while thick sheets may be countersunk

33.

What action is taken to prevent cracks from forming while dimpling magnesium or some hard sheet metals: Hot dimpling equipment is used to preheat and soften the metal before the dimple is formed.

50.

Why should the various pieces of wood being joined be kept in the same room for at least 24 hours prior to joining: To allow the moisture content to equalize, thereby minimizing dimensional changes in the wood.

34.

What type of damage can occur when using a rivet set that does not properly fit the rivet: If the radius of the set is too small, the rivet head may be damaged, whereas a set with an over-sized radius may cause damage to the sheet metal.

51.

Why is it important to consider the open assembly time when gluing wooden structures: If the maximum openassembly time is exceeded, the joint may fail since the glue may begin setting up before the joint is assembled.

35.

Why is it important to use the proper size and weight bucking bar when performing sheet metal riveting: If bucking bar is too large or heavy it may be difficult to control and may cause damage to the surrounding structure, whereas a bucking bar that is too light will not properly upset the rivet before work hardening occurs.

52.

Why is it important to apply the proper clamping pressure to a glue joint: Clamping forces air out of the joint, brings the wood surfaces together evenly and is, in part, responsible for the strength of the glue line.

53.

Describe some of the methods used to apply pressure to glue joints: Clamps, nailing strips, power presses, brads, nail, and small screws.

36.

What procedures should be followed to properly remove a solid-shank rivet: Center punch the rivet and then drill just to the base of the rivet head with the same size or one size smaller drill. Once drilled, use a pin punch to tip off the rivet head and drive the remaining shank out of the hole while supporting the surrounding metal.

54.

What minimum curing temperature should be observed when joining wood with various adhesives: 70 degrees Fahrenheit or as specified by the glue manufacturer.

55.

When inspecting wood structures, why might it be important to consider stains and discolored areas: Stains and discoloration usually accompany decay and or rot.

37.

What are the two special calculations that must be made when bending sheet metal: Bend allowance and setback What factors must be considered in order to determine setback: The thickness of the metal and the bend radius. What is done to a corner where two bends intersect to percent cracking: Relief holes are drilled in the corner

57. 56.

Describe the acceptable methods used to repair elongated bolt holes found in a wooden wing spar: Remove the section containing the elongated holes and splice in a new section or replace the entire spar What type of joint is used to splice a solid or rectangular wood spar: A scarf joint In what areas are splices to a wood spar prohibited: Under an attachment fitting for the wing root, landing gear, engine-mount, lift, or inter-plane strut

38.

39.

40.

What are the two reasons for installing lightening hole in a sheet metal wing rib: Lightening holes reduce the weight and increase stiffness

58.

41.

Describe a joggle and explain it function: A joggle is an offset formed at an intersection of two or more sheets of metal to allow the multiple sheets to be stacked flat against each other

59.

What is the maximum number of splices allowed for any single spar: Two. Describe the characteristics of a scarf joint: The pieces to be joined are tapered or beveled on a slope of 1 to 10 or 1 to 12. Why must the beveled cut be accurate on both pieces of wood being repaired with a scarfed joint: The two pieces must match exactly to ensure a tight joint.

42.

When repairing an all metal aircraft, how do you determine what metals should be used: Always use metal of the same type and thickness as the original structure.

60.

43.

What are the three forms of wood commonly used in aircraft construction: Solid, laminated, and plywood What type of wood should be used when splicing or reinforcing plywood webs: The same type of plywood as originally used.

61.

44.

62.

What are the two primary uses for plywood in aircraft construction: Gusset (or reinforcing) plates and aircraft skin. Provide examples of at least three types of plywood skin repairs: Splayed patches, surface patches, plug patches, and scarfed patches.

45.

Name at least four different types of defects found in wood: Knots, checks, splits, pitch pockets, cross grain, curly grain, decay, dry rot, etc..

63.

46.

Can a section of wood containing a hard knot be used: Yes, within specified limits. What type of glue may have been used in older wooden aircraft construction that requires careful inspection to detect deterioration: Casein glue.

64.

What type of patch should be used to repair small holes in thin plywood skin if the skin is less than 1/10th inch thick: A splayed patch may be used if the hole can be cleared out to diameter of less than 15 thicknesses of the skin.

47.

65.

What should be done to prevent a plywood patch and the pressure plate from sticking together if glue is extruded from the joint: Place a piece of waxed paper or vinyl plastic between the patch and the pressure plate.

48.

What are the three types of glues in modern aircraft construction and repair: Resorcinol glue. Phenolformaldehyde glue. and epoxy resin glue.

66.

Why are lightweight steel bushings sometimes used in wooded structures: Bushings prevent the wood from being crushed when bolts are tightened

49.

Is compression wood acceptable for structural repairs: No

67.

What is the purpose of large surface area washers when used on wooden structures: Large washers provide additional bearing area for hardware to help preclude damage to the wood when the hardware is tightened Name several facings and core materials used in bonded honeycomb structures intended for special applications: Stainless steel, titanium, magnesium, plywood, glass, nylon, and cotton cloth. Describe the construction of a bonded honeycomb structure: It is a laminated structure that has a solid facing bonded to either side of a core consisting of open, six-sided cells. What must be done with a damaged area in a bonded honeycomb structure prior to beginning repairs: The damaged area must be completely removed. A drill bit used for drilling composites should have an included angle of how many degrees: 135 degrees What are the most common causes for delamination of a composite structure: Sonic vibration, expansion of internal moisture, liquid leakage, and manufacturing error What type of defect in, or damage to, a bonded honeycomb structure can be repaired using the potted repair method: Filling a hole. Name some of the factors that cause crazing in transparent plastic windows and windshields: Exposure to ultraviolet light, stress, solvents, and improper handling. How should a hole be drilled in Plexiglas to avoid damage to the hole when drill breaks through to the underside: Back up the plastic with a piece of wood and feed the drill slowly.

68.

69.

70.

71. 72.

73.

74.

75.

Anda mungkin juga menyukai

- Eventbrite - 31st Rio Grande Symposium On Advanced MaterialsDokumen2 halamanEventbrite - 31st Rio Grande Symposium On Advanced MaterialsAbu Bakar SiddiqueBelum ada peringkat

- Core TrainingDokumen2 halamanCore TrainingAbu Bakar SiddiqueBelum ada peringkat

- BooksDokumen1 halamanBooksAbu Bakar SiddiqueBelum ada peringkat

- Alienware Aurora Mid Tower Gaming Desktop - Dell United StatesDokumen10 halamanAlienware Aurora Mid Tower Gaming Desktop - Dell United StatesAbu Bakar SiddiqueBelum ada peringkat

- ECE 514 Nonlinear and Adaptive Control Problem SetDokumen2 halamanECE 514 Nonlinear and Adaptive Control Problem SetAbu Bakar SiddiqueBelum ada peringkat

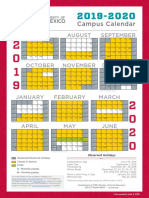

- Campus Calendar 2019 2020Dokumen1 halamanCampus Calendar 2019 2020Abu Bakar SiddiqueBelum ada peringkat

- Art Wafer Clean Room Activity GuideDokumen8 halamanArt Wafer Clean Room Activity GuideAbu Bakar SiddiqueBelum ada peringkat

- Symmetries in network dynamics and their effect on evolutionary gamesDokumen28 halamanSymmetries in network dynamics and their effect on evolutionary gamesAbu Bakar SiddiqueBelum ada peringkat

- 2014 04 MSW Usltr Format-multiple-AuthorsDokumen5 halaman2014 04 MSW Usltr Format-multiple-AuthorsAbu Bakar SiddiqueBelum ada peringkat

- IEEE FormateDokumen5 halamanIEEE FormatelizaBelum ada peringkat

- Markov Chain NRG StorageDokumen10 halamanMarkov Chain NRG StorageAbu Bakar SiddiqueBelum ada peringkat

- Hw6 TemplateDokumen6 halamanHw6 TemplateAbu Bakar SiddiqueBelum ada peringkat

- Drawing1 ModelDokumen1 halamanDrawing1 ModelAbu Bakar SiddiqueBelum ada peringkat

- Graph GeneralDokumen38 halamanGraph GeneralAbu Bakar SiddiqueBelum ada peringkat

- hw6 Template PDFDokumen1 halamanhw6 Template PDFAbu Bakar SiddiqueBelum ada peringkat

- Text32 Text23 Text26 Text28 Auth2Dokumen21 halamanText32 Text23 Text26 Text28 Auth2Abu Bakar SiddiqueBelum ada peringkat

- Towers of HanoiDokumen35 halamanTowers of HanoiAbu Bakar SiddiqueBelum ada peringkat

- (Speyer J.L., Jacobson D.H.) Primer On Optimal ConDokumen314 halaman(Speyer J.L., Jacobson D.H.) Primer On Optimal ConUsKhanBelum ada peringkat

- TFY4305 Solutions Exercise Set 1 2014: Problem 2.2.3Dokumen4 halamanTFY4305 Solutions Exercise Set 1 2014: Problem 2.2.3Abu Bakar SiddiqueBelum ada peringkat

- 37Dokumen6 halaman37Abu Bakar SiddiqueBelum ada peringkat

- Caption MoviesDokumen1 halamanCaption MoviesAbu Bakar SiddiqueBelum ada peringkat

- Asad 1Dokumen61 halamanAsad 1Abu Bakar SiddiqueBelum ada peringkat

- Neuron ConnectDokumen129 halamanNeuron ConnectAbu Bakar SiddiqueBelum ada peringkat

- Dhaka Electric Supply Company LTDDokumen5 halamanDhaka Electric Supply Company LTDAbu Bakar SiddiqueBelum ada peringkat

- Bangla FishesDokumen1 halamanBangla FishesAbu Bakar SiddiqueBelum ada peringkat

- Text32 Text23 Text26 Text28 Auth2Dokumen18 halamanText32 Text23 Text26 Text28 Auth2Abu Bakar SiddiqueBelum ada peringkat

- Neuron ConnectDokumen129 halamanNeuron ConnectAbu Bakar SiddiqueBelum ada peringkat

- Preliminary: 1. Short Title and ApplicationDokumen31 halamanPreliminary: 1. Short Title and ApplicationAbu Bakar SiddiqueBelum ada peringkat

- Document QA Log SummaryDokumen27 halamanDocument QA Log SummaryAbu Bakar SiddiqueBelum ada peringkat

- Preliminary: 1. Short Title and ApplicationDokumen31 halamanPreliminary: 1. Short Title and ApplicationAbu Bakar SiddiqueBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Piper Cherokee PA-28 D checklistDokumen3 halamanPiper Cherokee PA-28 D checklisttmorachBelum ada peringkat

- Cessna 172 ChecklistDokumen38 halamanCessna 172 Checklistesubalew galloBelum ada peringkat

- List of SB 1121Dokumen6 halamanList of SB 1121Albaz DarwishBelum ada peringkat

- CE-525 OSD Flight CrewDokumen42 halamanCE-525 OSD Flight CrewbrianBelum ada peringkat

- 717 Fleet Bulletin Provides Details on All-Attitude Upset Recovery StrategyDokumen12 halaman717 Fleet Bulletin Provides Details on All-Attitude Upset Recovery StrategyChristogratia Immanuel SimbolonBelum ada peringkat

- Rigging The Pitts: by Doug Sowder, IAC #14590Dokumen7 halamanRigging The Pitts: by Doug Sowder, IAC #14590Rodrigo SouzaBelum ada peringkat

- B190 POHbeechcraftDokumen92 halamanB190 POHbeechcraftJohn Plapan67% (3)

- Visualized Flight Maneuvers Handbook: For High Wing AircraftDokumen10 halamanVisualized Flight Maneuvers Handbook: For High Wing AircraftSilvioBelum ada peringkat

- 3270 Operators ManualDokumen35 halaman3270 Operators ManualBrad AllenBelum ada peringkat

- P180 Avanti-Flight ControlsDokumen5 halamanP180 Avanti-Flight ControlsravBelum ada peringkat

- DCS FA-18C Early Access Guide EN PDFDokumen311 halamanDCS FA-18C Early Access Guide EN PDFcRi SocietyBelum ada peringkat

- Hawker 850xpDokumen7 halamanHawker 850xplocoboeingBelum ada peringkat

- Capsule and Question DA40Dokumen44 halamanCapsule and Question DA40AlokBelum ada peringkat

- Maxum 4600 SupplementDokumen48 halamanMaxum 4600 SupplementAli IrvaliBelum ada peringkat

- B744 SIM ProfileDokumen6 halamanB744 SIM ProfilekotaroyanoyanokotaroBelum ada peringkat

- A2A 172R Checklist PDFDokumen2 halamanA2A 172R Checklist PDFBrunoViniciusBelum ada peringkat

- Ecqb PPL 51 Pfa Ppla - enDokumen23 halamanEcqb PPL 51 Pfa Ppla - enRadu CiolpanBelum ada peringkat

- Super Rocket Trigear mt7235Dokumen37 halamanSuper Rocket Trigear mt7235daniel gaudencioBelum ada peringkat

- Paramotor TutorialDokumen18 halamanParamotor TutorialLuiz Maywitz100% (1)

- B200 MTF ChecklistDokumen3 halamanB200 MTF ChecklistplhoughtBelum ada peringkat

- Note Principle of FlightDokumen21 halamanNote Principle of Flightdu_sasi100% (1)

- Beechjet 400A: Cockpit Reference HandbookDokumen486 halamanBeechjet 400A: Cockpit Reference Handbookeduardo ruizBelum ada peringkat

- Section 1 - IntroductionDokumen24 halamanSection 1 - IntroductionAllexx NashBelum ada peringkat

- Pa31 Normal ProceduresDokumen9 halamanPa31 Normal ProceduresIvan OggeroBelum ada peringkat

- Formula Pre Delivery InspectionDokumen2 halamanFormula Pre Delivery InspectionClay WalkerBelum ada peringkat

- North American Aviation T-28B/C TrojanDokumen75 halamanNorth American Aviation T-28B/C TrojanRichard LundBelum ada peringkat

- 022 - Instrumentation - AnswersDokumen57 halaman022 - Instrumentation - AnswersEASA ATPL Question BankBelum ada peringkat

- Check List Cessna c172s Nav IIIDokumen4 halamanCheck List Cessna c172s Nav IIIGourav DasBelum ada peringkat

- Checklist Resumida C441Dokumen7 halamanChecklist Resumida C441EnrriqueercolibersovineBelum ada peringkat

- A2A B17 Accusim ManualDokumen159 halamanA2A B17 Accusim ManualEduardoMCraft PLUSBelum ada peringkat