Isme 3 T-MAS, The Detector of Scuffing Before Excessive Wear

Diunggah oleh

Muhammad Shamraiz DarJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Isme 3 T-MAS, The Detector of Scuffing Before Excessive Wear

Diunggah oleh

Muhammad Shamraiz DarHak Cipta:

Format Tersedia

Proceedings of the 7th International Symposium on Marine Engineering Tokyo, October 24th to 28th, 2005

T-MAS, the Detector of Scuffing before Excessive Wear

Yuji WAKATSUKI*, Kei WATANABE**, Tetsuya YAMAMOTO**

ABSTRACT The Temperature Monitoring and Alarming System (T-MAS) is a unique system which can detect scuffing on the running surface of cylinder liner of large two-stroke diesel engine before the occurring of excessive wear. An excessive wear of cylinder liner is a very high impact on the vessel schedule and operating cost. T-MAS detects the symptom of scuffing on the surface of cylinder liner by monitoring temperature. Normally, there is enough cylinder lubricating oil on the surface of cylinder liner. When the scuffing is started on the very small local part, cylinder lubricating oil has gone by the metal-to-metal contact and combustion gas with high temperature blows on this part. At that time, the temperature behavior of this surface is unique. Therefore, ship operators can avoid the excessive wear by taking a properly countermeasure when T-MAS detects such phenomenon.

Key Words: Diesel Engine, Cylinder Liner, Temperature Monitoring, Scuffing, Alarming

1. INTRODUCTION Since long-long ago, ship operators, and also engine manufacturers, have been worried about scuffing problem on the cylinder liner inner surface of main two-stroke large diesel engines. The causes of damage were able to consider many things; water invention, lubricating oil degradation, fuel oil characteristics, torque rich operation, rough sea condition, poor engine maintenance, poor material, etc. However, every time, the scuffing coming suddenly and shipowner spends much money in order to repair the damage as soon as possible. An engine manufacturer completed the system which detected scuffing before excessive cylinder liner wear occurred.

2. CIRCUMSTANCES Recently, the marine diesel engines are becoming to larger size, higher speed and higher power. Additionally, maintenance interval is longer and quality of maintenance is lower. On the other hand, the schedule of vessel is very busy condition, then, the vessel cannot stop any longer. In such circumstances, ship operators inquire reliability first. One of the most important parts of marine diesel engine is a cylinder liner. Excessive wear of a cylinder liner is one of the most unfavourite things of ship operators. Stopping of the vessel bones high additional cost and loses their credit with their customer. Furthermore, recently, fuel oil quality is also decreased and opportunity of excessive wear of cylinder liner is increased. * Mitsubishi Heavy Industries, Ltd., Diesel Engine Department, Kobe Shipyard & Machinery Works, 1-1-1 Wadasaki-cho, Hyogo-ku, Kobe 652-8585, JAPAN FAX: +81-78-672-5985, E-mail: yuji_wakatsuki@mhi.co.jp ** Mitsubishi Heavy Industries, Ltd.

Especially, scuffing, adhesive wear in other ward, occur with large wear amount and it is often necessary to renew a cylinder liner. Renewing of a cylinder liner is together with dismantling a cylinder cover and a piston. Complete work of renewing one cylinder liner on board is necessary about fifteen hours with eight men. Cost of new cylinder liner is not cheep, too. Considering with such cost, damage of a cylinder liner means a very expensive thing. Therefore, fuel quality is one of an important thing for reliability. For recent ten years, a lot of marine fuel oil has come from a fluid catalyst cracking (FCC) refinery plant with a desulphurization process. The feature of this fuel oil is high density, high micro carbon residue and low sulphur. These fuel oil often occur the excessive wear of cylinder liner. Real reason of the excessive wear is still not clear, however, such low sulphur heavy fuel oil is not suitable for marine diesel engines in recent common sense. May of this year (2005), Annex VI of MARPOL 73/78 Protocol 97 of IMO was come into effect. In this protocol, in order to prevent SOx emission, sulphur content of bunker fuel is regulated. In the special area called SECA, sulphur content of bunker fuel must be under 1.5% mass. The special area will start at the Baltic Sea in 2006 and expand to the North Sea and the English Channel in 2007. Many merchant vessels calling at northern Europe area will be regulated by this legislation. These vessels will have to use low sulphur fuel oil in this area. It will be worry about the excessive wear of cylinder liners of main diesel engines on these vessels. It is considered that the low sulphur fuel oil have problems with combustion characteristics, lubrication ability and running-in performance. Furthermore, with cat fine, used lubricant oil or other foreign contamination, this problem comes out easier. The vessel operators know how to avoid excessive wear when scuffing occur; decreasing load, increasing cylinder lubricating oil feed rate, etc. However, they cannot find when scuffing occur.

-1-

In this paper, it is not described about the causes of scuffing on cylinder liner surface. It is mentioned that how to detect the scuffing before cylinder liner are worn out excessively.

3. CYLINDER LINER MONITORING There were some trying items to detect the scuffing of cylinder liner of marine diesel engine. For example, the measuring of oil film thickness on the surface of cylinder liner, the measuring of iron particles in the piston underside drain oil by ferrography, the analysis of bunker fuel oil, the rough measurement of cylinder liner temperature (Fig.1 3), etc. However, all of them have presented unclear result after occurring of the scuffing like a certificate of death.

Scuffing, in other words, adhesive wear is a phenomenon of breaking oil film on a surface of cylinder liner. After breaking oil film, a cylinder liner with piston rings occurs metal-tometal contact. This means metal surface of one side adhere with metal surface of another side. The temperature of cylinder liner is increased at that time, with energy of peeling off of metal construction, like friction heat.

Fig. 4. Surface condition of the scuffed piston rings However, why the temperature is decreased after some period? It is considered that, on a very initial stage of phenomenon of scuffing, enough cylinder lubricating oil is still exited on a surface of cylinder liner and lubricating oil film is recovered at local oil film breakage area and then temperature is decreased. However, this area is under condition which is easy to break an oil film on a surface of cylinder liner. Therefore, this oil film is broken again soon if the condition of an engine is not changed. On the initial stage of scuffing, this phenomenon is repeated and made zigzag temperature behavior on a surface of cylinder liner. Then, it is considered that the avoiding of scuffing would be possible by the detection of this phenomenon.

Fig. 1. Cylinder liner temperatures trend data (1)

Fig. 2. Cylinder liner temperatures trend data (2)

Fig. 3. Cylinder liner temperatures trend data (3) Sometimes in our detailed measurement systems of cylinder liner temperature, it was found that the phenomenon which zigzag temperature behaviors were existed before increasing temperature as a phenomenon of scuffing. After finding of this zigzag signal, some countermeasures, increasing of cylinder oil feed rate, decreasing of engine load, etc., were carried out, then, these vessel could avoid the scuffing of cylinder liners and the temperature of cylinder liner would decrease. After receiving the reports for these similar experiences, it was understood that this phenomenon with fluctuated temperature is a symptom of scuffing of cylinder liner.

1Hr. Paper feeding Fig. 5. Field data of cylinder liner temperature measurement Zigzag temperature phenomenon is not regularly. Interval of wave peak, amplitude and mean temperature are also not fixed. Furthermore, when the gap of piston ring comes to the

-2-

measuring position, the temperature measured is also increased. And it is decreased after the gap passes. Accordingly, the phenomenon mentioned is not able to analyze functionally. The chief engineer always minds the wave behavior of cylinder liner temperature. Finally, he could not leave in front of temperature recorder in all day and he could not sleep. Sometime, the monitoring system makes new job for ship staffs like that. Therefore, it is considered that the alarming system must be necessary on this monitoring system. Then, it is restarted to investigate how to separate zigzag signal from cylinder liner temperature data. The zigzag temperature phenomenon is recognized by the inclination and amplitude of the temperature data curve. Depending on the number of peaks in the limited period, the system indicates and calls an alarm signal. This system also has a high temperature alarm and a high deviation alarm. Normally, the temperature will increase gradually when zigzag phenomenon appears. Therefore, these high temperature alarms are secondary signals of scuffing.

approximately 10 mm from surface. Two sensors are fixed on the pump side and the exhaust side with 180 degrees pitch. A hybrid recorder and thermocouples are connected by compensation wires through a junction box on an engine.

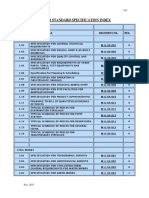

Fig. 7. Temperature sensor on the cylinder liner 4. OUTLINE OF T-MAS T-MAS constructed by temperature sensors, cables, a junction box, a hybrid recorder and a personal computer. Fig. 6 shows system outline of the standard specification of T-MAS. In standard specification, two temperature sensors are installed on one cylinder liner. Additionally, temperatures of cylinder jacket cooling water inlet and outlet, a load indicator signal and an engine speed signal are also taken in this system. Ethernet cable connects between a hybrid recorder and a personal computer. Normally, a hybrid recorder and a personal computer are installed in a control room. A hybrid recorder is able to acquire multi signal data and dispose of them in one time. The data recorded are plotted on a recording paper and sent to a personal computer at same time. This hybrid recorder changes the voltage of thermocouple to the value signal of temperature. And it also changes of sensor signals of a load indicator position and engine speed to the process-able data. Fig. 8 shows the actual used hybrid recorder.

Fig. 8. Hybrid recorder in the control room

Fig. 6. Outline of T-MAS The temperature sensor is selected sheath thermocouple type of Chromel-Alumel which is able to measure from -200 to 1000 degrees Celsius. The temperature measuring points are upper part of running surface of cylinder liner and depth is

Fig. 9. Control room

-3-

The personal computer is programmed alarm functions. TMAS has three kinds of alarming; high temperature, high temperature deviation and zigzag wave. Each setting of temperature is depended on an engine type. Alarming signal from personal computer is delivered to vessel control system and ring the alarm. The personal computer also indicates the alarm on the console picture and records the alarm history.

for only a problem cylinder with changing of fuel injection pump setting as for temporary action. Because they have many experiences of such problems, they can mention above things. Avoiding invasion of cat fine or other particles, it is necessary proper using of fine filters and purifiers and cleaning of piston underside space. Keeping on the engine performance, it is necessary maintenance of turbocharger and fuel injection valves. Avoiding over torque, it is necessary control of torque limiter in rough sea operation and reduction of engine load. And keeping on strength of cylinder lubricating oil on cylinder liner running surface, it is necessary increasing of cylinder lubricating oil feed rate and decreasing of temperature of jacket cooling water in order to increase its viscosity. All items of them are effective to avoid scuffing actually.

5. FIELD EXPERIENCES On the initial stage of this system, as mentioned above, it was only monitoring system and recoding temperature by a hybrid recorder. Normal cylinder liner temperature curves are very smooth and plain. Depend on the engine load, the temperatures are changed smoothly. Sometime, one big peak of temperature is appeared. This peak signal is indicated pass of a gap of top piston ring. It is said that piston rings run around a piston crown when the condition is normal. Therefore, this peak signal means condition barometer of a cylinder liner and piston rings. This peak signal of temperature is appeared clearly sometime and not clearly sometime. This temperature phenomenon is still not understood clearly at this present. T-MAS detects zigzag wave which is a symptom of scuffing and does not detect peak curve which is a piston ring gaps passing signal. Average temperature of zigzag condition is usually higher than normal condition at the same load. Indicated temperature on this system is not a surface temperature of cylinder liner. It is an actual temperature of the measuring position of a thermocouple. However, the intention of temperature is described the surface condition of cylinder liner. The value of measured temperature is in proportion to the temperature of cylinder liner surface. On the vessel which is installed this temperature monitoring system, the chief engineer can control the temperature by increasing of a feed rate of cylinder lubricating oil or decreasing of an engine load. Actually, after installing the TMAS, the replacement of cylinder liner with excessive wear has decreased extremely. Before installing the T-MAS, a vessel which often occur the scuffing of cylinder liner, replaced cylinder liners in many times. Many causes of excessive wear are existed. The engine designers and engineers on the vessel consider many things and take countermeasure against the causes. However, they are not perfect. Rough sea condition, heavy fuel characteristics, cylinder lubricating oil feed rate, engine operating load, fuel pretreatment system condition, engine maintenance condition, cylinder liner running surface condition, engine performance and torque condition, etc. Especially, recent vessels have very busy schedule and very short maintenance period with very long maintenance interval. They cannot achieve perfection. Therefore, T-MAS is very useful to detect the scuffing before the excessive wear which will come some time. The engineers can take a countermeasure against the occurring phenomenon depending on the output signal from T-MAS. The engine designers can provide the countermeasures against the detected phenomenon to the vessel engineers. They recommend that checking of fine filter condition, multi operation of the purifiers, torque limit control in rough sea, cleaning of the piston underside space, cleaning of the turbocharger and maintenance of fuel injection valves. Additionally, increasing of cylinder lubricating oil feed rate, decreasing of jacket cooling water temperature, operation of purifiers with minimum flow rate and reduction of engine load

Fig. 10. One of the consol descriptions of T-MAS

Alarm show disp.

Alarm Level 3

Time : 1999/05/07 06:49:10 Position : #2CylinderF Alarm : Frequent fluctuation Temperature : 194.0 Max.Amplitude: 11.0

OK

Fig. 11. One of the consol descriptions of T-MAS 6. CONCLUSION The best way to avoid scuffing of a cylinder liner is detection of a symptom of phenomenon. Then, users can take countermeasures against the detected phenomenon depending on the engine designers advices. The cause of phenomenon is considered many ways; abrasive wear, corrosive wear, water invasion, torque rich operation, abnormal combustion, low grade of fuel, etc. Under the every causes of phenomenon, the lubricating oil film breakage is occurred when scuffing starts. At that time, engineers on the vessel must consider to stop the phenomenon as soon as possible. This paper announces some ways to decide on the vessel. This behavior makes the best

-4-

result for not only the vessels stuffs but also vessel owner and other relatives. The engine developers always wish the comfortable and safety voyages of vessel. At the end of this paper, the authors recommend to shipowners to install T-MAS for your vessels again strongly.

8. REFERENCES [1] Wakatsuki, Y., Watanabe, K., Yamamoto, T. and Takaishi, T., Relation between Recent Low Grade Fuel and Reliability of Marine Diesel Engines, Paper No. TS-66, 6th ISME 2000, Tokyo, Japan, October 23-27, 2000

7. ACKNOWLEDGEMENTS Special thanks should be extended to the shipowners and vessels staffs of vessels which installed the T-MAS and our service engineers who visit the vessels in worldwide.

-5-

Anda mungkin juga menyukai

- Business Communication Solved Mcq's With PDF Download (Set-2)Dokumen5 halamanBusiness Communication Solved Mcq's With PDF Download (Set-2)Muhammad Shamraiz DarBelum ada peringkat

- PHYSICS MCQS FOR IIT JEE NEET IAS SAT MAT Multiple Choice Questions Answers Fully Solved IITJEE Main Advanced Trust Education PDFDokumen1.487 halamanPHYSICS MCQS FOR IIT JEE NEET IAS SAT MAT Multiple Choice Questions Answers Fully Solved IITJEE Main Advanced Trust Education PDFRajendra100% (2)

- Tutorial 2Dokumen57 halamanTutorial 2msohail_kawishBelum ada peringkat

- 2 Anmol Khazaney by Hakeem Muhammad Tariq MahmoodDokumen34 halaman2 Anmol Khazaney by Hakeem Muhammad Tariq MahmoodSharifa SorathiaBelum ada peringkat

- Spice Day 1Dokumen20 halamanSpice Day 1Muhammad Shamraiz DarBelum ada peringkat

- HRM MCQ Sem IDokumen24 halamanHRM MCQ Sem ISuren Koundal71% (52)

- Form FDokumen1 halamanForm FzaahidaliBelum ada peringkat

- Digital Logic Design Lab: Department of Electrical EngineeringDokumen8 halamanDigital Logic Design Lab: Department of Electrical EngineeringHassan Khan100% (1)

- 110 Mcqs of HR Management SolDokumen21 halaman110 Mcqs of HR Management SolMuhammad Shamraiz Dar100% (1)

- Test Your I.Q 3rd Edition-SlicerDokumen127 halamanTest Your I.Q 3rd Edition-SlicerMuhammad Shamraiz Dar93% (15)

- Interpretation of Infrared Spectra, A Practical ApproachDokumen24 halamanInterpretation of Infrared Spectra, A Practical ApproachLucas TimmerBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Transformer REFDokumen4 halamanTransformer REFs_banerjeeBelum ada peringkat

- TERAO Presentation August 2022Dokumen48 halamanTERAO Presentation August 2022LuatNguyenBelum ada peringkat

- 568100Dokumen2 halaman568100Talha TariqBelum ada peringkat

- Electrical Network of The Automotive Multi-Sectional Thermoelectric Generator With MPPT Based Device UsageDokumen10 halamanElectrical Network of The Automotive Multi-Sectional Thermoelectric Generator With MPPT Based Device UsageMouna MorchidBelum ada peringkat

- Pipe Sizes and Flow Rates for Air Flush DrillingDokumen14 halamanPipe Sizes and Flow Rates for Air Flush DrillingzapspazBelum ada peringkat

- Curriculum Vitae Yosep Kurniawan Basa SogenDokumen19 halamanCurriculum Vitae Yosep Kurniawan Basa Sogenyosep kurniawanBelum ada peringkat

- KR AGILUS Hygienic Machine Fast Cleaning Food PharmaDokumen2 halamanKR AGILUS Hygienic Machine Fast Cleaning Food PharmaValke Athletes HandcareBelum ada peringkat

- Water Standard Specification Index As On Dec 2015Dokumen10 halamanWater Standard Specification Index As On Dec 2015afp15060% (1)

- WCR For Canon Motor Relay FailureDokumen1 halamanWCR For Canon Motor Relay FailureIqmal WahabBelum ada peringkat

- Siemens Actuator M3K20FXNDokumen10 halamanSiemens Actuator M3K20FXNbasil christopherBelum ada peringkat

- Kaplan Turbine Working As A Propeller CFD InvestigDokumen11 halamanKaplan Turbine Working As A Propeller CFD InvestigclaudehackerBelum ada peringkat

- Kinetic and Potential Energy PracticeDokumen1 halamanKinetic and Potential Energy Practicealchemist2000Belum ada peringkat

- Final Directory Handbook For ADIPEC 2023Dokumen54 halamanFinal Directory Handbook For ADIPEC 2023Zharif ZainiBelum ada peringkat

- American Zettler AZ8 1CH 24DSEDokumen4 halamanAmerican Zettler AZ8 1CH 24DSEadiegooscarBelum ada peringkat

- Equipment & Dimensions: EH4500: Standard Equipment Optional Equipment Eh4500 Ac Wheel MotorDokumen2 halamanEquipment & Dimensions: EH4500: Standard Equipment Optional Equipment Eh4500 Ac Wheel MotorAndi Wardiman AnwarBelum ada peringkat

- CH 3 Gas Refrigeration CycleDokumen20 halamanCH 3 Gas Refrigeration CycleMeleseBelum ada peringkat

- Introduction to Distillation and Flash DistillationDokumen19 halamanIntroduction to Distillation and Flash DistillationSalman HaniffaBelum ada peringkat

- Multidisciplinary Nature of Environmental StudiesDokumen6 halamanMultidisciplinary Nature of Environmental StudiesWiz Calvin ManutdBelum ada peringkat

- Dolphin by EnOcean enDokumen16 halamanDolphin by EnOcean en刘嘉伟Belum ada peringkat

- 4,5. Transformers (1 Phase & 3 Phase)Dokumen48 halaman4,5. Transformers (1 Phase & 3 Phase)nakkasrinuBelum ada peringkat

- Energy Manipulation and MeditationDokumen6 halamanEnergy Manipulation and Meditationapi-246292178100% (1)

- O Engineers 3rd Issue Oct 2017Dokumen51 halamanO Engineers 3rd Issue Oct 2017arsalanhamidBelum ada peringkat

- Budget of Lesson Science 9Dokumen14 halamanBudget of Lesson Science 9Hezl Valerie ArzadonBelum ada peringkat

- General Design Considerations for Chemical Plant DesignDokumen27 halamanGeneral Design Considerations for Chemical Plant DesignTeddy Ekubay GBelum ada peringkat

- CV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)Dokumen5 halamanCV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)toalok4723Belum ada peringkat

- Corrosion RingsDokumen1 halamanCorrosion RingsRichard More LeonBelum ada peringkat

- Short and Open Circuit Test On TransformerDokumen1 halamanShort and Open Circuit Test On TransformerRyan DagsilBelum ada peringkat

- SUPER PPTPPTDokumen15 halamanSUPER PPTPPTsrinuBelum ada peringkat

- Annual Syllabus 9 & 10Dokumen6 halamanAnnual Syllabus 9 & 10Kumar SiddhantBelum ada peringkat