1.a Sika 62 Coating Checklist Grid H1 & G2

Diunggah oleh

Prakash SIngh RawalJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

1.a Sika 62 Coating Checklist Grid H1 & G2

Diunggah oleh

Prakash SIngh RawalHak Cipta:

Format Tersedia

Page 1

Himalayan Builders and Engineers

EOB Steel Beam Upgrade Project at the American Embassy, Bangkok, Thailand Contract No.: SGE500- 12 - C - 0024

Check List for Steel Lining with Sikagard 62 Area: Steel Beam at Grid H1 and G2. Supervisor: Samrat Srabua Project Engineer: Prakash Singh Rawal Date: Dec 9, 2012.

SN. Description of work Who Measurement Date Accept Reject Signature

1 Material Preparation - Sikagard 62

Batch No. Quantity

HB

Component A Component B Paint will mix by machine (TONG HOR)

9 kg 3 kg

9kg of each bucket 3 kg of each bucket See photos attached

9-Dec

Yes

Paint will mix atleast 3 mins, Please see

Work procedure 2 Steel Surface Preparation - Perform steel surface preparation according to Sa 2 as defined by ISO 8501-1 (Shotblasting) HB Done. But, photos not taken.

17-Oct started and Complet ed 27Oct

Yes

- Replica tape testing for 5 location per beam for first 5 beams and 1 location for each beam afterwards

HB

Done at see

attached photos

10-Nov Yes

- Steel member thickness with Ultra Thickness Guage after shot blasting calculation of steel loss will be submitted.The required additional steel plate will be welded as per calculation to the beam sections.Refer to work procedure flow chart.After that start of coating of entire one beam.

HB

Steel thickness survey with ultrasonic thickness Guage test report submited.

Test Done on Nov-10 & report submit on 19 Nov

Yes

.......................... (Sika Thailand)

................................ (Applicator)

.............................. (Consultant representative)

Page 2

Himalayan Builders and Engineers

EOB Steel Beam Upgrade Project at the American Embassy, Bangkok, Thailand Contract No.: SGE500- 12 - C - 0024

Check List for Steel Lining with Sikagard 62 Area: Steel Beam at Grid H1 and G2. Supervisor: Samrat Srabua Project Engineer: Prakash Singh Rawal Date: Dec 9, 2012.

SN. Description of work Who Measurement Date Accept Reject Signature

st 3 Application of Sikagard 62 (1 Coat by Hand Roller) - Check no visible rust on steel surface HB / Sika and steel surface is free from dust and (Thailand) other friable matter. at start up and agreed time intervals

If rust found, Hand tool grinding and cleaner used for cleaning metal surface.

8-Dec

Yes

- Check material quantity per area before application of First coat 100microns (Sika Guard-62 coating datasheet reveals that the theoretical value of dry film thickness for each of 170micron coatings consumes approx. 0.24 kg/m2 material) Application of 1st Coat by Roller - Check substrate temp. > 3C above dew point, humidity should be 80%

HB

For Each beam qty is 36m2 (with 5% extra area), redq material = 8.64 kgs, so mixing 9kg of A and 3 kg of B = 12 kgs for each batch is enough for One beam 1st coatings

9-Dec

Yes

HB

Substrate temp 31.7 C, Humidity = 75% and Dew point = 24.9 C

1 day for 30 substrate temperature

9-Dec

Yes

- Allow coat to cure based on minimum / maximum intercoat waiting times - Check dry film thickness before application of 2nd coat for 5 location per beam face

HB

9-Dec

Yes

HB / Sika (Thailand) at start up and agreed time intervals nd 4 Application of Sikagard 62 (2 Coat by Hand Roller) - Check material quantity per area HB before application of 2nd coat 170 microns (Sika Guard-62 coating datasheet reveals that the theoretical value of dry film thickness for each of 170micron coatings consumes approx. 0.24 kg/m2 material) Application of nd 2 Coat by Roller

Done see attached photos 10-Dec

Yes

For Each beam qty is 36m2 (with 5% extra area), redq material = 8.64 kgs, so mixing 9kg of A and 3 kg of B for each batch is enough for One beam 2nd coatings

10-Dec

Yes

- Check substrate temp. > 3C above dew point, humidity should be 80%

HB

Substrate temp 28.3 C, Humidity = 75% and Dew point = 24.4 C

10-Dec

Yes

.......................... (Sika Thailand)

................................ (Applicator)

.............................. (Consultant representative)

Page 3

Himalayan Builders and Engineers

EOB Steel Beam Upgrade Project at the American Embassy, Bangkok, Thailand Contract No.: SGE500- 12 - C - 0024

Check List for Steel Lining with Sikagard 62 Area: Steel Beam at Grid H1 and G2. Supervisor: Samrat Srabua Project Engineer: Prakash Singh Rawal Date: Dec 9, 2012.

SN. Description of work Who Measurement Date Accept Reject Signature

1 day for 30 substrate temperature HB / Sika Done see attached - Check dry film thickness of coat's applied by Coating thickness Tester (Thailand) photos at start up and agreed time intervals rd 5 Application of Sikagard 62 (3 or Final Coat by Hand Roller) For Each beam qty - Check material quantity per area HB rd before application of 3 coat 170 is 36m2 (with 5% extra area), redq microns (Sika material = 8.64 Guard-62 coating datasheet reveals kgs, so mixing 9kg that the theoretical value of dry film of A and 3 kg of B thickness for each of 170micron for each batch is coatings consumes approx. 0.24 enough for One kg/m2 material) Application of rd beam 3rd coatings 3 Coat by Roller - Allow coat to cure based on minimum / maximum intercoat waiting times HB - Check substrate temp. > 3C above dew point, humidity should be 80% HB

10-Dec

Yes

11-Dec

Yes

11-Dec

Yes

Substrate temp 28.0 C, Humidity = 75% and Dew point = 25.3 C

11-Dec

Yes

- Allow coat to cure based on minimum / maximum intercoat waiting times - Check dry film thickness of coat's applied by Coating thickness Tester

1 day for 30 substrate temperature HB / Sika Done see attached (Thailand) photos at start up and agreed time intervals HB

11-Dec

Yes

12-Dec

Yes

With reference to the various Check listed above, Sika confirms with its signatures that, based on its respective site visits on the dates indicated above, the application of the above mentioned Sika products has been effected in accordance with Sikas written recommendations; Sika has not detected any visible defects in Sika's products as applied. However, the above confirmations are based only on a visual check of the actual status of the job site and the works executed as seen during Sikas site visit. Sikas responsibility is therefore limited to the results of its visual check and does not imply any further responsibility as to Sika's products, and/or their correct application by any third party.

.......................... (Sika Thailand)

................................ (Applicator)

.............................. (Consultant representative)

Anda mungkin juga menyukai

- Beam Design (Bikram Kasaju)Dokumen41 halamanBeam Design (Bikram Kasaju)Prakash SIngh RawalBelum ada peringkat

- Spring Mass Model For Seismic AnalysisDokumen12 halamanSpring Mass Model For Seismic AnalysisPrakash SIngh RawalBelum ada peringkat

- Rectangular Footing - DesignDokumen2 halamanRectangular Footing - DesignPrakash SIngh RawalBelum ada peringkat

- Design of Slab D: Check For Deflection F F Type of SlabDokumen4 halamanDesign of Slab D: Check For Deflection F F Type of SlabPrakash SIngh RawalBelum ada peringkat

- Calculation For Supporting WallDokumen1 halamanCalculation For Supporting WallPrakash SIngh RawalBelum ada peringkat

- α *w*h*√3*cos ϕ' (y/h-1/2* (y/h) ) Tanh√3 (R/h) : IS 1893-1984 Hydrodynamic Pressure in TanksDokumen6 halamanα *w*h*√3*cos ϕ' (y/h-1/2* (y/h) ) Tanh√3 (R/h) : IS 1893-1984 Hydrodynamic Pressure in TanksPrakash SIngh Rawal100% (1)

- Foundation Beam DesignDokumen15 halamanFoundation Beam DesignPrakash SIngh RawalBelum ada peringkat

- Thapa Danda School Final (Sept)Dokumen22 halamanThapa Danda School Final (Sept)Prakash SIngh RawalBelum ada peringkat

- Stone Masonry WallDokumen20 halamanStone Masonry WallPrakash SIngh Rawal71% (7)

- Design Concept of School PDFDokumen39 halamanDesign Concept of School PDFPrakash SIngh Rawal100% (1)

- Response Spectrum Specification As Per ISCODEDokumen5 halamanResponse Spectrum Specification As Per ISCODESaphal LamichhaneBelum ada peringkat

- Design of Isolated Square and Rectangular Footings (ACI 318-02)Dokumen6 halamanDesign of Isolated Square and Rectangular Footings (ACI 318-02)Luis Keçi100% (2)

- New Slab - DesignDokumen4 halamanNew Slab - DesignPrakash SIngh Rawal100% (1)

- Irc Class Vehicle LoadDokumen4 halamanIrc Class Vehicle LoadPrakash SIngh RawalBelum ada peringkat

- Retrofit Assessment ChecklistDokumen8 halamanRetrofit Assessment ChecklistPrakash SIngh RawalBelum ada peringkat

- Inspection Test Plan1Dokumen2 halamanInspection Test Plan1Prakash SIngh RawalBelum ada peringkat

- Inspection Test Plan: 1. Surface Preparation 2. Coating Applications 3. Concrete Repair 1. Surface PreparationDokumen17 halamanInspection Test Plan: 1. Surface Preparation 2. Coating Applications 3. Concrete Repair 1. Surface PreparationPrakash SIngh Rawal100% (1)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1091)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Guidance 118 Unplanned Cleanroom Power Outage Time Limit and Recovery SampleDokumen2 halamanGuidance 118 Unplanned Cleanroom Power Outage Time Limit and Recovery SampleCarla Luis MoralesBelum ada peringkat

- Determination of Suitable Thin Layer Drying Curve Model For Apple SlicesDokumen6 halamanDetermination of Suitable Thin Layer Drying Curve Model For Apple Slicesvele2ionut100% (1)

- HM1500LF - Relative Humidity Module: DescriptionDokumen5 halamanHM1500LF - Relative Humidity Module: DescriptionVan Lai PhamBelum ada peringkat

- Ams SeriesDokumen44 halamanAms SeriesAnddrixBelum ada peringkat

- Coolingtowerdryer 140208204949 Phpapp02 PDFDokumen22 halamanCoolingtowerdryer 140208204949 Phpapp02 PDFJel SalcedoBelum ada peringkat

- Standard FR4 TG135 Datasheet: Classification According To IPC-4101 E / 21Dokumen1 halamanStandard FR4 TG135 Datasheet: Classification According To IPC-4101 E / 21Bryanda RoBelum ada peringkat

- A2.30 Moisture TutorialID55VER20Dokumen26 halamanA2.30 Moisture TutorialID55VER20blem_0075Belum ada peringkat

- Technical Service Information Bulletin PDFDokumen141 halamanTechnical Service Information Bulletin PDFspeedkar9Belum ada peringkat

- Vol VII - PG B0 2 - Corrosion Protection and PaintingDokumen27 halamanVol VII - PG B0 2 - Corrosion Protection and PaintingSameer khanBelum ada peringkat

- GRADE 5 WEATHER and CLIMATE - NOTES-PA3Dokumen4 halamanGRADE 5 WEATHER and CLIMATE - NOTES-PA3ZABIHULLAH HABIBBelum ada peringkat

- Transmission Line Insulator Condition MonitoringDokumen3 halamanTransmission Line Insulator Condition MonitoringJ.92FlomBelum ada peringkat

- Detailed Lesson Plan in Science 5Dokumen5 halamanDetailed Lesson Plan in Science 5Benjamin S. Capuyan100% (2)

- Exercise No 1Dokumen9 halamanExercise No 1Novilyn VillanuevaBelum ada peringkat

- Low Cost Air Sensing SystemDokumen10 halamanLow Cost Air Sensing SystemJan Karina Lapeña PadlaBelum ada peringkat

- Your Perfect Atmosphere: Our MissionDokumen24 halamanYour Perfect Atmosphere: Our MissionDrago MimiBelum ada peringkat

- Meteorology Specific Objectives ActivityDokumen3 halamanMeteorology Specific Objectives ActivityRhyza Labrada Balgos - CoEdBelum ada peringkat

- NP6 PDFDokumen6 halamanNP6 PDFCristian MarchisBelum ada peringkat

- Differential Pressure Transmitter in Cleanroom-Conform Panel DesignDokumen4 halamanDifferential Pressure Transmitter in Cleanroom-Conform Panel DesignengenheiroalencarBelum ada peringkat

- Technical Catalogue Web enDokumen69 halamanTechnical Catalogue Web enWedoit FantasticBelum ada peringkat

- Cost EstimationDokumen52 halamanCost EstimationAlemlemmaBelum ada peringkat

- Atmospheric Pressure and WindsDokumen10 halamanAtmospheric Pressure and Windsavani khannaBelum ada peringkat

- Factors Affecting An Air Handling UnitDokumen7 halamanFactors Affecting An Air Handling UnitsrybsantosBelum ada peringkat

- Ficha Tecnica MG 5000Dokumen1 halamanFicha Tecnica MG 5000mazzingerzBelum ada peringkat

- Designing For Humidity Control in The Operating RoomsDokumen4 halamanDesigning For Humidity Control in The Operating RoomsMahmood EijazBelum ada peringkat

- BAKERTOP MIND - Maps ONE - CATALOGUE - ENDokumen27 halamanBAKERTOP MIND - Maps ONE - CATALOGUE - ENFabrice BBelum ada peringkat

- Boros Boros: Fire Fighting Boots Certified According To EN 15090Dokumen22 halamanBoros Boros: Fire Fighting Boots Certified According To EN 15090Forum PompieriiBelum ada peringkat

- Manual-monitor-A EcgDokumen94 halamanManual-monitor-A EcgCarlos R. SanchezBelum ada peringkat

- The Care of Historic Musical Instruments - Robert L. BarclayDokumen142 halamanThe Care of Historic Musical Instruments - Robert L. BarclaymamipookieBelum ada peringkat

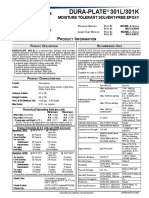

- Dura-Plate 301 L KDokumen4 halamanDura-Plate 301 L KhainguyenbkvhvBelum ada peringkat

- Weather Transmitter WXT530 Series: FlexibilityDokumen2 halamanWeather Transmitter WXT530 Series: Flexibilitycyz707Belum ada peringkat