36 - STR990-1 - Pressure Drop Data Y

Diunggah oleh

blindjaxxJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

36 - STR990-1 - Pressure Drop Data Y

Diunggah oleh

blindjaxxHak Cipta:

Format Tersedia

PRESSURE DROP DATA Y STRAINERS

Y STRAINER PRESSURE DROP LIQUIDS (Sizes 1/4" to 1-1/2")

FIGURE 1

Y STRAINER PRESSURE DROP LIQUIDS (Sizes 2" to 16")

FIGURE 2

Notes:

Pressure drop curves are based on water flow with standard screens See next page for correction factors to be used with other fluids and/or screen openings

Tel: 1-888-300-9155 Fax: 1-888-300-9160

www.COLTONIND.com info@coltonind.com

BULLETIN STR990-1

PRESSURE DROP DATA Y STRAINERS

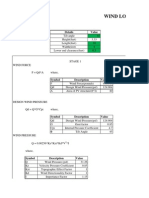

SCREEN CORRECTION FACTORS FOR NON-STANDARD AND MESH LINED SCREENS

Multiply values obtained from Figure 1 and 2 by the appropriate values shown below SIZE RANGE 1/4" to 1-1/2" 2" to 16"

Notes:

CHART 1 Mesh Lined Standard Screens % Screen Material Open Area 50% 40% 30% 1.05 1.05 1.2 1.05 1.05 1.2

SCREEN OPENINGS 60% 0.45 0.65 Perforated Plate % Screen Material Open Area 50% 40% 30% 0.55 0.7 1 0.8 1 1.4 20% 1.15 2.15

See our Replacement Screen data sheet for % open areas of perforated plate Standard screens for sizes 1/4" to 1-1/2" is approximately a 30% open area screen media Standard screens for sizes 2 to 16" is approximately a 40% open area screen media

EXAMPLE:

Strainer Size: Filtration: Flow Rate: Service: 1-1/4" 100 mesh lined 1/32" perf. 30 gpm Water a) Using FIGURE 1 the pressure drop is determined to be 1.0 psid using the standard screen b) Looking at the replacement screen data sheet, we find that the % open area of 100 mesh is 30% c) Using CHART 1 we read the correction factor to be 1.2 for 100 mesh lined screen d) Total pressure drop equals 1.0 x 1.2 = 1.2 psid clean.

VISCOSITY AND DENSITY CORRECTION FACTOR CHART

For use see instructions below: SIZE RANGE 1/4" to 1-1/2" 2" to 16" CHART 2 COMPONENT FACTOR (CF) 0.25 0.35 CHART 3 VISCOSITY Cp 10 25 100 200 500 1000 2000 BODY LOSS FACTOR (BF) 1 1.2 1.6 2.2 4.4 8 15.2 Perf Alone (PF) 1.15 1.25 1.4 1.5 1.6 1.7 1.9 SCREEN LOSS FACTOR 20 mesh lined 30, 40 mesh (MF) lined (MF) 1.3 1.4 2 2.2 3 4 4.5 7 10 15 15 30 30 60 60 to 300 mesh lined (MF) 1.5 2.5 6.5 11.5 25 50 100

HOW TO USE:

Step 1 Step 2 Step 3 Step 4 Step 5 Step 6 Step 7 Step 8

Using FIGURE 1 or 2 determine the pressure drop through the strainer with water flow and standard screens = (P1) If non-standard screens (i.e. 40 mesh, 60 mesh , etc..) are being used, apply factors in CHART 1 to determine corrected pressure drop = (P2) Multiply P1 or P2 by the specific gravity of the fluid flowing through the strainer = (P1 or P2 x specific gravity = P3) Using CHART 2 mutiply P3 by the appropriate Component Factor (CF) = (P3 x CF = P4) (P3 - P4 = P5) Multiply P4 by the appropriate Body Loss Factor (BF) in CHART 3 to get P6 = (P4 x BF = P6) Multiply P5 by the appropriate Screen Loss Factor (PF or MF) in CHART 3 to get P7 = (P5 x PF or MF = P7) P6 + P7 = Total Pressure Drop

EXAMPLE:

Strainer Size: Filtration: Flow Rate: Specific Gravity: Viscosity 1-1/4" 100 mesh lined 1/32" perf. 30 gpm 1 25 cP a) As shown in the above example, the corrected pressure drop (P2) = 1.2 psid b) Specific Gravity x P2 = P3 (1 x 1.2 = 1.2) P3 = 1.2 c) P3 x CF (from chart 2) = P4 (1.2 x 0.25 = 0.3) P4 = 0.3 d) P3 P4 = P5 (1.2 0.3 = 0.9) P5 = 0.9 e) P4 x BF (from chart 3) = P6 (0.3 x 1.2 = 0.36) P6 = 0.36 f) P5 x MF (from chart 3) = P7 (0.9 x 2.5 = 2.25) P7 = 2.25 g) P6 + P7 = Total Pressure Drop (0.36 + 2.25 = 2.61) Total Pressure Drop = 2.61 psid

Tel: 1-888-300-9155 Fax: 1-888-300-9160

www.COLTONIND.com info@coltonind.com

BULLETIN STR990-1

Anda mungkin juga menyukai

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportDari EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportBelum ada peringkat

- Digital Signal Processing Using the ARM Cortex M4Dari EverandDigital Signal Processing Using the ARM Cortex M4Penilaian: 1 dari 5 bintang1/5 (1)

- Pressure Drop - COLTON Strainers PDFDokumen2 halamanPressure Drop - COLTON Strainers PDFcavillalobosb8167Belum ada peringkat

- Strainer Drop PressureDokumen2 halamanStrainer Drop PressureJose Manuel Cervantes0% (1)

- Screen Openings For Y-StrainersDokumen6 halamanScreen Openings For Y-Strainersboom10Belum ada peringkat

- Strainer Sizing GuideDokumen20 halamanStrainer Sizing Guidealiscribd46Belum ada peringkat

- Fabrication Strainers Mesh SizingDokumen6 halamanFabrication Strainers Mesh SizingArun GuptaBelum ada peringkat

- B A S Ket Strainer Pressure Drop-LiquidsDokumen4 halamanB A S Ket Strainer Pressure Drop-LiquidsguillemaraBelum ada peringkat

- Anexo 2 Calculo DP FiltrosDokumen3 halamanAnexo 2 Calculo DP Filtrosedgardiaz5519Belum ada peringkat

- Calculate Strainer Pressure DropDokumen11 halamanCalculate Strainer Pressure DropBIDDU GHOSHBelum ada peringkat

- 0032 - Glass-Foil-Glass-Gas-Glass Plate: DescriptionDokumen5 halaman0032 - Glass-Foil-Glass-Gas-Glass Plate: DescriptionGicuBelum ada peringkat

- Sizing of StrainerDokumen20 halamanSizing of StrainerMASOMESE KIKILEBelum ada peringkat

- Calibration Procedure KrissDokumen12 halamanCalibration Procedure KrissALP69Belum ada peringkat

- MPX2010 PDFDokumen17 halamanMPX2010 PDFEnte Bliss OnixBelum ada peringkat

- Calculate Pressure Drop in Filters and Strainers - Separation TechnologiesDokumen5 halamanCalculate Pressure Drop in Filters and Strainers - Separation TechnologiesSumit Kaushik100% (1)

- Winches and Reels: Tension in Line and Pressure On The Drum and FlangesDokumen18 halamanWinches and Reels: Tension in Line and Pressure On The Drum and Flangesdrmauww100% (1)

- Fatigue Worked ExampleDokumen2 halamanFatigue Worked ExampleAndrei Răzvan SecuBelum ada peringkat

- In The Green CellsDokumen10 halamanIn The Green CellsUok RitchieBelum ada peringkat

- Models - Cfd.droplet BreakupDokumen16 halamanModels - Cfd.droplet BreakupMahdiBelum ada peringkat

- ADS Oscillator DesignDokumen23 halamanADS Oscillator Designnavvaba100% (1)

- 02 Airfoil ADokumen23 halaman02 Airfoil Abecool_bcn75Belum ada peringkat

- Development of A New Family of Normalized Modulus Reduction and Materials Dumping Curves Darendeli PhD-2008)Dokumen25 halamanDevelopment of A New Family of Normalized Modulus Reduction and Materials Dumping Curves Darendeli PhD-2008)omar45Belum ada peringkat

- Minimizing Pollution Treatment Costs for Three FactoriesDokumen3 halamanMinimizing Pollution Treatment Costs for Three FactoriesInho WooBelum ada peringkat

- Droplet Breakup in a T-JunctionDokumen20 halamanDroplet Breakup in a T-Junctionpaler35Belum ada peringkat

- Duct Size by Dp100Dokumen8 halamanDuct Size by Dp100haroub_nasBelum ada peringkat

- Mold Design Fundamental Calculation BATTERY COVERDokumen10 halamanMold Design Fundamental Calculation BATTERY COVERBoby SaputraBelum ada peringkat

- Models - Mfl.droplet BreakupDokumen20 halamanModels - Mfl.droplet Breakuppaler35Belum ada peringkat

- Induced Draft Cooling Tower PM Emissions SpreadsheetDokumen1 halamanInduced Draft Cooling Tower PM Emissions SpreadsheethuangjlBelum ada peringkat

- D41 1003 - C - EN - Compressive Strength - Flexible AlveolatDokumen9 halamanD41 1003 - C - EN - Compressive Strength - Flexible AlveolatTeoTyJayBelum ada peringkat

- 049 FrankDokumen12 halaman049 FrankMaroknightBelum ada peringkat

- Frequency Offset Reduction Methods in OFDM: Behrouz Maham Dr. Said Nader-EsfahaniDokumen59 halamanFrequency Offset Reduction Methods in OFDM: Behrouz Maham Dr. Said Nader-EsfahaniomjikumarpandeyBelum ada peringkat

- Using Flange Joint in Duct SiystemDokumen23 halamanUsing Flange Joint in Duct Siystematamete100% (1)

- ARO Final Review SessionDokumen48 halamanARO Final Review SessionZenon CortezBelum ada peringkat

- Removal of DC Offset in Current Waveforms Using Digital Mimic FilteringDokumen10 halamanRemoval of DC Offset in Current Waveforms Using Digital Mimic FilteringOscar Cabrera ChirreBelum ada peringkat

- Duct System Pressure Drop CalculationDokumen11 halamanDuct System Pressure Drop CalculationSam Jose100% (1)

- Ductwork System Calculation Input Data Sheet: Fixture Library Fixture Type, C, and DP Input by UserDokumen8 halamanDuctwork System Calculation Input Data Sheet: Fixture Library Fixture Type, C, and DP Input by UserJaspal SinghBelum ada peringkat

- Out of Roundnesscalculations:: Max MinDokumen6 halamanOut of Roundnesscalculations:: Max MinAdekimi EmmanuelBelum ada peringkat

- Porous Region Method TutorialDokumen6 halamanPorous Region Method TutorialLeonardo HintermannBelum ada peringkat

- Models - Mph.automotive MufflerDokumen14 halamanModels - Mph.automotive MufflerSumedh WaradeBelum ada peringkat

- Models - Pipe.heat Exchanger PlateDokumen14 halamanModels - Pipe.heat Exchanger Platetrymybest111Belum ada peringkat

- Transonic Wind TunnelDokumen3 halamanTransonic Wind TunnelKarthick Murugesan100% (1)

- FLUENT - Tutorial - VOF - Drop Ejection From A Printhead NozzleDokumen11 halamanFLUENT - Tutorial - VOF - Drop Ejection From A Printhead Nozzlemootaz_ahmed464Belum ada peringkat

- Moment Bs 5400Dokumen1 halamanMoment Bs 5400Sharyn PolleyBelum ada peringkat

- Trafo Found DesignDokumen6 halamanTrafo Found DesignIrshad Khan100% (1)

- Contaminant-Removal From Wastewater in A Secondary Clarifier by SedimentationDokumen22 halamanContaminant-Removal From Wastewater in A Secondary Clarifier by SedimentationMohamed TallyBelum ada peringkat

- Windload On Ground PV StructuresDokumen22 halamanWindload On Ground PV StructuresRaam Perumal100% (2)

- Three Hours: Structural IntegrityDokumen21 halamanThree Hours: Structural IntegrityLi'sBelum ada peringkat

- Flow Around An Inclined NACA 0012 AirfoilDokumen18 halamanFlow Around An Inclined NACA 0012 AirfoilZdzisław SztachetaBelum ada peringkat

- BS Example - SteelDokumen10 halamanBS Example - SteelDonald HamiltonBelum ada peringkat

- Group Assignment Plotting Q-P For Different Pressure SettingsDokumen12 halamanGroup Assignment Plotting Q-P For Different Pressure SettingsOmaroMohsenBelum ada peringkat

- MPX2010Dokumen12 halamanMPX2010Arni IrenawatiBelum ada peringkat

- Voltage Drop Calculation MethodsDokumen8 halamanVoltage Drop Calculation MethodssomaBelum ada peringkat

- Tech Drilling JetBitNozzleDokumen46 halamanTech Drilling JetBitNozzlealvarex007100% (1)

- MPX2202DDokumen19 halamanMPX2202DCristhian Omar Goicochea EscobarBelum ada peringkat

- WM c2002m 1ylydDokumen24 halamanWM c2002m 1ylydJanio Mima0% (1)

- LCD Module Specification for DMF-50840NFL-SFW DisplayDokumen18 halamanLCD Module Specification for DMF-50840NFL-SFW DisplaySanty JijonBelum ada peringkat

- Sizing of Grinding Equipment 3Dokumen9 halamanSizing of Grinding Equipment 3JazmínARBelum ada peringkat

- In CST To Choose A Point That Lies in The Center Between Two PointsDokumen10 halamanIn CST To Choose A Point That Lies in The Center Between Two PointsAlfredo DezoBelum ada peringkat

- Pump Pressure CalculationDokumen44 halamanPump Pressure CalculationVikas TiwariBelum ada peringkat

- Fundamentals of Electronics 3: Discrete-time Signals and Systems, and Quantized Level SystemsDari EverandFundamentals of Electronics 3: Discrete-time Signals and Systems, and Quantized Level SystemsBelum ada peringkat

- All Flanged TeeDokumen1 halamanAll Flanged TeeblindjaxxBelum ada peringkat

- Viking Johnson AquaGrip BrochureDokumen9 halamanViking Johnson AquaGrip BrochureFlorin LixandruBelum ada peringkat

- Flanged TaperDokumen1 halamanFlanged TaperblindjaxxBelum ada peringkat

- Flanged Spigot With Puddle FlangedDokumen1 halamanFlanged Spigot With Puddle FlangedblindjaxxBelum ada peringkat

- PAM FittingsDokumen2 halamanPAM FittingsblindjaxxBelum ada peringkat

- Next Generation: Ultragrip Reducing CouplingsDokumen1 halamanNext Generation: Ultragrip Reducing CouplingsblindjaxxBelum ada peringkat

- VFA - FittingsCatalogue DUKERDokumen130 halamanVFA - FittingsCatalogue DUKERblindjaxxBelum ada peringkat

- General Waterstop BrochureDokumen8 halamanGeneral Waterstop BrochureMuhammet Kızıl100% (1)

- SpecifyingDokumen4 halamanSpecifyingblindjaxxBelum ada peringkat

- SikaSwell - Waterproofing SolutionsDokumen5 halamanSikaSwell - Waterproofing SolutionsilijarskBelum ada peringkat

- Di Pipe and Fittings ElectrosteelDokumen20 halamanDi Pipe and Fittings ElectrosteelblindjaxxBelum ada peringkat

- 00.03 - Document HistoryDokumen1 halaman00.03 - Document HistoryblindjaxxBelum ada peringkat

- Klamflexproduct BrochureDokumen24 halamanKlamflexproduct BrochureblindjaxxBelum ada peringkat

- SADIP CatalogeDokumen60 halamanSADIP Catalogejaseer100% (1)

- General Waterstop BrochureDokumen8 halamanGeneral Waterstop BrochureMuhammet Kızıl100% (1)

- Air Test KitDokumen2 halamanAir Test KitblindjaxxBelum ada peringkat

- Guide To Trench ExcavationsDokumen43 halamanGuide To Trench ExcavationsmlakkissBelum ada peringkat

- Viking Johnson MaxiFit BrochureDokumen22 halamanViking Johnson MaxiFit BrochureblindjaxxBelum ada peringkat

- IPPI HDPE Pipe and Fittings Submittal Catalog - Ver 1.4.1 2009Dokumen184 halamanIPPI HDPE Pipe and Fittings Submittal Catalog - Ver 1.4.1 2009Hebert CcahuanaBelum ada peringkat

- Environmental Safety: Renching and Horing LANDokumen26 halamanEnvironmental Safety: Renching and Horing LANblindjaxxBelum ada peringkat

- GRP Manholes ChambersDokumen20 halamanGRP Manholes ChambersMohamed TahounBelum ada peringkat

- Qatar Construction Specifications 2010 (QCS 2010) IntroductionDokumen1 halamanQatar Construction Specifications 2010 (QCS 2010) IntroductionblindjaxxBelum ada peringkat

- General Materials and Workmanship: Section 1 2 Section 2 7 Section 3 13Dokumen14 halamanGeneral Materials and Workmanship: Section 1 2 Section 2 7 Section 3 13Muhammad EhtshamBelum ada peringkat

- 611 Large Orifice Air ValveDokumen2 halaman611 Large Orifice Air ValveblindjaxxBelum ada peringkat

- Hydro Testing ProcedureDokumen12 halamanHydro Testing ProcedureGaapchuBelum ada peringkat

- Pam Vca02 MF Gate ValveDokumen2 halamanPam Vca02 MF Gate ValveblindjaxxBelum ada peringkat

- 611 Large Orifice Air ValveDokumen2 halaman611 Large Orifice Air ValveblindjaxxBelum ada peringkat

- Hydro Testing ProcedureDokumen12 halamanHydro Testing ProcedureGaapchuBelum ada peringkat

- Pam Vca02 MF Gate ValveDokumen2 halamanPam Vca02 MF Gate ValveblindjaxxBelum ada peringkat

- Environmental Safety: Renching and Horing LANDokumen26 halamanEnvironmental Safety: Renching and Horing LANblindjaxxBelum ada peringkat