Induction Conveyor

Diunggah oleh

jay0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

189 tayangan5 halamanInduction Conveyor

Hak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniInduction Conveyor

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

189 tayangan5 halamanInduction Conveyor

Diunggah oleh

jayInduction Conveyor

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 5

Fabricom Airport Fabricom Airport Fabricom Airport Fabricom Airport

8ystems {Fr} 8ystems {Fr} 8ystems {Fr} 8ystems {Fr}

7, alle de la Seine BP 229

F-94203 Ivry-sur-Seine Cedex

Tel. +33 (0) 1 49 59 74 74

Fax. +33 (0) 1 46 71 35 24

systems@teleflex-gallet.com

Fabricom Airport Fabricom Airport Fabricom Airport Fabricom Airport

8ystems {Be} 8ystems {Be} 8ystems {Be} 8ystems {Be}

Rue Gatti de Gamond, 254

B-1180 Brussels

Tel. +32 (0) 2 370 35 49

Fax. +32 (0) 2 370 32 22

systems@fabricom.be

Fabricom Airport Fabricom Airport Fabricom Airport Fabricom Airport

8ystems {UK} 8ystems {UK} 8ystems {UK} 8ystems {UK}

Sutton Road

Hull HU7 0DR

Tel. +44 (0) 1482 78 56 00

Fax. +44 (0) 1482 78 56 99

marketing@fabricomairport.co.uk

Logan Fabricom, nc. Logan Fabricom, nc. Logan Fabricom, nc. Logan Fabricom, nc.

{United 8tates} {United 8tates} {United 8tates} {United 8tates}

4620-C Proximity Drive

Louisville, KY 40213

Tel. +1 502 964 4929

Fax. +1 502 964 1018

marketing@loganfabricom-us.com

Model 684

Induction Conveyor

Updated: Mar 2002

Model 684

Induction Conveyor

Features Application Benefits

Choice of Drive

Configurations:

Suit individual client

preferences

Underslung HTD Good speed flexibility

Shaft Mounted Ease of maintenance

Multiple Narrow

Belt Design

High availability. Unit still

operational with upto 2 belt

failures

Use of V Back

Belting

Guarantees belts will remain

tracked

Design for Continual

Running

Long life expectancy

Independent Belt

Take-Up Units

Accomodates discrepances

between individual belt stretch

Lagged Tail/Drive

Pulley

Minimises belt tensions and

slippage and maximises

conveyor life

Two Pulley

Configuration

Reduces conveyor inertia,

Improves motor / gearbox life

High Bearing Life Conveyor designed to 50,000

hour bearing life

Design Flexibility Accommodate variations such

as side wall height, bed width,

drive components etc.

Reinforced bed

plates

Increases load capacity of

conveyor

Fire Retardent

Belting to ISO 340

Reduces the spread of fire.

Quite Running

During Operation

Noise level below 70dBa

Application

The Model 684 Induction Conveyor is used in many different

applications within a baggage handling system, including:

Induction merge onto Tilt Tray Sorter

Merging of two conveyor lines into one

Take away conveyor from plough etc.

The merge unit is usually supplied as part of an integral baggage

handling system, usually including induction conveyors, belt curves,

queue and or transpotation conveyors etc.

Logan Model 684 Induction

Conveyor

The Model 684 induction conveyor is of a modular design enabling

the unit to be supplied at variable lengths and with varying

funtionality. It is also sufficiently flexible to accommodate variations

in sidewall height, belt speed, material finish etc.

When used in conjunction with the Model 570 Belt Conveyor, the

two products provide an effective solution to the requirements of a

modern airport baggage handling application.

State of the Art PLC

Controls

Use of standard PLC

technology enables clients

handling / screening schemes

to be complemented

Model 684 45

o

Induction Conveyor Specifications

Design Options Standard Variations

Induction Angle Available as 30

o

and 45

o

unit

Conveyor Speed 0.5 2.8 m/s for induction units

Belt Width 7 x 120mm strands. Effective

1000mm belt

Sidewall Height 50mm or 450mm

Belt Joint Clipper type

Material Finish Painted mild steel or galvanised

steel

Underguarding None, sheet or mesh

Additional Design Options

Alternative Geared Motor Manufacturer

Alternative Belt Manufacturer

Cladding to Floor / Platform Level

Either Floor or Ceiling Mounted

Belt Movement Sensor

Handsafe PECs

Raised Nip Guards

Debris Trays

General Construction

Bed Sections

The fabrication is press formed in 2.5mm painted mild steel or galvanised depending upon client preferences and comprises multiple

formed bed plates to create the running paths for the V backed belting. This multi slider bed configuration is bolted between two

flanged side frames. Rolled steel angle cross members provide a tie between the side frames. Model 684 Induction Conveyors are

normally fully assembled in our works.

Drive Configurations

Drive is imparted to the tail pulley via a helical geared motor, with final drive to the pulley via either a heavy duty timing belt or

shaft mounted gearbox. The drive components are totally enclosed within a sheet steel guard. The motor gearbox is normally

supplied with an integral brake, which, for rapid stop/start applications the brake is separately and directly excited.

Updated: Mar 2002

ISOMETRIC VIEW OF

TYPICAL MERGE CONVEYOR

BELTS REMOVED FOR CLARITY

Fabricom Airport Fabricom Airport Fabricom Airport Fabricom Airport

8ystems {Fr} 8ystems {Fr} 8ystems {Fr} 8ystems {Fr}

7, alle de la Seine BP 229

F-94203 Ivry-sur-Seine Cedex

Tel. +33 (0) 1 49 59 74 74

Fax. +33 (0) 1 46 71 35 24

systems@teleflex-gallet.com

Fabricom Airport Fabricom Airport Fabricom Airport Fabricom Airport

8ystems {Be} 8ystems {Be} 8ystems {Be} 8ystems {Be}

Rue Gatti de Gamond, 254

B-1180 Brussels

Tel. +32 (0) 2 370 35 49

Fax. +32 (0) 2 370 32 22

systems@fabricom.be

Fabricom Airport Fabricom Airport Fabricom Airport Fabricom Airport

8ystems {UK} 8ystems {UK} 8ystems {UK} 8ystems {UK}

Sutton Road

Hull HU7 0DR

Tel. +44 (0) 1482 78 56 00

Fax. +44 (0) 1482 78 56 99

marketing@fabricomairport.co.uk

Logan Fabricom, nc. Logan Fabricom, nc. Logan Fabricom, nc. Logan Fabricom, nc.

{United 8tates} {United 8tates} {United 8tates} {United 8tates}

4620-C Proximity Drive

Louisville, KY 40213

Tel. +1 502 964 4929

Fax. +1 502 964 1018

marketing@loganfabricom-us.com

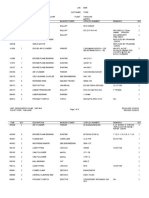

Other Products Within The Logan Range of Equipment

Model No. Product Description Product Type

571 Series III Belt Conveyor Transportation

571 Series III Queue Conveyor Metering / Queue

580 Series II Belt Conveyor Transportation

580 Series II Queue Conveyor Metering / Queue

585 Cabin Baggage Screening Unit Diverter

593 Parallel Pusher Sorting

594 Cam Sorter Sorting

595 Vertical Sortation Unit Sorting

598 Dual Lane Gravity Roller Transportation

599 Check-In Conveyors Check-In

656 Actuator Belt Plough Diverter

656A Fast Acting Belt Plough Sorting

684 Induction Conveyor Transportation

685 Sliding Shoe Sorter Sorting

687 Inclined Claim Conveyor Claim or Make-Up

688 Horizontal Claim Conveyor Claim or Make-Up

689 Cresent Plate Conveyor Claim or Make-Up

700 Tilt Tray Sorter Sorting

703 Cross Belt Sorter Sorting

- Chutes and Glacis Transportation / Accumulation

Anda mungkin juga menyukai

- Motor Selection CalculatorDokumen5 halamanMotor Selection Calculatorjay100% (5)

- Hyundai 210lc7 Hydraulic SystemDokumen35 halamanHyundai 210lc7 Hydraulic SystemMarco Olivetto100% (6)

- Elevator SystemDokumen6 halamanElevator SystemEdna Moreno100% (1)

- Io D PDFDokumen56 halamanIo D PDFGarcia LeeAnnBelum ada peringkat

- Technical Drawing - Class Handout PDFDokumen39 halamanTechnical Drawing - Class Handout PDFRicardo Rincon VegaBelum ada peringkat

- Leonardo Cross Belt Sorter For AirportDokumen4 halamanLeonardo Cross Belt Sorter For AirportraptorBelum ada peringkat

- SM-Encoder Plus - Encoder Output Plus User GuideDokumen42 halamanSM-Encoder Plus - Encoder Output Plus User GuideAngel GutierrezBelum ada peringkat

- M700 M701 Unidrive Manual PDFDokumen48 halamanM700 M701 Unidrive Manual PDFmecatronico87100% (1)

- ABB Lift Control ACSM 1 PDFDokumen280 halamanABB Lift Control ACSM 1 PDFSolrac ToneBelum ada peringkat

- 3BDD015188 en G Freelance DCS Product CatalogDokumen164 halaman3BDD015188 en G Freelance DCS Product Catalogckati100% (1)

- Additional Manual Siemen S7-200 PDFDokumen39 halamanAdditional Manual Siemen S7-200 PDFJoko Suwito UtomoBelum ada peringkat

- ControlNet - OverviewDokumen8 halamanControlNet - Overviewscorpion-acmBelum ada peringkat

- Manual ModCom M340Dokumen216 halamanManual ModCom M340Vilson Martins GonçalvesBelum ada peringkat

- Inverter v20 Siemens ModbusDokumen34 halamanInverter v20 Siemens ModbusAnh TúBelum ada peringkat

- Manual Rs Logix 5000: DownloadDokumen2 halamanManual Rs Logix 5000: DownloadRenanBelum ada peringkat

- PLC Based Inspection, Packaging and Storing of MaterialsDokumen5 halamanPLC Based Inspection, Packaging and Storing of MaterialsAlauddin khanBelum ada peringkat

- DC Drive System For EscalatorDokumen29 halamanDC Drive System For EscalatorMamta Mrjn100% (2)

- S7300ce 140903150130 Phpapp01Dokumen18 halamanS7300ce 140903150130 Phpapp01Suhendri SaputraBelum ada peringkat

- ES400 Manual v220915Dokumen122 halamanES400 Manual v220915Pablo Isaias IrahetaBelum ada peringkat

- GMWIN 01 The StartDokumen9 halamanGMWIN 01 The StartmidahsBelum ada peringkat

- Tebevert Iii Modular 5-25 Kva Inverter System: Key FeaturesDokumen2 halamanTebevert Iii Modular 5-25 Kva Inverter System: Key FeaturesMichael BesaBelum ada peringkat

- PLCDokumen21 halamanPLCThiagoLiraBelum ada peringkat

- 0515 PDFDokumen4 halaman0515 PDFCris CristyBelum ada peringkat

- KST ConveyorTech 71 enDokumen108 halamanKST ConveyorTech 71 enphong viBelum ada peringkat

- Geze Brochure Sensor Systems enDokumen56 halamanGeze Brochure Sensor Systems enAnonymous okYIFCKBelum ada peringkat

- PK1500 - Product-Data-Sheet-Deltav-Pk-Controller-Deltav-En-3583460Dokumen16 halamanPK1500 - Product-Data-Sheet-Deltav-Pk-Controller-Deltav-En-3583460ahmrdsabryBelum ada peringkat

- s71200 System Manual en-US en-USDokumen1.352 halamans71200 System Manual en-US en-USHoàng BửuBelum ada peringkat

- AG081716 Checkweighers enDokumen16 halamanAG081716 Checkweighers enChandra NurikoBelum ada peringkat

- Warning: Complete Gearbox With MotorDokumen35 halamanWarning: Complete Gearbox With MotorSinaBelum ada peringkat

- AGI 4xx Installation Instructions 4189341102 UKDokumen5 halamanAGI 4xx Installation Instructions 4189341102 UKJOSE LUIS CRISTANCHO100% (1)

- Elevator Block DiagramDokumen3 halamanElevator Block Diagramangelie220% (1)

- Catalog ST70 2005 PDFDokumen644 halamanCatalog ST70 2005 PDFfkavernaBelum ada peringkat

- Magnetic Proximity SwitchDokumen9 halamanMagnetic Proximity SwitchSagar ChachondiaBelum ada peringkat

- Catalog - Essential Guide of Control Panel PDFDokumen172 halamanCatalog - Essential Guide of Control Panel PDFMircea MurarBelum ada peringkat

- Technology Objects For Motion ControlDokumen19 halamanTechnology Objects For Motion ControlAngel AdautaBelum ada peringkat

- Factoryio Parts EssentialsDokumen82 halamanFactoryio Parts EssentialsAlexander Diaz AlvarezBelum ada peringkat

- S-Curve Profile Without Motion ControllerDokumen7 halamanS-Curve Profile Without Motion ControllerJordi Castro ÁlvarezBelum ada peringkat

- The Design Development of Automated Programmable Orientation Tools For Vibratory Bowl Feeders PDFDokumen166 halamanThe Design Development of Automated Programmable Orientation Tools For Vibratory Bowl Feeders PDFmayank0738Belum ada peringkat

- Kepserverex V5 Help: © 2011 Kepware TechnologiesDokumen191 halamanKepserverex V5 Help: © 2011 Kepware TechnologiesFrancisco Luna MoraBelum ada peringkat

- PRSP Checkweigher GBDokumen5 halamanPRSP Checkweigher GBChandra NurikoBelum ada peringkat

- MASTER-K Series: Leader in Electrics & AutomationDokumen66 halamanMASTER-K Series: Leader in Electrics & AutomationParesh Chandra DebnathBelum ada peringkat

- Cimplicity SecureDeploymentGuide v2 PDFDokumen70 halamanCimplicity SecureDeploymentGuide v2 PDFMOHAMMADBelum ada peringkat

- Cat 620 PDFDokumen48 halamanCat 620 PDFVictor BugrovBelum ada peringkat

- 3G3RV V1Dokumen76 halaman3G3RV V1Omiga HatemBelum ada peringkat

- Rcon (Me0384 5B)Dokumen844 halamanRcon (Me0384 5B)Anh TaiBelum ada peringkat

- Hydraulic Buffer For ElevatorDokumen32 halamanHydraulic Buffer For ElevatorFERNSBelum ada peringkat

- Power Free BasicsDokumen5 halamanPower Free BasicsJShearer100% (1)

- ControLogixSIL2 PDFDokumen158 halamanControLogixSIL2 PDFGowtham KuppuduraiBelum ada peringkat

- Simatic S7-200Dokumen30 halamanSimatic S7-200Bui Hong PhongBelum ada peringkat

- SIMATIC RotaryKnife Changelog enDokumen17 halamanSIMATIC RotaryKnife Changelog enPhạm Tiến ĐạtBelum ada peringkat

- Motor Saver PDFDokumen88 halamanMotor Saver PDFManuelVargasRamirezBelum ada peringkat

- FCO752 User Guide - Issue 13Dokumen99 halamanFCO752 User Guide - Issue 13王根萌Belum ada peringkat

- FX5 CPU Function Block (Programming)Dokumen44 halamanFX5 CPU Function Block (Programming)Nguyen QuocBelum ada peringkat

- 3500/72M Recip Rod Position Monitor: Operation and Maintenance ManualDokumen158 halaman3500/72M Recip Rod Position Monitor: Operation and Maintenance ManualNOEMIBelum ada peringkat

- Poweflex 400 User Manual PDFDokumen218 halamanPoweflex 400 User Manual PDFRichie ChicolBelum ada peringkat

- OtisDokumen5 halamanOtisPrateek SinglaBelum ada peringkat

- SIMATIC RotaryKnife V130 enDokumen163 halamanSIMATIC RotaryKnife V130 enPhạm Tiến ĐạtBelum ada peringkat

- Active Disturbance Rejection Control for Nonlinear Systems: An IntroductionDari EverandActive Disturbance Rejection Control for Nonlinear Systems: An IntroductionBelum ada peringkat

- Motion Control ReportDari EverandMotion Control ReportPenilaian: 4 dari 5 bintang4/5 (1)

- Belt Curve ConveyorDokumen12 halamanBelt Curve ConveyorjayBelum ada peringkat

- Bulk Material Handling Belt-Conveyor-CatalogDokumen21 halamanBulk Material Handling Belt-Conveyor-CatalogjayBelum ada peringkat

- Pawl Mechanism of A Ratchet WrenchDokumen11 halamanPawl Mechanism of A Ratchet WrenchjayBelum ada peringkat

- Motor SizingDokumen10 halamanMotor SizingrafecarBelum ada peringkat

- Primer Trig PhysicsDokumen13 halamanPrimer Trig PhysicsjayBelum ada peringkat

- Basic Conveyor CalculationDokumen16 halamanBasic Conveyor CalculationjayBelum ada peringkat

- Pneumatic SymbolsDokumen2 halamanPneumatic SymbolsShanker ShankerBelum ada peringkat

- SWTips Tricks 2004 07Dokumen4 halamanSWTips Tricks 2004 07jayBelum ada peringkat

- SAE Project Workbook 2010Dokumen198 halamanSAE Project Workbook 2010jay100% (1)

- 2010 Bridge Design Project ENGDokumen113 halaman2010 Bridge Design Project ENGjay100% (4)

- Maintenance and Service Guide: HP 14 Laptop PCDokumen86 halamanMaintenance and Service Guide: HP 14 Laptop PCRodrigo Daniel Cortés ZepedaBelum ada peringkat

- BEEE Capstone ProjectDokumen3 halamanBEEE Capstone ProjectSritej ChowdaryBelum ada peringkat

- Manual ZB2L3-Medidor Capacidad BateriaDokumen2 halamanManual ZB2L3-Medidor Capacidad BateriaPetérBelum ada peringkat

- 8038014P 2Dokumen3 halaman8038014P 2swarajBelum ada peringkat

- Technical Specifications: Hydraulic ExcavatorDokumen18 halamanTechnical Specifications: Hydraulic ExcavatorFelipe Pisklevits LaubeBelum ada peringkat

- Lsa50 2Dokumen24 halamanLsa50 2José David Barrios PadrónBelum ada peringkat

- Mechanical Seal ESD32T: Dry-RunningDokumen2 halamanMechanical Seal ESD32T: Dry-RunningFelySaezBelum ada peringkat

- Parts-Manual 70380 Chipper-Shredders 12152 19961201 X00098-Y05265 199900098-200005265Dokumen18 halamanParts-Manual 70380 Chipper-Shredders 12152 19961201 X00098-Y05265 199900098-200005265JoeBelum ada peringkat

- Pasha Hawaii Guide - Preparing Your Vehicle ShipmentDokumen3 halamanPasha Hawaii Guide - Preparing Your Vehicle ShipmentUmrbek NazarovBelum ada peringkat

- CT Requirement For MicomsDokumen50 halamanCT Requirement For Micomsjaved shaikh chaandBelum ada peringkat

- Atasheet RG 213 U Coaxial Cable 50 Ohm: ApplicationDokumen1 halamanAtasheet RG 213 U Coaxial Cable 50 Ohm: ApplicationCat TanBelum ada peringkat

- The Output Voltages of A PC Power Supply Are in The Form ofDokumen8 halamanThe Output Voltages of A PC Power Supply Are in The Form ofsoegyBelum ada peringkat

- Digital Techniques/Electronic Instrument SystemsDokumen29 halamanDigital Techniques/Electronic Instrument SystemsE DBelum ada peringkat

- RAV, DFV, DCV DetailsDokumen7 halamanRAV, DFV, DCV DetailsDinakar NaikBelum ada peringkat

- 0 A 3 F 243Dokumen5 halaman0 A 3 F 243Rizvan HaciBelum ada peringkat

- OSA5533C Rev-L4 PDFDokumen67 halamanOSA5533C Rev-L4 PDFjohn100% (1)

- SVA Technical BrochureDokumen28 halamanSVA Technical BrochureFranco Hidalgo Cossio RamirezBelum ada peringkat

- Innovator Service Bulletin: Spared Assembly ImpactedDokumen1 halamanInnovator Service Bulletin: Spared Assembly Impactedpaulo michaelBelum ada peringkat

- S-40 (From Serial Number S4003-7001 To S4015-21540) PN. 89721Dokumen384 halamanS-40 (From Serial Number S4003-7001 To S4015-21540) PN. 89721albert michaelBelum ada peringkat

- TALEXXdriver LCA 120W 350-1050ma One4all C PRE OTD enDokumen9 halamanTALEXXdriver LCA 120W 350-1050ma One4all C PRE OTD enAlex FilipovicBelum ada peringkat

- Wiistron Raichu WL Pikachu WL 18730 R-1mDokumen106 halamanWiistron Raichu WL Pikachu WL 18730 R-1mPhan ThanhBelum ada peringkat

- Schema Sursa ATX 305w PsuDokumen42 halamanSchema Sursa ATX 305w Psupetrosani2005Belum ada peringkat

- Electrical and Ignition: Battery, Charging and Starting SystemDokumen15 halamanElectrical and Ignition: Battery, Charging and Starting SystemJim LassBelum ada peringkat

- PBB Spec ChartDokumen1 halamanPBB Spec ChartSamson Rajan BabuBelum ada peringkat

- Schneider Bang Gia Dai Ly 2018 PDFDokumen285 halamanSchneider Bang Gia Dai Ly 2018 PDFHồ Tấn TàiBelum ada peringkat

- Canon Finisher AD-1 Service ManualDokumen118 halamanCanon Finisher AD-1 Service Manualjovan_vukajlovic233% (3)

- Technical Datas IPS-System ITS-System SAX-System LTB/LTP-System WIPRO-System POCON-System FAME 1-System FAME 2-System FAME 3-System Technical DatasDokumen2 halamanTechnical Datas IPS-System ITS-System SAX-System LTB/LTP-System WIPRO-System POCON-System FAME 1-System FAME 2-System FAME 3-System Technical DatasAshroof AbdoBelum ada peringkat

- MT6768 (SBS) : MT6177M (LWG+LTG)Dokumen31 halamanMT6768 (SBS) : MT6177M (LWG+LTG)pc partnerBelum ada peringkat

- News Room Services Products Sales Network Manufacturing Units Corporate Profile Financial DataDokumen1 halamanNews Room Services Products Sales Network Manufacturing Units Corporate Profile Financial DataVarun PatelBelum ada peringkat