Re 15190

Diunggah oleh

Ahmed Abd ElhakeemDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Re 15190

Diunggah oleh

Ahmed Abd ElhakeemHak Cipta:

Format Tersedia

RE 15 190/10.

90

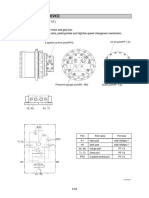

Hydraulic Motor (Radial Piston) Type MKM/MRM, Series 1X

Sizes 11 to 160

wide speed range control plate with backlash compensation smooth rotation even at very low speeds extremely small moment of inertia permitting high reversal frequency very suitable for control applications suitable for fire resistant fluids very low operating noise level model with: Type MKM 11 AZ 1X/M2 A0

RE 15 190/02.92

Replaces: 10.90

up to 315 bar

up to 161 cm3

up to 750 Nm

shaft for tachometer through shaft built-on valves brake (on request)

Type MKM 40 AZ 1X/M1 A0

Index of Contents

Description Functional description, Section, Symbols Survey of types of motor, characteristics Order data Technical data Bearing life, shaft strength Performance curves Feed pressure during pump operation Unit measurements: MKM 11 MKM 20, 40 MKM 32, 63, 90, 110 MRM 80, 125 MRM 160 MRM 80, 125, 160-SAE Shaft for tachometer, 2nd shaft end Valve, plates structure Page 2 3 4 5 6 7 to 11 12 13 14 15 16 17 18 19 20 to 24 Type MRM 160 AZ 1X/M1 A0

Type MKM 90 AZ 1X/M1 A1

1/24

RE 15 190/10.90

Functional Description, Section

9 6 3 Detail X-X D 7 F 4

A/B X

L

1

H 5

1 G 8

Type MKM and MRM hydraulic motors are constant displacement external radial piston motors. Structure The chief components are housing (1), crankshaft (2), cover (3), locking cover (4), tapered roller bearings (5), pistons (6), control (7). Transmission details The radial pistons (6) act on the crankshaft (2) via needle bearings (9) or via heptagonal rings with needle bearings. Crankshaft bearings: pre-stressed, generously-proportioned tapered roller bearings (5) with inner rings facing. Power transmission pistons (6) - crankshaft (2): Via needle bearings (9) (or heptagon ring with needle bearings Low friction losses, very long life, not sensitive to contamination, also suitable for maximum pressures and motor speeds, high starting torque, no stick/slip at low motor speeds, minimal leakage and high efficiency. Fluid operating medium, feed and return The fluid is supplied to and carried away from the motor by way of ports A or B. The cylinder chambers (E) are filled or emptied by way of the control and the channels (D) in the housing (1). Torque generation; operating stroke The fluid medium in the cylinder chambers (E), which are at present connected to the supply, is placed under pressure. The pistons (6) are pushed from outside (external loading) on to the crankshaft eccentric (operating stroke) and the crankshaft rotates.

Return of fluid medium The pistons (6), which are again pushed outwards by the rotation of the crankshaft (2) eccentric, expel the fluid from the cylinder chambers (E) which are at present connected to the return flow line. Control Construction: Flat distributor plate with radial movement and pressure compensation to counter internal leakage and backlashcompensating seal against external leakage. Purpose: Distribution of incoming volumetric flow to the cylinder chambers, collection of return volumetric flow. Operating principle: The control plate (7) incorporates an inner annular area (F) and forms with the annulus (8) an external annular chamber (G). By offsetting the control plate (7) radially between the motor housing (1) and locking cover (4) with the help of the eccentric which is connected firmly relative to the crankshaft (2) in the inner and the outer annular areas are alternately brought into contact with the cylinders. The annular areas themselves open out into ports A or B on the outside. Leakages Leakages occurring at pistons (6) and control (7) are collected up in the motor casing (H) and discharged via drain port (C).

Symbols

with 1st shaft end with 2nd shaft end with brake (on request)

2/24

RE 15 190/10.90

Motor types

Caracteristics

MKM

A/B

Transmission 7, 14 or 21 radial arrangement pistons

transmission piston - crankshaft: by means of pistons Power ia needle bearings or heptagonal ring with needle bearings

Control needle bearings between control plate and eccentric.

distributor with radial movement and balanced sealing to flat reduce leakage.

L

hydrostatic contact pressure plate with spring back-up. in external leakage with minimal friction reduction losses

MRM

B A

Transmission 5 or 10 radially arranged pistons

power transmission piston - crankshaft: by means of hydrostatically balanced pistons and pentagonal ring

with needle bearings Control

Roller bearings between control rings and eccentric distributor with radial movement and backlash Flat compensation

L

contact with spring back-up between control Hydrostatic rings and flat surfaces Hydrostatic backlash compensation at eccentric flat surfaces, with spring back-up backlash compensation even at high reversing Reliable frequencies

Only very slight leakage with minimal friction losses Miniaturised change-over valve: ensures that it is always the higher of the pressures in the vicinity of the motor

which is present in the annular area between the control rings.

3/24

RE 15 190/02.92

Order codes

M

Motor type Standard motor (size 11, 20, 32, 40, 63, 90, 110) Motor with running clearance (size 80, 125, 160) Displacement size 11 cm3 = size 11 20 cm3 = size 20 33 cm3 = size 32 40 cm3 = size 40 66 cm3 = size 63 81 cm3 = size 80 (RM) 89 cm3 = size 90 110 cm3 = size 110 126 cm3 = size 125 (RM) 161 cm3 = size 160 (RM) 1st shaft end cylindrical, key DIN 6885 Splined shaft DIN 5480 (motor type MRM only) Internally splined shaft DIN 5480 (motor type MKM only) 2nd shaft end without 2nd shaft end cylindrical 10 mm dia. for tacho connection splined ,dia 28 mm DIN 5480 (motor type MKM only) Series 10 to 19 (10 to 19, installation and connection dimensions remain unchanged)

1X

*

furter information in clear text e. g. brakes/gear unit tacho/valves Built-on valves/manifolds (only in conjunction with A1 line) No code = no additional items N = pressure feed valve (State pressure range in clear text) N6 = pressure feed valve valve port size 6 to DIN 24 340 N10 = pressure feed valve valve port size 10 to DIN 24 340 No code = E2 = Servo quality standard (size 11, 80, 125, 160) reduced clearances (sizes only 32, 63, 90, 110) Line connections threaded connection radial flanges connection radial (for sizes 80, 125, 160-SAE 3/4") threaded connection axial (sizes only 20, 32, 40, 63, 90, 110) Flange design face mounting, standard design (not for type MKM 11) flange mounting face mounting (only for sizes 32, 63, 90, 110) NB Rseals, suitable for HLP mineral oil nach to 51 524 part 2 Viton seals suitable, for HFD for HFB and HFCpressures reduced to 70%

= KM

= RM

= 11 = 20 = 32 = 40 = 63 = 80 = 90 = 110 = 125 = 160 =A =K =H A0 = A1 = B5 = = = Z M 1= = M10= 1X M= V= 2= 3=

Preferred Types (short term delivery)

MKM 11 AM 1X/VFA

MKM ... AZ 1X/M2 A0 MKM ... AZ 1X/M2 A1 MKM ... AM 1X/M2 A0 MKM ... AM 1X/M2 A1

MRM

MRM ... AZ 1X/M1 A0 MRM ... KZ 1X/M1 A0 MRM ... AM 1X/M1 A0 MRM ... KM 1X/M1 A0

4/24

RE 15 190/02.92

Technical data (for applications outside these parameters please consult us)

General

Design Type designation Type of mounting Type of connection Installation position Shaft loading, bearing life Moment of inertia Weight Radial piston motor, fixed displacement MKM; MRM Flange/face mounted Threaded/flange (depending on model) Optional see page 6 2,63 2,97 12 14

J m

kg cm2 kg

2,80 17,4

3,00 16

3,30 18,8

17 40

3,90 21,4

4,10 21,4

17 40

23 58

Hydraulic

Size Displacement Torque

specific theoretic specific mean continuous max.

NG V T T T T

cm Nm/bar Nm/bar Nm Nm bar bar bar bar bar rpm

11 11 0,17 0,15 21 31,5 140 210 250 250

20 20 0,32 0,27 27 43,2 100 160 200 200

32 33 0,52 0,48 76,8 120 160 250 315 315

40 40 0,64 0,54 54 86,4 100 160 200 200

63 66 1,05 0,95 152 237 160 250 315 315

80 81 1,29 1,16 290 365 250 315 400 400

90 89 1,41 1,27 178 266 140 210 250 250 5 to 900

110 110 1,75 1,59 223 334 140 210 250 250 5 to 750

125 126 2,00 1,80 360 567 200 315 350 350 5 to 800

160 161 2,56 2,38 595 750 250 315 400 400 5 to 1000

Pressure difference continuous pressure p operating pressure p max. pressure*) p Summated pressure at port A + B p Case drain pressure Speed range

p n

1,5 bar (special seal for higher pressures on request) 10 to 10 to 10 to 5 to 5 to 5 to 3000 2000 1500 1500 1200 1000

Please refer to Operating Manual for speeds 20 rpm; depending on operating conditions minimum speeds of up to 0,1 rpm are possible in the closed loop control circuit. Max. power.

kW

Hydraulic fluid

9,8 9 18,8 13,5 29,7 38,2 25 26,2 47,5 In continuous operation without motor flushing approx. 50 % of corner power can be achieved. HLP mineral oil to DIN 51 524 part 2 HFB and HFC fluids reduce pressure to 70 %. Calculate bearing life accordingly. HFD, Viton seals required.

78,5

Hydraulic fluid Temperature range Viscosity range

C mm /s

2

30 to + 90 20 to 150 Recommended operating range 30 to 50 up to 1000 on start-up Max. permissible level of contamination of hydraulic fluid to NAS 1638 class 9. For this we recommend a filter with a minimum retention rate of 10 100. To ensure longer life we recommend NAS 1638 class 8. Can be achieved using with minimum retention rate of 5 100.

Fluid cleanliness

*) Definition to DIN 24 312 Maximum pressure = pressure curve which temporarily exceeds the maximum operating pressure and at which the motor continues to remain operable.

5/24

RE 15 190/10.90

Bearing life, shaft strength

with a viscosity of - 36 mm /s in operating hours where 10% of the bearings may fail. 90% achieve a higher bearing life. The average mean bearing life L (n-hyd)50 with mineral oil is

2

L(n-hyd)10 is the modified nominal bearing life using mineral oil

L(n-hyd)50 can be expected for hydraulic drives with mineral oil. As the operating speed is incorporated in the calculation roughly as a proportionate figure, the table value is converted accordingly.

approximately 5xL(n-hyd)10. In practice a minimum of

Type

Speed

Ln-hyd10 in operating hours at pre-set pressure drop and speed With no external forces on drive shaft 100 bar 140 bar 160 bar 100 000 91 945 58 914 100 000 38 128 24 431 12 785 100 000 15 022 4 531 4 531 100 000 100 000 100 00 4 165 33 990 4 101 1 476 1 476 100 000 74 087 38 878 2 668 21 779 2 628 945 945 100 000 47 472 24 911 180 bar 39 784 210 bar 23 799 250 bar 315 bar

MKM 11 MKM 20 MKM 40 MKM 32 MKM 63 MKM 90 MKM 110 MRM 80 MRM 125 MRM 160

n in rpm 1000 500

500 500 350 250 250 400 400 400

14 707 1 774 638 638 100 000 32 057 16 822

8 797 1 061 382 382 84 887 19 176 10 063

589 593

47 482 10 724 5 627

21 972 4 963 2 604

Type

Speed

Ln-hyd10 in operating hours at pre-set pressure drop and speed MKM 11, 20, 40, 32, 63 max. permissible radial load at the centre of the output shaft 4500 N MKM 90, 110 max. permissible radial load at the centre of the output shaft 3000 N MRM 80, 125, 160 max. permissible radial load at the centre of the output shaft 10 000 N 100 bar 140 bar 160 bar 180 bar 210 bar 250 bar 315 bar 5141 4588 4300 4014 3601 6965 6435 4566 4993 3858 3858 88325 48594 42448 5697 2763 3320 2316 1349 1349 57527 26523 24433 4724 1918 2824 1650 880 880 46768 20102 17115 2406 1207 602 602 38288 15473 12345 1904 786 365 365 28749 10731 7923 1412 474

MKM 11 MKM 20 MKM 40 MKM 32 MKM 63 MKM 90 MKM 110 MRM 80 MRM 125 MRM 160

in rpm 1000 500 500 500 350 250 250 400 400 400

20102 6884 4712

11853 3659 2312

6/24

RE 15 190/10.90

Performance curves (average value) measured at = 36 mm /s; = 50 C; poutlet = 0 bar; pleakage oil = 0 bar

2

MKM 11

Flow Q in dm3/min

40 2 10 18 26 83 % 34

42 250

Effective torque T e in Nm

30 84 % 82 % 84,5 % 170 20 85 % 75 % 85,5 % 10 70 % 65 % 50 90 130 80 % 210

Inlet pressure pinlet in bar

leak oil volumetric flow Q L in L/min

Leak oil volumetric flow

at speed n = 500 rpm

0,4

0,2

1000

2000

3000

4000

50

100

150

200

250

Speed n in rpm

Pressure p in bar

MKM 20

60

Flow Q in dm3/min

5 40 15 25

35 155

Effective torque T e in Nm

85 %

84 % 83,5 % 83 %

82 % 80 % 81 % 79 %

140

84,5 %

110 77 % 20

Inlet pressure pinlet in bar

leak oil volumetric flow Q L in L/min

80

Leak oil volumetric flow

at speed n = 400 rpm

1,5 1 0,5 0 50 100 150

50

500

1000

1500

20 2000

2500

Speed n in rpm

Pressure p in bar

7/24

RE 15 190/10.90

Performance curves (average value) measured at = 36 mm2/s; = 50 C; poutlet = 0 bar; pleakage oil = 0 bar MKM 32

120

Flow Q in dm3/min

5 100 89,5 % 88,5 % 25 45 210

Effective torque T e in Nm

87 % 80 90 % 89 % 88 % 86% 60 130 84 % 40 80 % 170

Inlet pressure pinlet in bar

90

leak oil volumetric flow Q L in L/min

Leak oil volumetric flow

at speed n = 500 rpm

3 2 1 0 80 160 240

20 50

200

400

600

800

10 1000

1200

1400

1600

Speed n in rpm

Pressure p in bar

MKM 40

120

Flow Q in dm3/min

100 5 20 35 50 80 89,5 % 89 % 88,5 % 87 % 60 88 % 86 % 80 % 82 % 84 % 40 100 130 160

Effective torque T e in Nm

Inlet pressure pinlet in bar

90 %

leak oil volumetric flow Q L in L/min

Leak oil volumetric flow

at speed n = 400 rpm

1,5 1 0,5 0 50 100 150

70

20 40 10 0 200 400 600 800 1000 1200 1400 1600

Speed n in rpm

Pressure p in bar

8/24

RE 15 190/10.90

Performance curves (average value) measured at = 36 mm /s; = 50 C; poutlet = 0 bar; pleakage oil = 0 bar

2

MKM 63

250

Flow Q in dm3/min

5 200 15 25 35 45 55 75

Effective torque T e in Nm

90,5 % 91 % 89 % 90% 88 % 84 % 86%

190

150

130

100

Inlet pressure pinlet in bar

leak oil volumetric flow Q L in L/min

Leak oil volumetric flow

at speed n = 500 rpm

3 2 1 0 80 160 240

50

70

200

400

600

10 800 1000

1200

1400

1600

Speed n in rpm

Pressure p in bar

MRM 80

500

Flow Q in dm3/min

10 400 55 100 145

Effective torque T e in Nm

310 88 % 300 88,5 % 89 % 200 89,5 % 83 % 90 % 81 % 100 70 85 % 190 250 87 % 86 %

Inlet pressure pinlet in bar

leak oil volumetric flow Q L in L/min

Leak oil volumetric flow

at speed n = 400 rpm

3 2 1 0 100 200 300

130

10 0 500 1000 1500 2000

Speed n in rpm

Pressure p in bar

9/24

RE 15 190/10.90

Performance curves (average value) measured at = 36 mm2/s; = 50 C; poutlet = 0 bar; pleakage oil = 0 bar MKM 90

300 1 250 90,5 % 89,5 % 88% 190

Flow Q in dm3/min

31 46 61 76

Effective torque T e in Nm

200 91 % 90 % 89% 87 % 130 84 % 86 % 82 % 100

150

Inlet pressure pinlet in bar

leak oil volumetric flow Q L in L/min

Leak oil volumetric flow

at speed n = 500 rpm

3 2 1 0 80 160 240

70 50

100

200

300

400

500

10 600

700

800

900

Speed n in rpm

Pressure p in bar

MKM 110

400

Flow Q in dm3/min

2,5 12,5 22,5 32,5 42,5 52,5 62,5 72,5 82,5 210

300 90 % 89 % 170 86 % 90,5 % 200 130 91 % 88 % 84 %

Effective torque T e in Nm

89,5 %

Inlet pressure pinlet in bar

leak oil volumetric flow Q L in L/min

90 100

Leak oil volumetric flow

at speed n = 400 rpm

3 2 1 0 80 160 240

50

10 0 100 200 300 400 500 600 700 800

Speed n in rpm

Pressure p in bar

10/24

RE 15 190/10.90

Performance curves (average value) measured at = 36 mm /s; = 50 C; poutlet = 0 bar; pleakage oil = 0 bar

2

MRM 125

800

Flow Q in dm3/min

600 1 16 31 46 61 76 81 320 92 % 91,5 % 91 % 260

Effective torque T e in Nm

400 200 90,5 % 90 %

Inlet pressure pinlet in bar

leak oil volumetric flow Q L in L/min

140 88 % 200 89 % 86 % 84 % 80

Leak oil volumetric flow

at speed n = 500 rpm

3 2 1 0 100 200 300

20 0 100 200 300 400 500 600 700 800

Speed n in rpm

Pressure p in bar

MRM 160

1000

Flow Q in dm3/min

5 800 310 90 % 50 95 140 185

Effective torque T e in Nm

91 % 600 90,5 % 91,5 % 190 400 92 % 89 % 130 250

Inlet pressure pinlet in bar

leak oil volumetric flow Q L in L/min

Leak oil volumetric flow

at speed n = 400 rpm

6 4 2 0 100 200 300

87 % 200 85 %

70

200

400

600

800

10 1000

1200

1400

Speed n in rpm

Pressure p in bar

11/24

RE 15 190/10.90

Performance curves (average value) measured at = 36mm 2/s and t = 50C;and p leakage oil 1 bar

The minumum feed pressure required during pumping (overrun) operation is obtained from the value plotted plus the actual leakage oil pressure at the motor port.

MKM

20 NG 11

size 11

boost pressure p in bar

15

10

500

1000

1500

2000

2500

3000

3500

4000

Speed n in rpm

20

boost pressure p in bar

NG 110 size110 15

NG 90 size 90

NG 63 size 63

NG32/40 32/40 size NG 20 size

10

250

500

750

1000

1250

1500

1750

2000

Speed n in rpm

MRM

20

boost pressure p in bar

15

size NG 125 125

10 NG 80 80 size NG 160 160 size 5

250

500

750

1000

1250

1500

1750

2000

Speed n in rpm

12/24

RE 15 190/10.90

Unit Dimensions: MKM 11 for flange type2 (ISO 3019/2) line connection points A0

45

14H13

(Dimensions in mm)

45

5 44

5

15,85 +0,025

18

135

133

115

160

27,2 135

26 82 18,5 ~ 190

9 39

Detail "X"

15 2,6

1 2 3

1/2"BSP

60 60

14

4 5

Port A Port B Direction of rotation viewed on shaft end Right: with through flow from port B to A Left: with through flow from port A to B Leakage port Key A 5 x 5 x 20 DIN 6885 Recess for O ring 21.89 x 2.62

34

1/2

1,5

1/4"BSP G 1/4

25

line connection points A1

26 22

M12 x 14

60

15

30

6

44

4

25 G 1/4

1/4"BSP

100

70

34

13/24

125 h8

RE 15 190/10.90

Unit Dimensions: MKM 20 and 40 for flange type 1 line connection points A0

3

60

30

(Dimensions in mm)

4.1

25 G1/4 1/4"BSP

5

19

2,3

2

36

36

22

DIN 332

M8 30k6 80h8 120 h8

1/2"BSP G1/2

14 1,3

137 33

135

100

15

34

6 x M8; 17 26 L1 17

50 52 55

Type

L1 215 241

for flange type 2

DIN ISO 3019/2

MKM 20 MKM 40

1

175 L

18

1 2 3

Port A Port B Direction of rotation viewed on shaft end Right: with through flow from port B to A Left: with through flow from port A to B Leakage port

160 h8

2

20 0

4.1 Leakage port, drawn off-sett 5 Key A 8 x 7 x 45 6 DIN 6885 Recess for O ring 21.89 x 2.62

45

11

52 61

line connection points A1

26 22

line connection points B5

1 4

M12 x 14

G3/4 3/4"BSP

70

4 2

44

3 6

G1/4 1/4"BSP

42

36 36

100

70 34 18

25

3 6

0,5 14 18

36

1 8

14/24

RE 15 190/10.90

Unit Dimensions: MKM 32, 63, 90 and 110 for flange type 1 line connection points A0

3

178 8 26 L1 74 22 55 52 50 DIN 332

M8 30k6 80h8 120 h8

(Dimensions in mm)

135 2,3

33

1

1 /4 G 1"B SP 2 /4 5

72 36

M8

x6

3 0

34

17

for flange type 2

DIN ISO 3019/2

4

175 L

18

5

Type MKM 32 MKM 63 MKM 90 MKM 110 1 2 3 L1 203 221 243 243

1 2

0 20

160 h8

line connection points 3

11

52 61

Port A Port B Direction of rotation viewed on shaft end Right: with through flow from port B to A Left: with through flow from port A to B 4 Leakage port 5 6 Key A 8 x 7 x 45 DIN 6885 Recess for O ring 21.89 x 2.62

45

5

120 h8

140

51

36

,43

52 77 7 x M8, 10

line connection points A1

26 22 M12 x 14 70

line connection points B5

1

G3/4 3/4"BSP

1 6

100

25

4 2

44

3 6

G1/4 1/4"BSP

42

36 36

70 34 18

3 6

0,5 14 18

36

1 8

1, 3

0 10

1/2"BSP G1/2

19

7x

3 ,4 51

15/24

RE 15 190/02.92

Unit Dimensions: MRM 80 and 125 for flange type 1 with splined K line connection points A0

3

110 326 241 65

(Dimensions in mm)

70 50 36 1,85

126

R4

140

M16

125h8

M12

78

16

0

19

31 56

129

40j6

1"BSP G1

60

3/8"BSP 4 G 3/8,14 14 deep

54

47 17 174

60 7,5

10

for flange type 2

with through holes

1

1 2 3

2

Port A Port B Direction of rotation viewed on shaft end Right: with through flow from port B to A Left: with through flow from port A to B 4 Leakage port Recess dia. 28 mm, 72 offset in relation to ports A and B 5 Key A 12 x 8 x 56 DIN 6885 7 Shaft groove for retaining ring DIN 471

223 140h8

0 20 160

M12

72

8 9

Splined shaft connection DIN 5480 W40 x 2 x 18 x7h Splined shaft connection DIN 5480 N45 x 2 x 21 x 9H

11

36 60

25 38 18 6

shaft variant A

69 65

72

shaft variant H

5

12

35H7

45H7

M16

M10

43

DIN 332

40k6

DIN 332

9

79

3 141,5

16/24

60

185

37,5

72

RE 15 190/10.90

Unit Dimensions: MRM 160 for flange type 1 with splined K line connection points A0

378 257 283

(Dimensions in mm)

80 60 36 2,15

110

M12

M16

R4

125h8

72

78

16

41 66

50j6

19

1"BSP G1

47 17 54 216 10 7,5

70

42

3/8"BSP G 3/8,14 14 deep

3 1

7 2

1 Port A 2 Port B 3 Direction of rotation viewed on shaft end Right: with through flow from port B to A Left: with through flow from port A to B 4 Leakage port Recess dia. 28 mm, 72 offset in relation to ports A and B 5 Key A 14 x 9 x 70 DIN 6885 7 Shaft groove for retaining ring DIN 471 8 Splined shaft connection DIN 5480 W50 x 2 x 24 x 7h Splined shaft connection DIN 5480 N45 x 2 x 21 x 9H

for flange type 2

with through holes

223 140h8

M1

1 8

42

72

72

200 16 0

25

38 18 6

shaft variant A

69 65

shaft variant H

7

5

12

35H7 45H7

DIN 332

M10

M16

43

DIN 332

40k6

9

79

3 141,5

17/24

60

185

47

140

11

RE 15 190/10.90

Unit Dimensions: MRM 80, 125 and 160 MRM 80, MRM 125 for flange type 1 with splined K line connection points A1

dimension see page 16

(Dimensions in mm)

3

129 126

4

54 174

M12

M10, 18

28

30

47.63

20

68

0 16

MRM 160 for flange type 1 with splined K line connection points A1

3

M12

47.63

257

20

68

60

72

22.23

10

1 Port A SAE J 518 3/4" Standard 2 Port B SAE J 518 3/4" Standard 3 Direction of rotation viewed on shaft end Right: with through flow from port B to A Left: with through flow from port A to B 4 Leakage port 3/8"BSP Recess dia. 28 mm, 72 offset in relation to ports A and B 10 Flange height from centre of shaft 80 +0,5 mm

dimension see page 17

4

54 M10, 18

216 174

28

30

16 0

42

72

22.23

10

18/24

RE 15 190/10.90

Unit Dimensions: Motor with Parallel Tacho-Shaft

(Dimensions in mm)

Order Codes M

One size parallel tacho-shaft for all types, for measuring motor speed, transmits a maximum torque of 5 Nm (for higher output torques please consult us).

22

M 6x8 deep on 63 p. c. d.

4 20

10h6

Unit Dimensions: Motor with Through Output Shaft Order Codes M10

(Dimensions in mm)

All radial piston motors in series MKM can be supplied with a through output shaft, order code M10-, for full motor torque transmission.

56 4 50 35 19

40h8

M8

Connection to splined shaft DIN 5480 W 28 x 1,25 x 7h

28k6

40h6

19/24

RE 15 190/02.92

Valve Structure: Pressure Limiting, feed, MKM

(Dimensions in mm)

Series MKM radial piston motors with two boost pressure-feed valves, pilot control (RE 64 642), gauge ports 1/4"BSP, feed 1/4"BSP and line connection points 1/2"BSP.

100 67 33 65

A MA

B MB E

B MA

18 46,5

70 38

36

L

22

53,5 20,5

MB B A

Port

thread A B L E MA MB 1/2"BSP 1/2"BSP 1/4"BSP 1/4"BSP 1/4"BSP 1/4"BSP deep 14 14 14 12 12 12

Recess

dia. 28 28 25 20 20 20 deep 1,3+0,1 1,3+0,1 1,3-0,3 0,5 0,5 0,5

MA

29,5

Note: Valve cartridges are not included in the supply and must be ordered separately!

Symbol, functional description

A B L E

Two pressure relief valves MHDBN 16K2-1X/.. protect the drive from overloads. The maximum operating pressure can be set individually for each direction of rotation. The leakage occurring is fed back by way of feed valves at port E. The minimum feed pressure required for the different types of motor, depending on operating speed, can be calculated from the performance curves on page 12 plus 1.5 bar opening pressure at the feed valve.

MA A B

MB

20/24

32

87

RE 15 190/02.92

Valve Structure: Pressure Limiting, CETOP 3 - Mounting Pattern, MKM

(Dimensions in mm)

Radial piston motors series MKM with two boost pressure-feed valves, pilot control (RD 64 642), gauge ports 1/4"BSP, feed 1/4"BSP and valve connection CETOP 3, mounting pattern to DIN 24340 form A6.

100 70 38 65 50

T

50

158

MA

132

MB E

MA

18 46,5

38

36

L

22 53,5 22,5 20,5

MB

Port

P T L E MA MB thread 3/8"BSP 3/8"BSP 1/4"BSP 1/4"BSP 1/4"BSP 1/4"BSP deep 12 12 14 12 12 12

Recess

dia. 23 23 25 20 20 20 deep 0,5 0,5 1,3-0,3 0,5 0,5 0,5

T P

32

MA

29,5 30

Note: Valve cartridges are not included in the supply and must be ordered separately!

Symbol, functional description

A B L E

MA

MB

This block structure features valves with ports to DIN 24340 form A6 which are screwed directly on to the motor in order to achieve better control and regulation of the drive through the smaller volume of oil incorporated. Two pressure reducing valves MHDBN 16K2-1X/.. protect the drive from overloading. Maximum operating pressure can be individually set for each direction of rotation. Any leakage occurring is fed back by way of feed valves at port E. The necessary minimum feed pressure for the different motor types is calculated from the performance curves on page 12 plus 1.5 bar operating pressure at the feed valve.

70

21/24

87

RE 15 190/02.92

Valve Structure: Pressure Limiting, CETOP-5 Mounting Pattern, MKM

(Dimensions in mm)

Radial piston motors, series MKM, with two. boost pressure-feed valves, pilot control (RE 64 642), gauge ports 1/4"BSP, feed 1/4"BSP and valve port CETOP 5, mounting pattern to DIN 24340 form A10

65 50 100 4 25 17,5

P T T

186

P

78

MA

145

MB E

MA

18 46,5

38

36

L

22

53,5 20,5

Port

P T L E MA MB thread 1/2"BSP 1/2"BSP 1/4"BSP 1/4"BSP 1/4"BSP 1/4"BSP deep 14 14 14 12 12 12

Recess

dia. 28 28 25 20 20 20 deep 0,5 0,5 1,3-0,3 0,5 0,5 0,5

MB P

MA

29,5

Note: Valve cartridges are not included in the supply and must be ordered separately!

Symbol, functional description

A B L E

MA

MB

This block structure features valves with ports conforming to DIN 24340 form A 10 which are screwed directly on to the motor so as to achieve improved control and regulation of the drive by means of the smaller incorporated volume of oil. Two pressure relief valves MHDBN 16K2-1X/.. protect the drive from overloading. Maximum operating pressure can be individually set for each direction of rotation. Any leakage arising is fed back by way of feed valves at port E. The necessary minimum feed pressure for the different types of motor, depending on the operating motor speed, is calculated from the performance curves on page 12 plus 1.5 bar opening pressure at the feed valve.

22/24

32

70

87

50

RE 15 190/02.92

Valve Structure: Pressure Limiting, MRM

(Dimensions in mm)

Radial piston motors, series MRM, with two boost pressure-feed valves, pilot control (RE 64 642), gauge ports 1/4"BSP, feed 3/8"BSP and supply line ports 3/4"BSP. 100

74 50 26 5

72

40 70 46,5 80 16,5

MB E

MA

15

38 34

Port

A B L E MA MB thread 3/4"BSP 3/4"BSP 3/8"BSP 3/8"BSP 1/4"BSP 1/4"BSP deep 14 14 14 12 12 12

Recess

dia 33 33 28 25 20 20 deep 1,3+0,1 1,3+0,1 1,5 0,5 0,5 0,5 Note: Valve cartridges are not included in the supply and must be ordered separately!

Symbol, functional description

A B L E

Two pressure relief valves MHDBN 16K2-1X/... protect the drive from overloading. The maximum operating pressure can be individually set for each direction of rotation. Any leakage occurring is fed back by way of feed valves at port E. The required minimum feed pressure for the different types of motor, depending on the operating motor speed, is calculated from the performance curves on page 12 plus 1.5 bar opening pressure at the feed valve.

MA A B

MB

23/24

RE 15 190/02.92

Valve Structure: Pressure Limiting, CETOP 5-mounting pattern, MRM (Dimensions in mm)

Radial piston motors series MRM with two boost pressure-feed valves, pilot control (RE 64 642), gauge ports 1/4"BSP, feed 3/8"BSP and valve port CETOP 5, mounting pattern to DIN 24340 form A 10.

10 2 100 49

72

T MB E MA

T

40 147,5 157 198 75

15

34

38

thread P T L E MA MB 3/4" BSP 3/4" BSP 3/8" BSP 3/8" BSP 1/4" BSP 1/4" BSP

deep 16 16 14 12 12 12

dia 33 33 28 25 20 20

deep 0,5 0,5 1,5 0,5 0,5 0,5

P MB E MA L

26

Note: Valve cartridges are not included in the supply and must be ordered separately!

50 74

Symbol, functional description

A B L E

MA

MB

This block structure features valves with ports to DIN 24340 form A 10 which are screwed directly on to the motor in order to achieve improved control and regulation of the drive by means of the smaller incorporated oil volume. Two pressure relief valves MHDBN 16K2-1X/.. protect the drive from overloading. The maximum operating pressure can be individually set for each direction of rotation. Any leakage occurring is fed back by way of feed valves at port E. The required minimum feed pressure for the different types of motor, depending on the operating motor speed, is calculated from the performance curves on page 12 plus 1.5 bar opening pressure at the feed valve.

Mannesmann Rexroth GmbH D-97813 Lohr am Main Jahnstrae 3-5 D-97816 Lohr am Main Telefon 0 93 52 / 18-0 Telefax 0 93 52 / 18-10 40 Telex 6 89 418

G.L.Rexroth Ltd., Cromwell Road, St. Neots, Cambridgeshire, PE19 2ES. Tel: 0480 476041 Fax: 0480 219052 All rights reserved Subject to revision

24/24

70

46,5

Port

Recess

80

16,5

Anda mungkin juga menyukai

- Hägglunds - Choice of Hydraulic Fluid PDFDokumen2 halamanHägglunds - Choice of Hydraulic Fluid PDFAnibal RiosBelum ada peringkat

- Vickers PVB MVB Piston PumpDokumen29 halamanVickers PVB MVB Piston Pumppablo cofreBelum ada peringkat

- Re 29933Dokumen4 halamanRe 29933Ahmed Abd ElhakeemBelum ada peringkat

- Origins and Rise of the Elite Janissary CorpsDokumen11 halamanOrigins and Rise of the Elite Janissary CorpsScottie GreenBelum ada peringkat

- Fixed Displacement Pump Technical SpecsDokumen20 halamanFixed Displacement Pump Technical SpecsTaz Juan GBelum ada peringkat

- Rcoa1806 03 03Dokumen36 halamanRcoa1806 03 03Fernando Sabino100% (1)

- Re 15228 Radial Piston Hydraulic Motor With A Fixed DisplacementDokumen36 halamanRe 15228 Radial Piston Hydraulic Motor With A Fixed Displacementraj8378100% (1)

- Bomba Pistao Variavel A4vg PDFDokumen72 halamanBomba Pistao Variavel A4vg PDFtawfeeqsylanBelum ada peringkat

- A (A) 10vso18-140 Series 3x PDFDokumen36 halamanA (A) 10vso18-140 Series 3x PDFR.Ranjan PradhanBelum ada peringkat

- Re92105 01 X b2 - 2017 08Dokumen56 halamanRe92105 01 X b2 - 2017 08cln100% (1)

- Series 42 4T: Axial Piston Tandem PumpsDokumen56 halamanSeries 42 4T: Axial Piston Tandem PumpsRachid KerdidiBelum ada peringkat

- Denison HydraulicsDokumen48 halamanDenison HydraulicsPartagon PowBelum ada peringkat

- Bomba Denison Serie PremierDokumen50 halamanBomba Denison Serie Premiergineslopezruiz100% (1)

- Pet RainingDokumen57 halamanPet Rainingeddie2166100% (1)

- Open Center Control Block in Mono Block DesignDokumen12 halamanOpen Center Control Block in Mono Block DesignnksiavashBelum ada peringkat

- Denison Calzoni Type MRT Mrte MRTFDokumen24 halamanDenison Calzoni Type MRT Mrte MRTFSilvio RomanBelum ada peringkat

- Group 4 Travel Device: TYPE 1 (31N3-40010)Dokumen35 halamanGroup 4 Travel Device: TYPE 1 (31N3-40010)АлексейBelum ada peringkat

- Ronald Luis Quisurco PDFDokumen5 halamanRonald Luis Quisurco PDFmoisesBelum ada peringkat

- Ra 92003 PDFDokumen35 halamanRa 92003 PDFAgus Yulfizar100% (1)

- Axial Piston Variable Motor A6VM Series 71: RE 91610/06.2016, Bosch Rexroth AGDokumen76 halamanAxial Piston Variable Motor A6VM Series 71: RE 91610/06.2016, Bosch Rexroth AGFlorencio MaximilianoBelum ada peringkat

- Adjusting Max Displacement HPR-02Dokumen3 halamanAdjusting Max Displacement HPR-02ArleyTrujillo1224Belum ada peringkat

- General, Steering ComponentsDokumen60 halamanGeneral, Steering ComponentsIndra H BasriBelum ada peringkat

- Eaton EN-0201 ® Hydraulic MotorDokumen8 halamanEaton EN-0201 ® Hydraulic Motormemelo3Belum ada peringkat

- Ficha Técnica Control de Accionamiento de Traslación de Vehículos de Ruedas DRC Bosch Rexroth Inglés PDFDokumen36 halamanFicha Técnica Control de Accionamiento de Traslación de Vehículos de Ruedas DRC Bosch Rexroth Inglés PDFvivsBelum ada peringkat

- Tractor Hydraulics in Line with TrendsDokumen10 halamanTractor Hydraulics in Line with TrendsNelson PaicoBelum ada peringkat

- Hydraulic System Components of RH340B ExcavatorDokumen14 halamanHydraulic System Components of RH340B ExcavatorhectorBelum ada peringkat

- Motor MCR 15207-RDokumen24 halamanMotor MCR 15207-RDavid AltarribaBelum ada peringkat

- Motores HagglundsDokumen8 halamanMotores HagglundsThiago SilvaBelum ada peringkat

- 89-100 11069970 PDFDokumen44 halaman89-100 11069970 PDFeng13Belum ada peringkat

- Bomba Azpn Bosch RexrothDokumen5 halamanBomba Azpn Bosch RexrothHIDRAFLUID100% (1)

- HydraulicsDokumen253 halamanHydraulicsvelavansuBelum ada peringkat

- Relief Cartridge ValvesDokumen16 halamanRelief Cartridge Valvesvivek_11111987Belum ada peringkat

- RA 90 220 Rexroth Hydraulic Fluids On A Petroleum Oil Basis PDFDokumen8 halamanRA 90 220 Rexroth Hydraulic Fluids On A Petroleum Oil Basis PDFeng13Belum ada peringkat

- L20 Series: Service and Repair ManualDokumen28 halamanL20 Series: Service and Repair ManualJoe CorreaBelum ada peringkat

- PVB PVBQ A10vso PVHDokumen38 halamanPVB PVBQ A10vso PVHWilliam ValenciaBelum ada peringkat

- DM30 II Instruction Manual (English) 005 035033Dokumen520 halamanDM30 II Instruction Manual (English) 005 035033icatandhika77Belum ada peringkat

- Brochure R 9350 English 2013-04 - 11723-0 PDFDokumen22 halamanBrochure R 9350 English 2013-04 - 11723-0 PDFJulhefry Maroan Situngkir100% (1)

- Re92060 2014-04Dokumen28 halamanRe92060 2014-04Ibrahim GökmenBelum ada peringkat

- Re 91401Dokumen20 halamanRe 91401JozefBelum ada peringkat

- Re92709 2015-12 PDFDokumen12 halamanRe92709 2015-12 PDFnedimBelum ada peringkat

- Axial Piston Compact Unit A10CODokumen8 halamanAxial Piston Compact Unit A10COJohn SimmondsBelum ada peringkat

- Technical Manual ICVD 1111Dokumen24 halamanTechnical Manual ICVD 1111Angelo MedinaBelum ada peringkat

- 45 Series G Frame 74cc and 90cc Parts Manual (520L0582 REV AA Dec 2007)Dokumen56 halaman45 Series G Frame 74cc and 90cc Parts Manual (520L0582 REV AA Dec 2007)Sasko Dimitrov100% (2)

- Catalogo Vickers A Eaton Cross ReferenceDokumen43 halamanCatalogo Vickers A Eaton Cross ReferenceCapacitacion TodocatBelum ada peringkat

- 006 - 6060 - RH340B - Servo System - CATDokumen48 halaman006 - 6060 - RH340B - Servo System - CAThectorBelum ada peringkat

- Application Center Fork-Lift TrucksDokumen10 halamanApplication Center Fork-Lift TrucksQXNBelum ada peringkat

- Valve Amplifier For Proportional Directional Valve Type 2WFCDokumen36 halamanValve Amplifier For Proportional Directional Valve Type 2WFCessameldinBelum ada peringkat

- A17FODokumen16 halamanA17FOJose SalvadorBelum ada peringkat

- Axial Piston Fixed Motor A4Fm: Replaces: - . - English Series 1 and 3Dokumen48 halamanAxial Piston Fixed Motor A4Fm: Replaces: - . - English Series 1 and 3Anonymous bVi38aVBelum ada peringkat

- Load Sense and Pressure Adjustment GuideDokumen5 halamanLoad Sense and Pressure Adjustment Guidesatria adiBelum ada peringkat

- Directional Spool Valves, Pilot-Operated, With Electro-Hydraulic Actuation Type H-4WEH XDDokumen28 halamanDirectional Spool Valves, Pilot-Operated, With Electro-Hydraulic Actuation Type H-4WEH XDpedro 1Belum ada peringkat

- Modern Hydraulic Systems for Mini ExcavatorsDokumen22 halamanModern Hydraulic Systems for Mini ExcavatorsRaul RiveraBelum ada peringkat

- p1 PD XL Service Lte 00062 3 C 0707 075 100 140Dokumen42 halamanp1 PD XL Service Lte 00062 3 C 0707 075 100 140Bernardo Orozco LariosBelum ada peringkat

- Cat Hy14 1600 Denison Products PDFDokumen438 halamanCat Hy14 1600 Denison Products PDFEmiliano MercadoBelum ada peringkat

- RE15302Dokumen80 halamanRE15302Al-DaarisBelum ada peringkat

- A7V Piston Pump RexrothDokumen2 halamanA7V Piston Pump RexrothRidha AbbassiBelum ada peringkat

- Kobelco Construction Machinery Hydraulic Motors GuideDokumen26 halamanKobelco Construction Machinery Hydraulic Motors GuideHai VanBelum ada peringkat

- RE 10 436 Direct Controlled Vane PumpDokumen8 halamanRE 10 436 Direct Controlled Vane Pumpado_22Belum ada peringkat

- Re15205 02-98Dokumen12 halamanRe15205 02-98Timon2005100% (1)

- Re 15224Dokumen12 halamanRe 15224Ahmed Abd ElhakeemBelum ada peringkat

- External Gear PumpDokumen4 halamanExternal Gear PumpingenieroBelum ada peringkat

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDari EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceBelum ada peringkat

- WeldingDokumen38 halamanWeldingAhmed Abd ElhakeemBelum ada peringkat

- Funda05c PDFDokumen11 halamanFunda05c PDFAhmed Abd ElhakeemBelum ada peringkat

- Steering Unit Type LAGC: Nominal Sizes 50 To 630 Series 1X Nominal Pressure 175 Bar Maximum Flow 63 L/minDokumen10 halamanSteering Unit Type LAGC: Nominal Sizes 50 To 630 Series 1X Nominal Pressure 175 Bar Maximum Flow 63 L/minAhmed Abd ElhakeemBelum ada peringkat

- Test Proportional & Servo ValvesDokumen12 halamanTest Proportional & Servo ValvesAhmed Abd ElhakeemBelum ada peringkat

- En Automotive Auto Electric Basic Technology Part2 PDFDokumen56 halamanEn Automotive Auto Electric Basic Technology Part2 PDFAhmed Abd ElhakeemBelum ada peringkat

- Check Valve Type Z2SRK 10 Technical SpecificationsDokumen4 halamanCheck Valve Type Z2SRK 10 Technical SpecificationsAhmed Abd ElhakeemBelum ada peringkat

- Re 29929Dokumen4 halamanRe 29929Ahmed Abd ElhakeemBelum ada peringkat

- Mechanical engineering termsDokumen8 halamanMechanical engineering termsAhmed Abd ElhakeemBelum ada peringkat

- Piston PDFDokumen1 halamanPiston PDFAhmed Abd ElhakeemBelum ada peringkat

- Re 10223Dokumen26 halamanRe 10223Ahmed Abd ElhakeemBelum ada peringkat

- Vane Pumps, Internal Gear Pumps, Radial Piston Motors, Internal Gear MotorsDokumen2 halamanVane Pumps, Internal Gear Pumps, Radial Piston Motors, Internal Gear MotorsAhmed Abd ElhakeemBelum ada peringkat

- OpenDokumen1 halamanOpenAhmed Abd ElhakeemBelum ada peringkat

- Re 57020Dokumen8 halamanRe 57020Ahmed Abd ElhakeemBelum ada peringkat

- RE 22 371/03.98 - 4/3 and 4/2 directional control valves with hand lever Type WMMDokumen8 halamanRE 22 371/03.98 - 4/3 and 4/2 directional control valves with hand lever Type WMMAhmed Abd ElhakeemBelum ada peringkat

- Re 10460Dokumen20 halamanRe 10460Ahmed Abd ElhakeemBelum ada peringkat

- Test Point Card for Monitoring SignalsDokumen2 halamanTest Point Card for Monitoring SignalsAhmed Abd ElhakeemBelum ada peringkat

- Combination Pumps R4 + G3 Radial Piston Pump Type R4, Series 1X + Gear Pump Type G3, Series 3XDokumen4 halamanCombination Pumps R4 + G3 Radial Piston Pump Type R4, Series 1X + Gear Pump Type G3, Series 3XAhmed Abd ElhakeemBelum ada peringkat

- Combination Pumps R4 + G3 Radial Piston Pump Type R4, Series 1X + Gear Pump Type G3, Series 3XDokumen4 halamanCombination Pumps R4 + G3 Radial Piston Pump Type R4, Series 1X + Gear Pump Type G3, Series 3XAhmed Abd ElhakeemBelum ada peringkat

- Combination Pumps R4 + G3 Radial Piston Pump Type R4, Series 1X + Gear Pump Type G3, Series 3XDokumen4 halamanCombination Pumps R4 + G3 Radial Piston Pump Type R4, Series 1X + Gear Pump Type G3, Series 3XAhmed Abd ElhakeemBelum ada peringkat

- Piston PumpDokumen4 halamanPiston PumpAhmed Abd ElhakeemBelum ada peringkat

- Re 20375Dokumen2 halamanRe 20375Ahmed Abd ElhakeemBelum ada peringkat

- Solenoid-actuated directional poppet valves overviewDokumen4 halamanSolenoid-actuated directional poppet valves overviewAhmed Abd ElhakeemBelum ada peringkat

- Re 20375Dokumen2 halamanRe 20375Ahmed Abd ElhakeemBelum ada peringkat

- Re 92012Dokumen12 halamanRe 92012Ahmed Abd Elhakeem100% (1)

- Re 20375Dokumen2 halamanRe 20375Ahmed Abd ElhakeemBelum ada peringkat

- صمامات مؤازرةDokumen10 halamanصمامات مؤازرةAhmed Abd ElhakeemBelum ada peringkat

- Re 20375Dokumen2 halamanRe 20375Ahmed Abd ElhakeemBelum ada peringkat

- Re 21536Dokumen4 halamanRe 21536Ahmed Abd ElhakeemBelum ada peringkat

- Hyper-Threading Technology Architecture and Microarchitecture - SummaryDokumen4 halamanHyper-Threading Technology Architecture and Microarchitecture - SummaryMuhammad UsmanBelum ada peringkat

- Case StudyDokumen2 halamanCase StudyBunga Larangan73% (11)

- Movement and Position: Question Paper 4Dokumen14 halamanMovement and Position: Question Paper 4SlaheddineBelum ada peringkat

- Inventory Control Review of LiteratureDokumen8 halamanInventory Control Review of Literatureaehupavkg100% (1)

- PandPofCC (8th Edition)Dokumen629 halamanPandPofCC (8th Edition)Carlos Alberto CaicedoBelum ada peringkat

- Inside Animator PDFDokumen484 halamanInside Animator PDFdonkey slapBelum ada peringkat

- House Rules For Jforce: Penalties (First Offence/Minor Offense) Penalties (First Offence/Major Offence)Dokumen4 halamanHouse Rules For Jforce: Penalties (First Offence/Minor Offense) Penalties (First Offence/Major Offence)Raphael Eyitayor TyBelum ada peringkat

- DELcraFT Works CleanEra ProjectDokumen31 halamanDELcraFT Works CleanEra Projectenrico_britaiBelum ada peringkat

- Evolution of Bluetooth PDFDokumen2 halamanEvolution of Bluetooth PDFJuzerBelum ada peringkat

- Ujian Madrasah Kelas VIDokumen6 halamanUjian Madrasah Kelas VIrahniez faurizkaBelum ada peringkat

- Why Genentech Is 1Dokumen7 halamanWhy Genentech Is 1panmongolsBelum ada peringkat

- Trading As A BusinessDokumen169 halamanTrading As A Businesspetefader100% (1)

- Astera Data Integration BootcampDokumen4 halamanAstera Data Integration BootcampTalha MehtabBelum ada peringkat

- En dx300lc 5 Brochure PDFDokumen24 halamanEn dx300lc 5 Brochure PDFsaroniBelum ada peringkat

- April 26, 2019 Strathmore TimesDokumen16 halamanApril 26, 2019 Strathmore TimesStrathmore Times100% (1)

- Personalised MedicineDokumen25 halamanPersonalised MedicineRevanti MukherjeeBelum ada peringkat

- تاااتتاااDokumen14 halamanتاااتتاااMegdam Sameeh TarawnehBelum ada peringkat

- Requesting A Query in Zemanta Using PHPDokumen10 halamanRequesting A Query in Zemanta Using PHPAther SajjadBelum ada peringkat

- PLC Networking with Profibus and TCP/IP for Industrial ControlDokumen12 halamanPLC Networking with Profibus and TCP/IP for Industrial Controltolasa lamessaBelum ada peringkat

- Leaked David Fry II Conversation Regarding Loopholes and Embezzlement at AFK Gamer LoungeDokumen6 halamanLeaked David Fry II Conversation Regarding Loopholes and Embezzlement at AFK Gamer LoungeAnonymous iTNFz0a0Belum ada peringkat

- NewspaperDokumen11 halamanNewspaperКристина ОрёлBelum ada peringkat

- Lifespan Development Canadian 6th Edition Boyd Test BankDokumen57 halamanLifespan Development Canadian 6th Edition Boyd Test Bankshamekascoles2528zBelum ada peringkat

- Multiple Choice: CH142 Sample Exam 2 QuestionsDokumen12 halamanMultiple Choice: CH142 Sample Exam 2 QuestionsRiky GunawanBelum ada peringkat

- Biagioli Did Galileo Copy The TelescopeDokumen28 halamanBiagioli Did Galileo Copy The TelescopeGregory HooBelum ada peringkat

- Impact of IT On LIS & Changing Role of LibrarianDokumen15 halamanImpact of IT On LIS & Changing Role of LibrarianshantashriBelum ada peringkat

- M8-2 - Train The Estimation ModelDokumen10 halamanM8-2 - Train The Estimation ModelJuan MolinaBelum ada peringkat

- BPL Millipacs 2mm Hardmetrics RarDokumen3 halamanBPL Millipacs 2mm Hardmetrics RarGunter BragaBelum ada peringkat

- #### # ## E232 0010 Qba - 0Dokumen9 halaman#### # ## E232 0010 Qba - 0MARCOBelum ada peringkat