Syallabus

Diunggah oleh

axatpgmeHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Syallabus

Diunggah oleh

axatpgmeHak Cipta:

Format Tersedia

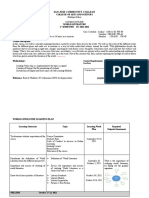

ME - 204 Manufacturing Processes I 3rd Semester and 2nd Year

Credit and Hours: Teaching Theory Practical Total Credit Scheme Hours/week 4 2 6 5 Marks 100 50 150 A Objective of the Course: To introduce the students various manufacturing and fabrications techniques. To provide background for higher level subjects in Engineering like B Production Technology. Out line of the Course: Sr. No. 1. Title of the Unit Minimum number of hours 08

Introduction to Metal Casting 2. Melting Practices 10 3. Casting Processes 12 4. Principles of Welding 02 Processes 5. Gas Welding 06 6. Electric Arc Welding 05 7. MIG welding 05 8. TIG welding 05 9. Resistance welding 07 Total hours (Theory): 60 Total hours (Lab): 30 Total: 90 C Detailed Syllabus: 1. Introduction to Metal Casting 08 20 Hours 1. 1 1. 2 Metal Casting, Sand Casting, Patterns, Cores, Gating & Risering Systems, Casting Defects & Inspection %

2. Melting Practices 2. 1 2. 2 Cupola: Charge calculations, construction

10 Hours

15 %

Other Furnaces working of induction furnace, crucible furnace, and reverberate furnace 12 Hours 15 %

3. Casting Processes 3. 1 3. 2 3. 3 4. Principles of Welding Processes 4. 1 5. Gas Welding 5. 1 Classification of Welding, Soldering and Brazing Centrifugal Casting, Carbon dioxide molding process Investment casting, Continuous casting Shell molding, Die casting, Vacuum-Sealed casting process

02 Hours

10 %

02

07 %

Hours Gas Welding, Fuel Gases, Oxy-Acetylene Welding Equipment and techniques, Gas Cutting Processes 05 Hours

6. Electric Arc Welding 6. 1 6. 2 7. MIG Welding 7. 1 Types of Arc Welding, Principle of Arc, Arc Welding Equipment

10 %

ISI electrode classification, current and voltage selection for electrodes

05

07

Hours % Process details, shielding gases, electrode wires, their sizes, and welding current ranges 05 06

8. TIG Welding

8. 1 8. 2

Hours % Process details, power sources requirements, electrode sizes and materials Current carrying capacities of different electrodes, shielding gases, application of process 07 10 Hours % General principle of heat generation in resistance welding, Process details and working principle of spot, seam, and. projection welding Electrode materials, shapes of electrodes, electrode cooling, selection of welding currents Voltages, manufacture of resistance seam welded (RSW) tubes by seam welding, various application of resistance welding processes.

9. Resistance Welding 9. 1 9. 2 9. 3

D Instructional Methods and Pedagogy: At the start of course, the course delivery pattern, prerequisite of the subject will be discussed. Lectures will be conducted with the aid of multi-media projector, black board, OHP etc. Attendance is compulsory in lectures and laboratory which carries 5 Marks weightage. Two internal exams will be conducted and average of the same will be converted to equivalent of 15 Marks as a part of internal theory evaluation. Assignments based on course content will be given to the students at the end of each unit/topic and will be evaluated at regular interval. It carries a weightage of 5 Marks as a part of internal theory evaluation. Surprise tests/Quizzes/Seminar will be conducted which carries 5 Marks as a part of internal theory evaluation. The course includes a laboratory, where students have an opportunity to build an appreciation for the concepts being taught in lectures. Experiments/Tutorials related to course content will be carried out in the laboratory.

In the lectures and laboratory discipline and behavior will be observed strictly.

Student Learning Outcomes : After learning the course, students will be able to understand casting and welding processes.

F Recommended Study Material: Text Books: 1. Rao P. N., Manufacturing Technology Foundry, Forming & Welding, Vol. 2, 3rd Edition, Tata McGraw-Hill 2004 2. Ghosh A. and Mallik A. K., Manufacturing Science, Prentice Hall PTR 2001/ 9780135526057 3. Kalpakjian S. and Schmid S.R., Manufacturing Engineering and Technology, 6th Edition, Prentice Hall, ISBN 0136081681 Reference books: 1. DeGarmo E. P., Black J. T. and Kohser R. A., Materials and Processes in Manufacturing, Prentice - Hall of India 2. Groover M. P., Fundamentals of Modern Manufacturing, John Wiley & Sons 3. Lindberg R. A., Processes and Materials of Manufacture, Prentice-Hall of India 4. Schey J., Introduction to Manufacturing Processes, Tata McGraw Hill 5. Pye R. G. W., Injection Mold Design, Longman Scientific & Technical, Essex, 1989 Reading Materials, web materials with full citations: 1. http://nptel.iitm.ac.in/courses/Webcourse-contents/IITROORKEE/MANUFACTURING-PROCESSES/index.htm 2. Foundry Informatics Centre, New Delhi http://www.foundry info-india.org Other materials 1. Journal of Material Processing Technology (Elsevier Publication) 2. Production Engineering (IE) http://www.ipcourseline.org 3. Sadhna http://www.ias.ac.in/sadhana/

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Employee List RevisedDokumen39 halamanEmployee List RevisedaxatpgmeBelum ada peringkat

- Post Crimp Assembly : Dynalloy, IncDokumen1 halamanPost Crimp Assembly : Dynalloy, IncaxatpgmeBelum ada peringkat

- Requiring This Telescope For The Student Project Perpose - Axatpatel - Me@ecchanga - AcDokumen1 halamanRequiring This Telescope For The Student Project Perpose - Axatpatel - Me@ecchanga - AcaxatpgmeBelum ada peringkat

- Nptel Copying Course ListDokumen33 halamanNptel Copying Course ListaxatpgmeBelum ada peringkat

- SatgrhygsdrDokumen1 halamanSatgrhygsdraxatpgmeBelum ada peringkat

- Phone NumbersDokumen2 halamanPhone NumbersaxatpgmeBelum ada peringkat

- Eula 1033Dokumen2 halamanEula 1033Taurus_PereaBelum ada peringkat

- FEA-Academy Course On-Demand - Practical Basic FEADokumen35 halamanFEA-Academy Course On-Demand - Practical Basic FEAaxatpgmeBelum ada peringkat

- Result V: No Series Connection Paralle Connection 10 VAB VBC VAC VPN VAC 2.24 2.24 4.48 Vac Vab +VBC 4.23 4.23Dokumen2 halamanResult V: No Series Connection Paralle Connection 10 VAB VBC VAC VPN VAC 2.24 2.24 4.48 Vac Vab +VBC 4.23 4.23axatpgmeBelum ada peringkat

- Celestron 8 - Schmidt-Cassegrain OTA With CGE Mount Plate - All Telescopes - Telescopes - OPT TelescopesDokumen1 halamanCelestron 8 - Schmidt-Cassegrain OTA With CGE Mount Plate - All Telescopes - Telescopes - OPT TelescopesaxatpgmeBelum ada peringkat

- Test Checklist For Dark RoomDokumen1 halamanTest Checklist For Dark RoomaxatpgmeBelum ada peringkat

- Computer Desk Dimensions GuideDokumen1 halamanComputer Desk Dimensions GuideaxatpgmeBelum ada peringkat

- 1st Sem CLDokumen3 halaman1st Sem CLaxatpgmeBelum ada peringkat

- Odd Sem Acedemic Calender 2013 - 14Dokumen1 halamanOdd Sem Acedemic Calender 2013 - 14axatpgmeBelum ada peringkat

- 7th BE ME-1 Attendance - Odd Sem 2013-2014Dokumen132 halaman7th BE ME-1 Attendance - Odd Sem 2013-2014axatpgmeBelum ada peringkat

- 7th Sem ME Backlog ListDokumen6 halaman7th Sem ME Backlog ListaxatpgmeBelum ada peringkat

- Sno STN Code STN Name Route No. Arrival Time Dep. Time Halt Time (In Minutes) Distance Day RemarkDokumen1 halamanSno STN Code STN Name Route No. Arrival Time Dep. Time Halt Time (In Minutes) Distance Day RemarkaxatpgmeBelum ada peringkat

- Solar Power Primer - Panel QtiltDokumen2 halamanSolar Power Primer - Panel QtiltaxatpgmeBelum ada peringkat

- Ed DiplomaDokumen5 halamanEd Diplomahari1008108Belum ada peringkat

- M Tech 2012 Charusat Acedemic CalenderDokumen1 halamanM Tech 2012 Charusat Acedemic CalenderKedar PatilBelum ada peringkat

- IIT Kanpur's Technical Details of Jugnu Nanosatellite MissionDokumen5 halamanIIT Kanpur's Technical Details of Jugnu Nanosatellite MissionaxatpgmeBelum ada peringkat

- Journal Impact FactorDokumen1 halamanJournal Impact FactoraxatpgmeBelum ada peringkat

- Control EngineeringDokumen1 halamanControl Engineeringaxatpgme100% (1)

- SyallabusDokumen4 halamanSyallabusaxatpgmeBelum ada peringkat

- ME322 Module 6iDokumen43 halamanME322 Module 6iaxatpgmeBelum ada peringkat

- Guide To Understanding Your Form-16Dokumen3 halamanGuide To Understanding Your Form-16axatpgmeBelum ada peringkat

- New Consolated Time Table - 14!6!13Dokumen9 halamanNew Consolated Time Table - 14!6!13axatpgmeBelum ada peringkat

- Control EngineeringDokumen1 halamanControl Engineeringaxatpgme100% (1)

- Control EngineeringDokumen1 halamanControl Engineeringaxatpgme100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- CVDokumen16 halamanCVAviwe ApleniBelum ada peringkat

- 1443835153Dokumen268 halaman1443835153Nori LofindieBelum ada peringkat

- Research 2: First Quarter - Week 5 and 6Dokumen20 halamanResearch 2: First Quarter - Week 5 and 6Rutchel100% (2)

- Iii-Ii Final PDFDokumen44 halamanIii-Ii Final PDFChinsdazz KumarBelum ada peringkat

- San Jose Community College: College of Arts and SciencesDokumen5 halamanSan Jose Community College: College of Arts and SciencesSH ENBelum ada peringkat

- Early Warning System RevisitedDokumen4 halamanEarly Warning System RevisitedViatorTheonBelum ada peringkat

- Extension Cord MakingDokumen3 halamanExtension Cord MakingAaron VillanuevaBelum ada peringkat

- M1-Lesson 1 Part 2 Context Clue Week 2Dokumen26 halamanM1-Lesson 1 Part 2 Context Clue Week 2Jeneros PartosBelum ada peringkat

- Cetscale in RomaniaDokumen17 halamanCetscale in RomaniaCristina RaiciuBelum ada peringkat

- Memoir Reflection PaperDokumen4 halamanMemoir Reflection Paperapi-301417439Belum ada peringkat

- Grading SystemDokumen2 halamanGrading SystemNikka Irah CamaristaBelum ada peringkat

- Newsletter 3.1Dokumen12 halamanNewsletter 3.1mrifenburgBelum ada peringkat

- 101 2014 3 eDokumen11 halaman101 2014 3 eSimbarashe MarisaBelum ada peringkat

- DepEd issues guidelines for ALS presentation portfolio assessmentDokumen27 halamanDepEd issues guidelines for ALS presentation portfolio assessmentJessica MataBelum ada peringkat

- Brief Syllabus in School Administration and SupervisionDokumen2 halamanBrief Syllabus in School Administration and SupervisionEingilbert BenoliraoBelum ada peringkat

- C/Nursing: Addis Ababa Medical and Business CollegeDokumen3 halamanC/Nursing: Addis Ababa Medical and Business CollegeBora AbeBelum ada peringkat

- Icpap Membership FormDokumen4 halamanIcpap Membership FormMuhammad Ammar IftikharBelum ada peringkat

- A Comparative Study of Volleyball Skill Between National and College Level Player Through Volleyball TestDokumen56 halamanA Comparative Study of Volleyball Skill Between National and College Level Player Through Volleyball TestMullah 302Belum ada peringkat

- Examining Conflicts and Sharing Ideas in Panel DiscussionsDokumen4 halamanExamining Conflicts and Sharing Ideas in Panel DiscussionsOfficial Lara Delos SantosBelum ada peringkat

- Music in Movies Lesson PlanDokumen2 halamanMusic in Movies Lesson Planapi-448118853Belum ada peringkat

- Scoliosis Guide: Causes, Symptoms, Diagnosis & TreatmentDokumen5 halamanScoliosis Guide: Causes, Symptoms, Diagnosis & TreatmentDimple Castañeto CalloBelum ada peringkat

- From Observation To HypothesisDokumen2 halamanFrom Observation To HypothesiszkottBelum ada peringkat

- QUarter 2 Week 1 MILDokumen8 halamanQUarter 2 Week 1 MILSalbich TvBelum ada peringkat

- AP Lit 2020 Test Study GuideDokumen3 halamanAP Lit 2020 Test Study GuideSusan ShankBelum ada peringkat

- Expert SystemDokumen72 halamanExpert SystemMandeep RanaBelum ada peringkat

- Oracle's PrimaveraDokumen4 halamanOracle's PrimaveraLam Thanh HoangBelum ada peringkat

- Lesson Plan - HomophonesDokumen3 halamanLesson Plan - Homophonesapi-359106978Belum ada peringkat

- 3rd Monthly ExamDokumen4 halaman3rd Monthly ExamRoselyn PinionBelum ada peringkat

- Contenido Temático Curso Testout Linux Pro PDFDokumen20 halamanContenido Temático Curso Testout Linux Pro PDFWilliam Baskerville0% (1)