30rb 2sb

Diunggah oleh

Maria DazaDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

30rb 2sb

Diunggah oleh

Maria DazaHak Cipta:

Format Tersedia

30RB-2SB

30RB060-390 AIR-COOLED LIQUID CHILLERS WITH COMFORTLINK CONTROLS 60 Hz

PERFORMANCE DATA CERTIFIED DIMENSIONAL PRINTS FIELD WIRING DIAGRAM

Copyright 2005 Carrier Corporation Syracuse, New York 13221 Form 30RB-2SB Replaces: 30RB-1SB Printed in U.S.A. 5-05 Catalog No. 04-51300001-01

Date:

Supersedes:

30RB060-390 AIR-COOLED LIQUID CHILLERS

30RB

Rev: -2SB

JOB NAME: BUYER: UNIT NUMBER: PERFORMANCE DATA CERTIFIED BY:

LOCATION: BUYER P.O.# MODEL NUMBER: DATE: CARRIER#

DESCRIPTION

All 30RB060-390 units are packaged air-cooled liquid chillers that are factory wired, refrigerant piped, and charged with R-410a refrigerant. Any 30RB units with the remote cooler option require field-installed piping, controls, and must be field charged with additional refrigerant. Weatherproof construction and compact design makes 30RB units ideal for rooftop or ground level installation. Upward discharge airflow minimizes directional sound and dissipates heat away from surrounding areas.

FEATURES

Compression Hermetic scroll compressors are maintenance free and protected by an auto-adaptive control that minimizes compressor wear. External and internal compressor motor protection. Complete oil charge. Refrigerant Circuit Unit sizes 060-190 have dual independent refrigerant circuits. Unit sizes 210-300 have three independent refrigerant circuits. Unit sizes 315-390 have four independent refrigerant circuits. Low and high side fusible plugs. Moisture indicating sight glass. Electronic expansion valve with integral sight glass. Filter drier, removable core. Optional non-removable core filter drier is available for unit sizes 060-100. Discharge and liquid line service valves. An optional suction service valve is available. Complete operating refrigerant charge, except for remote cooler option. Air-Cooled Condenser Air-cooled condenser coils are constructed with aluminum plate fins (copper fins optional) mechanically bonded to seamless copper tubes with an integral subcooling circuit. Specially designed 3-phase, direct-drive, condenser-fan motors, permanently lubricated bearings. External and internal fan motor protection. Condenser fans are 9-blade, shrouded axial type, statically and dynamically balanced, discharging air vertically. Cooler Integral shell and tube cooler with 3/4-in. (19 mm) closed cell polyvinyl chloride foam insulation with a maximum waterside pressure of 300 psig (2068 kPa). Controls Microprocessor-based leaving water temperature control with return water compensation. Loss of charge protection included. Automatic lead-lag circuit operation. Seven-day time schedule. Chilled water pump start/stop control and primary/stand-by sequencing to ensure equal pump run time. Dual chiller control for parallel chiller applications without additional hardware, modules, or control panels. Unoccupied low sound operation to limit condenser fan sound during scheduled periods. Maintenance scheduling to signal maintenance activities for pumps and strainers. Low chilled water flow protection is provided via an electronic thermal dispersion flow switch. High-pressure switch. Intermediate season head pressure control. Microprocessor control includes keypad with diagnostic display with access to set points, time and date, system status including % capacity, operating temperatures and pressures, and alarm conditions. Periodic pump start to ensure pump seals are properly maintained during off-season. Cabinet Cabinet constructed of galvanized steel, phosphatized zinc, with electrostatically applied high solids, polyester baked enamel finish with hinged access panels. Hydronic Package Option Optional hydronic pump packages are available (unit sizes 060190) in single and dual pump arrangements with a maximum waterside pressure of 150 psi (1034 kPa). A strainer, combination valve, and pressure taps are provided with the package.

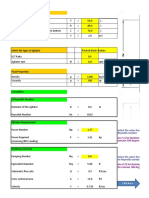

PERFORMANCE DATA (English)

UNIT Capacity ____________________________________________Tons Compressor Power Input ________________________________kW Unit Power Input ______________________________________kW Max. Operating Outdoor Temperature _______________________ F Capacity Control Steps ____________________________________ Minimum Capacity______________________________________ % Condenser Entering Air Temperature________________________ F COOLER Entering Water Temperature _______________________________F Leaving Water Temperature ________________________________F Chilled Water Flow ___________________________________ gpm Chilled Water Pressure Drop ____________________________ft wg Fouling Factor _________________________________ hr ft2 F/Btu Fluid ___________________________________________________ Concentration__________________________________________ %

PERFORMANCE DATA (SI)

UNIT Capacity _____________________________________________kW Compressor Power Input ________________________________kW Unit Power Input ______________________________________kW Max. Operating Outdoor Temperature _______________________ C Capacity Control Steps ____________________________________ Minimum Capacity______________________________________ % Condenser Entering Air Temperature________________________ C COOLER Entering Water Temperature ______________________________ C Leaving Water Temperature _______________________________ C Chilled Water Flow _____________________________________ l/s Chilled Water Pressure Drop ___________________________ m wg Fouling Factor ___________________________________ m2 C/W Fluid ___________________________________________________ Concentration__________________________________________ %

CUT ALONG DOTTED LINE

ELECTRICAL DATA

Power Supply to Unit ______________________________V, 3 ph, 60 Hz Power Connection Minimum Circuit Ampacity Max. Fuse Amps Recommended Fuse Amps Single _____________ _____________ _____________ Dual ______________ ______________ ______________

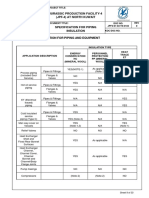

OPTIONS AND ACCESSORIES

FACTORY-INSTALLED OPTIONS Pre-Coat Aluminum Fin/Copper Tube Condenser Coil E-Coat Aluminum Fin/Copper Tube Condenser Coil Copper Fin/Copper Tube Condenser Coil E-Coat Copper Fin/Copper Tube Condenser Coil BACnet Translator Compressor Sound Enclosures Condenser Coil Trim Panels Cooler Heaters Energy Management Module Hail Guards LON Translator Minimum Load Control Low Ambient Temperature Head Pressure Control Non-Fused Disconnect Non-Removable Core Filter Drier (060-100) Remote Cooler (060-190) Service Package (GFI-CO, Remote Service Port) Security Grilles, Upper and Lower Suction Line Insulation Suction Service Valve Medium Temperature Brine Operation Hydronic Package Single Dual ______ Hp FIELD-INSTALLED ACCESSORIES BACnet Translator Chillervisor System Manager Condenser Coil Trim Panels DataLINK Control DataPort Control Energy Management Module Ground Fault Interrupter-Convenience Outlet (GFI-CO) Hail Guards LON Translator Minimum Load Control Low Ambient Temperature Head Pressure Control Navigator Display Remote Cooler (060-190) Remote Enhanced Display Remote Service Port Security Grilles, Lower Security Grilles, Upper Signal Repeater Signal Repeater, Power Supply _______________________________________________ _______________________________________________

CUT ALONG DOTTED LINE

CERTIFIED DIMENSION PRINT

TOP VIEW

SIDE VIEW FRONT VIEW

CUT ALONG DOTTED LINE

CUT ALONG DOTTED LINE

CERTIFIED DIMENSION PRINT

TOP VIEW

FRONT VIEW

SIDE VIEW

CERTIFIED DIMENSION PRINT

TOP VIEW

FRONT VIEW SIDE VIEW

CUT ALONG DOTTED LINE

CUT ALONG DOTTED LINE

CERTIFIED DIMENSION PRINT

TOP VIEW

FRONT VIEW SIDE VIEW

CERTIFIED DIMENSION PRINT

TOP VIEW

FRONT VIEW SIDE VIEW

CUT ALONG DOTTED LINE

CUT ALONG DOTTED LINE

CERTIFIED DIMENSION PRINT

TOP VIEW

FRONT VIEW

SIDE VIEW

10

CERTIFIED DIMENSION PRINT

TOP VIEW

FRONT VIEW SIDE VIEW

CUT ALONG DOTTED LINE

CUT ALONG DOTTED LINE

CERTIFIED DIMENSION PRINT

TOP VIEW

FRONT VIEW SIDE VIEW

11

12

CERTIFIED DIMENSION PRINT

TOP VIEW

FRONT VIEW

SIDE VIEW

CUT ALONG DOTTED LINE

CUT ALONG DOTTED LINE

CERTIFIED DIMENSION PRINT

TOP VIEW

FRONT VIEW

SIDE VIEW

13

14

CERTIFIED DIMENSION PRINT

TOP VIEW

SIDE VIEW FRONT VIEW

CUT ALONG DOTTED LINE

CUT ALONG DOTTED LINE

CERTIFIED DIMENSION PRINT

TOP VIEW

SIDE VIEW

FRONT VIEW

15

16

FIELD WIRING DIAGRAM

Anda mungkin juga menyukai

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Phasec2d Data SheetDokumen2 halamanPhasec2d Data SheetMaria DazaBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- H Im pcs1Dokumen42 halamanH Im pcs1Maria DazaBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Locator 3s Phasec 2s Phasec 2d: Technical Reference and Operating ManualDokumen136 halamanLocator 3s Phasec 2s Phasec 2d: Technical Reference and Operating ManualMaria DazaBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- H Im 68Dokumen12 halamanH Im 68Maria DazaBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- H Im 81eDokumen28 halamanH Im 81eMaria DazaBelum ada peringkat

- H Im 65BDokumen16 halamanH Im 65BMaria DazaBelum ada peringkat

- H Im 67GDokumen52 halamanH Im 67GMaria DazaBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- 06 CC AccessoriesDokumen1 halaman06 CC AccessoriesMaria DazaBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- CcarrierProduct Data Air Cooled Cond 09aw, Az-2pdDokumen36 halamanCcarrierProduct Data Air Cooled Cond 09aw, Az-2pdrikechBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Bonh 1Dokumen38 halamanBonh 1Maria DazaBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- J Series ManualDokumen144 halamanJ Series ManualMaria DazaBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- 35391SSG Rev 07Dokumen111 halaman35391SSG Rev 07Maria DazaBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- 2.properties & Testing MethodsDokumen87 halaman2.properties & Testing MethodsSamuel EsparteroBelum ada peringkat

- Oil Well Cementing Instruments Data Acquisition and Control SystemDokumen2 halamanOil Well Cementing Instruments Data Acquisition and Control Systemसागर फुकटBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Brinch Hansens MethodDokumen5 halamanBrinch Hansens MethodahmedBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- ChE125 NUNEZ ParticleTechnologyDokumen3 halamanChE125 NUNEZ ParticleTechnologyJohn Patrick Sanay NunezBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Complete GT Investigation Report Dt. 22.05.2013Dokumen26 halamanComplete GT Investigation Report Dt. 22.05.2013parvez100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Unit-2 Solar CollectorsDokumen168 halamanUnit-2 Solar CollectorsAbhinav SahuBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Lab ReportDokumen16 halamanLab ReportSandra Enn Bahinting100% (1)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Steam Calculators - Steam Turbine Calculator2Dokumen2 halamanSteam Calculators - Steam Turbine Calculator2Adam GordonBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- TF-8694 - Therminol - XP - Technical - BulletinDokumen8 halamanTF-8694 - Therminol - XP - Technical - BulletingabrielBelum ada peringkat

- SAB 2513 Hydraulic Chapter 4Dokumen33 halamanSAB 2513 Hydraulic Chapter 4Tuan Jalai100% (1)

- EXP7 WATER TANK-minDokumen15 halamanEXP7 WATER TANK-mingoblinsbrideBelum ada peringkat

- Vehicle Aerodynamics PDFDokumen15 halamanVehicle Aerodynamics PDFRohit KoreBelum ada peringkat

- DEFORM 2D TutorialDokumen31 halamanDEFORM 2D Tutorialdarwin_huaBelum ada peringkat

- Concrete Shear Wall Design - Singular Wall Using ETABS Questions and AnswersDokumen3 halamanConcrete Shear Wall Design - Singular Wall Using ETABS Questions and Answersronnie_syncinBelum ada peringkat

- Lift Load Distribution and Structural Load DistributionDokumen3 halamanLift Load Distribution and Structural Load DistributionPrajeesh RajBelum ada peringkat

- Agitator Power Requirement and Mixing Intensity CalculationDokumen26 halamanAgitator Power Requirement and Mixing Intensity CalculationWael Abdel-Mageed100% (1)

- Nota Padat Fizik F4 Forces and Pressure NotesDokumen24 halamanNota Padat Fizik F4 Forces and Pressure Notesslokkro98% (61)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- 2008 Aurelio MuttoniDokumen11 halaman2008 Aurelio MuttoniSonja PavicBelum ada peringkat

- InsulationDokumen5 halamanInsulationjaleelBelum ada peringkat

- Tutorial 1Dokumen3 halamanTutorial 1Vinoth KumarBelum ada peringkat

- Thermal Methods of Analysis: Principles, Applications and ProblemsDokumen296 halamanThermal Methods of Analysis: Principles, Applications and ProblemsAthlur Sai KiranBelum ada peringkat

- Liquid Mass Diffusivity: - No Rigorous Theories - Diffusion As Molecules or Ions - Eyring Theory - Hydrodynamic TheoryDokumen27 halamanLiquid Mass Diffusivity: - No Rigorous Theories - Diffusion As Molecules or Ions - Eyring Theory - Hydrodynamic TheoryDiego KevinBelum ada peringkat

- Lecture 2Dokumen27 halamanLecture 2ABHINAV KUMAR SHUKLABelum ada peringkat

- eArt-Calculating Overpressure From BLEVE ExplosionsDokumen6 halamaneArt-Calculating Overpressure From BLEVE ExplosionsJurizal Julian LuthanBelum ada peringkat

- Theory of Elasticity Timoshenko J N GoodierDokumen519 halamanTheory of Elasticity Timoshenko J N GoodierThotho Kennedy100% (2)

- Tie Beam (7pg)Dokumen7 halamanTie Beam (7pg)dheeraj SureshBelum ada peringkat

- Drying of PaperDokumen38 halamanDrying of PaperLingga MediatamaBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Midterm Study Guide 08Dokumen2 halamanMidterm Study Guide 08carolynshinBelum ada peringkat

- 01 - Dispersion of A Free Non-Buoyant Fluid JetDokumen5 halaman01 - Dispersion of A Free Non-Buoyant Fluid JetJoren HuernoBelum ada peringkat

- MIN-305 Heat & Mass Transfer Tutorial - 1Dokumen2 halamanMIN-305 Heat & Mass Transfer Tutorial - 1Ayush JaiswalBelum ada peringkat