Dis Estribo H5.5m L15m A7m Oct09

Diunggah oleh

Carlos VilteJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Dis Estribo H5.5m L15m A7m Oct09

Diunggah oleh

Carlos VilteHak Cipta:

Format Tersedia

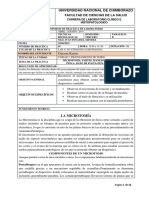

Calculo de Estribo Central

Pte No 1,2,3

CALCULO Y DIMENSIONAMIENTO DE ESTRIBO DE H A

DISEO FINAL PUENTE VEHICULAR PROG. 1+637, 2+095, 6+595 L15m. (Asfaltado Manquiri)

ALTURA DE ESTRIBO = 5.50 m

TERRENO NATURAL - ESTADO PASIVO

30

Angulo de rozamiento interno

=

Cohesion

c=

0.90 [tn/m2]

3

1.70

Peso

especfico del suelo seco

st =

[tn/m ]

qadm =

1.80 [tn/m3]

1.00 [tn/m3]

15.00 [tn/m2]

0.58

ACI 318/99

AASHTO 97

Elaborado por:

1. DATOS DEL ESTUDIO DE SUELOS

st' =

w=

Norma Utilizada:

Peso especfico del suelo saturado

RELLENO GRANULAR - ESTADO ACTIVO

30

recomendable

=

c=

0.90 [tn/m2]

Cohesion

3

1.70

sg =

[tn/m ]

st' =

1.80 [tn/m3]

Peso especfico del agua

Capacidad vertical Admisible del suelo

Datos a reemplazar

Coeficiente de friccin suelo concreto

Datos a reemplazar pero se recomienda mantener el valor indicado

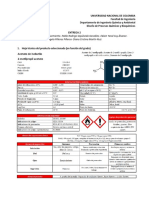

2. DATOS DEL Ho Ao

H=

2.40 [tn/m3]

f'c =

250.00 [kg/cm 2]

fy = 5000.00 [kg/cm 2]

r=

5.00 [cm]

Peso Especfico del Ho Ao

Resistencia de compresin del Ho a los 28 das

Fluencia especfica del acero de refuerzo

recubrimiento

3. COMBINACIONES DE CARGA

D = Carga Muerta

Grupos de Carga para diseno a ROTURA

Grupos de Carga para diseno a SERVICIO (Estabilidad)

L = Carga Viva

Grupo I : 1.3(D + 5/3L + 1.3E)

Grupo I : (D + 5/3L + E)

E = Empuje de suelos

Grupo II : (D + E + W)

Grupo II : 1.3(D + 1.3E + W)

Grupo III : 1.3(D + L + 1.3E + 0.3W + WL + SF + F))

Grupo III : (D + L + 1.3E + 0.3W + WL + SF + F))

W = WL = SF = F = 0

4. REACCIONES SOBRE EL ESTRIBO CV + CM

No de Vigas exteriores = 2

LV = 16.849 Tn

DV = 22.884 Tn

Reaccion de carga viva corresponde a viga exterior

Reaccion de carga muerta corresponde a viga exterior

No de Vigas interiores = 1

LV = 16.849 Tn

DV = 22.884 Tn

Reaccion de carga viva corresponde a viga interior

Reaccion de carga muerta corresponde a viga interior

LV =

DV =

RV =

50.55 Tn

68.65 Tn

119.20 Tn

Reaccion sobre el estribo correspondiente a todas las vigas

5. PREDIMENSIONAMIENTO

hv =

1.00 [m]

Altura de viga

eL =

0.18 [m]

eR =

0.02 [m]

hd =

0.12 [m]

eN =

0.03 [m]

Espesor de la losa

Espesor de la capa de rodadura

Altura de los dados

Espesor de neopreno

ha =

hbl =

hf =

0.28 [m]

1.37 [m]

2.50 [m]

Altura nivel de agua encima el terreno (+) por debajo (-)

Altura Borde libre

Cota mnima de fundacin

1 / 10

Calculo de Estribo Central

sg

1.35

1.65

PS3

2.00 m

2.70

=27.05 tn

tipo

figura

=107.19 tn

P6

n o

1.40

0.50

C

Area

m2

hEps

0.50

PS5

P5

l l1

0.2

0.3

h h1

Dimensiones (m)

b

h

p2'

1.60S

L transv Peso Esp

m

tn/m3

Peso

tn

Brazo

tn

w2

Momento

tn-m

P1

0.35

1.70

rec

0.595

7.00

2.40

10.00

2.28

22.74

P2

0.35

0.60

triang

0.105

7.00

2.40

1.76

2.22

3.91

P3

3.65

0.40

rec

1.460

7.00

2.40

24.53

1.90

46.60

P4

3.65

0.10

triag

0.183

7.00

2.40

3.07

1.67

5.11

P5

0.50

3.50

0.20 trap irreg

0.400

7.00

2.40

6.72

1.79

12.01

P6

3.50

0.30

rec

TOTALES

1.050

3.793

7.00

2.40

DH =

17.64

63.714

1.75

MoDH =

30.87

121.246

Ps1

1.05

5.00

rec

5.250

7.00

1.70

62.48

2.98

185.86

Ps2

3.30

2.70

0.35 trapecio

1.050

7.00

1.70

12.50

2.28

28.50

Ps3

1.65

1.60

2.00 trapecio

3.255

7.00

1.80

41.06

0.81

33.41

Ps4

1.40

0.20

triang

0.140

7.00

1.70

1.67

3.03

5.05

Ps5

1.60

0.20

triang

0.160

7.00

1.70

1.90

0.57

1.08

Pw1

1.72

1.65

0.472

10.327

7.00

1.00

Ds =

3.30

122.90

0.84

MoDs =

2.79

256.69

0.28 trapecio

TOTALES

Ep

Ew

Eps'

P4

PS4

=134.2 tn

p1'

st'

hEp

PS2

w1

PW1

P3

hEw

sg'

a2'

P2

0.6

hEa21

a1'

g

H ESTRIBO

SUELO - AGUA

P1

PS1

hEas2

hEw

hEa

w2

d

1.7

RT

1.70

Eas1 =23.68 tn

0.35

a0

1.05

0.40

Eas2 =46.43 tn

tn

E=27.05

w

Descripcion

Altura de total del estribo

Dimension perpendicular a la seccion (estimar)

CL

s0

5.50 m

3.50 m

E=97.16

a

tn

w1

5.50 [m]

7.00 [m]

5.50 m

H = hv + ha + hbl + hf =

L=

2.78 m

3.50 m

Dimensiones del estribo

m = 1.40 m

n = 0.40 m

o = 0.10 m

p = 1.60 m

e = 1.70 m

f = 0.60 m

g = 2.70 m

h = 0.30 m

h1 = 0.20 m

i = 1.35 m

j = 1.65 m

k = 2.00 m

l = 0.30 m

l 1= 0.20 m

a = 1.05 m

b = 0.35 m

c = 0.40 m

d = 1.70 m

t = 2.78 m

X

X =

h 2a + b

(

)

3 a +b

h a + 2b

(

)

3 a+b

0.05

0.06

2 / 10

Calculo de Estribo Central

GRUPO I: ETAPA DE SERVICIO

Peso Total

Estados para Estabilidad

PT = ( DH + DS + DV + 5/3LV ) =

<

15.00 [tn/m2]

<

441.37 [tn]

qadm

7.00

= PT / A =

13.86 [tn/m2]

Estados de rotura

PT = 1.3( DH + DS + DV + 5/3LV ) =

339.51 [tn]

A=

OK

24.50 [m2]

m+n+o+p

3.50 m

X1 =

2 p 2 + 3(n + o) [2 p + (n + o)] + m [3 p + 3(n + o) + m]

3 [ p + 2(n + o) + m]

2m + 3(n + o) [2m + ( n + o)] + p [3m + 3( n + o) + p ]

3 [m + 2(n + o) + p ]

2

X=

6. CARGAS SOBRE ESTRIBOS

So

Peso de camion Tipo HS25 =

Area de apoyo del camion Sobre la losa de aproximacion:

3.00

x

4.27 =

So =

7. PRESION DE TIERRAS

Ecuacin de Rankine - Estado Activo

Material Granular de Relleno

Coeficiente Activo del suelo

1.70 [tn/m3]

sg =

1.80 [tn/m3]

st' =

2

ka = tan 45 ( 2 ) =

p = k p

30

Ka = ( 1 - Sen ) / ( 1 + Sen ) =

ao =

a1' =

w1 =

a2' =

a = ka

0.333

0.47 [tn/m2]

2.01 [tn/m2]

2.78 [tn/m2]

18.18 [tn]

12.81 [m2]

1.419 [tn/m2]

Ecuacin de Rankine - Estado Pasivo

Material Terreno Natural

+ 2c k p Coeficiente pasivo del suelo

1.80 [tn/m3]

st' =

30

=

2c k

a

c=

0.90 [tn/m2]

Kp = ( 1 + Sen ) / ( 1 - Sen ) =

p1 =

p2' =

w1 =

k p = tan 2 45 + ( 2 )

3.000

3.12 [tn/m2]

9.13 [tn/m2]

2.78 [tn/m2]

2.76 [tn/m2]

Eas1 =

23.68 [tn]

Eps =

107.19 [tn]

hEas1 =

1.08 [m]

hEps =

1.05 [m]

Eas2' =

46.43 [tn]

hEas2' =

1.32 [m]

Ew =

27.05 [tn]

Ew =

27.05 [tn]

hw =

0.93 [m]

hw =

0.93 [m]

3 / 10

Calculo de Estribo Central

Ea =

97.16 [tn]

Ep =

134.24 [tn]

hEa =

1.83 [m]

hEP =

1.02 [m]

MEa =

177.64 [tn-m]

MEP =

137.12 [tn-m]

8. MOMENTO POR LA REACCION DE LA CARGA VIVA Y MUERTA DE LA VIGAS

50.55 [tn]

LV =

DV =

XRV =

MLV =

M DV =

68.65 [tn]

83.40 [tn]

113.28 [tn]

1.65 [m]

9. VERIFICACION DE LA ESTABILIDAD (Esfuerzos en estados de servicio s/mayorar)

Factor de Seguridad al Deslizamiento

GRUPO I:

etapa de servicio

FR = * ( DH + DS + DV + 5/3LV ) =

FSdesl = ( FR + EP ) / Ea =

GRUPO II:

GRUPO III:

196.02 [tn]

3.40

>

1.50 .....OK

etapa de construccion

FR = * ( DH + DS + DV ) = 147.38 [tn]

FSdesl = ( FR + EP ) / Ea =

2.90

>

1.50 .....OK

etapa de servicio

FR = * ( DH + DS + DV + LV ) =

FSdesl = ( FR + EP ) / Ea =

176.56 [tn]

3.20

>

1.50 .....OK

Factor de Seguridad al Vuelco

GRUPO I:

etapa de servicio

Momento resistente al Vuelco

MRvu = MoDh+MoDS+MDV+5/3MLV+MEp=

FSvuelco = MRvu / Mvu =

4.32

GRUPO II:

etapa de construccion

Momento resistente al Vuelco

MRvu = MoDh+MoDS+MDV+MEp=

FSvuelco = MRvu / Mvu =

3.54

GRUPO III:

etapa de servicio

Momento resistente al Vuelco

MRvu = MoDh+MoDS+MDV+MLV+1.3MEp=

FSvuelco = MRvu / Mvu =

3.26

Momento de Vuelco

767.34 [tn m]

Mvu = MEa =

>

2.00 .....OK

Momento de Vuelco

628.34 [tn m]

Mvu = MEa =

>

177.64

2.00 .....OK

Momento de Vuelco

752.88 [tn m]

Mvu = 1.3MEa =

>

177.64 [tn m]

230.93 [tn m]

2.00 .....OK

Verificacion a Capacidad Portante

GRUPO I:

etapa de servicio

Distancia de "O" a la linea de accion de cargas resultante

PT = ( DH + DS + DV + 5/3LV ) = 339.51 [tn]

X = MR / PT =

1.74 [m]

! eCL ! =

0.01 [m]

q1 = PT / A)*(1 - 6*eCL/B) =

q2 = PT / A)*(1 + 6*eCL/B) =

Excentricidad a la linea central

MR = MRuv - Muv =

589.70 [tn m]

<

13.55

<

14.17

<

GRUPO II:

etapa de construccion

Distancia de "O" a la linea de accion de cargas resultante

0.0131 [m]

eCL = (base/2) - X =

B/6 =

0.58 [m] .....OK

qadm = 15.00 [tn/m2]

.OK

qadm = 15.00 [tn/m2]

.OK

Excentricidad a la linea central

4 / 10

Calculo de Estribo Central

PT = ( DH + DS + DV ) =

255.27 [tn]

MR = MRuv - Muv =

X = MR / PT =

1.77 [m]

eCL = (base/2) - X =

! eCL ! =

0.02 [m]

q1 = PT / A)*(1 - 6*eCL/B) =

q2 = PT / A)*(1 + 6*eCL/B) =

<

10.70

<

10.14

<

B/6 =

0.58 [m] .....OK

qadm = 15.00 [tn/m2]

.OK

qadm = 15.00 [tn/m2]

.OK

GRUPO III:

etapa de servicio

Distancia de "O" a la linea de accion de cargas resultante

PT = ( DH + DS + DV + LV ) = 305.81 [tn]

X = MR / PT =

1.71 [m]

! eCL ! =

0.04 [m]

q1 = PT / A)*(1 - 6*eCL/B) =

q2 = PT / A)*(1 + 6*eCL/B) =

450.70 [tn m]

-0.0156 [m]

Excentricidad a la linea central

MR = MRuv - Muv =

521.94 [tn m]

0.0433 [m]

eCL = (base/2) - X =

<

11.56

13.41

B/6 =

0.58 [m] .....OK

<

qadm =

<

qadm =

[tn/m2]

15.00

[tn/m ]

15.00

.OK

.OK

10. DISEO ESTRUCTURAL DEL ESTRIBO

De aca adelante todos los esfuerzos seran determninados por unidad de ancho (b =1 m = 100 cm)

Mtodo de servicio

ACI

fc' =

25 [MPa] =

250.00 [kg/cm 2]

corte

0.85

flexion

0.9

fy =

500 [MPa] = 5000.00 [kg/cm 2]

rec

Corte resistido por el concreto

c = 0.53* * fc' 0.5 =

7.39 [kg/cm 2]

CL

10.1 DISEO ESTRUCTURAL DE LA PANTALLA

s0

a0

hEa21

Eas1

H-t

RT

w1

H = 5.50 [m]

alt zapata = 0.50 [m]

Eax

a1'

hEas2

j + k = 3.65 [m]

ax

hz

l l1

wx

t = 2.78 [m]

t-X

Easx

Ewx

hEw

hEax

n o

C

L

O

S

5 / 10

Calculo de Estribo Central

L

Se deben analizar varias secciones con el objeto de ir disminuyendo armadura a medida que el momneto es menor

para tal efecto

0.50 [m]

<

X

<

5.50 [m]

para el efecto se analizaran

secciones

Momento en la base a

5.00 [m] de profundidad

X=

0.50 [m]

H-X=

t-X=

Seccion No: 1

ao =

a1' =

wx =

ax' =

0.47 [tn/m2]

2.01 [tn/m ]

Datos de la seccion analizada

2.28 [tn/m ]

Eas1 =

hEas1 =

Easx' =

hEasx' =

Ewx =

hwx =

b = 100 [cm]

h=

d=

[tn/m ]

[tn]/m

[m]

[tn]/m

Eax

7.22 [tn]

LV =

DV =

3938285.22 [kg-cm]/m ;

3938285.22 [kg-cm]/m

39.38 [tn-m]/m =

39.38 [tn-m]/m =

12.6 cm2 /m ancho

= 16

mm

Seccion No: 2

As max =

2.45 [tn]

.OK

Mult sap =

73.6 cm2 /m ancho

20.6 cm2 /m ancho

..Prosiga

(As x L)

As 116 =2.01 cm2

Momento en la seccion 2-2 a

X=

2.33 [m]

Eas1 =

hEas1 =

Easx' =

hEasx' =

Ewx =

hwx =

1.81 [tn]

Sep = 9.50 cm

# Barras = 72

72 16mm c/9.5 cm

=> USAR

ao =

a1' =

wx =

ax' =

19.10 [tn-m]/m

< c = 0.53* * fc' 0.5 = 7.39

As =

Elegir

11.27 [tn]/m

1.70 [m]

MLV =

M DV =

9.81 [tn]

4.23 [kg/cm 2]

Mult = 1.3(MDV+5/3MLV+1.3MEaX) =

Mult prom =

143.87 cm2

Ea =

hEa =

o[ j + k + ( x hz )]

j+k

19.05 [tn]/m

v ult =

As Total =

h = n+

MEax =

Vult = 1.3(1.3Ea) =

As min =

50 [cm]

45 [cm]

Eas 1 [( t x ) + hEas 1 ]+ E asx hEasx + EWx hEWx

hEax =

0.25 [m]

h cal = 0.50 [m]

Eax = Eas1 + Es 2 + Ew

1.09 [m]

2.60 [tn]/m

0.76 [m]

XRV

H - t = 2.72 [m]

si X > t => Eas'x = 0 ; Ewx = 0

2.62

3.38

1.08

5.29

5.00 [m]

2.28 [m]

0.47 [tn/m2]

2

2.01 [tn/m ]

Datos de la seccion analizada

b = 100 [cm]

0.46 [tn/m ]

XRV

[tn/m ]

[tn]/m

[m]

[tn]/m

[m]

[tn]/m

[m]

0.25 [m]

Vult = 1.3(1.3Ea) =

H - t = 2.72 [m]

si X > t => Eas'x = 0 ; Ewx = 0

2.14

3.38

1.08

0.94

0.23

0.10

0.15

3.18 [m] de profundidad

H-X=

3.18 [m]

t-X=

0.46 [m]

h=

d=

45 [cm]

40 [cm]

Eax = Eas1 + Es 2 + Ew

hEax =

Eas 1 [( t x ) + hEas 1 ]+ E asx hEasx + EWx hEWx

LV =

DV =

h cal = 0.45 [m]

Eax

7.22 [tn]

9.81 [tn]

Ea =

hEa =

4.43 [tn]/m

1.22 [m]

MEax =

5.42 [tn-m]/m

MLV =

M DV =

1.81 [tn]

2.45 [tn]

7.49 [tn]/m

6 / 10

Calculo de Estribo Central

v ult =

Mult = 1.3(MDV+5/3MLV+1.3MEaX) =

As min =

< c = 0.53* * fc' 0.5 = 7.39

1.87 [kg/cm 2]

1625554.32 [kg-cm]/m

16.26 [tn-m]/m =

11.2 cm2 /m ancho

9.3 cm2 /m ancho

= 16

mm

As 116 =2.01 cm2

Sep = 18.00 cm

# Barras = 39

39 16mm c/18 cm

=> USAR

Momento en la seccion 3-3 a 1.35 [m] de profundidad

X=

4.15 [m]

H-X=

1.35 [m]

t-X=

0.00 [m]

Seccion No: 3

ao =

a1' =

wx =

ax' =

0.47 [tn/m2]

1.24 [tn/m ]

Datos de la seccion analizada

0.00 [tn/m ]

0.00

1.16

0.57

0.00

0.00

0.00

0.00

As min =

b = 100 [cm]

h=

d=

[tn/m ]

[tn]/m

[m]

[tn]/m

[m]

[tn]/m

[m]

35 [cm]

30 [cm]

Eax = Eas1 + Es 2 + Ew

hEax =

Elegir

1.95 [tn]/m

v ult =

0.65 [kg/cm 2]

Mult =

1.12 [tn-m]/m =

8.4 cm2 /m ancho

=> USAR

= 10

Eax

Elegir

0.66 [tn-m]/m

<

= 0.53* * fc' 0.5 = 7.39

.OK

112123.369 [kg-cm]/m

Asmax =

49.1 cm2 /m ancho

0.8 cm2 /m ancho

..Prosiga

(As min x L)

As 110 =0.79 cm2

# Barras = 75

Sep = 9.00 cm

# Barras = 30

Sep = 12.00 cm

75 10mm c/9 cm

ARMADURA HORIZONTAL

b = 100 [m]

h=

48 [m]

d=

43 [m]

As Total =

mm

hEa =

MEax =

Vult =

58.80 cm2

1.16 [tn]/m

0.57 [m]

Ea =

Eas 1 [( t x ) + hEas 1 ]+ E asx hEasx + EWx hEWx

As =

As Total =

H - t = 2.72 [m]

si X > t => Eas'x = 0 ; Ewx = 0

Eas1 =

hEas1 =

Easx' =

hEasx' =

Ewx =

hwx =

=> USAR

..Prosiga

(As min x L)

78.40 cm2

Elegir

65.5 cm2 /m ancho

Asmax =

As =

As Total =

.OK

As =

23.27 cm2

= 10

mm

6.4 cm2 /m ancho

As x (k+j)

As 110 =0.79 cm2

30 10mm c/12 cm

(colocados en cada cara)

ARMADURA VERTICAL DEL ESTRIBO DE LA CARA NO TRACCIONADA

b=

h=

100 [m]

48 [m]

As =

6.4 cm2 /m ancho

7 / 10

Calculo de Estribo Central

d=

43 [m]

As Total =

Elegir

44.63 cm2

= 10

=> USAR

mm

As x (L)

As 110 =0.79 cm2

57 10mm c/12 cm

# Barras = 57

Sep = 12.00 cm

(colocados en cada cara)

10.2 DISEO ESTRUCTURAL DE LA ZAPATA

GRUPO I:

etapa de servicio

Momento resistente al Vuelco

Momento de Vuelco

MRvu = 1.3(MoDh+MoDS+MDV+5/3MLV+1.3MEp)= 1051.02 [tn m]

Mvu = 1.3(1.3MEa) =

PTr = 1.3( DH + DS + DV + 5/3LV ) = 441.37 [tn]

MRr = MRuv - Muv =

Distancia de "O" a la linea de accion de cargas resultante

X = MRr / PTr =

1.70 [m]

300.21 [tn m]

750.81

Excentricidad a la linea central

eCL = (base/2) - X = 0.0489 [m]

Tension maxima sobre la zapata debido a esfuerzos de rotura

q1 = (PTr / A)*(1 - 6*eCL/B) = 16.50 [tn/m2]

q2 = (PTr / A)*(1 + 6*eCL/B) = 19.52 [tn/m2]

Tensiones en las esquinas

A (Tn/m2) 19.525

B(Tn/m2) 16.505

C (Tn/m2) 16.505

D (Tn/m2) 19.525

Tensiones en los puntos medios

E = ( A + D ) 2

F = ( B + C ) 2

G = ( A + B ) 2

H = ( C + D ) 2

E (Tn/m2) 19.525

F(Tn/m2) 16.505

G (Tn/m2) 18.015

H (Tn/m2) 18.015

8 / 10

Calculo de Estribo Central

Verificacion a esfuerzo cortante como viga

dm =

dp

1.40

0.50

q1 + qdm

2

Vm =

n+o

hz

dp

dm

0.50

dm

0.30

1.60

0.39 m

d p = 0.40 m

qdm = 17.37 Tn/m2

qdp = 18.49

(m d m ) =

Vp =

17.04 Tn

q2 + qdp

2

43.29

( p d p ) =22.81 Tn

57.02

Las condiciones a satisfacer son:

q + q m (h r )

vm = 1 dm

vc = 0.53 f ' c

2 hz r

q1

16.50

[tn/m2]

qdm

vm

qdp

vm =

Vm

dm 1

q2 + qdp p ( h r )

vp =

vc = 0.53 f ' c

2 hz r

[tn/m2]

q2 19.52

vp vum = ( q1 +qdm ) m h1 + r ) = 43.29

2

h r

3.50 m

vP =

VP

yp

= vup =

q2 + qdp

2

Tn/m2

vc = 71.23 Tn/m2

vum < vc; BIEN => Prosiga

ph( h1r r ) =

57.02 Tn/m2

vc = 71.23 Tn/m2

vup < vc; BIEN => Prosiga

Diseo a flexion

qm =

2

Rm = ( q1 +2qm )m =

0.50

h

1.40

0.50

xm

16.50

[tn/m2]

vm

qm

qp

3.50 m

vp

q2

mm

Elegir

As Total = 88.20 cm2

As 116 = 2.01 cm2

# Barras = 44

=> USAR

(As min x L)

Sep = 16.00 cm

44 16mm c/16 cm

1656948.18 Kg-cm

As Total =

As 110 = 0.79 cm2

# Barras = 20

Elegir

As Total = 88.20 cm2

As 116 = 2.01 cm2

# Barras = 44

mm

(As x B)

15.44 cm2

Sep = 17.50 cm

20 10mm c/17.5 cm

Asp dist = 4.41 cm2 /m ancho

As min = 12.60 cm2 /m ancho

mm

= 10

=> USAR

Para el acero de refuerzo en la parte de "p"

Asp = 12.46 cm2 /m ancho

= 16

16.57 Tn-m =

Asm dist = 4.41 cm2 /m ancho

As min = 12.60 cm2 /m ancho

Elegir

) p = 30.14 Tn

19.52

[tn/m2]

Para el acero de refuerzo en la parte de "m"

Asm = 8.37 cm2 /m ancho

= 16

q p + q2

2

xp

B

Elegir

Rp = (

23.95 Tn

18.14 Tn/m2

M P = 24.40 Tn-m = 2440274.79 Kg-cm

2440274.8 [kg-cm]/m

Mult prom =

24.40 [tn-m]/m =

Estos valores de momento actan sobre la sgte seccin:

b = 100 cm

d = 45 cm

1.60

Mult sap =

q1

qp =

17.71 Tn/m2

Mm =

n+o

b = 100.00 cm

d = 40.00 cm

hz

0.30

b = 100.00 cm

d = 39.38 cm

(As min x L)

Sep = 16.00 cm

= 10

mm

As Total =

As 110 = 0.79 cm2

# Barras = 20

(As x B)

15.44 cm2

Sep = 17.50 cm

9 / 10

Calculo de Estribo Central

=> USAR

44 16mm c/16 cm

=> USAR

20 10mm c/17.5 cm

10 / 10

Anda mungkin juga menyukai

- Diseño de Estribos de Concreto Reforzado DerechoDokumen17 halamanDiseño de Estribos de Concreto Reforzado DerechoCarlos VilteBelum ada peringkat

- Diseño de Estribos de Concreto Reforzado IzquierdoDokumen13 halamanDiseño de Estribos de Concreto Reforzado IzquierdoCarlos VilteBelum ada peringkat

- Diseño de ZapatasDokumen18 halamanDiseño de ZapatasCarlos VilteBelum ada peringkat

- Compresion Simple Costaneras ModificadoDokumen13 halamanCompresion Simple Costaneras ModificadoNahir Gise RojasBelum ada peringkat

- Pasarela 20m 110 MMDokumen5 halamanPasarela 20m 110 MMCarlos VilteBelum ada peringkat

- Pasarela L 15 M Hdpe 1100 Pn6Dokumen6 halamanPasarela L 15 M Hdpe 1100 Pn6Carlos VilteBelum ada peringkat

- Pasarela L 15 M Hdpe 1100 Pn6Dokumen6 halamanPasarela L 15 M Hdpe 1100 Pn6Carlos VilteBelum ada peringkat

- Diseño de BarandaDokumen3 halamanDiseño de BarandaCarlos VilteBelum ada peringkat

- Diseño SanitarioDokumen19 halamanDiseño SanitarioCarlos VilteBelum ada peringkat

- Pasarela L 15 M Hdpe 1100 Pn6Dokumen6 halamanPasarela L 15 M Hdpe 1100 Pn6Carlos VilteBelum ada peringkat

- Diagrana de Interaccion Col 30X30Dokumen2 halamanDiagrana de Interaccion Col 30X30Carlos VilteBelum ada peringkat

- Diseño de Viga 25X80Dokumen2 halamanDiseño de Viga 25X80Carlos VilteBelum ada peringkat

- Pasarela L 15 M Hdpe 1100 Pn6Dokumen6 halamanPasarela L 15 M Hdpe 1100 Pn6Carlos VilteBelum ada peringkat

- Pasarela L 15 M Hdpe 1100 Pn6Dokumen6 halamanPasarela L 15 M Hdpe 1100 Pn6Carlos VilteBelum ada peringkat

- Pasarela L 15 M Hdpe 1100 Pn6Dokumen6 halamanPasarela L 15 M Hdpe 1100 Pn6Carlos VilteBelum ada peringkat

- Pasarela L 15 M Hdpe 1100 Pn6Dokumen6 halamanPasarela L 15 M Hdpe 1100 Pn6Carlos VilteBelum ada peringkat

- Pasarela L 15 M Hdpe 1100 Pn6Dokumen6 halamanPasarela L 15 M Hdpe 1100 Pn6Carlos VilteBelum ada peringkat

- Pasarela L 15 M Hdpe 1100 Pn6Dokumen6 halamanPasarela L 15 M Hdpe 1100 Pn6Carlos VilteBelum ada peringkat

- Pasarela L 15 M Hdpe 1100 Pn6Dokumen6 halamanPasarela L 15 M Hdpe 1100 Pn6Carlos VilteBelum ada peringkat

- Pasarela L 15 M Hdpe 1100 Pn6Dokumen6 halamanPasarela L 15 M Hdpe 1100 Pn6Carlos VilteBelum ada peringkat

- Pasarela L 15 M Hdpe 1100 Pn6Dokumen6 halamanPasarela L 15 M Hdpe 1100 Pn6Carlos VilteBelum ada peringkat

- Pasarela L 15 M Hdpe 1100 Pn6Dokumen6 halamanPasarela L 15 M Hdpe 1100 Pn6Carlos VilteBelum ada peringkat

- Puente 40 M y 4 PulgadasDokumen6 halamanPuente 40 M y 4 PulgadasCarlos VilteBelum ada peringkat

- Pasarela L 15 M Hdpe 1100 Pn6Dokumen6 halamanPasarela L 15 M Hdpe 1100 Pn6Carlos VilteBelum ada peringkat

- Pasarela L 15 M Hdpe 1100 Pn6Dokumen6 halamanPasarela L 15 M Hdpe 1100 Pn6Carlos VilteBelum ada peringkat

- 04 DesarenadoresDokumen12 halaman04 DesarenadoresCarlos VilteBelum ada peringkat

- Pasarela L 15 M Hdpe 1100 Pn6Dokumen6 halamanPasarela L 15 M Hdpe 1100 Pn6Carlos VilteBelum ada peringkat

- Pasarela L 15 M Hdpe 1100 Pn6Dokumen6 halamanPasarela L 15 M Hdpe 1100 Pn6Carlos VilteBelum ada peringkat

- Hidrologia FinalDokumen69 halamanHidrologia FinalCarlos VilteBelum ada peringkat

- 03 Calculo Estructural Muros TomaDokumen5 halaman03 Calculo Estructural Muros TomaCarlos VilteBelum ada peringkat

- Medicina 2 AnticoaguladosDokumen25 halamanMedicina 2 AnticoaguladosfiorellaBelum ada peringkat

- Agua destiladaDokumen27 halamanAgua destiladaAlexander EMendez100% (1)

- Cuestionario de RepasoDokumen10 halamanCuestionario de RepasoAlex SeanBelum ada peringkat

- Experimento 11 Analisis de LecheDokumen8 halamanExperimento 11 Analisis de LecheAaron Quispe ChambiBelum ada peringkat

- Programa Fisico Quimica PDFDokumen8 halamanPrograma Fisico Quimica PDFSilBelum ada peringkat

- Initial Materiales Plásticos ESDokumen2 halamanInitial Materiales Plásticos ESBeatriz Alexia Pacheco ParraBelum ada peringkat

- Costos Operación PTAP FiMEDokumen1 halamanCostos Operación PTAP FiMEManukoArteagaBelum ada peringkat

- 1Dokumen10 halaman1Arlet BibriescaBelum ada peringkat

- Analisis de La PeliculaDokumen9 halamanAnalisis de La PeliculaVictorESGOBelum ada peringkat

- Ciclo Rankine Regenerativo o Con Extracciones SucesivasDokumen7 halamanCiclo Rankine Regenerativo o Con Extracciones SucesivasJosé Luis Torres GBelum ada peringkat

- Ensayo Bloques de MotoresDokumen3 halamanEnsayo Bloques de MotoresLauraHernandezBelum ada peringkat

- Nutrición Humana Digestión y RespiraciónDokumen13 halamanNutrición Humana Digestión y Respiraciónjoaquin mendozaBelum ada peringkat

- THB 07 Informe de Microtomia - Karen GarzonDokumen26 halamanTHB 07 Informe de Microtomia - Karen GarzonKaren Veronica Garzon SalazarBelum ada peringkat

- Poes y GoesDokumen79 halamanPoes y GoesjosisBelum ada peringkat

- Qué es acetona y para qué sirve? Guía completa sobre compuestos cetónicosDokumen6 halamanQué es acetona y para qué sirve? Guía completa sobre compuestos cetónicosRosario AdriBelum ada peringkat

- Calidad Del AireDokumen8 halamanCalidad Del AirePedro Alexis Lopez VazquezBelum ada peringkat

- KAFH OT 2E 07-18 16072018 ES Web 2 PDFDokumen24 halamanKAFH OT 2E 07-18 16072018 ES Web 2 PDFGabriela CanaviriBelum ada peringkat

- Tarabita PlayonDokumen4 halamanTarabita PlayonGlenda_20100% (1)

- Proteccion Catodica (Monografia) - CorrosionDokumen36 halamanProteccion Catodica (Monografia) - CorrosionBenjamin Palma Inocente100% (1)

- Procesamiento de Minerales 2019Dokumen194 halamanProcesamiento de Minerales 2019Cristian P OlmosBelum ada peringkat

- TEMA 18. Conectologia y Liquidos (Fresenius)Dokumen10 halamanTEMA 18. Conectologia y Liquidos (Fresenius)PieroBelum ada peringkat

- MargaritaDokumen124 halamanMargaritaGustavo OrtegaBelum ada peringkat

- Calcantita MineralogiaDokumen7 halamanCalcantita MineralogiaMaydde Cutipa0% (1)

- WurtzitaDokumen7 halamanWurtzitaAnonymous R4wRmP6EBelum ada peringkat

- Redes de BravaisDokumen3 halamanRedes de BravaisNicolas SalazarBelum ada peringkat

- Compuestos NitrogenadosDokumen20 halamanCompuestos NitrogenadosIvanAguilarGalvanBelum ada peringkat

- Cap 31 ContamAmbientalYBacteriasProdDePlastBiodegrDokumen21 halamanCap 31 ContamAmbientalYBacteriasProdDePlastBiodegrDany AriasBelum ada peringkat

- Lagunas FacultativasDokumen21 halamanLagunas FacultativasCinthiaMilagrosTincoDominguezBelum ada peringkat

- Grupo 2 Equipo 5 Entrega 2 - Acetato de IsobutiloDokumen25 halamanGrupo 2 Equipo 5 Entrega 2 - Acetato de IsobutiloSantiago MartinezBelum ada peringkat

- Fertilizante - AbonoDokumen20 halamanFertilizante - AbonoTRITURADOS Y MEZCLAZBelum ada peringkat