Root Cause Analysis

Diunggah oleh

Sick LoveHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Root Cause Analysis

Diunggah oleh

Sick LoveHak Cipta:

Format Tersedia

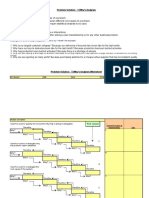

PROBABLE CAUSE

BEARING HOUSING CONDITION Bearing Housing condition

ANALYSIS

ACTION TAKEN

As per SPF, shots used during blasting impregnate with casting. This loosen shots contribute to high iron content. Ruled out by SPF considering std & proven design. No vibration problem Aligned many times & witnessed by Aramco. No misalignment issue During pump opening installation was found OK Checked by JGC/SA. Perfectly OK. Everytime pump returned to factory new bearings are installed even when not worn out When checked by opening breather, good oil circulation can be seen. ISO VG 46 is standard & proven oil.

SPF is now using high pressure steam wash for all pumps returned to factory. High iron content was seen only in first report. Subsequent report show Fe content well within Aramco limit. There is no problem of bearing over/underloading because : a Once bearing housing properly washed high iron problem disappeared. b Only once scoring mark observed. After that whenever pump opned no scoring marks were observed. c No vibrations showing bearing loading Considering this no corrective action is required to be taken on this issue

PRESENCE OF IRON BEARING OVERLOADING / UNDERLOADING

Wrong bearing selection Misalignment wrong installation at factory Improper tolerance Defective bearings

OIL DISCOLORATION

IMPENDING BEARING FAILURE

Improper lubrication Oil flinger design LOCAL OVERHEATING Wrong lubricant selected

SPF maintained that oil flinger design & oil selected have no problem considering long experience. As such bearing temp was always found within limit. No corrective action required.

PRESENCE OF SILICON

RUBBING OF LIP SEAL

Improper maching of shaft Insufficient clearance bet lip seal/shaft Inferior quality of lip seal material

Machine cut was visible on lip seal when pump was opened for insp Clearance is much less. During run, lip seal touch shaft due to thermal expansion. Visible from visual inspection

Different ways suggested to SPF to change the design of shaft & lip seal assembly. But finally offered superior solution by removing rubber lip seal & using diaphragm type seal (brand name : InproSeal) normally used in API pumps Subsequent running & report shows that this solution worked.

By : Mr. Ako Amegah (SA-HNRP), Mr. Husain Abdulla (SA-HNRP), Mr. Rajesh Manjarekar (JGC)

Anda mungkin juga menyukai

- RCA Intro and ToolsDokumen102 halamanRCA Intro and Toolswaran87100% (1)

- Problem Solution - 5 Why's Analysis Worksheet: Be Sure The 5 Why's Is Grounded in Observation Not DeductionDokumen2 halamanProblem Solution - 5 Why's Analysis Worksheet: Be Sure The 5 Why's Is Grounded in Observation Not DeductionSyafiq SulaimanBelum ada peringkat

- Root Cause AnalysisDokumen9 halamanRoot Cause AnalysisAl Engg100% (9)

- Root Cause Analysis Report FormDokumen7 halamanRoot Cause Analysis Report Formbenaoumeur benounaBelum ada peringkat

- Quadrajet TuningDokumen10 halamanQuadrajet Tuningjet406100% (1)

- Root Cause TemplateDokumen19 halamanRoot Cause TemplateFiroz Khan100% (3)

- FMEADokumen5 halamanFMEAmz007Belum ada peringkat

- 5 Why FormDokumen1 halaman5 Why Formvandukul100% (1)

- Problem Solving A3: Encore Repair ServicesDokumen2 halamanProblem Solving A3: Encore Repair ServicesRamon Alexander De La Cruz MartinezBelum ada peringkat

- Sucker Rod Pump BasicsDokumen76 halamanSucker Rod Pump BasicsDumitrescu GabrielBelum ada peringkat

- Sta-P08-02 Non Conforming ProductDokumen6 halamanSta-P08-02 Non Conforming ProductAnonymous B7pghhBelum ada peringkat

- Defect Repair Vs Corrective Action Vs Preventive ActionDokumen4 halamanDefect Repair Vs Corrective Action Vs Preventive Actionshahed100% (1)

- MHS 06. Statistical Process Control-KWODokumen55 halamanMHS 06. Statistical Process Control-KWOKevin SinagaBelum ada peringkat

- Fmea Process TemplateDokumen20 halamanFmea Process TemplateLazarasBenny IsprithiyoneBelum ada peringkat

- Root Cause Analysis ToolsDokumen15 halamanRoot Cause Analysis ToolscmlimBelum ada peringkat

- Mechanical Seal ReplacementDokumen21 halamanMechanical Seal ReplacementshahjahanhashimaliBelum ada peringkat

- Root Cause Analysis ReportDokumen4 halamanRoot Cause Analysis ReportMaria Len GalaponBelum ada peringkat

- 5 Whys TrainingDokumen14 halaman5 Whys TrainingPanch BBelum ada peringkat

- MGB Competition Preparation ManualDokumen39 halamanMGB Competition Preparation ManualasrwBelum ada peringkat

- The Root Cause Analysis Process Should Follow These 7 StepsDokumen5 halamanThe Root Cause Analysis Process Should Follow These 7 StepsFaisal AbbasBelum ada peringkat

- 5 Whys Analysis SheetDokumen3 halaman5 Whys Analysis SheetTanvi SharmaBelum ada peringkat

- 2014 06 23 FMEA SlidesDokumen19 halaman2014 06 23 FMEA SlidesMadhan RajBelum ada peringkat

- Determining The Root Cause of A Problem: Approved For Public ReleaseDokumen22 halamanDetermining The Root Cause of A Problem: Approved For Public ReleaseLucia M. AceroBelum ada peringkat

- Highway Material ManualDokumen59 halamanHighway Material ManualHany Seif-Aldien NasserBelum ada peringkat

- 5 Why TrainingDokumen22 halaman5 Why Trainingcpalfas100% (1)

- QP 74301 Rev 08 Incoming Inspection ProcedureDokumen9 halamanQP 74301 Rev 08 Incoming Inspection ProcedureAngeline D'AlmaidaBelum ada peringkat

- ABC Sdn. BHD.: First (1S) Audit ChecklistDokumen2 halamanABC Sdn. BHD.: First (1S) Audit ChecklistRamesh KumarBelum ada peringkat

- 5 Why Training Presentation3Dokumen49 halaman5 Why Training Presentation3Vivek Shrivastava100% (1)

- Cause and Effect Diagram: CA/PA-RCA: Basic ToolDokumen21 halamanCause and Effect Diagram: CA/PA-RCA: Basic Toolsiddiquiee74100% (1)

- 4JX1Dokumen8 halaman4JX1Luis Alberto Gomez Sanchez100% (1)

- 5S - Step by Step Guide PDFDokumen17 halaman5S - Step by Step Guide PDFvanausabBelum ada peringkat

- Case Study - MousetrapDokumen6 halamanCase Study - Mousetrapjanela bautistaBelum ada peringkat

- 8D TemplateDokumen7 halaman8D Templatemuhammad_mmd100% (1)

- DFMEADokumen7 halamanDFMEAPersonaMeraBelum ada peringkat

- Rotary CoatingDokumen5 halamanRotary Coatinggalati12345Belum ada peringkat

- ArgonDokumen8 halamanArgonariane8910Belum ada peringkat

- Bill No. 5 - Cluster B, D & FDokumen204 halamanBill No. 5 - Cluster B, D & FmimrusfanBelum ada peringkat

- How To Use The 5-Whys For Root Cause AnalysisDokumen10 halamanHow To Use The 5-Whys For Root Cause AnalysisSlim100% (2)

- Dust Control Handbook (Osha) - CompleteDokumen214 halamanDust Control Handbook (Osha) - CompleteRaul SilanesBelum ada peringkat

- 05 Rolled Throughput YieldDokumen19 halaman05 Rolled Throughput Yieldcpkakope100% (1)

- FMEA - A Guide For Continuous ImprovementDokumen36 halamanFMEA - A Guide For Continuous Improvementvipin_chaudhary100% (1)

- QEHS ManualDokumen100 halamanQEHS ManualRob WillestoneBelum ada peringkat

- Smith Industries WaterBath Indirect Heater PDFDokumen29 halamanSmith Industries WaterBath Indirect Heater PDFcassindromeBelum ada peringkat

- Basic 7 Tools of Quality: Presentation By: Carla Scardino The Pennsylvania State UniversityDokumen37 halamanBasic 7 Tools of Quality: Presentation By: Carla Scardino The Pennsylvania State Universityjitenderbhati07Belum ada peringkat

- Presentation: Reliability of Hydrogen Area Diaphragm CompressorDokumen43 halamanPresentation: Reliability of Hydrogen Area Diaphragm CompressorBiju_Pottayil100% (1)

- Petrorabigh VGO Pump Mechanical Seal Failures AnalysisDokumen10 halamanPetrorabigh VGO Pump Mechanical Seal Failures AnalysisAbdulrahman AlkhowaiterBelum ada peringkat

- Synergic Safety Engineers: Environmental Aspect & It'S ImpactDokumen22 halamanSynergic Safety Engineers: Environmental Aspect & It'S ImpactS.N. Automats100% (1)

- 8d-Report (Ishikawa)Dokumen12 halaman8d-Report (Ishikawa)Miro Vincek100% (1)

- Visual Management Audit ChecklistDokumen1 halamanVisual Management Audit ChecklistOswald mBelum ada peringkat

- Pump Learning Guide1Dokumen171 halamanPump Learning Guide1password2013Belum ada peringkat

- A3 Problem Solving TemplateDokumen2 halamanA3 Problem Solving Templateksathis100% (1)

- CTQ VocDokumen9 halamanCTQ VocFran JimenezBelum ada peringkat

- Gage R&RDokumen16 halamanGage R&RAl-Kawthari As-SunniBelum ada peringkat

- Red Flags SurveyDokumen6 halamanRed Flags Surveyhmp90Belum ada peringkat

- What: Where (Location) : When (Date) : Who (Name) : HowDokumen3 halamanWhat: Where (Location) : When (Date) : Who (Name) : HowDaniswara Krisna PrabathaBelum ada peringkat

- 3 Legged 5 Why - Effective Root Cause AnalysisDokumen40 halaman3 Legged 5 Why - Effective Root Cause AnalysisJohn OoBelum ada peringkat

- 3 Zero Quality ControlDokumen6 halaman3 Zero Quality ControlShreyas KolheBelum ada peringkat

- Falls - Root Cause Analysis FinalDokumen1 halamanFalls - Root Cause Analysis FinalMohammed KhatibBelum ada peringkat

- Sampling Plan Some IdeaDokumen10 halamanSampling Plan Some IdeaPrashant Puri100% (1)

- Manufacturing Facilities A Complete Guide - 2019 EditionDari EverandManufacturing Facilities A Complete Guide - 2019 EditionBelum ada peringkat

- Root Cause Failure Analysis: Refinery Fines Blower Frequent Bearing Failures Year 2007Dokumen7 halamanRoot Cause Failure Analysis: Refinery Fines Blower Frequent Bearing Failures Year 2007Laxminarayan NayakBelum ada peringkat

- Ashok LeylanadDokumen11 halamanAshok LeylanadJay SuryaBelum ada peringkat

- Reducing Wear Particle GenerationDokumen6 halamanReducing Wear Particle GenerationFraz AhmadBelum ada peringkat

- Oil SludgeDokumen5 halamanOil SludgeZvonko DinkicBelum ada peringkat

- Kawasaki VN800 GrampsizeDokumen23 halamanKawasaki VN800 Grampsizetw4nnyBelum ada peringkat

- Replacing The Volvo Oil Trap and Oil Pan SumpDokumen6 halamanReplacing The Volvo Oil Trap and Oil Pan SumpsaifrulBelum ada peringkat

- Pneumatic Structures: The Fascination of Pneumatic Structures Begins With The Fascination of The SkyDokumen9 halamanPneumatic Structures: The Fascination of Pneumatic Structures Begins With The Fascination of The SkyTangha Muklom KunchaBelum ada peringkat

- Review On Metallization Approaches For High-Efficiency Silicon Heterojunction Solar CellsDokumen16 halamanReview On Metallization Approaches For High-Efficiency Silicon Heterojunction Solar Cells蕭佩杰Belum ada peringkat

- Non-Catalytic and Heterogeneous Acid/base-Catalyzed Biodiesel Production: Recent and Future DevelopmentsDokumen34 halamanNon-Catalytic and Heterogeneous Acid/base-Catalyzed Biodiesel Production: Recent and Future DevelopmentsJelian GraceBelum ada peringkat

- Analysis of Tenement 1Dokumen84 halamanAnalysis of Tenement 1IyswariyaBelum ada peringkat

- Proceedings of ACEID-2014!6!7 February, 2014Dokumen320 halamanProceedings of ACEID-2014!6!7 February, 2014PtpgStucBelum ada peringkat

- TOC - Table of Compliance Arsitek SimDokumen40 halamanTOC - Table of Compliance Arsitek SimImran nasution0% (1)

- Instructions:: Environmental Education and Awareness For ParentsDokumen1 halamanInstructions:: Environmental Education and Awareness For ParentsJea RodegerioBelum ada peringkat

- DONE - GoodMechanical Properties of 3D Printed Polymeric Gyroid CONFRONTO Con Altre TPMSDokumen9 halamanDONE - GoodMechanical Properties of 3D Printed Polymeric Gyroid CONFRONTO Con Altre TPMSMoad BouzidaBelum ada peringkat

- Trends in Period 3Dokumen47 halamanTrends in Period 3abby jacksonBelum ada peringkat

- CIVL311 - CIVL 911 - 2023 - Week 5 - Design of Columns and Walls - 4 Slides Per PageDokumen19 halamanCIVL311 - CIVL 911 - 2023 - Week 5 - Design of Columns and Walls - 4 Slides Per PageAsfin HaqueBelum ada peringkat

- Igneous Rock TexturesDokumen18 halamanIgneous Rock TexturesWWW.1580.L0GN.CFBelum ada peringkat

- Two Bedroom Apartment 2Dokumen1 halamanTwo Bedroom Apartment 2RUTH ELIZABETH NAMUTEBIBelum ada peringkat

- BearingDokumen22 halamanBearingbbmokshBelum ada peringkat

- Mindmap 1 PDFDokumen1 halamanMindmap 1 PDFnoorafifahabubakarBelum ada peringkat

- Tropic Ocean Silicon MetalDokumen14 halamanTropic Ocean Silicon MetalLin FarrellBelum ada peringkat

- Weld Metal CertificateDokumen1 halamanWeld Metal CertificatePhương Do QuangBelum ada peringkat

- S355G10 GBDokumen4 halamanS355G10 GBH41GAMINGBelum ada peringkat

- H1 Atmospheric CorrosionDokumen4 halamanH1 Atmospheric CorrosionJahnabi BasumataryBelum ada peringkat

- Co ., LT D.: ASME A-106/A-106M - 2019 EDITION Material Verification The Original Markings On ProductionDokumen2 halamanCo ., LT D.: ASME A-106/A-106M - 2019 EDITION Material Verification The Original Markings On ProductionBalaji SelvarajBelum ada peringkat

- Analytical Study On The Dynamic Properties of Viscoelastically Coupled Shear Walls in High-Rise BuildingsDokumen11 halamanAnalytical Study On The Dynamic Properties of Viscoelastically Coupled Shear Walls in High-Rise BuildingsKrishnakumar ThanirosanBelum ada peringkat

- Structure and Properties of WaterDokumen6 halamanStructure and Properties of WaterBrendan Lewis DelgadoBelum ada peringkat

- TOTAL PEMAKAIAN ROL-aprilDokumen6 halamanTOTAL PEMAKAIAN ROL-aprilHarisanto AsBelum ada peringkat

- 2020 Flow Control Choke Valve: SeriesDokumen4 halaman2020 Flow Control Choke Valve: SeriesDaniel AcostaBelum ada peringkat

- Advanced Energy Materials - 2019 - Sultan - Single Atoms and Clusters Based Nanomaterials For Hydrogen Evolution OxygenDokumen48 halamanAdvanced Energy Materials - 2019 - Sultan - Single Atoms and Clusters Based Nanomaterials For Hydrogen Evolution Oxygenkangwei MaoBelum ada peringkat