SA 516M GR 485: If Actual Thickness of Head After Forming 9 MM

Diunggah oleh

Mehta MehulJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

SA 516M GR 485: If Actual Thickness of Head After Forming 9 MM

Diunggah oleh

Mehta MehulHak Cipta:

Format Tersedia

THE ANUP ENGG. LTD. THICKNESS OF TORISHERICAL TOP HEAD ITEM NO.

: DATE : 30/7/05 NOMENCLATURE REFERENCES P= Internal Design Pressure 1.00 MPa O T = Design Temperature 60.00 C UG-20 Di = Inside Diameter of Vessel 1000.00 mm Ci = Corrosion Allowance Internal 3.00 mm Material Of Construction SA 516M GR 485 S = Maximum Allowable Stress At Design Temp. 138.00 MPa (SEC. II D, TABLE 1A) L = Inside Spherical or Crown Radius (Corroded) 903.00 mm <= OD of Skirt 1020mm r = Inside Knuckle Radius (Corroded) 153.00 mm >= 6% OD =61.2mm (A) t1 = Head Thickness as Per UG-16(b)(4) = 2.5 ( COMPRESSED AIR SERVICE) (B) THICKNESS OF TORISPHERICAL HEAD Radiography SPOT UW-11(a)(5)(b) Eht = Joint Efficiency 1.00 UW-12(d) (Seamless) t2 = Required Thickness of Head (APPENDIX 1.4(d)) M = 1/4 [ 3 + SQRT ( L / r ) ] = 1/4 [ 3 + SQRT (903/153)] 1.36 t2 = ( P x L x M ) / ( 2 x S x Eht - 0.2 x P ) = (1 x 903 x 1.36) / ( 2 x 138 x 1 - 0.2 x 1) 4.44 mm Note: a) Torisspherical Heads with (t2 / L) = (4.44/903)=0.0049>=0.002 Therefore rule Appendix 1-4(d) can be used. b) Material SA 516M Gr 485 having specified minimum tensile strength 485 MPa is not exceeding 500 MPa , S =138 MPa is OK. (C) THICKNESS OF HEMISPHERICAL HEAD (UG-32(f)) E2 = Joint Efficiency 1.00 UW-12(d) (Seamless) t3 = Required Thickness of Head (APPENDIX 1.4(d)) t3 = ( P x L ) / ( 2 x S x E2 - 0.2 x P ) = ( 1 x 903) / ( 2 x138 x 1 - 0.2 x1) 3.27 mm Eh1 = Top-Head to Shell Joint Efficiency 0.80 (Type-2, Category-B) t3= =( t / Eh1) = (3.27 / 0.8) 4.09 mm UG-32(b) t = Minimum Required Thickness of Head = Max( t1, t2, t3) = Max(2.5,4.44,4.09) 4.44 mm th= Design Thickness of Head = (t + Ci) = (4.44+3) = 7.44 mm tmin= Minimum Thickness shown In Drawing 8.00 mm tnom= Nominal Thickness Prior to forming 10.00 mm UG-32 (j) a) The Inside crown radius L = 903 mm is not Greater than Outside Diameter of Skirt =1020mm b) The inside knuckle radius of Torispherical head =153mm is not greater than 6% Outside dia. Of skirt =61.2mm c) The inside knuckle radius of Torispherical head = 153mm is not less than 3 x tnom = 30mm UG-32 (l) The head has been provide with 50mm Skirt length, through it is not mandatory as per UG-32(I) and Fig. UW-13.1. UG-32 (n) The taper at a welded joint within a formed head as per UW-9 is not required as difference between nominal thickness of shell (8mm) and head (10mm) at shell to head junction is not exceeding 2mm. Forming Head [UCS-79 (d)] Rf = Final center line radius, Ro = Original center line radius(infinity for flat plate) Extrim Fiber Elongation = (75 x (th / Rf) x (1-(Rf/R0)) = ( 75 x 10 / 153 ) x ( 1 - 0) Head is cold formed(Yes/no) Fiber elongation Vessel carries lethal substances (Yes/no) Impact testing is required (Yes/no) Greater than 10% reduction in thickness (Yes/no) Formed between 120 and 480 0C Shell is greater than 16mm thick before forming Heat Treatment Required ?

153.00 mm infinity mm

4.90 % Yes 4.90% < 5 % no no Yes If Actual thickness of Head after

forming < 9 mm.

no no Yes If Actual thickness of Head after forming < 9 mm.

158599319.xls.ms_office/TORISPHERICAL HEAD

CHECKED BY

APPROVED BY

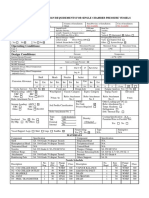

THE ANUP ENGG. LTD. THICKNESS OF TORISHERICAL BTM. HEAD NOMENCLATURE REFERENCES P= Internal Design Pressure 1.00 MPa O T = Design Temperature 60.00 C UG-20 Di = Inside Diameter of Vessel 1000.00 mm Ci = Corrosion Allowance Internal 3.00 mm Material Of Construction SA 516M GR 485 S = Maximum Allowable Stress At Design Temp. 138.00 MPa (SEC. II D, TABLE 1A) L = Inside Spherical or Crown Radius (Corroded) 903.00 mm <= OD of Skirt 1020mm r = Inside Knuckle Radius (Corroded) 153.00 mm >= 6% OD =61.2mm (A) t1 = Head Thickness as Per UG-16(b)(4) = 2.5 ( COMPRESSED AIR SERVICE) (B) THICKNESS OF TORISPHERICAL HEAD Radiography SPOT UW-11(a)(5)(b) Ehb = Joint Efficiency 1.00 UW-12(d) (Seamless) t2 = Required Thickness of Head (APPENDIX 1.4(d)) M = 1/4 [ 3 + SQRT ( L / r ) ] = 1/4 [ 3 + SQRT (903/153)] 1.36 t2 = ( P x L x M ) / ( 2 x S x Ehb - 0.2 x P ) = (1 x 903 x 1.36) / ( 2 x 138 x 1 - 0.2 x 1) 4.44 mm Note: a) Torisspherical Heads with (t2 / L) = (4.44/903)=0.0049>=0.002 Therefore rule Appendix 1-4(d) can be used. b) Material SA 516M Gr 485 having specified minimum tensile strength 485 MPa is not exceeding 500 MPa , S =138 MPa is OK. (C) THICKNESS OF HEMISPHERICAL HEAD (UG-32(f)) E2 = Joint Efficiency 1.00 UW-12(d) (Seamless) t3 = Required Thickness of Head (APPENDIX 1.4(d)) t3 = ( P x L ) / ( 2 x S x E2 - 0.2 x P ) = ( 1 x 903) / ( 2 x138 x 1 - 0.2 x1) 3.27 mm Eh2 = Bottom Head to Shell Joint Efficiency 0.80 (Type-2, Category-B) t3= =( t / Eh2) = (3.27 / 0.8) 4.09 mm UG-32(b) t = Minimum Required Thickness of Head = Max( t1, t2, t3) = Max(2.5,4.44,4.09) 4.44 mm th= Design Thickness of Head = (t + Ci) = (4.44+3) = 7.44 mm tmin= Minimum Thickness shown In Drawing 8.00 mm tnom= Nominal Thickness Prior to forming 10.00 mm UG-32 (j) a) The Inside crown radius L = 903 mm is not Greater than Outside Diameter of Skirt =1020mm b) The inside knuckle radius of Torispherical head =153mm is not greater than 6% Outside dia. Of skirt =61.2mm c) The inside knuckle radius of Torispherical head = 153mm is not less than 3 x tnom = 30mm UG-32 (l) The head has been provide with 50mm Skirt length, through it is not mandatory as per UG-32(I) and Fig. UW-13.1. UG-32 (n) The taper at a welded joint within a formed head as per UW-9 is not required as difference between nominal thickness of shell (8mm) and head (10mm) at shell to head junction is not exceeding 2mm.) Forming Head [UCS-79 (d)] Rf = Final center line radius, Ro = Original center line radius(infinity for flat plate) Extrim Fiber Elongation = (75 x (th / Rf) x (1-(Rf/R0)) = ( 75 x 10 / 153 ) x ( 1 - 0) Head is cold formed(Yes/no) Fiber elongation Vessel carries lethal substances (Yes/no) Impact testing is required (Yes/no) Greater than 10% reduction in thickness (Yes/no) Formed between 120 and 480 0C Shell is greater than 16mm thick before forming Heat Treatment Required ?

153.00 mm infinity mm

4.90 % Yes 4.90% < 5 % no no Yes If Actual thickness of Head after

forming < 9 mm.

no no Yes If Actual thickness of Head after forming < 9 mm.

158599319.xls.ms_office/TORISPHERICALBTM. HEAD

CHECKED BY

APPROVED BY

Anda mungkin juga menyukai

- Shell and Tube HE CalculationDokumen16 halamanShell and Tube HE CalculationPradip ShindeBelum ada peringkat

- Toriconical Head Ver 1.1Dokumen4 halamanToriconical Head Ver 1.1Iqbal AhmadsBelum ada peringkat

- Pd5500 Flange CalculationDokumen6 halamanPd5500 Flange CalculationAliBelum ada peringkat

- IBR - 1950 - Reg. 366Dokumen2 halamanIBR - 1950 - Reg. 366Vijay ParmarBelum ada peringkat

- Studding Outlet Calculation - PV Elite 2016Dokumen8 halamanStudding Outlet Calculation - PV Elite 2016Liu YangtzeBelum ada peringkat

- Dish End Calculations As Per ASME Section VII Div 1Dokumen2 halamanDish End Calculations As Per ASME Section VII Div 1sksiddique83% (6)

- External Template UG-29 UG-80 - 81 Calculation - Rev.0Dokumen5 halamanExternal Template UG-29 UG-80 - 81 Calculation - Rev.0souren1975100% (1)

- Small Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFDokumen6 halamanSmall Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFhussamammarBelum ada peringkat

- Compress CalculationDokumen106 halamanCompress CalculationKrupal Patel100% (1)

- Design Procedure For Aes He PDFDokumen30 halamanDesign Procedure For Aes He PDFRyan Goh Chuang HongBelum ada peringkat

- UG-39 - Flat Head ReinforcementDokumen3 halamanUG-39 - Flat Head ReinforcementAshish DhokBelum ada peringkat

- Heat Treatment Requirement Heat Treatment Requirement: o o o oDokumen2 halamanHeat Treatment Requirement Heat Treatment Requirement: o o o ofizanlaminBelum ada peringkat

- Ibr Calc GSRDokumen4 halamanIbr Calc GSRAniket GaikwadBelum ada peringkat

- Documents - Tips - Pressure Vessel Design Calc Asme VIII Div 1Dokumen35 halamanDocuments - Tips - Pressure Vessel Design Calc Asme VIII Div 1bainBelum ada peringkat

- Ibr Stand PipeDokumen11 halamanIbr Stand PipeP s JagatheesanBelum ada peringkat

- Extreme Fiber Elongation Calcs - J.SDokumen1 halamanExtreme Fiber Elongation Calcs - J.SJ.SIVIRA100% (1)

- IB-PRO Welding FiguresDokumen12 halamanIB-PRO Welding FiguresSUNNY GUPTABelum ada peringkat

- New - Reinforcement of NozzleDokumen31 halamanNew - Reinforcement of NozzleNithin ZsBelum ada peringkat

- UHX CalcsDokumen5 halamanUHX CalcsRajesh Panchal100% (1)

- ASME VIII A13 - Vessels of Noncircular Cross Section (Type 13-2 (A) (6) )Dokumen14 halamanASME VIII A13 - Vessels of Noncircular Cross Section (Type 13-2 (A) (6) )hardik5818100% (2)

- Ligament Efficiency and Thickness of The Support PlateDokumen10 halamanLigament Efficiency and Thickness of The Support PlatePankajDhobleBelum ada peringkat

- Tolerance-E and Chord LengthDokumen2 halamanTolerance-E and Chord LengthLcm TnlBelum ada peringkat

- IBR CalculationsDokumen20 halamanIBR CalculationsSivi NallamothuBelum ada peringkat

- Check Safety Requirements For Clutch Door According To ASMEDokumen3 halamanCheck Safety Requirements For Clutch Door According To ASMEtranhonghakd5533Belum ada peringkat

- Skirt Support Analysis Per en 13445Dokumen13 halamanSkirt Support Analysis Per en 13445karthik1amar100% (1)

- Ped Eam-0526-24-1-2006-03Dokumen6 halamanPed Eam-0526-24-1-2006-03nathachaiBelum ada peringkat

- Air Coolers HeadsDokumen30 halamanAir Coolers HeadsSergio PluchinskyBelum ada peringkat

- Weld Shear Stress Check For FAVID Clips Welded On CladDokumen3 halamanWeld Shear Stress Check For FAVID Clips Welded On CladrsubramaniBelum ada peringkat

- Tube Sheet CalculationDokumen3 halamanTube Sheet CalculationAbhay UpadhyayBelum ada peringkat

- Flange Pad CalcsDokumen4 halamanFlange Pad CalcstomBelum ada peringkat

- Extreme Fiber Elongation To UCS-79Dokumen1 halamanExtreme Fiber Elongation To UCS-79Azwan Shah100% (2)

- U Stamp - KK Form - SampleDokumen5 halamanU Stamp - KK Form - SampleshazanBelum ada peringkat

- Cs & Las Impact Req - Asme Sec Viii Div 2Dokumen16 halamanCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareBelum ada peringkat

- Amine Stripper Column Crack 3501-1-T-004: PQR Test CouponDokumen2 halamanAmine Stripper Column Crack 3501-1-T-004: PQR Test Couponpstechnical_43312697100% (1)

- Flange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gDokumen10 halamanFlange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gAsep MulyadiBelum ada peringkat

- E.4 Leg Support CalculationDokumen2 halamanE.4 Leg Support Calculationnaim100% (1)

- S-Stamp Calculation Nozzle ShellDokumen4 halamanS-Stamp Calculation Nozzle ShellmukeshBelum ada peringkat

- Ferrofab Fze: Collar Bolt Sizing CalculationDokumen2 halamanFerrofab Fze: Collar Bolt Sizing CalculationMohammad Zahid50% (2)

- Design of HCL FRP Storage TANKDokumen21 halamanDesign of HCL FRP Storage TANKHaries Bugarin GarciaBelum ada peringkat

- Deaera DesignDokumen13 halamanDeaera DesignBhanu K PrakashBelum ada peringkat

- External Pressure ToleranceDokumen4 halamanExternal Pressure ToleranceAKSHAY BHATKAR100% (1)

- ASME VIII Corroded Nozzle - Shell With Repad - UG-45 - UG-37 CalcDokumen32 halamanASME VIII Corroded Nozzle - Shell With Repad - UG-45 - UG-37 CalcIonut FloricaBelum ada peringkat

- Pd5500 Flange CalculationDokumen6 halamanPd5500 Flange CalculationMakrand SakpalBelum ada peringkat

- Ladder Rung Calc.Dokumen1 halamanLadder Rung Calc.Azwan ShahBelum ada peringkat

- Lug Support DesignDokumen3 halamanLug Support DesignSajal KulshresthaBelum ada peringkat

- Section VIII CalDokumen21 halamanSection VIII CalRuben Samoel Barros RochaBelum ada peringkat

- Design Calculation Sheet: H2So4 Neutralization TankDokumen43 halamanDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunBelum ada peringkat

- Section VIII CalDokumen19 halamanSection VIII CalPradeep Kothapalli100% (1)

- Aspen HX Design ReportDokumen78 halamanAspen HX Design ReportberylqzBelum ada peringkat

- Reinforcement of Openings On Tori-Dish (Trial)Dokumen23 halamanReinforcement of Openings On Tori-Dish (Trial)Sajal KulshresthaBelum ada peringkat

- Asme Viii Shell & Se HeadDokumen5 halamanAsme Viii Shell & Se HeadSnr George RaczBelum ada peringkat

- Mud Gas Separator CalculationDokumen16 halamanMud Gas Separator CalculationErwin Gomop-asBelum ada peringkat

- Design Calculations For Pressure ShellDokumen33 halamanDesign Calculations For Pressure ShellGeorge GeorgianBelum ada peringkat

- Mud Gas Separator CalculationDokumen16 halamanMud Gas Separator CalculationErwin Gomop-as100% (2)

- Nozzle CalculationsDokumen2 halamanNozzle CalculationsBaher Elsheikh100% (3)

- WRC CalculationsDokumen20 halamanWRC Calculationsanu radha50% (2)

- Asme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoDokumen72 halamanAsme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoSivateja NallamothuBelum ada peringkat

- Calculation Validation ReportDokumen18 halamanCalculation Validation Reportvijay10484Belum ada peringkat

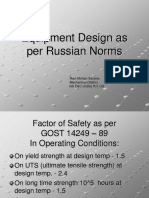

- Equipment Design As Per Russian Norms - 20090218Dokumen45 halamanEquipment Design As Per Russian Norms - 20090218vikas100% (1)

- Reinforcement Calculations For Nozzle (N1) : OD ID Thick NessDokumen15 halamanReinforcement Calculations For Nozzle (N1) : OD ID Thick NessMuhammad Hassan MaqsoodBelum ada peringkat

- Iso 7089-Din 125Dokumen8 halamanIso 7089-Din 125serzo75Belum ada peringkat

- AlgorDokumen7 halamanAlgorMehta MehulBelum ada peringkat

- Is 5624 - 1993Dokumen8 halamanIs 5624 - 1993Mehta MehulBelum ada peringkat

- Twisted Tube Heat Exchanger TechnologyDokumen8 halamanTwisted Tube Heat Exchanger TechnologyhuangjlBelum ada peringkat

- FRP Lining PDFDokumen6 halamanFRP Lining PDFMehta MehulBelum ada peringkat

- Filler Metal Selection GuideDokumen2 halamanFiller Metal Selection GuideMehta Mehul100% (1)

- Vibration in Heat ExchangerDokumen4 halamanVibration in Heat ExchangerMehta MehulBelum ada peringkat

- 309 LMo PDFDokumen1 halaman309 LMo PDFMehta MehulBelum ada peringkat

- Effect of Fouling FactorDokumen5 halamanEffect of Fouling FactorMehta Mehul100% (1)

- Reduction in MFG TimeDokumen6 halamanReduction in MFG TimeMehta MehulBelum ada peringkat

- Information For HIC Material PDFDokumen1 halamanInformation For HIC Material PDFMehta MehulBelum ada peringkat

- 2011 Addenda ASME Code Synopsis by OneCIS Insurance Co PDFDokumen59 halaman2011 Addenda ASME Code Synopsis by OneCIS Insurance Co PDFMehta MehulBelum ada peringkat

- Tubesheet LayoutDokumen5 halamanTubesheet LayoutMehta MehulBelum ada peringkat

- Construction Materials and TestingDokumen23 halamanConstruction Materials and TestingJaymark S. GicaleBelum ada peringkat

- Spelling RulesDokumen5 halamanSpelling RulesvijthorBelum ada peringkat

- ELEMAGDokumen1 halamanELEMAGJasper BantulaBelum ada peringkat

- FST 3000Dokumen4 halamanFST 3000ariksyaiful82Belum ada peringkat

- Hungarian NotationDokumen6 halamanHungarian NotationmelpaniBelum ada peringkat

- Rekonfigurasi Jaringan Distribusi Radial Untuk Mengurangi Rugi Daya Pada Penyulang Jatirejo Rayon Mojoagung Menggunakan Metode BinaryDokumen4 halamanRekonfigurasi Jaringan Distribusi Radial Untuk Mengurangi Rugi Daya Pada Penyulang Jatirejo Rayon Mojoagung Menggunakan Metode BinaryNurindra CahyantaBelum ada peringkat

- Essay 1 Weight and BalanceDokumen4 halamanEssay 1 Weight and BalanceHamdan Merchant83% (6)

- 2nd Grading LAA Grade 10Dokumen54 halaman2nd Grading LAA Grade 10Urduja Kyle OdiacerBelum ada peringkat

- Lec1 PDFDokumen12 halamanLec1 PDFtogarsBelum ada peringkat

- Numerical ModelDokumen61 halamanNumerical ModelAlbert AguileraBelum ada peringkat

- List of Books s8 ElectiveDokumen2 halamanList of Books s8 ElectivemaniBelum ada peringkat

- Comptector & Chiller (Cdu) Controller (Fx32C Series) : Precaution For UseDokumen5 halamanComptector & Chiller (Cdu) Controller (Fx32C Series) : Precaution For UseFcma0903100% (1)

- Leonardo Romero SR High School: Republic of The Philippines Region Xii - Soccsksargen Schools Division Office of CotabatoDokumen4 halamanLeonardo Romero SR High School: Republic of The Philippines Region Xii - Soccsksargen Schools Division Office of CotabatoDulce M. LupaseBelum ada peringkat

- Processing of Synthetic Aperture Radar Images - H. Maitre (Wiley, 2008) WWDokumen411 halamanProcessing of Synthetic Aperture Radar Images - H. Maitre (Wiley, 2008) WWbehzad100% (4)

- Odp-090r16bv 17KV PDFDokumen1 halamanOdp-090r16bv 17KV PDFAlberto LinaresBelum ada peringkat

- 86-Article Text-596-1-10-20211030Dokumen7 halaman86-Article Text-596-1-10-20211030adel bbBelum ada peringkat

- Ce2202 - Mechanics of FluidsDokumen3 halamanCe2202 - Mechanics of FluidsPrashant GaradBelum ada peringkat

- HPC168 Passenger CounterDokumen9 halamanHPC168 Passenger CounterRommel GómezBelum ada peringkat

- Magnetophoresis and Electromagnetophoresis of Microparticles in LiquidsDokumen7 halamanMagnetophoresis and Electromagnetophoresis of Microparticles in Liquids3issazakaBelum ada peringkat

- Vensim User ManualDokumen34 halamanVensim User ManualMahdan LondoBelum ada peringkat

- The Guitar in The Sixteenth CenturyDokumen16 halamanThe Guitar in The Sixteenth CenturyPat BrandtBelum ada peringkat

- Solution Manual For Investment Science by David LuenbergerDokumen94 halamanSolution Manual For Investment Science by David Luenbergerkoenajax96% (28)

- Industrial Engineering KTU M TechDokumen7 halamanIndustrial Engineering KTU M Techsreejan1111Belum ada peringkat

- 417 Model E Alarm Check ValvesDokumen4 halaman417 Model E Alarm Check ValvesM Kumar MarimuthuBelum ada peringkat

- Measures of Central Tendency: Mean Median ModeDokumen20 halamanMeasures of Central Tendency: Mean Median ModeRia BarisoBelum ada peringkat

- Betriebsanleitung SM-RI-X - Q-75 Rev2Dokumen65 halamanBetriebsanleitung SM-RI-X - Q-75 Rev2ABDULSALAMBelum ada peringkat

- LETRIST Locally Encoded Transform Feature HistograDokumen16 halamanLETRIST Locally Encoded Transform Feature HistograHARE KRISHNABelum ada peringkat

- TribunaloLo Ex#6Dokumen14 halamanTribunaloLo Ex#6Jaylou OpondaBelum ada peringkat

- PLX7100A Digital Mobile C-Arm X-Ray Machine: 1. Technical SpecificationDokumen3 halamanPLX7100A Digital Mobile C-Arm X-Ray Machine: 1. Technical SpecificationAbdalhakeem AlturkyBelum ada peringkat

- Jazz Piano VoicingsDokumen19 halamanJazz Piano Voicingskeybiank86% (58)