Design of Box Culvert Bridge

Diunggah oleh

Val BeltranJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Design of Box Culvert Bridge

Diunggah oleh

Val BeltranHak Cipta:

Format Tersedia

DESIGN CRITERIA

Structural Design Criteria of the Proposed

CASTELLANO BRI DGE MAY 2013

1.0 GENERAL

This document defines the structural engineering requirements and design

philosophy for the structure. Included herein is a list of applicable codes,

standards, and specifications used as reference in determining the parametric

values; the basis upon which the design criteria are established and

methods/procedures used for the analysis and design of the structures included

in Castellano Bridge.

Noteworthy among the design requirements is the DPWH Advisory for

Seismic Design of Bridges, Dept. Order No. 75 that specifies for earthquake

analysis the requirements of AASHTO Guide Specifications for Seismic

Design.

Following the above-mentioned DPWH Advisory and the AASHTO Guide for

Seismic Design, the followings are the important design concepts adopted in

our structural design:

a. The stiffness of the bridge as a whole was considered in the

analysis

b. The provision of column transverse reinforcements for

confinement at expected plastic hinge regions.

c. The adaptation, in general of the design forces and analysis, and

design procedures for piers, abutments and foundation as required

by the AASHTO Guide Specifications for Seismic Design.

2.0 CODES AND STANDARDS

A summary of the codes and industry standards used in the design shall be as

follows:

2.1 Design Codes and Standards

2.1.1 DPWH Standard Specification, Highway, Bridges and

Airport, 1995.

2.1.2 National Structural Code of the Philippines (NSCP), Volume

2 - Bridges, 1997.

2.1.3 American Association of State Highway and Transportation

Officials (AASHTO), Standard Specifications for Highway

Bridges, 17

th

Edition, 2002.

2.2 Material Codes and Standards

2.2.1 American Society for Testing Materials (ASTM).

Structural Design of the Proposed

CASTELLANO BRI DGE MAY 2013

3.0 BRIDGE DESCRIPTION

Based on requirement as indicated in design report a proposed new bridge is to

be constructed to replace the existing Castellano Bridge.

The new bridge shall have a new span of 14.0 meters with no central pier and

shall function as a box culvert serving as spillway for flush flooding during

heavy rain conditions. The same level as the existing bridge shall be

maintained.

The new bridge shall be constructed using reinforced concrete materials. The

superstructure shall be flat slab from end to end of the abutment walls. The

bridge structure shall be founded on four (4) bored pile deep foundations

based on the recommendation of the geotechnical study. The river bed under

the bridge shall be covered by reinforced concrete slab for smooth channel

flow.

Separate apron structures with cut-off walls and compacted stones at ends are

provided at the upstream and downstream side of the bridge to protect

surrounding areas from the destructive effect of scouring. The new apron

retaining wall and floor slab structures shall be founded using shallow mat

footing and shall be provided with edge beams/walls to minimize the effect of

foundation settlements due to the existing poor soil condition.

PROFILE OF THE PROPOSED CASTELLANO BRIDGE

Structural Design of the Proposed

CASTELLANO BRI DGE MAY 2013

4.0 MATERIALS

4.1 Concrete

The following concrete compressive strengths (fc) shall be based on

the 28-day strength of 150 x 300 mm cylinder:

Structural Member fc

Box Culvert 28.0 MPa (4,000 Psi)

Bored Pile 21.0 MPa (3,000 Psi)

Sidewalk, railings, parapet, median 21.0 MPa (3,000 Psi)

Other concrete 21.0 MPa (3,000 Psi)

Lean concrete 17.0 MPa (2,400 Psi)

Non Shrink Grout 58.0MPa (8,000Psi)

4.2 Reinforcing Steel

Steel reinforcing deformed bars shall conform to AASHTO M31

ASTM A615) Grade 40 (276 MPa) for 10mm diameter below and

Grade 60 (414MPa) for 12mm diameter above.

5.0 STRUCTURAL DESIGN CONCEPT

5.1 Method of Analysis

5.1.1 Superstructure

The box culvert bridge superstructure was modeled in three-

dimensional space frame using STAAD Pro 2007 software.

The maximum stresses produced by the design loads

(combination of loads will be used to investigate and

strengthened every component of the superstructure.

5.1.2 Substructure

The substructures of the bridges were analyzed using the

Multimode Spectral Analysis Method (Procedure 3 of Div. IA,

Seismic Design, AASHTO 2002). The structures were modeled

as three dimensional space frames and the analysis was

performed using a structural analysis computer program called

STAAD Pro 2007. The member forces and displacements were

estimated by combining the respective response quantities from

individual modes by the Complete Quadratic Combination

(CQC) method as recommended in AASHTO Guide

Specification for Seismic Design Section 4.5.5

Structural Design of the Proposed

CASTELLANO BRI DGE MAY 2013

5.1.2.1 Determination of Elastic Forces and Displacements

The elastic forces and displacements shall be determined

independently along two perpendicular axes by use of analysis

procedure. Typically, the perpendicular axes are the

longitudinal and transverse axes of the bridge.

5.1.2.2 Combination of Orthogonal Seismic Forces

A combination of orthogonal seismic forces is used to account

for the directional uncertainty of earthquake motions and the

simultaneous occurrences of earthquake forces in two

perpendicular horizontal directions. The elastic seismic forces

and moments resulting from analyses in the in the two

perpendicular horizontal directions shall be combined to form

two (2) load cases as follows:

LOAD CASE 1: Seismic forces and moments on each of the

principal axes of a member shall be obtained by adding 100

percent of the absolute value of the member elastic seismic

forces and moments resulting from the analysis in one of the

perpendicular (longitudinal) directions to 30 percent of the

absolute value of the corresponding member elastic seismic

forces and moments resulting from the analysis in the second

perpendicular direction (transverse). (NOTE: The absolute

values are used because a seismic force can be positive or

negative.)

LOAD CASE 2: Seismic forces and moments on each of the

principal axes of a member shall be obtained by adding 100

percent of the absolute value of the member elastic seismic

forces and moments resulting from the analysis in the second

perpendicular direction (transverse) to 30 percent of the

absolute value of the corresponding member elastic seismic

forces and moments resulting from the analysis in the first

perpendicular direction.

For seismic design of structural components, Loading

Combination VII shall be modified.

Group Load = 1.0(D + B + SF + E + EQM or EQF)

Where,

D = dead load

B = buoyancy

SF = stream flow pressure

E = earth pressure

Structural Design of the Proposed

CASTELLANO BRI DGE MAY 2013

EQM or EQF = elastic seismic force for either Load Case

I or Load Case 2 modified by

dividing the appropriate R-Factor

5.2 Method of Design

5.2.1 Reinforced Concrete Structural Member

Design of reinforced concrete members shall be based on Strength

Design Method (Load Factor Design) shall be used for the design of

reinforced concrete structural members (abutments, piers, pile caps,

piles, deck slabs, wing walls, approach slabs), wherein the required

strength of a section is the strength necessary to resist the factored

loads and forces applied to the structure in the load combinations. All

sections of structures shall have design strengths at least equal to the

design strength as specified in Article 8.16 of NSCP Volume 2,

Bridges Part A, 2

nd

Edition, 1997.

6.0 LOADINGS

6.1 Dead Loads

The dead loads shall consist of the weight of the entire structure

including the roadway, sidewalks, car tracks, pipes, conduits, cables,

and other public utility services.

The following unit weights of construction materials were used in

computing the dead loads.

Materials

Unit Weight

(kN/m

3

)

Concrete, plain or reinforced 24

Compacted earth, sand, gravel,

or ballast

18.9

Structural Steel 77

Cast Iron 71

Water (without sediment) 9.81

Bituminous wearing surface

(50 mm thk)

1.05 kPa

6.2 Live Loads

The live loads shall consist of the weight of applied moving loads of

the vehicles, cars and pedestrians.

6.2.1 Highway Loads

Structural Design of the Proposed

CASTELLANO BRI DGE MAY 2013

The highway live loading on the bridges or incidental structures

shall conform to the following highway live load, whichever

governs;

6.2.1.1 MS18 (HS20) Loading

For bridges that may carry heavy truck traffic the

minimum live load shall be MS18 (HS20) as designated

herein and shown in the following figures.

Structural Design of the Proposed

CASTELLANO BRI DGE MAY 2013

STANDARD MS (HS) TRUCKS

6.2.1.2 Alternate Military Loading

The alternate military loading shall consist of two axles,

1.22m apart with each axle weighing 107kN (see figure

below).

6.2.1.3 Permit Design Loading

The permit loading was developed to ensure sufficient

bridge live load capacity to carry extra legal live loads

allowed by permit (see figure below).

6.2.2 Impact

Highway Live Loads shall be increased for those structural elements in

Group A, below, to allow for dynamic, vibratory and impact effects.

Impact allowance shall not be applied to items in Group B. It is

intended as part of the loads transferred for superstructure to

Structural Design of the Proposed

CASTELLANO BRI DGE MAY 2013

substructure, but shall not be included in loads transferred to footings

nor to those parts of piles or columns that are below ground.

a) Group A Impact shall be included

(1) Superstructure, including legs of rigid frames.

(2) Piers, (with or without bearings regardless of type)

excluding footings and those portions below the ground

line.

(3) The portions above the ground line of concrete or steel piles

that support the superstructure.

b) Group B Impact shall not be included

(1) Abutments, retaining walls, piles except as specified in

6.2.2.a (3).

(2) Foundation pressures and footings.

(3) Timber structure.

(4) Sidewalk loads.

(5) Culverts and structures having 0.90m or more cover.

Impact Formula

The amount of this allowance or increment is expressed as a

fraction of live load stress, and shall be determined by the

following formula:

38

24 . 15

+

=

L

I

Where,

I = impact factor (maximum of 30 percent)

L = length in meters of the portion of the span that is

loaded to produce the maximum stress in the

member

6.3 Sidewalk, Curb, and Railing Loading

6.3.1 Sidewalk Loading

Sidewalk floors, stringers and their immediate supports shall be

designed for a live load of 4070 Newton per square meter of

sidewalk area. Girders, trusses, arches, and other members shall

be designed for the following sidewalk live loads:

Span 0 to 7.80 m in length .. 4070 Pa

Span 7.80 to 30.5 m in length . 2870 Pa

Span over 30.5 m in length according to the formula

Structural Design of the Proposed

CASTELLANO BRI DGE MAY 2013

|

.

|

\

|

|

.

|

\

|

+ =

2 . 15

7 . 16 800 , 43

435 , 1

W

L

P

In which

P = live load in Pa. max. 2870 Pa.

L = loaded length of sidewalk in meters

W = width of sidewalk in meters

Bridges for pedestrian and/or bicycle traffic shall be designed

for a live load of 4070 Pa.

6.3.2 Railing Loading

Although the primary purpose of traffic railing is to contain the

average vehicle using the structure, consideration should be

given to (a) protection of the occupants of a vehicle in collision

with railing, (b) protection of other vehicles near the collision,

(c) protection of vehicles or pedestrians on roadways

underneath the structure, and (d) appearance and freedom of

view from passing vehicles.

6.4 Seismic Loads

Structure shall be designed to resist earthquake motions by considering

the relationship of the site to active faults, the seismic response of the

soil at the site, and the dynamic response characteristics of the total

structure in accordance with the criteria as prescribed in Section 21 of

Division IA- Seismic Design of the AASHTO Standard Specifications

for Highway Bridges, 17

th

Edition, 2002.

6.4.1 Acceleration Coefficient

The coefficient A to be used for the area shall be 0.4.

6.4.2 Importance Classification

An importance classification (IC) of I shall be assigned for the

structure with a classification of being an essential structure.

6.4.3 Seismic Performance Categories

Seismic Performance Category (SPC) D shall be assigned to

the structure, based on the Acceleration Coefficient (A) of

0.40g and the Importance Classification (IC) of I.

Structural Design of the Proposed

CASTELLANO BRI DGE MAY 2013

6.4.4 Site Effect

The effects of site condition on bridge response shall be

determined from site coefficient (S) based on soil profile types

defined as follows:

Acceleration Coefficient

Importance

Classification

(IC)

A I II

A 0.29 C C

0.29 < A D C

SOIL PROFILE TYPE I is a profile with either

1) Rock of any characteristics, either shale-like or crystalline

in nature (such material may be characterized by a shear

wave velocity greater than 760m/sec, or by other

appropriate means of classification); or

2) Stiff soil conditions where the soil depth is less than 60m

and the soil types overlying rock are stable deposits of

sands, gravels, or stiff clays.

SOIL PROFILE TYPE II is a profile with stiff clay or deep

cohesionless conditions where the soil depth exceeds 60m and

the soil types overlying rock are stable deposits of sands,

gravels, or stiff clays.

SOIL PROFILE TYPE III is a profile with soft to medium-stiff

clays and sands, characterized by 10m or more of soft to

medium-stiff clays with or without intervening layers of sand

or other cohesionless soils.

In location where the soils properties are not known in

sufficient detail to determine the soil profile type or where the

profile does not fit any of the three types, the site coefficient for

Soil Profile Type II shall be used. The soil profile coefficients

apply to all foundation types including pile supported and

spread footings.

6.4.5 Site Coefficient

The site coefficient (S) approximated the effects of the site

conditions on the elastic coefficient or spectrum of Article

21.5.2 of NSCP Volume 2 - Bridges, 2

nd

edition, 1997, is given

below:

Structural Design of the Proposed

CASTELLANO BRI DGE MAY 2013

Soil Profile Type

I II III

S 1.0 1.2 1.5

6.4.6 Response Modification Factors

Seismic design forces for individual members and connections

of bridges classified as SPC C and D are determined by

dividing the elastic forces by the appropriate Response

Modification Factor (R) as specified in Article 21.4.6 of NSCP

Volume 2 - Bridges, 2

nd

edition, 1997. The Response

Modification Factors for the various components are given

below

Substructure

1

R Connections R

Wall Type Pier

2

2 Superstructure to Abutment 0.8

Reinforced Concrete Pile

Bents

a. Vertical Piles only 3

Expansion Joints within a

Span

b. One or more Batter

Piles 2 of the Superstructure 0.8

Single Columns 3

Columns, Piers or Pile Bents

to

Steel or Composite Steel and

Cap Beam or

Superstructure

3

1.0

Concrete Pile Bents Columns or Piers to

a. Vertical Piles only 5 Foundations

3

1.0

b. One or more Batter

Piles 3

Multiple Column Bent 5

1

The R-Factor is to be used for both orthogonal axes of the substructure.

2

A wall-type pier may be designed as column in the weak direction of

the pier provided all the provisions for columns in Article 21.8 of NSCP

Volume 2 - Bridges, 2

nd

edition, 1997 are followed. The R-factor for a

single column can then be used.

3For bridges classified as SPC C and D it is recommended that the

connections be designed for the maximum forces capable of being

developed by plastic hinging of the column bent as specified in Article

21.4.6.6 of NSCP Volume 2 - Bridges, 2

nd

edition, 1997. These forces

will often be significantly less than obtained using an R-factor of 1.

6.5 Earth Pressure

6.5.1 Active Earth Pressure Coefficient

Structural Design of the Proposed

CASTELLANO BRI DGE MAY 2013

Lateral earth pressures shall be computed assuming active

stress conditions and wedge theory using a planar surface of

sliding defined by Coulombs Theory.

(

=

) sin( ) sin(

) ' sin( ) ' sin(

1 ) sin( sin

) ' ( sin

2

2

| u o u

o | o |

o u u

| u

a

k

Where,

k

a

= active earth pressure coefficient

= effective unit weight

= effective angle of internal friction

= angle of wall friction

= slope angle

= wall face batter

All angles are positive (+) as shown.

For seismic lateral earth pressures, the pseudo-static approach

developed by Mononobe-Okabe specified in Division IA,

Seismic Design of the AASHTO was used to estimate the

equivalent static forces for seismic loads. The estimation of

seismic design forces also accounted for structure inertial

forces in addition to the equivalent static forces.

) cos( 2 cos cos

) ( cos

2

u | o | u

| u |

+ +

=

ae

k

Where,

k

ae

= total Mononobe-Okabe seismic lateral earth

pressure coefficient

H = height of soil face

= unit weight of soil

Structural Design of the Proposed

CASTELLANO BRI DGE MAY 2013

= angle of friction of soil

= arc tan (k

h

/1-k

v

)

= angle of friction between soil and abutment

= backfill slope angle

k

h

= horizontal acceleration coefficient

k

v

= vertical acceleration coefficient

=

2

) cos( ) cos(

) sin( ) sin(

1

(

+ +

+

+

| u | o

u | o |

i

i

6.5.2 Earth Load

2

2

1

H k Pa

a

|

.

|

\

|

= for normal condition

2

) 1 (

2

1

H k k Pa

v ae

|

.

|

\

|

= for seismic condition

6.6 Load Combinations

Every structure component shall be designed to withstand the forces

resulting from each load combination according to the requirements of

Division I Article 3.22 and to the additional requirements of Division

IA Article 7.2 (AASHTO Standard Specifications for Highway

Bridges).

The following Groups represent various combination of loads and

forces to which a structure may be subjected. Each component of the

structure, or the foundation on which it rests, shall be proportioned to

withstand safely all group combinations of these forces that are

applicable to the particular site or type. Group loading combinations

for Service Load Design and Load Factor Design are given by:

Group (N) = {

D

D +

L

(L + I) +

C

CF +

E

E +

B

B +

S

SF +

W

W +

WL

WL +

L

LF +

R

( R + S + T ) +

EQ

EQ}

Where,

N = group number,

= load factor,

= coefficient,

Structural Design of the Proposed

CASTELLANO BRI DGE MAY 2013

D = dead load;

L = live load;

I = live load impact;

E = earth pressure;

B = buoyancy;

W = wind load on structure;

WL = wind load on live load --- 1.46 kN/m;

LF = longitudinal force from live load;

CF = centrifugal force;

R = rib shortening;

S = shrinkage;

T = temperature;

EQ = earthquake;

SF = stream flow pressure;

TABLE OF COEFFICIENTS AND

COL.

No. 1 2 3 3A 4 5 6 7 8 9 10 11 12 13

FACTORS

GROUP D

( L +

I)

n

( L +

I)

n

CF E B SF W WL LF

R + S

+ T EQ %

S

E

R

V

I

C

E

L

O

A

D

I 1.0 1 1 0 1

E

1 1 0 0 0 0 0 100

IA 1.0 1 2 0 0 O 0 0 0 0 0 0 0 150

IB 1.0 1 0 1 1

E

1 1 0 0 0 0 0 **

Culverts

II 1.0 1 0 0 0 1 1 1 1 0 0 0 0 125

III 1.0 1 1 0 1

E

1 1 0.3 1 1 0 0 125

IV 1.0 1 1 0 1

E

1 1 0 0 0 1 0 125

V 1.0 1 0 0 0 1 1 1 1 0 0 1 0 140

VI 1.0 1 1 0 1

E

1 1 0.3 1 1 1 0 140

VII 1.0 1 0 0 0 1 1 1 0 0 0 0 1 133

VIII 1.0 1 1 0 1 1 1 1 0 0 0 0 0 140

IX 1.0 1 0 0 0 1 1 1 1 0 0 0 0 150

X 1.0 1 1 0 0

E

0 0 0 0 0 0 0 100

Structural Design of the Proposed

CASTELLANO BRI DGE MAY 2013

TABLE OF COEFFICIENTS AND

For seismic design of structural member, loading combination VII shall be modified

as per section 5.1.2 of the design criteria.

7.0 DEFLECTION

7.1 Members having simple or continuous spans preferably should be

designed so that the deflection due to service live load plus impact shall not

exceed 1/800 of the span, except on bridges in urban areas used in part by

pedestrians whereon the ratio preferably shall not exceed 1/1000. For checking

deflection, the service live load preferably shall not exceed HS 20 Loading.

7.2 The deflection of cantilever arms due to service live load plus impact

preferably should be limited to 1/300 of the cantilever arm except for the case

including pedestrian use, where the ratio preferably should be 1/375.

8.0 FOUNDATIONS

The foundation shall be designed based on the allowable bearing capacity of

bored piles/ driven piles recommended in the Geotechnical Investigation

Report conducted by A. M. Geoconsult & Associates dated January 21, 2013.

COL.

No. 1 2 3 3A 4 5 6 7 8 9 10 11 12 13

Culverts

FACTORS

GROUP D

( L +

I)

n

( L +

I)

n

CF E B SF W WL LF

R + S

+ T EQ %

L

O

A

D

F

A

C

T

O

R

D

E

S

I

G

N

I 1.3

D

1.67* 0 1.0

E

1 1 0 0 0 0 0

N

o

t

A

p

p

l

i

c

a

b

l

e

IA 1.3

D

2.20 0 0 O 0 0 0 0 0 0 0

IB 1.3

D

0 1 1.0

E

1 1 0 0 0 0 0

II 1.3

D

0 0 0

E

1 1 1 0 0 0 0

III 1.3

D

1 0 1

E

1 1 0.3 1 1 0 0

IV 1.3

D

1 0 1

E

1 1 0 0 0 1 0

V 1.25

D

0 0 0

E

1 1 1 0 0 1 0

VI 1.25

D

1 0 1

E

1 1 0.3 1 1 1 0

VII 1.3

D

0 0 0

E

1 1 0 0 0 0 1

VIII 1.3

D

1 0 1

E

1 1 0 0 0 0 0

IX 1.20

D

0 0 0

E

1 1 1 0 0 0 0

X 1.30 1 1.67 0 0

E

0 0 0 0 0 0 0 100

Structural Design of the Proposed

CASTELLANO BRI DGE MAY 2013

9.0 ALLOWABLE STRESSES FOR ALLOWABLE STRESS DESIGN

9.1 Allowable Stresses for Steel

A. Allowable Tensile Stress

On gross section Fy Ft 55 . 0 =

On net section Fu Ft 50 . 0 =

B. Allowable Axial Compressive Stress

When

r

kl

Cc

(

(

(

(

|

.

|

\

|

=

E

Fy

r

kl

FS

Fy

Fa

2

2

4

1

t

When

r

kl

> Cc

2

2

|

.

|

\

|

=

r

kl

FS

E

Fa

t

Where,

Cc =

Fy

E

2

2t

FS = 2.12

C. Allowable Compressive Bending Stress

When compression flange is supported laterally in its full

length by embedment in concrete,

Fy Fb 55 . 0 =

When compression flange is partially supported or is unsupported,

2

87 . 9

772 . 0 344750

|

.

|

\

|

+

|

|

.

|

\

|

=

d

I

J

I

S

C

Fb

yc

yc

xc

b

Fy 55 . 0 s

Where,

C

b

= 3 . 2 3 . 0 05 . 1 75 . 1

2

2

1

2

1

s

|

|

.

|

\

|

+

|

|

.

|

\

|

+

M

M

M

M

Structural Design of the Proposed

CASTELLANO BRI DGE MAY 2013

|

.

|

\

|

2

1

M

M

= positive when moments cause reverse curvature

|

.

|

\

|

2

1

M

M

= negative when bent is in single curvature.

C

b

= 1.0 for unbraced cantilevers and for member

when the moment within a significant point of

the unbraced segment is greater than or equal to

the larger of the segment end moments.

= length in meters

yc

I = moment of inertia of compression flange about

the vertical axis in the plane of the web, mm

4

d = depth of girder, mm

J =

( ) ( )

3

3 3 3

Dtw bt bt

t c

+ +

,where b and t

represent the flange thickness of the

compression and tension flange, respectively

(mm

4

)

xc

S = section modulus with respect to compression

flange, mm

3

E = modulus of elasticity of steel

r = governing radius of gyration

L = actual unbraced length

k = effective length factor

FS = 2.12

D. Allowable Shear Stress

Shear in girder, webs, gross section Fy Fv 33 . 0 =

E. Combined Stresses

1. Axial Compression and Bending Stresses

a. At intermediate points

0 . 1

'

1

'

1

s

|

|

.

|

\

|

+

|

|

.

|

\

|

+

y

y

y my

x

x

x mx

Fb

Fe

fa

Fb C

Fb

Fe

fa

fb C

Fa

fa

b. At point of supports (points braced in the plane of bending

5

0 . 1

472 . 0

s + +

y

y

x

x

Fb

Fb

Fb

fb

Fy

fa

Structural Design of the Proposed

CASTELLANO BRI DGE MAY 2013

Where,

Fe =

2

2

|

|

.

|

\

|

b

b b

r

L k

FS

E t

fa = computed axial stress

fbx of fby = computed compressive bending

stress about the x-axis and y-axis,

respectively

Fa

=

axial stress that would be

permitted if axial force alone

existed, regardless of the plane of

bending

Fb

x

, Fb

y

= compressive bending stress that would

be permitted if bending moment alone

existed about the x-axis and the y-axis

respectively evaluated according to

AASHTO Table 10.32.1A

Fe = Euler Buckling stress divided by a factor

of safety

E = modulus of elasticity of steel

k

b

= effective length factor in the plane of

bending (see AASHTO Appendix C)

L

b

= actual unbraced length in the plane of

bending

r

b

= radius of gyration

Cm

x

, Cm

y

= coefficient about the x-axis and the y-

axis, respectively, whose value is taken

from AASHTO Table 10.36A

FS = 2.12

2. Axial Tension and Bending Stress

a. At intermediate points

0 . 1 s + +

y

y

x

x

Fb

Fb

Fb

fb

Ft

ft

b. At point of supports (points braced in the plane of bending

0 . 1

472 . 0

s + +

y

y

x

x

Fb

Fb

Fb

fb

Fy

ft

DESIGN

CALCULATIONS

Design of Box Culvert with Seismic Design Code

Backfill Slope Angle i = 0 (deg)

Angle of Friction of Soil = 30 (deg)

Height of Soil Face H = 7.6 m

Total Span of Box Culvert Bridge S= 14 m

Total Width of Box Culvert Bridge W= 10.2 m

Tributary Width considered in analysis tW = 10.2 m

Acceleration Coefficient a = 0.4

Unit Weight of Soil soil = 18 kN/m

3

st = 17 (Static Condition)

se = 8.5 (Seismic Condition)

Horizontal Seismic Coefficient k

h

= 1/2 a = 0.2

Vertical Seismic Coefficient k

v

: 0.3k

h

< k

v

< 0.5 kh

0.06 < k

v

< 0.10 thus, use

k

v

= 0.08

Seismic Internal Angle = arc tan (kh / (1-kv))

= 12.265 (deg)

Slope of Soil Face = 0 (deg)

radian = 0.0175

K 0 4459

Compute Seismic Active Earth Pressure Using the Mononobe-Okabe Equation

Angle of Friction between

Soil and Abutment

Seismic Active Earth Pressure K

AE

= 0.4459

Seismic Active Earth Pressure PAE = 1/2 (soil) (H)

2

(1-K

V

) (K

AE

)

P

AE

= 213.25 kN /m

K

A

= 0.2994

Static Active Earth Pressure P

A

= 155.66 kN /m

Concentrated force of P

A

= 1587.7 kN (Applied at 1/3*H)

Thrust factor, Ft = [P

A

(H/3) + (P

AE

- P

A

)(0.6)H] / [P

A

(H1.6659

Ft (P

A

) = 259.31 kN/m

Dynamic Earth Pressure, EQL= 2645 kN (Applied at 0.6H)

Seismic Active Earth Pressure

Coefficient

Static Active Earth Pressure

Coefficient

Compute Equivalent Pressure Determine a single equivalent pressure:

Static pressure acting at H/3 & Seismic pressure at 6/10 of H

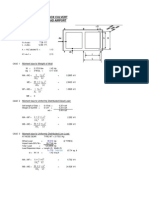

DESIGN OF BOX CULVERT TYPE CASTELLANO BRIDGE

1.0 FIGURE

2.0 LOADINGS

2.1 DEAD LOAD

a. Selfweight

b. Wearing Surface

c. Sidewalks/Curbs

d. Railings

2.2 LIVE LOAD

a. Truck Load MS 18 (HS20-44) & Equivalent Lane Loading

b. Permit design live load

Sid lk 2870 kP c. Sidewalk 2870 kPa

IMPACT FORMULA

I = 15.24 / (S + 38)

I = impact fraction, maximum 30 percent

I = 0.293

2.3 EARTH'S PRESSURE

a. Static Earth's Pressure

b. Dynamic Earth's Pressure (Mononobe-Okabe)

3.0 MATERIALS

3.1 CONCRETE

Unit Wt.of Concrete = 24 kN/m3

Compressive strength, f'c = 27.6 Mpa

Modulus Of Elasticity = 27336 Mpa

3.2 STEEL

Yield Strength Bars = 414 Mpa

Modulus Of Elasticity = 200000 Mpa

4.0 DESIGN MOMENTS (Kn-m)

B C D E F G I J Des Moment Des Axial

-2690 2760 2760 575 -1611 2195 2195 -1295 154 2183

-802 661 662 276 -110 33 33 33 49 160

-604 414 414 173 -69 21 21 21 31 181

-137 122 122 51 -20 6 6 6 9 37

161 161 161 -499 199 74 74 74 111 0

355 355 355 -1020 323 -101 -101 -101 151 0

-2827 2882 2882 626 -1631 2201 2201 -1289 163 2220

-802 661 662 276 -110 33 33 33 49 181

-137 122 122 51 -20 6 6 6 9 37

355 355 355 -1020 323 -101 -101 -101 151 0

4.1 LOAD COMBINATION

GROUP g D(L+I)n E A B C D E F G I J Des Moment Des Axial

I 1.3 1 1.7 1.3 4926 -3764 4925 4926 -668 -1670 2720 2720 -1817 510 3049

IA 1.3 1 2.2 0 4460 -4526 4459 4460 1111 -2239 2897 2897 -1640 265 3086

IB 1.3 1 0 1.3 4505 -3254 4505 4505 -844 -1600 2699 2699 -1838 479 2934

II 1.3 1 0 1.3 4505 -3254 4505 4505 -844 -1600 2699 2699 -1838 479 2934

III 1.3 1 1 1.3 4757 -3559 4757 4757 -739 -1642 2712 2712 -1825 497 3003

IV 1.3 1 1 1.3 4757 -3559 4757 4757 -739 -1642 2712 2712 -1825 497 3003

V 1.3 1 0 1.3 4332 -3128 4332 4332 -811 -1539 2595 2595 -1767 460 2821

VI 1.3 1 1 1.3 4574 -3422 4574 4574 -710 -1579 2607 2607 -1755 478 2887

VII 1.3 1 0 1.3 4505 -3254 4505 4505 -844 -1600 2699 2699 -1838 479 2934

VIII 1.3 1 1 1.3 4757 -3559 4757 4757 -739 -1642 2712 2712 -1825 497 3003

IX 1.2 1 0 1.3 4158 -3003 4158 4158 -779 -1477 2491 2491 -1697 442 2709

X 1.2 1 1.7 1.3 4547 -3474 4547 4547 -617 -1542 2511 2511 -1677 471 2815

4926 -4526 4925 4926 1111 -2239 2897 2897 -1838 510 3086

4.2 FLEXURAL REINFORCEMENT

Pile Head

Pile Head

DEAD LOAD

TRUCK LOAD

LANE LOADS

SIDEWALK 122

EARTH'S

DYNAMIC

A

2760

355

SIDEWALK

STATIC

662

414

122

161

DEAD LOAD 2882

LIVE LOAD 662

355

Design Data:

Bridge width 10200 mm db= 28 mm db= 20 mm

Bridge Span As= 615.8 mm

2

As= 314.2 mm

2

Clear cover 50 mm

t1= 700 mm db= 25 mm

t2= 900 mm tmid= 800 mm As= 490.9 mm

2

t3= 600 mm

footing= 1500 mm

Mu d w reqd design As

4926 811 0.0301 0.002 0.0032 26471

4526 711 0.0361 0.0024 0.0032 23207

4925 811 0.0301 0.002 0.0032 26471

4926 611 0.0538 0.0036 0.0036 22347

1111 611 0.0118 0.0008 0.0032 19943

2239 611 0.024 0.0016 0.0032 19943

2897 486 0.0499 0.0033 0.0033 16482

2897 486 0.0499 0.0033 0.0033 16482

1838 486 0.0313 0.0021 0.0032 15863

4.3 TEMPERATURE REINFORCEMENT

As Asb

1620 490.9

1440 490.9

2700 490.9

1260 490.9

1260 490.9

1260 490.9

2700 490.9

2700 490.9

1080 490.9

5.0 DESIGN SHEAR (Kn)

B C D E F G I J Des Moment Des Shear

Pile Head

28mm @ 200

28mm @ 200

bw=

Section Spacing

A

B

28mm @ 200

28mm @ 200

28mm @ 200

D

E

F

G

I

J

28mm @ 200

28mm @ 200

28mm @ 200

28mm @ 200

Section

C

cc=

As Spacing

A

B

C

0.0018bt

0.0018bt

0.0018bt

25mm @ 150

D

E

F

G

I

J

0.0018bt

0.0018bt

0.0018bt

0.0018bt

0.0018bt

0.0018bt

25mm @ 190

25mm @ 200

25mm @ 150

25mm @ 150

25mm @ 190

25mm @ 190

25mm @ 190

25mm @ 190

A

3 -1556 -659 -659 -659 845 846 0 154 -30

36 -320 -27 -27 -27 0 0 0 49 7

80 -131 -41 -41 -41 -1 -1 -1 31 6

0 -74 -23 -23 -23 0 0 0 9 1

0 0 -216 -216 451 0 0 0 111 -40

0 0 -673 440 440 0 0 0 151 -59

3 -1630 -682 -682 -682 845 846 0 163 -29

80 -320 -41 -41 -41 -1 -1 -1 49 7

0 -74 -23 -23 -23 0 0 0 9 1

0 0 -673 440 451 0 0 0 151 -59

DEAD LOAD 1556

TRUCK LOAD 320

LANE LOADS 362

SIDEWALK 74

STATIC 0

DYNAMIC 0

TRANSV

DEAD LOAD 1630

LIVE LOAD 362

SIDEWALK 74

EARTH'S 0

TRANSV

5.1 LOAD COMBINATION

GROUP g D(L+I)n E A B C D E F G I J Des Moment Des Shear

I 1.3 1 1.7 1.3 2446 55 -2419 -2081 -201 -181 1098 1099 0 510 -132

IA 1.3 1 2.2 0 2519 71 -2484 -952 -952 -952 1098 1099 -1 265 -31

IB 1.3 1 0 1.3 2215 4 -2215 -2054 -174 -155 1099 1100 0 479 -137

II 1.3 1 0 1.3 2215 4 -2215 -2054 -174 -155 1099 1100 0 479 -137

III 1.3 1 1 1.3 2353 35 -2337 -2070 -190 -170 1098 1100 0 497 -134

IV 1.3 1 1 1.3 2353 35 -2337 -2070 -190 -170 1098 1100 0 497 -134

V 1.3 1 0 1.3 2130 4 -2130 -1975 -168 -149 1056 1058 0 460 -131

VI 1.3 1 1 1.3 2263 33 -2247 -1990 -183 -164 1056 1057 0 478 -129

VII 1.3 1 0 1.3 2215 4 -2215 -2054 -174 -155 1099 1100 0 479 -137

VIII 1.3 1 1 1.3 2353 35 -2337 -2070 -190 -170 1098 1100 0 497 -134

IX 1.2 1 0 1.3 2045 4 -2045 -1896 -161 -143 1014 1015 0 442 -126

X 1.2 1 1.7 1.3 2257 51 -2233 -1921 -185 -167 1014 1015 0 471 -122

2519 71 -2484 -2081 -952 -952 1099 1100 0 510 -31

5.2 CHECK SHEAR

Vu=Vn =0.85

Vn=Vc+Vs

Vc=1 / 6 (f'c)(bw)(d)

Vu bw d Vn Vc

2519 10200 811 2963 38052

71 10200 711 83.989 33360

2484 10200 811 2921.9 38052

2081 10200 611 2447.8 28668

952 10200 611 1120.2 28668

952 10200 611 1120.2 28668

1099 10200 486 1292.4 22803

1100 10200 486 1293.9 22803

0 10200 486 0 22803

Pile Head

Section

A

B

F

G

I Ok

C

D

E

Ok J

Ok

Ok

REMARK

Ok

Ok

Ok

Ok

Ok

Anda mungkin juga menyukai

- Design of box culvert with internal dimensionsDokumen9 halamanDesign of box culvert with internal dimensionsANKESH SHRIVASTAVABelum ada peringkat

- STRUCTURAL Design CriteriaDokumen11 halamanSTRUCTURAL Design Criteriamdkml2Belum ada peringkat

- Samaila Consultant Limited design calculations for single box culvertDokumen8 halamanSamaila Consultant Limited design calculations for single box culvertebed_meleck100% (2)

- Manual RC Box Culvert Analysis and DesigningDokumen25 halamanManual RC Box Culvert Analysis and DesigningInternational Journal of Innovative Science and Research TechnologyBelum ada peringkat

- 25m Single Lane Bridge Design Calculations LatestDokumen16 halaman25m Single Lane Bridge Design Calculations Latestntah84100% (4)

- Box CulvertDokumen24 halamanBox CulvertRidhima488% (8)

- CT-631. Design Calculation Sheet. Rev.0 PDFDokumen101 halamanCT-631. Design Calculation Sheet. Rev.0 PDFErnest Navarro100% (1)

- Analysis of Industrial Slabs-On-groundDokumen273 halamanAnalysis of Industrial Slabs-On-groundbatteekhBelum ada peringkat

- Hydraulic Analysis: For Reinforced Concrete Box CulvertDokumen7 halamanHydraulic Analysis: For Reinforced Concrete Box Culvertmarkgil1990Belum ada peringkat

- Bs 5400 - Concrete DesignDokumen1 halamanBs 5400 - Concrete Designcaner_kurtoglu-1Belum ada peringkat

- Calculation For 1.4m X 1.5m RCC Box CulvertDokumen4 halamanCalculation For 1.4m X 1.5m RCC Box CulvertManish BhatkarBelum ada peringkat

- Structural Analyses of 3 KW HAWTDokumen191 halamanStructural Analyses of 3 KW HAWTFakhrulIzzuddinBelum ada peringkat

- STRUCTURAL DESIGN OF TRANSFORMER PADDokumen17 halamanSTRUCTURAL DESIGN OF TRANSFORMER PADArchilles P. AdverderadaBelum ada peringkat

- Design criteria for Castellano BridgeDokumen25 halamanDesign criteria for Castellano BridgeAl Patrick Dela CalzadaBelum ada peringkat

- Box Culvert Design 2Dokumen9 halamanBox Culvert Design 2sundar_s_2k100% (2)

- Design of Culvert - Excel SheetDokumen17 halamanDesign of Culvert - Excel Sheethafiz zain saeed67% (3)

- REPORTDokumen49 halamanREPORTSalin ShresthaBelum ada peringkat

- Box Culvert Design ManualDokumen40 halamanBox Culvert Design ManualAnil Kumar Kothamacha71% (21)

- RC box culvert design calculationsDokumen15 halamanRC box culvert design calculationsYoshua Yang62% (21)

- Structural Design of A Reinforced Box CulvertDokumen33 halamanStructural Design of A Reinforced Box CulvertSamson Odunola85% (27)

- Guidelines Bridge DesignDokumen208 halamanGuidelines Bridge Designaa19100% (13)

- FW Pipe Rack DocumentDokumen38 halamanFW Pipe Rack DocumentSumanthBelum ada peringkat

- Winkler Spring Calculation ForAbutment BoredPileDokumen1 halamanWinkler Spring Calculation ForAbutment BoredPileVal Beltran100% (2)

- Design Review ReportDokumen11 halamanDesign Review ReportAziz ul Hakeem0% (1)

- Aircraft comparison report summarizes key specsDokumen50 halamanAircraft comparison report summarizes key specsMukesh KarunanethyBelum ada peringkat

- Box Culvert Two CellDokumen29 halamanBox Culvert Two Celldhwani86% (7)

- Bridge Design Using STAADDokumen38 halamanBridge Design Using STAADpheron200390% (10)

- Box Culvert Design and Analysis CalculationsDokumen11 halamanBox Culvert Design and Analysis CalculationscoreteamBelum ada peringkat

- Modern Steel Construction July 2010Dokumen70 halamanModern Steel Construction July 2010Melissa FloresBelum ada peringkat

- Mechanics of Materials Solutions Chapter08 Probs19 30 PDFDokumen15 halamanMechanics of Materials Solutions Chapter08 Probs19 30 PDFVirgilio VelascoBelum ada peringkat

- Structuran Design of Reinforced Concrete Culverts PDFDokumen48 halamanStructuran Design of Reinforced Concrete Culverts PDFflavbom95% (41)

- Timber Beam DesignDokumen5 halamanTimber Beam DesignnurulselangorBelum ada peringkat

- Seismic Design StorageTanks Ed2010Dokumen39 halamanSeismic Design StorageTanks Ed2010VladSimionBelum ada peringkat

- Loading and Design of Box Culverts To EurocodesDokumen35 halamanLoading and Design of Box Culverts To Eurocodeslnanescu83% (6)

- BOX CULVERT Spread SheetDokumen20 halamanBOX CULVERT Spread Sheetdsananda0% (1)

- IRS Seismic Code Nov-2017Dokumen39 halamanIRS Seismic Code Nov-2017Mohd AftabBelum ada peringkat

- Culvert Load CalculationsDokumen3 halamanCulvert Load CalculationsIrfan Ali100% (1)

- Design of box type culvert reinforcementDokumen39 halamanDesign of box type culvert reinforcementYasika199078% (9)

- Culvert Outlet ProtectionDokumen12 halamanCulvert Outlet ProtectionjaffnaBelum ada peringkat

- Reinforced Concrete Buildings: Behavior and DesignDari EverandReinforced Concrete Buildings: Behavior and DesignPenilaian: 5 dari 5 bintang5/5 (1)

- Analysis and Design of A Continuous R. C. Raker Beam Using Eurocode 2Dokumen13 halamanAnalysis and Design of A Continuous R. C. Raker Beam Using Eurocode 2Ubani Obinna Ranks100% (7)

- Culvert DesignDokumen18 halamanCulvert Designseagull700% (1)

- Ejma 8TDokumen3 halamanEjma 8TpiziyuBelum ada peringkat

- Two Cell Box CulvertDokumen12 halamanTwo Cell Box CulvertAhmad Arslan Rafique71% (7)

- CE66a: Reinforced Concrete Design 1: University of Science and Technology of Southern PhilippinesDokumen55 halamanCE66a: Reinforced Concrete Design 1: University of Science and Technology of Southern PhilippinesKatherine Shayne YeeBelum ada peringkat

- Slope Deflection Examples and Sway MechanismsDokumen20 halamanSlope Deflection Examples and Sway MechanismsMlg JoséBelum ada peringkat

- EN1993 Design of Steel StructuresDokumen52 halamanEN1993 Design of Steel StructuresPatrick Refalo100% (1)

- Culvert Design Write UpDokumen8 halamanCulvert Design Write UpifylasyBelum ada peringkat

- Load Types and CombinationsDokumen5 halamanLoad Types and CombinationsKutty MansoorBelum ada peringkat

- 13chapter STEEL-CONCRETE COMPOSITE STRUCTURAL MEMBERSDokumen23 halaman13chapter STEEL-CONCRETE COMPOSITE STRUCTURAL MEMBERSTarif Aziz MarufBelum ada peringkat

- Design Criteria FGDokumen6 halamanDesign Criteria FGvigil vigilBelum ada peringkat

- Design Criteria FG x3cDokumen6 halamanDesign Criteria FG x3cvigil vigilBelum ada peringkat

- Monitoring of A Tall Building To Develop Axial Shortening Models Incorporating High Strength ConcreteDokumen7 halamanMonitoring of A Tall Building To Develop Axial Shortening Models Incorporating High Strength ConcreteRico PadillaBelum ada peringkat

- 1 Technical Part (Structures) FS Design and Reconstruction of BridgesDokumen8 halaman1 Technical Part (Structures) FS Design and Reconstruction of BridgesUmar UmarBelum ada peringkat

- Concrete Encased Composite Column ACI - AISCDokumen14 halamanConcrete Encased Composite Column ACI - AISCAli KhalafBelum ada peringkat

- Design Criteria AA 3363Dokumen3 halamanDesign Criteria AA 3363vigil vigilBelum ada peringkat

- Load Transfer in Composite ColumnsDokumen12 halamanLoad Transfer in Composite ColumnsRonnie BarreraBelum ada peringkat

- Structure Design CriteriaDokumen18 halamanStructure Design CriteriaAdam SanchezBelum ada peringkat

- Analysis of reinforced concrete membersDokumen44 halamanAnalysis of reinforced concrete membersSiul OnarbmazBelum ada peringkat

- SARASWOTIDokumen48 halamanSARASWOTISalin ShresthaBelum ada peringkat

- Design Criteria AA 3363 x2cDokumen3 halamanDesign Criteria AA 3363 x2cvigil vigilBelum ada peringkat

- En STAS 10111-2-87 PART 1 - Suprastructuri - BetonDokumen12 halamanEn STAS 10111-2-87 PART 1 - Suprastructuri - BetonFantana AdrianBelum ada peringkat

- DTP - Deerfield River BridgeDokumen5 halamanDTP - Deerfield River Bridgefdesdunes00Belum ada peringkat

- Seismic Design and Performance of Two Isolation Systems Used For Reinforced Concrete Bridge ConstructionDokumen10 halamanSeismic Design and Performance of Two Isolation Systems Used For Reinforced Concrete Bridge ConstructionGourab GhoshBelum ada peringkat

- Seismic Design of Steel-Concrete Composite StructuresDokumen24 halamanSeismic Design of Steel-Concrete Composite StructuresCristian BlanaruBelum ada peringkat

- 21 International Conference On Science, Engineering and Technology (ICSET), 2020Dokumen35 halaman21 International Conference On Science, Engineering and Technology (ICSET), 2020Nihal ChoudharyBelum ada peringkat

- AIJ Proposal (ACI SP123)Dokumen19 halamanAIJ Proposal (ACI SP123)hbookBelum ada peringkat

- Design Requirements of Reinforced Concrete Beam-Column Joints in International Codes and ECP-RC-2018Dokumen12 halamanDesign Requirements of Reinforced Concrete Beam-Column Joints in International Codes and ECP-RC-2018محمد حسن محمد حسنBelum ada peringkat

- Design Criteria XXDokumen7 halamanDesign Criteria XXvigil vigilBelum ada peringkat

- Maximum Floor Displacement Profiles for Displacement-Based Seismic DesignDokumen8 halamanMaximum Floor Displacement Profiles for Displacement-Based Seismic DesignRushabbBelum ada peringkat

- Moment Capacity of BeamsDokumen3 halamanMoment Capacity of BeamsVal BeltranBelum ada peringkat

- Static&Seismic Passive Soil Resistance Calc ForAbutBoredPileDokumen1 halamanStatic&Seismic Passive Soil Resistance Calc ForAbutBoredPileVal BeltranBelum ada peringkat

- Static&Seismic Passive Soil Resistance Calc ForAbutBoredPileDokumen1 halamanStatic&Seismic Passive Soil Resistance Calc ForAbutBoredPileVal BeltranBelum ada peringkat

- 2 Hinged ArchDokumen19 halaman2 Hinged ArchSaeed_HassaniurscorpBelum ada peringkat

- Mechanics of Materials IntroductionDokumen29 halamanMechanics of Materials IntroductionengrrrrBelum ada peringkat

- Chapter 11. Member Hysteresis Models: LoadingDokumen58 halamanChapter 11. Member Hysteresis Models: LoadingRenato TomasBelum ada peringkat

- Chapter 1Dokumen43 halamanChapter 1ali3 ALAA100% (2)

- p810495 A1b PDFDokumen82 halamanp810495 A1b PDFYanyan2009Belum ada peringkat

- Dubai Towers at The Lagoon 1 PDFDokumen64 halamanDubai Towers at The Lagoon 1 PDFMai KawayapanikBelum ada peringkat

- Silt Gravel Removal GateDokumen16 halamanSilt Gravel Removal GateRaja SinghBelum ada peringkat

- EFFICIENT USE OF STEEL JOISTSDokumen9 halamanEFFICIENT USE OF STEEL JOISTSinsane88Belum ada peringkat

- Torsion of Cold-Formed Steel Lipped Channels Dominated by Warping ResponseDokumen13 halamanTorsion of Cold-Formed Steel Lipped Channels Dominated by Warping ResponseJoseAngelFernandezOrtegaBelum ada peringkat

- SimplySupportedBeam PointloadDokumen6 halamanSimplySupportedBeam PointloadNeelakantheswar KunkulaguntaBelum ada peringkat

- Analysis CompDokumen10 halamanAnalysis CompJose David Tobo RamosBelum ada peringkat

- Strength of Materials - Axial Force Shear Force Bending Moment Diagrams - Hani Aziz AmeenDokumen28 halamanStrength of Materials - Axial Force Shear Force Bending Moment Diagrams - Hani Aziz AmeenHani Aziz AmeenBelum ada peringkat

- Civil Engineering Syllabus Sem V Mumbai UniversityDokumen72 halamanCivil Engineering Syllabus Sem V Mumbai UniversityNikita SaxenaBelum ada peringkat

- Cantilever Beam Experiment B58SBDokumen9 halamanCantilever Beam Experiment B58SBSunBelum ada peringkat

- Generalized Single-Degree-of-Freedom Systems: Chopra: Prentice-Hall PAGES JUL. 19, 2000 14:21 ICC Oregon (503) 221-9911Dokumen38 halamanGeneralized Single-Degree-of-Freedom Systems: Chopra: Prentice-Hall PAGES JUL. 19, 2000 14:21 ICC Oregon (503) 221-9911MakaraSoyBelum ada peringkat

- Me331 2008Dokumen451 halamanMe331 2008akshaygiitmBelum ada peringkat

- Memo STRUCTURAL ANALYSIS II - SAN2601 Assignments 2020Dokumen28 halamanMemo STRUCTURAL ANALYSIS II - SAN2601 Assignments 2020Rachel Du PreezBelum ada peringkat

- Experimental CalculationsDokumen5 halamanExperimental CalculationsmomenBelum ada peringkat

- Built Up MembersDokumen6 halamanBuilt Up Membersalberto rosadoBelum ada peringkat

- PWD Questions Answers by Rahul VhanmaneDokumen41 halamanPWD Questions Answers by Rahul VhanmaneRahul VhanmaneBelum ada peringkat

- Chapter 4: Kekem Case Study / Local Analysis: Slab Design 4.1. Geometry of The Deck SlabDokumen15 halamanChapter 4: Kekem Case Study / Local Analysis: Slab Design 4.1. Geometry of The Deck SlabbertinBelum ada peringkat