The Latest in PVC Additives and Compounds - High-Tech Solutions

Diunggah oleh

Victor CastrejonDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

The Latest in PVC Additives and Compounds - High-Tech Solutions

Diunggah oleh

Victor CastrejonHak Cipta:

Format Tersedia

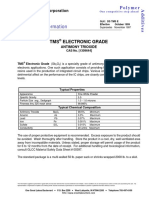

Trends&Innovations Materials&Solutions Training&Education Channels CommunityPulse OpenInnovation

TheLatestinPVCAdditivesandCompoundsHighTechSolutions!

SpecialChem|DonRosato Feb20,2012

NovelPVCTechnologies

PVCStabilizerDevelopment

NanoscaledMg(OH)

2

FlameRetardantAdditive

MultifunctionalAntioxidantAdvances

PVCAdditivesandCompoundsTechnologySources

PolyvinylChlorideLandscape

Polyvinylchloride(PVC)isathermoplasticpreparedbyfreeradicalpolymerizationofvinylchlorideviadispersion(emulsion),bulkor

suspension processes. A small amount of comonomer is sometimes added to enhance adhesion or other properties. Unmodified

PVCsarerigidsotheyrequireplasticizerstomakethemflexible.Themanufactureofawiderangeofplasticsispossiblebecauseof

PVC'smiscibilitywithavarietyofplasticizers.

Global consumptionof PVC has reached a level of about 35 million tons in 2011. PVCis an established polymerwith an average

growth rate less than World GDP (Gross Domestic Product), but is seeing good expansion in Asia due to more emphasis on

infrastructure and construction. In fact, markets indicate that the power of business in PVC and related sectors is shifting to Asia,

where PVC is growing atabout 7% or almostat the samerate asAsia'sGDP growth. NorthAmerica and Europeareboth mature

marketsforPVC.Theseregionsareexpectedtogrowatlessthan3%inthecomingfiveyears.Theplasticsadditivesglobalmarket

of$35.5Bisexpectedtoincreaseto$46.3Bby2015foracompoundedannualgrowthrateof4.5%.PVCcompoundsconsumemore

than65%ofthetotalvolumeof10milliontonnesofadditives,withmajorportionofthisvolumearisingfromplasticizers.Theglobal

plasticizermarketisan$11 Billionindustry.Plasticizersare thelargestcategoryofadditivesaccountingfor54%ofthe totaloverall

marketvolume.AdditivesforPVCexcludingplasticizers,amounttoavolumeofover1.5milliontons.

Heatstabilizerscontributemorethan30%oftheremaining35%oftheglobalPVCadditivedemand.Heavymetalbasedstabilizers

likeleadbasedproducts verywidelyusedforstabilizationofpipeinEuropeandAsia(exceptJapan),areresponsibleforverylarge

proportionoftheseproductsintheheatstabilizergroup.Pipeconstitutesalmost40%oftheglobalPVCconsumption.Inpipes,lead

content is about 11.5 %. PVC wire and cable sector also consumes lead stabilizers and will continue to use them because of

inherentadvantagesofferedbyleadintermsofsuperiorelectricalresistance.Whilethewireandcablesectorconstitutesonlyabout

23% of the total PVC resin consumption, it requires a heavy dosage of lead stabilizer at about a 23% level. Lead stabilizers are

beingdramaticallyphasedoutinEurope.Leadisbeingreplacedbylightermetalslikecalciumorzinc,aswellasorganicstabilizers.

Mostofthereplacementofleadwilltakeplaceinthepipesector.Thewireandcablesectorisexpectedtostay withleadstabilizer

longeruntilasuitablealternativeisdevelopedmatchingthefulltechnicalperformanceoflead.

Anothergroupofadditivescalledimpactmodifierprocessingaidsconstituteanother30%oftheremaining35%ofthePVCadditive

spectrum. More than 60% of compounded PVC is in the form of unplasticized or rigid products. They are not soft and flexible

becauseoftheabsenceofplasticizers.Toimpartbetterflexibilityandimpactstrengthwithoutaffectingrigidity,agroupofpolymeric

additives called impact modifiers are used. They are used at the level of 210% depending upon the impact strength requirement.

The MBS(MethylButadiene Styrene)copolymer acrylatesretaininherentPVC clarity and is usedfor packagingfilms and sheets.

There are other impact modifiers (predominately acrylates and chlorinated polyethylene) that also help in providing weather

resistanceduetobetterretentionofimpactstrengthoveralongperiodoftimeandareusedforwindowprofilesandothersimilarend

use applications. Rigid PVC is quite difficult to process since it has high viscosity. To improve its processability without reducing

mechanicalpropertiesappreciably,agroupofpolymericadditives(PMMA,orpolymethylmethacrylate,acrylic,ofspecificmolecular

weightandparticlesizedistribution)areused.Whilepipemayormaynotuseprocessingaids(onlylargerpipesrequireprocessing

aids), profile, rigid film and sheet need processing aid for ease of processability. Higher dosing and larger volumes of PVC are

responsibleforhigherusageofimpactmodifierprocessingaidandheatstabilizer.

PVC, with its chlorine content, is inherently more flame retardant (FR) than the other commodity polymers. However, addition of

plasticizers reduces flame resistance. For instance, limiting oxygen index of unplasticized PVC is 40 but plasticized PVC

compositions can have oxygen index as low as 22 to as high as 28. These compositions therefore arerequired to be made more

resistanttoflamebyincorporationofflameretardantadditives.Theflameretardantadditivesusedareantimonytrioxide,zincborate

ormolybdenumoxide.Whileantimonytrioxideincreasesoxygenindex,bothzincborateandmolybdenumoxidehelpinsuppression

ofsmokeafterthefireiscaughtbyPVCproduct.Tofurtherreducesmoke,additives(morelikefillers)suchasaluminumhydroxide

areincorporated.Theseadditivesarerequiredtobeincorporatedatmuchhigherdosagecomparedtoheatstabilizer,processingaid,

andotheradditiveconstituents.FRadditivesconstitute15%oftheremaining35%ofPVCadditives.PVCcompoundmeltgetsstuck

onhotmetalequipmentsurfacesduringprocessing.ItthereforerequiresahigherleveloflubricantstopreventstickingofPVCmelt

tohotmetal.Also,flowisimprovedbytheadditionofPVCcompatibleadditivescalledinternallubricants.Lubricantsofalltypesare

addedatabout0.51%levels.Approximately15%oftheremaining35%ofPVCadditivesarelubricants.

Antioxidantisgenerallyusedbypolyolefins,butPVCisquiteresistanttooxidativedegradation.Howeverthedosageofantioxidantis

lowerthan0.2%comparedtoaverage23%ofheatstabilizerusedinPVC.Antioxidantsmakeuponly3%oftheremaining35%of

PVCadditivesbyvolume,leaving7%35%inotherPVCadditivecombinations(i.e.,processingaids,antistaticadditives,andother

specialtyrubberimpactmodifiers).

NovelPVCTechnologies

PhthalatePlasticizersCovalentlyBondedtoPVC

Researchers at the Institute of Polymer Science & Technology in Madrid are developing technology to prevent potentially harmful

plasticizers such as DEHP (DOP) from migratingfromPVC.The advancecould lead to anew generation of PVCplastics that are

potentially safer than those now used in packaging, medical tubing, toys, and other products. The permanent plasticizer effect will

alsoensurePVCflexibilityismaintainedwiththepossibilityofextendingusefulproductlife.ThefunctionalizedplasticizerDOPSH[di

0 2 More

Figure1:PolyvinylChloride(PVC)Structure

(Source:PlasticsInstituteofAmerica)

Plastics&Elastomers

FormulationBulletin(bimonthly)

PolymerFormulationInsight

(weekly)

M|."

M|."

Youremail

Whatisyourmainissue

whiledesigningplastic

parts?

*'^

Cost/performanceratio

*'^

Performance

*'^

Aesthetics

*'^

Sustainability

*'^

Useofrenewableplastics

*'^

Carbonfootprint

Article UnderstandingChain

ExtendersandCrosslinkers

SolutionCaseStudy Replaceyour

MineralFillerreinforcementwitha

Performing...

Article LookingAheadinPlastics

ColorTrendsandNovelPigment

Advances

Article

Ultraviolet/AntioxidantStabilizer

SystemAdvancesServe&Protect!

HighTemperatureRubbers&

Elastomers:Innovative&

ConventionalOutlookson...

WhatsthelatestinFoams?

Bio andNanoplasticBarrier

MaterialDevelopmentAdvances

TheLatestinPVCAdditivesand

CompoundsHighTechSolutions!

.stayconnected

Newsletters

RSS

Twitter

VictorCastrejon

Share

News IndustryEvents PatentWatch R&DHighlights Articles Glossary Newsletters

Pgina1de4 TheLatestinPVCAdditivesandCompoundsHighTechSolutions! Article

04/08/2012 http://www.specialchem4polymers.com/resources/articles/article.aspx?id=6896&lr=m...

(2ethylhexyl) 4mercaptophthalate]wasdevelopedwithphysiochemicalpropertiessimilartothoseofcommercialDOP,butwithan

additionalfunctionalgroupabletoestablishacovalentbondtothepolymericbackbone.Thepercentageofplasticizerthatcouldbe

covalentlylinkedtothePVCbackbonewassimilartoplasticizeramountsusuallycommerciallyemployed.Theapproachcompletely

suppressedplasticizermigration.WhiletheplasticizerefficiencyofthenovelplasticizersislessthanconventionalDEHP(DOP) the

glasstransitiontemperatureofmodifiedPVCislargelyreducedandisaround0Cforthehighestmodifiedsamples.Thisapproach

mayopennewwaystoprepareflexiblePVCwithpermanentplasticizereffectandzeromigration.

RigidandFlexiblePVCRequirements

PVC, an economic, high volume compounded material is one of the most important thermoplastics available, as a result of its

processability,adaptability,usefulproperties,andcapacitytoacceptmanydifferentadditives.Ingeneralthematerialismarketedas

unplasticizedorrigidPVCusedinpipe,sidingandwindowdoor profiles,andplasticizedorflexiblePVCusedinsuchapplications

asflooring,wallcovering,coatedfilmsfabricandtoysaswellaswireandcablejacketing.

PVC,whichisunstableatprocessingtemperatures,willdegraderapidlyintheabsenceofaheatstabilizer.Toperformsatisfactorily,

bothrigidandflexiblePVCcallforanefficientadditivepackagethatincludesheatstabilizers,andnumerousotheradditivesthatmay

potentiallyinteract,andalsomustbeoptimizedforgoodcostperformanceinagivenapplication.Heatstabilizers,whichareessential

componentsofaPVCformulationprotectthepolymerduringelevatedprocessingtemperatures,aswellaspreventlongertermheat

degradation in the ultimate enduse. They also prevent dehydrochlorination of the PVC and neutralize hydrochloric acid that may

have formed as well as prevent the plastic's discoloration. Rigid PVC is processed at higher temperatures and higher shear rates

thanflexiblePVCandasaresultrequiresmoreeffectiveheatstabilizers.Severalfamiliesofheatstabilizers(basedonsaltsoflead,

mixedmetals[calciumzinc,bariumzinc],organotinandorganicmaterials)arecompetingintherigidandorflexiblePVCmarkets

with stabilizer development beingdriven by both regulatory andcostperformance issues. Cadmium based heat stabilizers have in

generalbeeneliminatedandinEuropeleadbasedheatstabilizersarealsobeingphasedout.

PVCStabilizerDevelopment

CalciumBasedStabilizerSystems

In Europe, leadbased heat stabilizers have traditionally been used to protect rigid PVC for the construction industry as well as

flexiblePVCusedinwireandcablejackets.LeadstabilizedPVChasabroadprocessingrangeallowingPVCgoodstobeproduced

on a range of converting equipment. These formulations offer excellent performance versus cost and high heat stability, with less

wear on manufacturing equipment and permit inhouse scrap material recycling however lead use is becoming increasingly

controversial or outright banned. The leadbased stabilizers are therefore being replaced primarily by solid mixed metal stabilizer

systems (mainly calcium zinc based systems) for rigid PVC applications and liquid mixed metal stabilizer systems (essentially

calciumzinc,orbariumzinc)forflexiblePVCsystemssuchaswireandcablePVCjackets.

Incomparisontoleadbasedstabilizers,calciumbasedstabilizersystemsarecostperformancecomparableandhaveadvantagesin

handlingandproductpropertiessuchasoutdoorweatheringbutaremoreproductspecific,oftencallingforcustomformulation.Asa

resultreplacementofleadbasedstabilizersaroundtheworldisoccurringatdifferentrates,dependingontheapplication.InEurope,

theELV(EndofLife)Vehicledirectivemadeitdifficulttodisposeofleadcontainingmaterialsandasaresulttheautomotiveindustry

hasmovedmorerapidlytowardscalciumbasedstabilizers.

ManufacturershaverespondedtoincreaseddemandforCabasedstabilizers.BaerlocherGmbHhascommercializedBaerostabNT

3521P, asolid Cabased stabilizer for rigid PVC films and sheets.The stabilizer featuresexcellent heat stability,has approvalfor

FDA,EC200272andwithitslowemissionvolatilesissuitableforodorlessformulations.

Figure2:PlasticationwithSuppressedMigration

ExtractionofPlasticizedPVCSheetswithHeptaneatRoomTemperature

(Source:InstituteofPolymerScience&TechnologyMadrid)

Experttipstobetterchooseplasticizers&optimizecompetitivenessofyourPVC

compounds:

PVCPlasticizerSelectionStrategies

OnlineshortcourseonWed.September12,2012

Figure3:RigidandFlexiblePVCApplications

(Source:GrandorthSpecialtyChemicals)

Facebook

Pgina2de4 TheLatestinPVCAdditivesandCompoundsHighTechSolutions! Article

04/08/2012 http://www.specialchem4polymers.com/resources/articles/article.aspx?id=6896&lr=m...

Also in response togrowingmarketdemand fornonleadadditives,Halstab,a division ofHammond GroupInc.addedafull lineof

calciumzincpowderstabilizerstoitsPlastiStabproductlineforPVCwireandcableapplications.Thedivisionalsocustomformulates

calciumzincstabilizersaroundspecificcompoundstomeetUL(UnderwritersLaboratories)specifications.

TinBasedStabilizerSystems

While much of the world has used leadbased heat stabilizers to protect rigid PVC and are transitioning to calcium zinc and even

organicalternatives,tinbasedheatstabilizersareusedinNorthAmericawhereitisexpectedtoremaintheprincipleheatstabilizer

of choice, with mixed metal and organic stabilizer systems finding certain niche applications. There are two main groups of tin

stabilizers. Members of the first group, with tinsulfur bonds, are referred to as tin mercaptide stabilizers. These sulfur containing

organotincompounds arehighly efficient and allowproduction of rigid PVC under themost demanding processingconditions. The

mostcommonlyusedareusuallymixturesofdialkylandmonoalkyltincompoundswiththealkylgroupsbeingmethyl,butyl,octylor

lauryl.While tin mercaptide stabilizers have very goodheat stability,they show moderate light stability which is often offsetby the

use of titanium dioxide,a whitepigment.As aresult,tinmercaptide stabilizers are notsuitedfor darkcoloredapplications suchas

dark coloredsidingandprofiles. Theyalso have a characteristicodor whichmaybeofconcern in certainapplications.The second

groupoftinbasedheatstabilizerscontainstinoxygen bonds.Membersof thisgroup includetin maleateandtincarboxylatebased

stabilizers. While not as good in terms of heat stability in comparison to tinmercaptide stabilizers, these heat stabilizers provide

excellent light stability and are finding growing use especially in outdoor applications such as transparent and translucent double

walledpanelsforgreenhouses,andsiding/windowprofiles.

ArkemahasaddednewcosteffectivebutyltinmercaptidestabilizerstoitsestablishedThermoliteproductrange.Thermolite130and

Thermolite 135 tinstabilizerscanbeused asasinglestabilizer,permitting loweroverall tincontentwithoutimpactingthequalityof

rigidPVCpipeextrusionsusedinsuchdemandingpipeapplicationsasthinwallagricultural,largediameter,andsewerpipe.These

stabilizerscanalsobeusedinextrusionofelectricalconduitandtelephoneducts.Inadditiontoreducingmaterialcosts,theuseofa

single stabilizer can decrease inventory costs and cut blending errors. A third new cost effective grade of butyltin mercaptide

stabilizersisThermolite150designedforhighoutputextrusionofwindowprofilesandotherdemandingrigidapplications.

Addressingthetypical'sulfurlike'odorofmanyorganotinsduetothepresenceoffreemercaptans,AkcrosChemicalshasdeveloped

anewlowodorreverseesterorganotinmercaptidestabilizerforthePVCsiding,fencingandprofileextrusionmarkets.AkcrostabT

5311containsamercaptanchemicaltrapdesignedtocreateauniquelylowodororganotinmercaptideheatstabilizer.

NanoscaledMg(OH)

2

FlameRetardantAdditive

Aqueous colloidal chemistry is also being successfully applied to the development of nanoscaled flame retardants. Headwaters

Technology Innovation Group (HTIG) develops and deploys a range of breakthrough technologies that improve natural resource

utilizationthrough the application of nanotechnology. One such material is a nanoscaled magnesium hydroxide,'NxCat' Mg(OH)

2

,

which is primarily used as a flame retardant additive and is PVC compounding applicable. As halogenated flame retardants are

graduallyphasedoutforenvironmentalandlegislativereasonsnew'greener'FRsarebeingsought.EnvironmentallyfriendlyMg(OH)

2

hasbeenused asalternative however,upto 60%loading isrequiredas aresultofthelowefficiencyofthe microsize Mg(OH)

2

.

Suchhighloadinglevelsontheotherhandimpairthemechanicalperformanceofplastic.Inordertomaximizethewaterreleaseand

flame extinguishing effect of Mg(OH)

2

, HTIG is using its manufacturing process which allows very small crystallites (~3 nm) of Mg

(OH)

2

toformandresultsinaverylargesurfaceareaandsuperiordispersionofthenanoscaledMg(OH)

2

inthepolymer/composite

materials.

MultifunctionalAntioxidantAdvances

Irgatec NC 66 is proprietary antioxidant system developed by BASF to address the unique stabilizing requirements of nanoclay

basednanocomposites.Thematerialisspecificallydevelopedtoenhancetheheatstabilityofnanoclaycompositeswhileprocessing,

to permit faster, hotter processing conditions. The additive package also reduces odor upon processing, retards yellowing during

aging, and improves longterm heat and light stability. This patented blend of phenolic and other antioxidant functionalities, plus

calcium organic salts, and metal oxides works on the different elements of a nanocomposite that are known to increase risk of

degradation,includingthenanoclay,compatibilizer,andimpactmodifier.

Multifunctional antioxidants are a relatively recent advance that beneficially combines both primary and secondary antioxidant

functionsinonecompound.Combiningmultiplestabilizingfunctionsinonemoleculeeliminatestherequirementforcostabilizersto

be used (i.e., phosphites, thioesters) greatly simplifying antioxidant storage, handling, and formulation. Irganox 1520 and Irganox

1726fromBASFaretwoprincipalantioxidantproductsinthisnewclassofstabilizers.Thesetypeantioxidantsareusedinpolyvinyl

chloride(PVC),aswellaslinearlowdensitypolyethylene(LLDPE),highdensitypolyethylene(HDPE),andstyrenebutadienerubber

(SBR).

Figure4:BaerostabNT3521PStaticHeatStability

(Source:BaerlocherGmbH)

Figure5:NanoscaledMg(OH)

2

(Source:HeadwatersTechnology

InnovationGroup)

Pgina3de4 TheLatestinPVCAdditivesandCompoundsHighTechSolutions! Article

04/08/2012 http://www.specialchem4polymers.com/resources/articles/article.aspx?id=6896&lr=m...

PVCAdditivesandCompoundsTechnologySources

JoinSpecialChemExpertTeam:WriteArticles/AnswerTechnicalRequests/ConductOnlineTrainingCourses...

Defineyourexpertiseandapplyhere!

SpecialChem4PolymersMembersReactions

Jul11,2012

postedbyAbdulKarimQasim,Production/ManufacturingatNationalCo.forSponge&PlasticIND

Jun13,2012

postedbyMichaelWorns,R&DApplied/Formulation/ProductdevelopmentatDampingTechnologies,Inc.

Figure6:MultifunctionalAntioxidant

(Source:BASF)

Table1:PVCAdditivesandCompoundsTechnologySources

Company Website

PlasticsInstituteofAmerica www.plasticsinstitute.org

InstituteofPolymerScience&Technology www.ictp.csic.es

GrandorthSpecialtyChemicals www.grandorth.com

Baerlocher www.baerlocher.com

Arkema www.arkemainc.com

AkcrosChemicals www.akcros.com

ArchnowpartofLonza

http://www.specialchem4polymers.com/tc/biocides

solutions/index.aspx

LearnmoreaboutLonza'sSolutions:

http://www.specialchem4polymers.com/tc/antioxidant/index.aspx?

id=productselection

HeadwatersTechnologyInnovationGroup www.headwaters.com

BASFPerformanceProducts

http://www.basf.com/group/corporate/en/aboutbasf/profile/performance

products

alertmoderator|addyourreaction

alertmoderator|addyourreaction

RatethisDocument

TitleofyourReaction

YourReaction

Advice:

Beconcise(you'llhavebetterchancestobereadbyother

Members!)

Becourteous

Don'tpostdiscriminatoryorcommerciallyorientedmessage(s)

Wereservetherighttoremovesomecommentsnotalignedwith

thischarter.

^ ^

" "

Selectinfoyouwouldliketobepublishedwithyour

Reaction:

M|."

Name VictorCastrejon

M|."

Company PolymerAdditivess.l.

M|."

JobDepartment " Marketing/Sales

AboutSpecialChem AboutSpecialChem4Polymers CommercialAccelerationServices Advertisewithus

ContactUs ForgotyourUserID/Password? SiteMap RSS TermsandConditions SpecialChemPortal

Copyright2012SpecialChemS.A.

Pgina4de4 TheLatestinPVCAdditivesandCompoundsHighTechSolutions! Article

04/08/2012 http://www.specialchem4polymers.com/resources/articles/article.aspx?id=6896&lr=m...

Anda mungkin juga menyukai

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Technical Information: TMS - VHPDokumen1 halamanTechnical Information: TMS - VHPVictor CastrejonBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Tmse PDFDokumen1 halamanTmse PDFVictor CastrejonBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Technical Information: Pyrobloc® Sap2 and Sap5Dokumen2 halamanTechnical Information: Pyrobloc® Sap2 and Sap5Victor CastrejonBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Technical Information: TMS D Catalyst GradeDokumen1 halamanTechnical Information: TMS D Catalyst GradeVictor CastrejonBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Technical Information: Sodium Antimonate-EDokumen1 halamanTechnical Information: Sodium Antimonate-EVictor CastrejonBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Technical Information: Microfine VHPDokumen1 halamanTechnical Information: Microfine VHPVictor CastrejonBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Technical Information: Antimony Trioxide Wetted GradesDokumen1 halamanTechnical Information: Antimony Trioxide Wetted GradesVictor CastrejonBelum ada peringkat

- Pyrobloc SAP-2 PDFDokumen1 halamanPyrobloc SAP-2 PDFVictor CastrejonBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Technical Information: TMS Catalyst Grade PHPDokumen1 halamanTechnical Information: TMS Catalyst Grade PHPVictor CastrejonBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Technical Information: Atc-HclDokumen1 halamanTechnical Information: Atc-HclVictor CastrejonBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- PolymerAdditives - Thanox 1010 - TDS - 2011-AugustDokumen1 halamanPolymerAdditives - Thanox 1010 - TDS - 2011-AugustVictor CastrejonBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- PolymerAdditives - Thanox 1098 - TDS - April-2013Dokumen1 halamanPolymerAdditives - Thanox 1098 - TDS - April-2013Victor CastrejonBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Technical Information: Antimony MetalDokumen1 halamanTechnical Information: Antimony MetalVictor CastrejonBelum ada peringkat

- Technical Information: Antimony TrichlorideDokumen1 halamanTechnical Information: Antimony TrichlorideVictor CastrejonBelum ada peringkat

- PolymerAdditives - Thanox 1076 - TDS - 2012-JuneDokumen1 halamanPolymerAdditives - Thanox 1076 - TDS - 2012-JuneVictor CastrejonBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Technical Information: Microfine Catalyst Grade PHP Antimony TrioxideDokumen1 halamanTechnical Information: Microfine Catalyst Grade PHP Antimony TrioxideVictor CastrejonBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Technical Information: Antimony Trioxide GG Antimony TrioxideDokumen1 halamanTechnical Information: Antimony Trioxide GG Antimony TrioxideVictor CastrejonBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- PolymerAdditives - Thanox 1035 - TDS - 2013-MayDokumen1 halamanPolymerAdditives - Thanox 1035 - TDS - 2013-MayVictor CastrejonBelum ada peringkat

- Thanox 412S - TDS - 2011-August PDFDokumen1 halamanThanox 412S - TDS - 2011-August PDFVictor CastrejonBelum ada peringkat

- PolymerAdditives - Thanox 626 - TDS - May-2013 PDFDokumen1 halamanPolymerAdditives - Thanox 626 - TDS - May-2013 PDFVictor CastrejonBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- PolymerAdditives - Rianlon Chemical - Thanox 168 - MSDS - 2011-AugustDokumen5 halamanPolymerAdditives - Rianlon Chemical - Thanox 168 - MSDS - 2011-AugustVictor CastrejonBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1091)

- GLS - 2013 Feiplast Brazil PDFDokumen60 halamanGLS - 2013 Feiplast Brazil PDFVictor CastrejonBelum ada peringkat

- Latihan Soal CausativeDokumen1 halamanLatihan Soal Causativeanakosagista anakosagistaBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Form Filling & Submission QueriesDokumen3 halamanForm Filling & Submission QueriesMindbanBelum ada peringkat

- Vishnu Dental College: Secured Loans Gross BlockDokumen1 halamanVishnu Dental College: Secured Loans Gross BlockSai Malavika TuluguBelum ada peringkat

- Direct Method (Education) : Navigation SearchDokumen5 halamanDirect Method (Education) : Navigation Searcheisha_91Belum ada peringkat

- Industrial Thread (Sewing Thread)Dokumen8 halamanIndustrial Thread (Sewing Thread)sandhyaishtaBelum ada peringkat

- Formulating Affective Learning Targets: Category Examples and KeywordsDokumen2 halamanFormulating Affective Learning Targets: Category Examples and KeywordsJean LabradorBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Auto Loan Application Form - IndividualDokumen2 halamanAuto Loan Application Form - IndividualKlarise EspinosaBelum ada peringkat

- Em Swedenborg THE WORD EXPLAINED Volume IX INDICES Academy of The New Church Bryn Athyn PA 1951Dokumen236 halamanEm Swedenborg THE WORD EXPLAINED Volume IX INDICES Academy of The New Church Bryn Athyn PA 1951francis batt100% (2)

- Dbms QuoteDokumen2 halamanDbms QuoteAnonymous UZFenDTNMBelum ada peringkat

- RAW TM & HM Users Manual V 11Dokumen8 halamanRAW TM & HM Users Manual V 11arcangelus22Belum ada peringkat

- Revalida ResearchDokumen3 halamanRevalida ResearchJakie UbinaBelum ada peringkat

- Cambridge IGCSE: PHYSICS 0625/63Dokumen16 halamanCambridge IGCSE: PHYSICS 0625/63...Belum ada peringkat

- Icecream ScienceDokumen6 halamanIcecream ScienceAnurag GoelBelum ada peringkat

- Partnership Liquidation May 13 C PDFDokumen3 halamanPartnership Liquidation May 13 C PDFElla AlmazanBelum ada peringkat

- All About Me - RubricDokumen3 halamanAll About Me - Rubricapi-314921155Belum ada peringkat

- Class 10 Science Super 20 Sample PapersDokumen85 halamanClass 10 Science Super 20 Sample PapersParas Tyagi100% (1)

- Drug StudyDokumen1 halamanDrug StudyBSN 3-2 RUIZ, Jewel Anne F.Belum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Silent Reading With Graph1Dokumen2 halamanSilent Reading With Graph1JonaldSamueldaJoseBelum ada peringkat

- Decoding The Ancient Kemetic CalendarDokumen9 halamanDecoding The Ancient Kemetic CalendarOrockjo75% (4)

- Discuss Both Views Introduction PracticeDokumen3 halamanDiscuss Both Views Introduction PracticeSang NguyễnBelum ada peringkat

- Death and Dying: Presented by Dr. Judith SugayDokumen21 halamanDeath and Dying: Presented by Dr. Judith SugayMichelle HutamaresBelum ada peringkat

- Windows Server Failover Clustering On HPE SimpliVity Technical White Paper-A50000833enwDokumen15 halamanWindows Server Failover Clustering On HPE SimpliVity Technical White Paper-A50000833enwYeraldo MarinBelum ada peringkat

- 01.performing Hexadecimal ConversionsDokumen11 halaman01.performing Hexadecimal ConversionsasegunloluBelum ada peringkat

- Services Marketing-Unit-Ii-ModifiedDokumen48 halamanServices Marketing-Unit-Ii-Modifiedshiva12mayBelum ada peringkat

- Due Process of LawDokumen2 halamanDue Process of Lawjoe100% (4)

- Top German AcesDokumen24 halamanTop German AcesKlaus Richter100% (1)

- The Java Collections Framework: InterfacesDokumen22 halamanThe Java Collections Framework: InterfacesSourav DasBelum ada peringkat

- Micro Analysis Report - Int1Dokumen3 halamanMicro Analysis Report - Int1kousikkumaarBelum ada peringkat

- The Wolves of The CoastDokumen10 halamanThe Wolves of The CoastJose David DíazBelum ada peringkat

- Class 11 Biology Notes Chapter 2 Studyguide360Dokumen10 halamanClass 11 Biology Notes Chapter 2 Studyguide360ABelum ada peringkat

- Process Plant Equipment: Operation, Control, and ReliabilityDari EverandProcess Plant Equipment: Operation, Control, and ReliabilityPenilaian: 5 dari 5 bintang5/5 (1)

- The Certified Oil and Gas Project ManagerDari EverandThe Certified Oil and Gas Project ManagerPenilaian: 4 dari 5 bintang4/5 (2)

- Well Control for Completions and InterventionsDari EverandWell Control for Completions and InterventionsPenilaian: 4 dari 5 bintang4/5 (10)

- Well Integrity for Workovers and RecompletionsDari EverandWell Integrity for Workovers and RecompletionsPenilaian: 5 dari 5 bintang5/5 (3)