Pohnpei Hospital Preliminary Engineering Report

Diunggah oleh

Usman FaarooquiHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pohnpei Hospital Preliminary Engineering Report

Diunggah oleh

Usman FaarooquiHak Cipta:

Format Tersedia

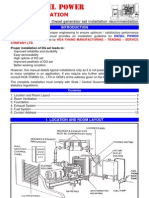

Preliminary Engineering Report Pohnpei State Hospital Emergency Generator

June 29, 2010 Pohnpei State submitted the attached pre-Design Planning Document for funding of the replacement of the State Hospitals Emergency Generator. The project was to include: 1. The removal and disposal of the old 600 KW Emergency Generator. 2. The procurement and installation of a new 600 KW Emergency Generator. 3. The procurement and installation of a new Automatic Transfer Switch (ATS). (No allowance was made in their cost estimate to remove and dispose of the old ATS.) 4. The procurement and installation of a 550 gallon fuel storage tank on a new concrete pad. JEMCO approved the project only for a Preliminary Engineering Report to clarify the project scope and cost estimate. The attached PDP indicates that the ATS was inoperable and that the generator had reached its peak usage and required a major overhaul. It was further stated that an overhaul could not be performed because the Hospital did not have parts and service manuals. The emergency generator was inspected in April of 2010 by members of the PMU professional staff. They confirmed that the ATS was inoperable due to a failed actuator. Contacts with the manufacturer revealed that parts were no longer available for the unit. The ATS Is a 1000 Amp switch manufactured by Russelectric of Hingham, Mass, model SRMT-10004CT, Serial No. 8747. A replacement switch is estimated to cost approximately $20,000 (see attached quote), with another $5,000 required for installation of the new ATS and disposal of the old switch. The generator is a 600 kW Caterpillar 3412, Serial Number 81Z03362, Arrangement 2W7900. The unit was found to be fully operational and with the exception of a few minor maintenance problems was in excellent condition. The unit did not have a running hour meter, but from discussions with the maintenance staff, is estimated to have only about 2000 running hours. This model engine requires a top end overhaul at 10,000 hours and a major overhaul at 24,000 hours. An overhaul is not required at this time. The minor maintenance items noted were: 1. The fan drive belts were worn and required replacement. 2. The battery cable terminals had been replaced with automotive units which are undersized. These should be replaced with OEM parts from Caterpillar.

3. One core had been cut out of the radiator to repair a leak. It is estimated that this has reduced the cooling capacity of the radiator by up to 5%. Since the generator is only loaded to about 50% of capacity, this will have no adverse effect on generator operation. No action is recommended at this time. 4. There was a minor oil seepage from the breather in the valve cover. This is normal for an engine without positive crankcase ventilation and no action is recommended at this time. Parts and Service manuals are available from Caterpillar at an estimated cost of $300 (see attached quote). The existing generator is served by 2 existing bulk storage tanks with an estimated capacity of 20,000 gallons each. There was no evidence of leakage or extensive corrosion and the tanks are considered to be in good condition. Both tanks require painting, inside and out and repainting. A large ironwood tree next to the perimeter fence should be removed to avoid future root damage to the foundation. It is recommended that the replacement of the ATS be accomplished by contract funded as an Infrastructure Project. It is recommended that the maintenance problems with the generator and the fuel tanks be accomplished by the Hospital maintenance staff funded as an Infrastructure Maintenance Project.

Prepared by:

Robert A. Westerfield, III, P.E. PMU Resident Engineer, Yap

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Turbine ErectionDokumen131 halamanTurbine ErectionSam92% (12)

- Guide For Electrical Design Engineers - Chapter 5: Mitigation of Voltage UnbalanceDokumen16 halamanGuide For Electrical Design Engineers - Chapter 5: Mitigation of Voltage UnbalanceHans De Keulenaer100% (5)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Role of Needs Analysis in Adult ESL Programme Design: Geoffrey BrindleyDokumen16 halamanThe Role of Needs Analysis in Adult ESL Programme Design: Geoffrey Brindleydeise krieser100% (2)

- Mis Report On Ola CabsDokumen18 halamanMis Report On Ola CabsDaksh MaruBelum ada peringkat

- NATF Dallas 20150604 JContoDokumen16 halamanNATF Dallas 20150604 JContoUsman FaarooquiBelum ada peringkat

- Application Challenges GFMDokumen12 halamanApplication Challenges GFMUsman Faarooqui100% (1)

- A Review of Optimization Techniques For Hybrid Renewable Energy SystemsDokumen16 halamanA Review of Optimization Techniques For Hybrid Renewable Energy SystemsUsman FaarooquiBelum ada peringkat

- NATF Dallas 20150604 JContoDokumen16 halamanNATF Dallas 20150604 JContoUsman FaarooquiBelum ada peringkat

- BlackBerry - PlayBook - Tablet User - Guide 1526983 0418113733 001 1.0 US PDFDokumen48 halamanBlackBerry - PlayBook - Tablet User - Guide 1526983 0418113733 001 1.0 US PDFUsman FaarooquiBelum ada peringkat

- OdzDokumen62 halamanOdzTudor RatiuBelum ada peringkat

- Basis MATLABDokumen4 halamanBasis MATLABUsman FaarooquiBelum ada peringkat

- Reporting of M. Tech. Candidates For AdmissionDokumen3 halamanReporting of M. Tech. Candidates For AdmissionDevender SharmaBelum ada peringkat

- Hoa Thang Genset Installation GuidelineDokumen8 halamanHoa Thang Genset Installation GuidelineUsman FaarooquiBelum ada peringkat

- Apr Jun12 PetrofedDokumen92 halamanApr Jun12 PetrofedUsman FaarooquiBelum ada peringkat

- Hoa Thang Genset Installation GuidelineDokumen8 halamanHoa Thang Genset Installation GuidelineUsman FaarooquiBelum ada peringkat

- GeneratorDokumen1 halamanGeneratorelectricalconsultantBelum ada peringkat

- SHAW Superdew 3 Specification SheetDokumen3 halamanSHAW Superdew 3 Specification SheetGeetha ManoharBelum ada peringkat

- Lecture 11 - Performance AppraisalsDokumen23 halamanLecture 11 - Performance AppraisalsCard CardBelum ada peringkat

- INSTRUCTIONAL SUPERVISORY PLAN 1st Quarter of SY 2023 2024 Quezon ISDokumen7 halamanINSTRUCTIONAL SUPERVISORY PLAN 1st Quarter of SY 2023 2024 Quezon ISayongaogracelyflorBelum ada peringkat

- Relay G30 ManualDokumen42 halamanRelay G30 ManualLeon KhiuBelum ada peringkat

- DYCONEX Materials en 2020 ScreenDokumen2 halamanDYCONEX Materials en 2020 ScreenhhaiddaoBelum ada peringkat

- Apps Android StudioDokumen12 halamanApps Android StudioDaniel AlcocerBelum ada peringkat

- Riveted JointsDokumen28 halamanRiveted Jointsgnbabuiitg0% (1)

- Lesson 2 (Probability of An Event)Dokumen4 halamanLesson 2 (Probability of An Event)MarlBelum ada peringkat

- Vectors Notes (Answers)Dokumen24 halamanVectors Notes (Answers)ScionBelum ada peringkat

- 22-28 August 2009Dokumen16 halaman22-28 August 2009pratidinBelum ada peringkat

- Chapter 07Dokumen16 halamanChapter 07Elmarie RecorbaBelum ada peringkat

- Review Rachna WasteDokumen9 halamanReview Rachna WasteSanjeet DuhanBelum ada peringkat

- 3.15.E.V25 Pneumatic Control Valves DN125-150-EnDokumen3 halaman3.15.E.V25 Pneumatic Control Valves DN125-150-EnlesonspkBelum ada peringkat

- AB-005-2020 Dated 10.09.2020 (SKF-Prestine)Dokumen3 halamanAB-005-2020 Dated 10.09.2020 (SKF-Prestine)AliasgarBelum ada peringkat

- IDL6543 ModuleRubricDokumen2 halamanIDL6543 ModuleRubricSteiner MarisBelum ada peringkat

- Chen 2021Dokumen13 halamanChen 2021Aitor UzkudunBelum ada peringkat

- Pre Intermediate Talking ShopDokumen4 halamanPre Intermediate Talking ShopSindy LiBelum ada peringkat

- Florida Motor Fuel Tax Relief Act of 2022Dokumen9 halamanFlorida Motor Fuel Tax Relief Act of 2022ABC Action NewsBelum ada peringkat

- Selecting Appropriate Instructional Materials For Edukasyong Pantahanan at Pangkabuhayan/ Technology and Livelihood EducationDokumen35 halamanSelecting Appropriate Instructional Materials For Edukasyong Pantahanan at Pangkabuhayan/ Technology and Livelihood EducationJhenn Mhen Yhon100% (1)

- GoodElearning TOGAF Poster 46 - Adapting The ADMDokumen1 halamanGoodElearning TOGAF Poster 46 - Adapting The ADMFabian HidalgoBelum ada peringkat

- Dimmable Bulbs SamplesDokumen11 halamanDimmable Bulbs SamplesBOSS BalaBelum ada peringkat

- Activity 2Dokumen5 halamanActivity 2DIOSAY, CHELZEYA A.Belum ada peringkat

- Each Life Raft Must Contain A Few ItemsDokumen2 halamanEach Life Raft Must Contain A Few ItemsMar SundayBelum ada peringkat

- Video Tutorial: Machine Learning 17CS73Dokumen27 halamanVideo Tutorial: Machine Learning 17CS73Mohammed Danish100% (2)

- N6867e PXLP 3000Dokumen7 halamanN6867e PXLP 3000talaporriBelum ada peringkat

- Pursuit of Performance Findings From The 2014 Miller Heiman Sales Best Practices StudyDokumen37 halamanPursuit of Performance Findings From The 2014 Miller Heiman Sales Best Practices StudyLoredanaBelum ada peringkat

- Operations and Service ManualDokumen311 halamanOperations and Service ManualELARD GUILLENBelum ada peringkat

- Yumemiru Danshi Wa Genjitsushugisha Volume 2Dokumen213 halamanYumemiru Danshi Wa Genjitsushugisha Volume 2carldamb138Belum ada peringkat