FCAW Temper Bead Iamot - Org

Diunggah oleh

Claudia MmsDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

FCAW Temper Bead Iamot - Org

Diunggah oleh

Claudia MmsHak Cipta:

Format Tersedia

The Maintenance and Integrity of Thick Walled Pressure Vessels by Using Temper Bead Welding Technique

R.N. Ibrahim, Department of Mechanical Engineering, Monash University T. Shehata, Department of Mechanical Engineering, Monash University Abstract This paper investigates the Temper Bead welding (TBW) technique using the Flux Cored Arc Welding (FCAW) process. The FCAW process increases productivity, improves welding efficiency and provides a more cost-effective method of Temper Bead Welding (TBW) repairs compared with the other commonly used TBW techniques such as manual metal arc welding (MMAW) and gas metal arc welding (GMAW) which use solid wire. An automatic welding rig was created so that the TBW process could be tested using flux cored wire under different conditions. An experimental investigation was conducted to find the optimal welding parameters of the TBW using FCAW. This experimental investigation was done in order to provide the desired mechanical properties and microstructures without PostWelding Heat Treatment (PWHT). Due to the difficulties encountered in the determination of residual stresses, the weld penetration depth into the base material was used as a guide to control residual stresses. In this study, analytical solution was used to support the use of TBW to repair damaged structures. This solution was based on statistical and experimental data. These data were used to establish the relationships between the technological parameters of TBW and the factors responsible for the quality of the required structure. Keywords: Temper bead welding, Flux cored arc welding, Solid wires, Post welding heat treatment, Manual metal arc welding, Gas metal arc welding and Penetration Introduction According to the ASME standard, the conventional repair welding for wall steel constructions, which have a thickness of more than 40 mm requires PWHT to achieve the desired microstructure properties. The microstructure of the welding surrounded area is affected by the heat of the welding process. This affected area is known as the heat-affected zone (HAZ). The desired microstructure properties of HAZ are these properties which are as close as possible to the parent material properties. For some structures, however, PWHT is very expensive or difficult. Publications to date [1,2], have shown that the temper bead welding (TBW) can provide the desired microstructure properties of the welding without PWHT. The TBW provides that satisfactorily and solid wire welding processes such as MMAW or GMAW are applied to TBW successfully. TBW is used to heat-treat the welded part or parts during the welding process instead of PWHT. TBW employs a multiple-pass deposition of the welding metal. Each layer of beads provides heat for the thermal treatment of the microstructure of the previous weld bead or the layer, as shown in figure 1. TBW techniques have been used successfully for a number of repairs in USA and Canada, by using manual metal arc welding (MMAW) process or gas metal arc welding (GMAW) process, and its use is accepted and specified by the ASME Boiler and Pressure Vessel codes [3].

The quality of the temper bead-welding repair is very sensitive to some welding parameters [2] specific to the welding process employed. These parameters are the welding position and its effect on the bead shape, the bead deposition sequence, the welding current, the traverse speed, the arc length, the wire feeding speed, the torch angle, the preheat and inter-run temperatures and the heat inputs.

B - Maximum fusion boundary, II - layer U - Maximum fusion boundary, I layer C - average layer height, I -layer R - Maximum depth of refining zone, II-Layer.

---Weld metal ---Coarse Grained HAZ ---Fine Grained HAZ ---Partial Transformation

Figure 1. Two-layer section shown schematically exhibiting approximately 85% refinement of the first layer coarse grained HAZ by the second layer [3]. There are several industry-attractive aspects of TBW that need further investigation. One of these is the application of the flux-cored arc welding (FCAW) process that uses hollow welding wire filled with flux. There has been limited research into the effectiveness of this process [2,3] but a preliminary study [4 and 5] indicates that FCAW might have a number of advantages over the commonly used solid wires such as MMAW or GMAW process. The welding parameters that can provide the required microstructure and minimum residual stresses in thick walled weldments need to be established to validate the application of flux cored arc welding (FCAW). The Relationship between the Welding Parameters and the Depth of Penetration The depth of penetration is a direct result of the welding heat input. It is necessary to have a desirable depth of penetration to gain sufficient bonding between the parent material and the welding material. Normally, the process of quickly heating and cooling the welding region is associated with residual stresses and different grain sizes across the HAZ. The welding heat source is the applied electrical power (E) and the amount of the welding heat input (H) depends on the welding traverse speed (v ) along the parent material beside the applied electrical power. E=I*V* Watt---------------------------------------------( 1 ) Where I is the welding electrical current in Amp, V is the welding voltage in volt and is the electrical power transmission efficiency. () can be considered equal one in case of measuring I and V as close as possible to the welding spot. Welding heat input can be calculated by applying equation (2) H = (0.06 * I * V) / v kJ/mm----------------------------------------( 2 )

Where v is traverse speed in mm/min In the FCAW process, the welding electrical current (I) is adjusted automatically according to the wire feeding speed. The welding voltage adjusted for the welding electrode size. It is clear, therefore, that the effects of (I) and (V) are limited and controlled, which means that the traverse speed (v) has the main effect on the welding heat input (H). Another parameter that should be considered is the arc length (A). The (A) represents the intensity of the welding heat source. Experimental work The investigation was conducted by using the automatic welding rig shown in figure 2. The traveling mechanism (A) was operated with constant speeds varying from 120 mm/min to 700 mm/min. The wire feeding system (15) was operated at 820 to 5600 mm/min. The welding machine (B) was worked at up to 400A. Experimental data was collected to study the relationship between the depth of penetration and the welding main parameters as presented in Table 1. The welds were divided into three groups, Group 1, Group 2 and Group 3. In each group only one parameter was changed. For Groups 1 and 2 the arc length was changed, for Group 3 the traverse speed was changed. Two different gases were used in the manufacturing of the welds, for Groups 1 and 3, Argon Shield 100 gas was used, but for Group 2 CO2 gas was used. Commercially manufactured C-Mn steel plates of 10 and 12 mm thickness were used for all welds in this investigation. A steel plate of 12 mm thickness was used for Groups 1 and 2, but a plate of 10 mm thickness was used for Group 3. The voltage for Groups 1; 2 and 3 were 30, 29 and 29 volts respectively. The electrical current for welds of Groups 1; 2 and 3 were 350, 380 and 380 respectively. The weldments (see Table 1) were manufactured using the basic flux-cored wire (AWS A5.20:E70T-4). Table 1. The temper bead welding carried out using different Shield gases and Traverse speeds. Group No. Pass No. Traverse Speed mm/min. 620 620 620 620 620 620 1000 253.5 600 Arc length (A) mm. 25 29 23 23 28 25 25 25 25 Penetration (P) Mm. 5 4.5 6 4.5 4 5 4 8 6

1 2 3 4 5 6 7 8 9

1500

1200

Figure 2. Experimental Installation A) Traveling mechanism B) Welding machine C) 12-channel chart recorder. D) Real time-temperature chart recorder. E) Preheating elements controller. 1. 240V low speed motor. 2. Fine current control for motor. 3. Travel speed gauge. 4. Frame carriage. 5. Steel wheels. 6. Gear. 7. Variable head. 8. Welding torch. 9. Work piece. 10.Electrical heating elements. 11. Main frame. ( horizontal beam) 12. Main frame. ( Supporting legs) 13. Table 14. Welding lead. 15.Welding wire feeding system. Results and Discussion By applying Merit Function 2 on Groups 1 and 3, a mathematical relationship between the depth of penetration (P) as output and the traverse speed (v ) and the arc length (A) as inputs can be presented as following: P = -0.0054 v + 0.93 A - 0.023 A2 (3) From equation (3), the relationship between the depth of penetration (P) and either the traverse speed (v ) at different arc lengths or the arc length (A) at different traverse speeds can be plotted as shown in Figures (3) and (4) respectively.

Penetration P

6 4 2 2 0 0 4 0 0 20 6 0 0 800 1000 15 25

30

in mm

Arc Length A in mm

Traverse Speed v in mm/min

Figure 3. The relationship between Traverse Speed v , Arc Length A and Penetration P of welds (groups 1 and 3, Argon Shield 100 gas).

arc length in different traverse speeds 10 9 8 7

v = 100 mm/min

The Depth of Penetration P in mm

6 5 4 3 2 1 0 5 10 15 20 25 30

v = 200 mm/min v = 300 mm/min v = 400 mm/min v = 500 mm/min v = 600 mm/min v = 700 mm/min v = 800 mm/min v = 900 mm/min v = 1000 mm/min

35

40

The Arc Length A in mm

Figure 4. The relationship between the depth of penetration (P) and the arc length (A) in different traverse speeds. The relationship between the depth of penetration (P) and the arc length (A) at different traverse speeds (as shown in Figures 3 and 4) demonstrates that a decrease in the traverse speed at the same arc length is associated with an increase in the depth of penetration. Between arc length 5and 20.22 mm, any increase in the arc length at the same traverse speed is associated with an increase in the depth of penetration. Therefore, with increasing heat, the spark heat, more heat transfers through the parent material. In the case of the small arc length, the welding torch absorbed a fraction of the heat. The heat conductivity of the torch material is higher than that of the low carbon steel, so less heat transfers to the parent material. Also at this stage, the same penetration was achieved when an increase in the arc length was associated with an increase in the traverse speed. Furthermore, any increase in the arc length between 20.22 and 30 mm was associated with a decrease in the depth of penetration as the surrounding ambient absorbs more heat. A comparison of the results from [4&5] for FC wires and the results from [7] for solid wires, reveals that FC wires achieved deeper penetration for the same welding conditions (heat input, arc length and traverse speed). Therefor if the same welding conditions, to achieve the same depth of penetration, then FC wires should be operated in faster speed than the solid wire. Therefore, the FCAW process can provide higher productivity than solid wire processes. Conclusion Using FCAW process with TBW technique will increase the productivity, improve welding operation and efficiency and provide a more cost-effective method of weld repairs to the industry in comparison with the other commonly processes known with TBW technique such as MMWA and GMAW.

Reference [1] Lundin,C.D., "Overview of Results from PVRC Program on Half-Bead / Temper-Bead / Controlled Deposition Technique for Improvement of Fabrication and Service Performance of Cr-Mo Steel", 1996, WRC Bulletin 412, p. 16 - 26. [2] Lau, T. W., Lau M. L. et al., "Development of Controlled Deposition Repair Welding Procedures at Ontario Hydro", 1996, WRC Bulletin 412, p. 35 - 42. [3] Edgley J. S. and Pitrun M., "The Temper Bead Weld Repair of the Hazelwood Steam Drums", Pressure Vessels and Pipwork Conference, Sydney April 27 - 28, 1993. [4] Ibrahim R. N., and Shehata T., "Effect of Flux Wire on Tempered Bead Welding Technique to Repair Damaged Carbon Steel Structure", ICM8, 8th International Conference on the Mechanical Behavior of Materials, Canada, British Colombia, May 16 - 21, 1999. [5] Ibrahim R. N., and Shehata T., "Effect of Welding Operation Parameters on the Depth of Penetration in Flux Cored Arc Welding Applications", 9th International Conference on Pressure Vessels Technology, Australia, Sydney, April 9 - 14, 2000. [6] Sato, M., Suda, K. et al., How to Weld Using Flux Cored Wires Journal of Japan Welding Society, 1996, 65, (6), p. 13 20. [7] Ahmed, N. U. and Jarvis, B. L., The effect of welding condition on the thermal cycles in single electrode submerged arc welding Australian welding journal, V43, 3rd. Quarter 1998.

Title: The Maintenance And Integrity Of Thick Walled Pressure Vessels By Using Temper Bead Welding Technique R.N.Ibrahim, Department of Mechanical Engineering, Monash University 900 Dandenong Road, Caulfield East, 3145, Victoria, Australia. T.Shehata, Department of Mechanical Engineering, Monash University 900 Dandenong Road, Caulfield East, 3145, Victoria, Australia.

Anda mungkin juga menyukai

- Study On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelDokumen8 halamanStudy On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelIJMERBelum ada peringkat

- Titipan ZahraDokumen7 halamanTitipan ZahraDikaAfriandiBelum ada peringkat

- Transient High-Frequency Welding Simulations of Dual-Phase SteelsDokumen9 halamanTransient High-Frequency Welding Simulations of Dual-Phase Steelsc131508Belum ada peringkat

- The Effect of Gas Metal Arc Welding (GMAW) Processes On Different Welding Parameters - DoneDokumen5 halamanThe Effect of Gas Metal Arc Welding (GMAW) Processes On Different Welding Parameters - DoneAsim AliBelum ada peringkat

- Study On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelDokumen8 halamanStudy On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelAngga Pamilu PutraBelum ada peringkat

- Scad 2012 3 3 228Dokumen6 halamanScad 2012 3 3 228Cyril J PadiyathBelum ada peringkat

- WAAM by HarpuneetDokumen25 halamanWAAM by Harpuneethpsingh0078Belum ada peringkat

- Kobelco Flux Coated Wires 2009Dokumen28 halamanKobelco Flux Coated Wires 2009Uthanmalliah NagarajanBelum ada peringkat

- Revista - Materials Science ForumDokumen5 halamanRevista - Materials Science Forum0741005518Belum ada peringkat

- Nik Weld ParameterDokumen5 halamanNik Weld ParameterHarmish BhattBelum ada peringkat

- Optimizing Tensile Strength of Low-Alloy Steel Joints in Upset WeldingDokumen5 halamanOptimizing Tensile Strength of Low-Alloy Steel Joints in Upset Weldingabraham silva hernandezBelum ada peringkat

- Fracture Behaviour of Dissimilar Metallic Welds: Specimens and Pipe Weld With CrackDokumen9 halamanFracture Behaviour of Dissimilar Metallic Welds: Specimens and Pipe Weld With Crackmade dwi payanaBelum ada peringkat

- Journal of Materials Processing Technology: Se-Yun Hwang, Yooil Kim, Jang-Hyun LeeDokumen12 halamanJournal of Materials Processing Technology: Se-Yun Hwang, Yooil Kim, Jang-Hyun LeeGrantHermanBelum ada peringkat

- MET 48 3 181 185 Samardzic PDFDokumen5 halamanMET 48 3 181 185 Samardzic PDF0000Belum ada peringkat

- Ijret20150403006 PDFDokumen5 halamanIjret20150403006 PDFPatricio G. ArrienBelum ada peringkat

- 2020-Le Van Thao-TCSJDokumen13 halaman2020-Le Van Thao-TCSJlethao2011Belum ada peringkat

- 11 2002 BANG SDokumen10 halaman11 2002 BANG SsumoomusBelum ada peringkat

- Temper Bead TechniqueDokumen4 halamanTemper Bead TechniqueOctavio ChableBelum ada peringkat

- The Effect of Rotational Speed On Flow BDokumen8 halamanThe Effect of Rotational Speed On Flow Bالسيد ابراهيم عبدالعزيز عبداللهBelum ada peringkat

- Experimental Investigation On The Effects of Process Parameters of GMAW and Transient Thermal Analysis of AISI321 SteelDokumen16 halamanExperimental Investigation On The Effects of Process Parameters of GMAW and Transient Thermal Analysis of AISI321 SteelumisaaadahBelum ada peringkat

- Lázaro Plata 2020 J. Phys. Conf. Ser. 1587 012034Dokumen8 halamanLázaro Plata 2020 J. Phys. Conf. Ser. 1587 012034fernandoBelum ada peringkat

- Ipc2012 90242Dokumen8 halamanIpc2012 90242Marcelo Varejão CasarinBelum ada peringkat

- Effect of Welding Speed and Post Weld Heat Treatment On Microstructural and Mechanical Properties of Alpha Beta Titanium Alloy EB WeldsDokumen13 halamanEffect of Welding Speed and Post Weld Heat Treatment On Microstructural and Mechanical Properties of Alpha Beta Titanium Alloy EB Weldsvamsi krishnaBelum ada peringkat

- Effect of Cooling Rate On Microstructure of Saw Welded Mild Steel Plate (Grade C 25 As Per IS 1570)Dokumen7 halamanEffect of Cooling Rate On Microstructure of Saw Welded Mild Steel Plate (Grade C 25 As Per IS 1570)sivaBelum ada peringkat

- MRT-10-2 Arc Welding Principle and SSWDokumen27 halamanMRT-10-2 Arc Welding Principle and SSW1026Aniket TankBelum ada peringkat

- Fitup Tolerances For Mechanized Gas Tungsten Arc Welding Large Diameter PipeDokumen10 halamanFitup Tolerances For Mechanized Gas Tungsten Arc Welding Large Diameter Piperahulchitrakoot123Belum ada peringkat

- Dumkal Institute of Engineering & TechnologyDokumen6 halamanDumkal Institute of Engineering & TechnologyabcBelum ada peringkat

- Group H Lab7-8Dokumen12 halamanGroup H Lab7-8tkovacs22Belum ada peringkat

- A Review Paper On Optimization of Shield PDFDokumen8 halamanA Review Paper On Optimization of Shield PDFZen KingBelum ada peringkat

- Microstructure Analysis of Arc Welded Mild Steel Plates: IOP Conference Series: Materials Science and EngineeringDokumen7 halamanMicrostructure Analysis of Arc Welded Mild Steel Plates: IOP Conference Series: Materials Science and EngineeringAniekanBelum ada peringkat

- Effect of Heat Treatment On Corrosion Resistance of Friction Stir Welded AA 2024 Aluminum Alloy - Hani Aziz AmeenDokumen10 halamanEffect of Heat Treatment On Corrosion Resistance of Friction Stir Welded AA 2024 Aluminum Alloy - Hani Aziz AmeenHani Aziz AmeenBelum ada peringkat

- Saw Weld ProcedureDokumen21 halamanSaw Weld ProcedurePhani KumarBelum ada peringkat

- The Mechanical Properties and Microstructures of 9% Chromium Steel P92 WeldmentsDokumen23 halamanThe Mechanical Properties and Microstructures of 9% Chromium Steel P92 WeldmentspkguptaqaqcBelum ada peringkat

- 191 Ijmperdjun2019191Dokumen8 halaman191 Ijmperdjun2019191TJPRC PublicationsBelum ada peringkat

- Welding Procedures Specification For Flux Cored Arc Welding of Wind TowersDokumen10 halamanWelding Procedures Specification For Flux Cored Arc Welding of Wind TowersMuhammad Nursalam ZulkifliBelum ada peringkat

- Tungsten Inert Gas WeldingDokumen5 halamanTungsten Inert Gas WeldingMohak PatelBelum ada peringkat

- Weld Repair of Manganese Frogs For Enhanced Safety Shared Service PDFDokumen20 halamanWeld Repair of Manganese Frogs For Enhanced Safety Shared Service PDFpumud pumudBelum ada peringkat

- Unit-3 Metal Joining Processes-1Dokumen20 halamanUnit-3 Metal Joining Processes-1Himanshu TiwariBelum ada peringkat

- Mmech AprilDokumen6 halamanMmech AprilVidyut KumarBelum ada peringkat

- 3 13Dokumen8 halaman3 13pitoulabeteBelum ada peringkat

- A10 Effects of Welding Processes On The Mechanical Properties of HY 80 Steel WeldmentsDokumen9 halamanA10 Effects of Welding Processes On The Mechanical Properties of HY 80 Steel WeldmentsXBelum ada peringkat

- Welding MP-IDokumen28 halamanWelding MP-IPIYUSH SHARMABelum ada peringkat

- GMAWDokumen42 halamanGMAWMuhammed SulfeekBelum ada peringkat

- Optimization of Welding Parameters of Submerged Arc Welding Process: A ReviewDokumen6 halamanOptimization of Welding Parameters of Submerged Arc Welding Process: A ReviewsettaBelum ada peringkat

- 1.8.1 - MIG - MAG WeldingDokumen88 halaman1.8.1 - MIG - MAG WeldingReza DhonyBelum ada peringkat

- Laser-TIG Welding of Titanium AlloysDokumen8 halamanLaser-TIG Welding of Titanium AlloysRobert ShinBelum ada peringkat

- Process Design Multi Stage Wire DrawingDokumen8 halamanProcess Design Multi Stage Wire DrawingoscarBelum ada peringkat

- A IntroDokumen41 halamanA IntroPratik PatelBelum ada peringkat

- Penetration Estimation of GTAW With C-Type Filler by Net Heat Input RatioDokumen9 halamanPenetration Estimation of GTAW With C-Type Filler by Net Heat Input RatioBrad ReedBelum ada peringkat

- Investigation of Effect of Electric Arc Welding Parameters On Welding QualityDokumen5 halamanInvestigation of Effect of Electric Arc Welding Parameters On Welding QualityIOSRjournalBelum ada peringkat

- High-Speed Arc Welding of Sheet MetalDokumen14 halamanHigh-Speed Arc Welding of Sheet MetalJose JuanBelum ada peringkat

- Parametric Optimization of Mig WeldingDokumen8 halamanParametric Optimization of Mig WeldingMihaela NastaseBelum ada peringkat

- Optimization of Process Parameters Affecting Gas Tungsten Arc Welding of AA6082Dokumen5 halamanOptimization of Process Parameters Affecting Gas Tungsten Arc Welding of AA6082erpublicationBelum ada peringkat

- A Comparison of Mechanical Properties Between Plasma Arc Welding Paw and Four Popular Type of Welding Process Smaw Gmaw - Ilovepdf-CompressedDokumen13 halamanA Comparison of Mechanical Properties Between Plasma Arc Welding Paw and Four Popular Type of Welding Process Smaw Gmaw - Ilovepdf-CompressedAlireza KhodabandehBelum ada peringkat

- Welding ProcessDokumen2 halamanWelding ProcessRadhey KrishnaBelum ada peringkat

- How to prepare Welding Procedures for Oil & Gas PipelinesDari EverandHow to prepare Welding Procedures for Oil & Gas PipelinesPenilaian: 5 dari 5 bintang5/5 (1)

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysDari EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysBelum ada peringkat

- Advantages and Limitations of Martensitic Steels For FusionDokumen4 halamanAdvantages and Limitations of Martensitic Steels For FusionClaudia MmsBelum ada peringkat

- How To Become Certified by ASME 2010Dokumen2 halamanHow To Become Certified by ASME 2010quiron2010Belum ada peringkat

- What Is Bellows Pressure Thrust PDFDokumen2 halamanWhat Is Bellows Pressure Thrust PDFClaudia MmsBelum ada peringkat

- Titanium Spec - Chart PDFDokumen1 halamanTitanium Spec - Chart PDFClaudia MmsBelum ada peringkat

- An Introduction To Cathodic Protection PDFDokumen5 halamanAn Introduction To Cathodic Protection PDFGERMAN1979Belum ada peringkat

- Chemical Analysis Test Report: Element Sample T-1 Sample B-2 SAE/AISI Gr. A356.0Dokumen2 halamanChemical Analysis Test Report: Element Sample T-1 Sample B-2 SAE/AISI Gr. A356.0Claudia MmsBelum ada peringkat

- Expansion of The Sourcebook For Hydrogen Applications 03-10-2006Dokumen1 halamanExpansion of The Sourcebook For Hydrogen Applications 03-10-2006Claudia MmsBelum ada peringkat

- Inspection and Welding Repairs of Pressure VesselsDokumen9 halamanInspection and Welding Repairs of Pressure VesselsClaudia Mms100% (1)

- Condition of The Firetube Right After Removal From ServiceDokumen1 halamanCondition of The Firetube Right After Removal From ServiceClaudia MmsBelum ada peringkat

- Owen Barfield BibliographyDokumen50 halamanOwen Barfield BibliographyClaudia MmsBelum ada peringkat

- WRC Bulletin No 506 Half-Bead Temper-BeadDokumen2 halamanWRC Bulletin No 506 Half-Bead Temper-BeadClaudia MmsBelum ada peringkat

- DPVC 09 PetrobrasDokumen47 halamanDPVC 09 PetrobrasClaudia MmsBelum ada peringkat

- In Situ Repair Welding of Steam Turbine ShroudDokumen7 halamanIn Situ Repair Welding of Steam Turbine ShroudClaudia MmsBelum ada peringkat

- Welding of Stainless Steels and Other Joining Methods: A Designers' Handbook Series N 9 002Dokumen18 halamanWelding of Stainless Steels and Other Joining Methods: A Designers' Handbook Series N 9 002Sreenivas GuduruBelum ada peringkat

- EPRI Repair & Replacement Apps Center - Socket Weld Repair Issues 1013562Dokumen20 halamanEPRI Repair & Replacement Apps Center - Socket Weld Repair Issues 1013562Claudia Mms100% (1)

- Temper Bead Welding ProceduresDokumen8 halamanTemper Bead Welding ProceduresClaudia Mms100% (1)

- Metrode WPS SuperduplexDokumen4 halamanMetrode WPS SuperduplexClaudia Mms100% (3)

- Solidification Cracking in SS Welds Pe1119Dokumen24 halamanSolidification Cracking in SS Welds Pe1119Claudia Mms100% (1)

- Design and Development of SMA-actuated CPR SystemDokumen11 halamanDesign and Development of SMA-actuated CPR SystemHarsh NigamBelum ada peringkat

- Chemistry Love PoemDokumen1 halamanChemistry Love PoemMohd FarisBelum ada peringkat

- Cymel 1158Dokumen2 halamanCymel 1158sidneidecarvalhoBelum ada peringkat

- MSDS DECON Beton InstanDokumen5 halamanMSDS DECON Beton InstanMuhammad RidwanBelum ada peringkat

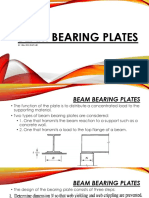

- 7-B. Beam Bearing PlatesDokumen14 halaman7-B. Beam Bearing PlatesMelchizedek EllBelum ada peringkat

- Properties Value: Ug-23 Maximum Allowable Stress ValuesDokumen2 halamanProperties Value: Ug-23 Maximum Allowable Stress ValuesMohamad Faiz ZulkipliBelum ada peringkat

- PRACRES Source Report: Use of Plastic Waste in Road ConstructionDokumen9 halamanPRACRES Source Report: Use of Plastic Waste in Road ConstructionadingmarasiganBelum ada peringkat

- 1 s2.0 S0950061820318560 MainDokumen7 halaman1 s2.0 S0950061820318560 MainElias SoaresBelum ada peringkat

- Lecture 1Dokumen22 halamanLecture 1Sameer HussainBelum ada peringkat

- Unit Test-II (SOM) 1Dokumen2 halamanUnit Test-II (SOM) 1hasanBelum ada peringkat

- Key Concept Chapter 10 ElectrolysisDokumen20 halamanKey Concept Chapter 10 ElectrolysisKim KatBelum ada peringkat

- Scraper Wiper LimpiadorDokumen100 halamanScraper Wiper LimpiadorRPINILLA (EICO S.A.)Belum ada peringkat

- Processing of Oil SeedsDokumen20 halamanProcessing of Oil SeedsRohit Ramesh KaleBelum ada peringkat

- Journey of DiamondDokumen7 halamanJourney of DiamondPratyusha AgarwalBelum ada peringkat

- Coordination CompoundsDokumen8 halamanCoordination CompoundsAbhishek SharmaBelum ada peringkat

- Pile Estimate Excel FileDokumen3 halamanPile Estimate Excel FileShakil AhamedBelum ada peringkat

- MasterTemp 125 High Performance Heater Installation and Users Guide EnglishDokumen56 halamanMasterTemp 125 High Performance Heater Installation and Users Guide Englishjesus javier ceme kooBelum ada peringkat

- C0051-11 Standard Terminology Relating To Lime and Limestone (As Used by The IndustryDokumen5 halamanC0051-11 Standard Terminology Relating To Lime and Limestone (As Used by The IndustryAnonymous YwFJrk0yCBelum ada peringkat

- L3 Rock-Forming MineralsDokumen35 halamanL3 Rock-Forming MineralsTJ gatmaitanBelum ada peringkat

- Mivan 9Dokumen40 halamanMivan 9vishaliBelum ada peringkat

- Mild Steel Hollow Section - Square, Rectangular, Circular - MetaDokumen10 halamanMild Steel Hollow Section - Square, Rectangular, Circular - MetaAshebir AjemaBelum ada peringkat

- Micro EdmDokumen58 halamanMicro EdmPranes RainaBelum ada peringkat

- Bill of Material: 103PW2 - PL5/16"X4" - 1'-3" - 2 REQ'DDokumen1 halamanBill of Material: 103PW2 - PL5/16"X4" - 1'-3" - 2 REQ'Dai ambaraBelum ada peringkat

- Lopez PrefiDokumen5 halamanLopez PrefiCarl Adrienne LopezBelum ada peringkat

- Unit-5 PTDokumen136 halamanUnit-5 PTTanay NaikBelum ada peringkat

- 1-Pentene: Cautionary Response InformationDokumen2 halaman1-Pentene: Cautionary Response InformationMumahmmad Rizwan RBelum ada peringkat

- Casting 1Dokumen32 halamanCasting 1Ahmed MahmoudBelum ada peringkat

- DSM-0329.1 WokaDur NiE ElectrodeDokumen4 halamanDSM-0329.1 WokaDur NiE ElectrodeAlireza KhodabandehBelum ada peringkat

- Light Rails: National Standard of The People's Republic of ChinaDokumen13 halamanLight Rails: National Standard of The People's Republic of ChinaBaoBelum ada peringkat

- Closed Drain PaperDokumen4 halamanClosed Drain PaperBehnam Hosseinzadeh100% (1)