Anton Paar - Inline Pump

Diunggah oleh

ikuzma_1Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Anton Paar - Inline Pump

Diunggah oleh

ikuzma_1Hak Cipta:

Format Tersedia

M

e

a

s

u

r

e

,

w

h

a

t

|

s

m

e

a

s

u

r

a

b

|

e

,

a

n

d

m

a

k

e

m

e

a

s

u

r

a

b

|

e

t

h

a

t

w

h

|

c

h

|

s

n

o

t

.

G

a

|

|

|

e

o

G

a

|

|

|

e

|

1

5

6

4

-

1

6

4

2

}

Instruction Manual

Inline Pump 5

Original Instructions

Instruction Manual

Inline Pump 5

Original Instructions

Anton Paar GmbH assumes no liability for technical or printing errors or omissions in this document.

Nor is any liability assumed for damages resulting from information contained in the document.

Anton Paar GmbH reserves the right to content changes. This also extends to changes to delivery

volumes or any features of delivered parts.

All rights reserved (including translation). This document, or any part of it, may not be reproduced,

changed, copied, or distributed by means of electronic systems in any form (print, photocopy, microfilm

or any other process) without prior written permission by Anton Paar GmbH.

Trademarks, registered trademarks, trade names, etc. may be used in this manual without being marked

as such. They are the property of their respective owner.

Published by Anton Paar

Printed: Anton Paar, Austria

Copyright 2010 Anton Paar GmbH, Graz, Austria

Address: Anton Paar GmbH

Anton-Paar-Str. 20

A-8054 Graz / Austria Europe

Tel: +43 316 257-0

Fax: +43 316 257-257

E-mail: info@anton-paar.com

Web: www.anton-paar.com

Date: 11.11.2010

Document number C99IB001EN-B

C99IB001EN-B 5

Contents

1 About the Instruction Manual ......................................................................................................... 7

2 Safety Instructions........................................................................................................................... 8

2.1 General Safety Instructions ..................................................................................................... 8

2.1.1 Liability..................................................................................................................... 8

2.1.2 Installation and Use of Inline Pump 5....................................................................... 8

2.1.3 Maintenance and Service......................................................................................... 9

2.1.4 Disposal.................................................................................................................... 9

2.1.5 Returns..................................................................................................................... 9

3 Inline Pump 5 An Overview........................................................................................................ 10

4 Checking the Supplied Parts ........................................................................................................ 13

5 Design of the Inline Pump 5.......................................................................................................... 14

5.1 Material Certificates............................................................................................................... 14

6 Installation and Putting into Operation........................................................................................ 15

6.1 Preparing the Instrument....................................................................................................... 15

6.2 Dry Run of the Inline Pump 5................................................................................................. 15

6.3 Process Connection of the Inline Pump 5.............................................................................. 16

6.3.1 Installation Position ................................................................................................ 16

6.3.2 Types of Installation................................................................................................ 16

6.3.2.1 Connection to DPRn 427S / DSRn 427S............................................... 16

6.3.2.2 Connection to DPRn 427 / DSRn 427..................................................... 20

6.3.2.3 Connection via Retrofit Kit Inline Fitting Varivent with Mounting Support22

6.3.2.4 Connection via Tri-Clamp Adapter.......................................................... 24

6.4 Electrical Cabling.................................................................................................................. 24

6.4.1 Connecting the Mains Supply................................................................................. 24

6.4.2 Grounding............................................................................................................... 26

6.4.3 Connecting the CAN-Bus ....................................................................................... 26

6.5 Self diagnosis of the Inline Pump 5....................................................................................... 27

6.5.1 Installation with mPDS 5........................................................................................ 27

6.5.2 Installation with mPDS 2000 V3............................................................................. 29

6.5.2.1 Differential relay for Inline Pump 5.......................................................... 29

6.6 Installation.............................................................................................................................. 30

6.6.1 Checklist for Putting into Operation........................................................................ 30

7 Cleaning the Instrument ................................................................................................................ 32

8 Maintenance and Service.............................................................................................................. 33

8.1 Inline Pump 5 Parameters..................................................................................................... 35

9 Document Numbers....................................................................................................................... 37

6 C99IB001EN-B

1 About the Instruction Manual

C99IB001EN-B 7

1 About the Instruction Manual

This instruction manual informs you about the installation and the safe handling

and use of the product. Pay special attention to the safety instructions and

warnings in the manual and on the product.

The instruction manual is a part of the product. Keep this instruction manual for

the complete working life of the product and make sure it is easily accessible to

all people involved with the product. If you receive any additions or revisions to

this instruction manual from Anton Paar GmbH, these must be treated as part of

the instruction manual.

Conventions for safety messages

The following conventions for safety messages are used in this instruction

manual:

CAUTION Caution indicates a risk of damage to goods.

TIP Tip gives extra information about the situation at hand.

WARNING

Warning indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

Warning: Hot surface

This symbol calls attention to the fact that the respective surface can get

very hot. Do not touch this surface without adequate protective measures.

2 Safety Instructions

8 C99IB001EN-B

2 Safety Instructions

Read the instruction manual at hand before using Inline Pump 5.

Follow all hints and instructions contained in this instruction manual to

ensure the correct use and safe functioning of Inline Pump 5.

2.1 General Safety Instructions

2.1.1 Liability

The instruction manual at hand does not claim to address all safety issues

associated with the use of the instrument and liquids to be pumped. It is your

responsibility to establish health and safety practices and determine the

applicability of regulatory limitations.

Anton Paar GmbH only warrants the proper functioning of

Inline Pump 5 if no adjustments have been made to the mechanics,

electronics, and software.

Only use the Inline Pump 5 for the purpose described in this instruction

manual. Anton Paar GmbH is not liable for damages caused by incorrect use

of the Inline Pump 5.

2.1.2 Installation and Use of Inline Pump 5

The installation procedure should only be carried out by authorized

personnel who are familiar with the installation instructions.

The Inline Pump 5 is safe to run dry. Regarding a long service performance

the pump should be switched off when the plant is stopped for a longer time.

There is a risk of injury whenever the pump head is open and during

activation of the pump. When working on the open pump head, make sure

the mains supply or the pump control is securely switched off and cannot be

switched on without authorization.

Make sure all operators are trained to use the instrument safely and correctly

before starting any applicable operations.

Do not use any accessories or wearing parts with the Inline Pump 5 other

than those supplied and/or approved by Anton Paar GmbH.

Mechanical knocks and vibrations may damage the pump. Work on the

instrument with care.

2 Safety Instructions

C99IB001EN-B 9

In case of damage or malfunction, do not continue operating the Inline Pump

5. Do not operate the instrument under conditions which could result in

damage to goods and/or injuries and loss of life.

Check that Inline Pump 5 is chemically resistant to the samples and

cleaning agents.

2.1.3 Maintenance and Service

There is a risk of injury whenever the pump head is open and during

activation of the pump. When working on the open pump head, make sure

the mains supply or the pump control is securely switched off and cannot be

switched on without authorization.

Inline Pump 5 is typically subject to harsh process conditions like shock

pressure, sudden temperature changes, aggressive samples, vibrations, etc.

Sudden changes of the measurement values or malfunctions may occur.

Check continuously that it is functioning perfectly.

Repair and service procedures may only be carried out by authorized

personnel or by service engineers from Anton Paar GmbH.

2.1.4 Disposal

Concerning the disposal of Inline Pump 5, observe the legal requirements in

your country.

2.1.5 Returns

For repairs send the cleaned Inline Pump 5 unit to your Anton Paar

representative. Only return the instrument together with the filled out

"Maintenance/Error Report and the "Standard Maintenance Contract. Find the

applicable forms on the Anton Paar homepage (www.anton-paar.com).

http://www.anton-paar.com/Safetydeclaration/Safetydeclaration.zip.

Make sure you pack Inline Pump 5 securely to prevent further damage occurring

during transport. This is especially important if you are sending back an

instrument under warranty. If possible, use the original packaging.

3 Inline Pump 5 An Overview

10 C99IB001EN-B

3 Inline Pump 5 An Overview

The Inline Pump 5 is a sample pump for non-corrosive liquids. It supplies a

number of measuring instruments with a constant flow of sample. The instrument

is a centrifugal pump with a magnetic coupling. The pump is suitable for hygienic

applications.

Fig. 3 - 1 Inline Pump with connection kit for DPRn/DSRn

3 Inline Pump 5 An Overview

C99IB001EN-B 11

Combination with different conntion kits

The modular design of the Inline Pump 5 means that it can be combined with

different connection kits in order to connect it to the main line using different

flanges and to a transducer. For more information on connector sets, see

Chapter Appendix A: "Technical Data".

Fig. 3 - 2 For example: Inline Pump 5 with connection kit for DPRn 427S /

DSRn 427S

Applications

Sample pump for liquids. Used to supply a transducer or measuring system

with constant flow of sample.

Suitable for use in the food industry.

Liquids to be measured

Alcoholic and non-alcoholic beverages, liquids in the food industry

All low-viscosity liquids as long as the wetted parts of the Inline Pump 5 are

resistant to the liquid.

3 Inline Pump 5 An Overview

12 C99IB001EN-B

Features and benefits

Robust housing made of stainless steel for operation under harsh process

conditions in interior and exterior areas

Modular design, combination with different connection and retrofit kits

Safe to run dry

Maintenance-free

Water-proof in accordance with IP67

Hygienic design according to EHEDG

Certified raw materials with material certificates for the metal parts and

O-rings which come into contact with the sample.

Fulfills the NAMUR recommendations NE 107 (self-diagnosis).

4 Checking the Supplied Parts

C99IB001EN-B 13

4 Checking the Supplied Parts

The Inline Pump 5 has been tested and packed carefully before shipment.

However, damage may occur during transport.

1. Keep the packaging material (box, foam piece, transport protection) for

possible returns and further questions from the transport and/or insurance

company.

2. Compare the supplied parts to those given in the table below to check that

the delivery is complete.

3. If a part is missing, contact your Anton Paar representative.

4. If a part is damaged, contact the transport company and your Anton Paar

representative.

Table 4.1: Supplied Parts

Symbol Pcs. Article Description Mat. No.

1 Inline Pump 5

(connection kits are optionally available,

see Chapter Appendix A: "Technical

Data").

89722

1 Instruction Manual

1 Optional:

connection kits are optionally available,

see Chapter Appendix A: "Technical

Data".

5 Design of the Inline Pump 5

14 C99IB001EN-B

5 Design of the Inline Pump 5

The Inline Pump 5 is for continuously filling a transducer. It can be installed

directly on the transducer and at the main line. The pump is a hermetically sealed

radial pump with a magnetically coupled drive, all built into a compact housing.

The design of the pump makes it suitable for hygienic applications.

The Inline Pump 5 consists of a housing which is dustproof and waterproof

according to IP67.

Inline Pump 5 is safe to run dry. However, to ensure a long working life avoid

running the pump dry if possible.

5.1 Material Certificates

The numbers of the material certificates of all wetted parts of the pump can be

traced via the pumps serial number.

6 Installation and Putting into Operation

C99IB001EN-B 15

6 Installation and Putting into Operation

CAUTION Before installation, read this instruction manual carefully. Incorrect operation

can lead to damage to the pump.

Mechanical knocks and vibrations may damage the pump. Work on the

instrument with care.

6.1 Preparing the Instrument

6.2 Dry Run of the Inline Pump 5

The Inline Pump 5 will not be destroyed by dry run. If the pump runs dry, the

impeller will lose pace and stop eventually. Only after switching the pump

electronics off and on, the pump starts again. Regarding a long service

performance the pump should be switched off when the plant is stopped for a

longer time.

It is recommended to stop the pump (installation with mPDS 5) or to disconnect

the power supply (installation with mPDS 2000) in case of empty line.

WARNING

Installation, putting into operation, maintenance and service work should

only be carried out by trained and authorized personnel.

Observe the permissible operating and ambient conditions for the pump

(see Appendix A: Technical Data).

There is a risk of minor or moderate injury whenever the pump head is

open and during activation of the pump. When working on the open pump

head, make sure the mains supply or the pump control is securely

switched off and cannot be switched on without authorization.

(Hot) liquids may spray out of the pump head!

Perform a visual check and check the leaktightness after working on the

pump.

For connecting the pump to the main line and/or to the density transducer,

only use the connection kits from Anton Paar.

Do not exceed the defined maximum pressure and maximum sample

temperature for the pump (see Chapter Appendix A: "Technical Data").

Risk of burns! The surfaces of the sample connections and the wetted

parts of the pump heat up to the temperature of the sample after a period

of time. The operator is responsible for ensuring protection from burns.

WARNING

When lifting and transporting the Inline Pump 5 with the corresponding

connection adapter, observe the valid regulations for the prevention of

accidents and the generally recognized codes of practice.

6 Installation and Putting into Operation

16 C99IB001EN-B

6.3 Process Connection of the Inline Pump 5

CAUTION When connecting the Inline Pump 5 to the process line, follow the instructions in

the following chapters concerning installation position and installation.

6.3.1 Installation Position

You can choose the installation location, depending on the connection kit.

To ensure that the pump can empty itself compeletely, the pump must be installed

vertically.

If the pump is installed in combination with an Anton Paar density transducer,

make sure that the pump does not transfer any vibrations from the pipe to the

transducer.

6.3.2 Types of Installation

The Inline Pump is connected to the main line via different connection kits. Some

of the different types of installation are listed below:

6.3.2.1 Connection to DPRn 427S / DSRn 427S

The connection kit with DPRn 427S/DSRn 427S connects DPRn 427S and DSRn

427S density transducers with the Inline Pump 5 and the main line. The Varivent

N type flange is installed directly in the main line. The sealing surfaces are sealed

using O-rings made of EPDM. All sealing elements which come into contact with

sample are FDA-conform.

WARNING

Make sure that the main line is empty and unpressurized before installing

or removing the pump.

The pipes and instruments may be hot. In this case wait for the entire plant

to cool off.

After installation in the pipe, the pump must be rinsed with a cleaning

agent.

Before filling with sample or cleaning agent, check the chemical resistance

of the wetted parts (see Chapter Appendix A: "Technical Data").

WARNING

Do not exceed the maximum operating pressure (see Chapter Appendix A:

"Technical Data") of the Inline Pump 5, the connection kits and the mounting

support.

6 Installation and Putting into Operation

C99IB001EN-B 17

TIP The pipe pressure must be at least 1.5 bar (21.8 psi) in order to guarantee a

perfect operation of the Inline Pump.

The highest pumpage account to the mounting position of the in- and outlet bore

holes (see Fig. 6 - 1 and Fig. 6 - 2) of the connection kit.

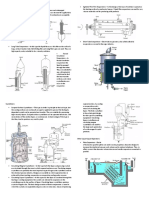

Fig. 6 - 1 Mounting position

Fig. 6 - 2 Direction of flow

6 Installation and Putting into Operation

18 C99IB001EN-B

Fig. 6 - 3 Assembly DrawingConnection Kit DPRn 427S / DSRn 427S

TIP In horizontal position the transducer must be supported (see fig. 6 - 4 and 6 - 5).

6 Installation and Putting into Operation

C99IB001EN-B 19

Fig. 6 - 4 Front view

Fig. 6 - 5 Lateral view

6 Installation and Putting into Operation

20 C99IB001EN-B

6.3.2.2 Connection to DPRn 427 / DSRn 427

The connection kit Inline DPRn 427 / DSRn 427 connects DPRn 427 and DSRn

427 density transducers to the Inline Pump 5 and the main line.

Installation also requires the mounting support Inline Fitting or mounting support

Inline Pump 5 (see Fig. 6 - 6). The Varivent N type flange is installed directly in

the main line. The sealing surfaces are sealed using O-rings made of EPDM. All

sealing elements which come into contact with sample are FDA-conform.

TIP The line pressure must be at least 1.5 bar (21.8 psi) in order to guarantee a

perfect operation of the Inline Pump.

6 Installation and Putting into Operation

C99IB001EN-B 21

Fig. 6 - 6 Assembly drawing Connection to DPRn 427 / DSRn 427

6 Installation and Putting into Operation

22 C99IB001EN-B

6.3.2.3 Connection via Retrofit Kit Inline Fitting Varivent with Mounting

Support

The retrofit kit Inline Fitting Varivent with Mounting Support is an extension of the

mounting support (Mat. No.: 17821, 18121, 18122, 19034, 18105, 21747 or

19978) to install the Inline Pump 5 instead of the Inline Fitting. The retrofit kit is

suitable when an existing Inline Fitting Varivent is not enough to produce sufficient

constant flow through the transducer.

TIP The line pressure must be at least 1.5 bar (21.8 psi) in order to guarantee a

perfect operation of the Inline Pump.

6 Installation and Putting into Operation

C99IB001EN-B 23

Fig. 6 - 7 Assembly drawing Modification of Inline Fitting Varivent with

Mounting Support

6 Installation and Putting into Operation

24 C99IB001EN-B

6.3.2.4 Connection via Tri-Clamp Adapter

The Triclamp connection kit is suitable for connecting Inline Pump 5 to any

instruments with a Triclamp connection.

Fig. 6 - 8 Connection via Tri-Clamp adapter

6.4 Electrical Cabling

6.4.1 Connecting the Mains Supply

Power supply:

SELV DC 24 V, 3 A

Required cables:

Mains supply cable: 2-pole shielded cable

Choose the cables diameters to ensure optimal sealing at the cable gland

(4.5 - 10 mm).

Cross section of the cable:

Recommended cable type: LiYCY.

TIP The power supply unit and connecting cables are not included in the delivery.

To connect the cable to the Inline Pump 5, you must open the lid of the electronic

housing. Make sure that no humidity or other contaminations are introduced into

the electronics housing.

WARNING

The Inline Pump 5 may only be operated with SELV DC 24 V (3 A)

Disconnect from the mains supply before connecting or disconnecting the

electrical cables.

6 Installation and Putting into Operation

C99IB001EN-B 25

1. Unscrew the three screws at the rear and open the electronics housing.

2. Unscrew the cable gland and feed the cable through.

3. Place the shielding appropriately.

Fig. 6 - 9 Placing the shielding

4. Fix the connecting terminals (see Fig. 6 - 10)

(DC 24 V to terminal +; GND to terminal -)

Fig. 6 - 10 Cabling plan

5. Close the electronics housing and tighten the cable glands. Pay attention to

leak-tightness.

6. The Inline Pump 5 must be grounded via the plant.

6 Installation and Putting into Operation

26 C99IB001EN-B

6.4.2 Grounding

The Inline Pump 5 must be grounded via the plant. To ground the pump, connect

the connnecting adapter to the main line.

6.4.3 Connecting the CAN-Bus

CAN is a 2 wire bus system. All members are connected parallel to this bus

system. A 120 Ohm terminating resistor must be connected at each end to avoid

reflections.

All Smart Sensors and Inline Pumps are delivered with a 120 Ohm resistor

between "CAN H" and "CAN L" at "CAN out". If more Inline pumps or Smart

Sensors are connected to an mPDS 5 remove the resistors and connect the CAN

cable.

TIP The maximum cable length for a CAN bus system is 250 m.

You can order the CAN cable Mat. No. 94268 for the Inline Pump 5 optionally.

Specifications CAN cable 94268:

2 x 2 x 2.22 mm

2

twisted pair

shielded

Characteristic impedance (1 MHz). 126 Ohm

Conductor resistance 186 Ohm/km

Cable sheath: PVC violet, external diameter 7.1 mm

Temperature range -40C to +70C

Cabling Plan

6 Installation and Putting into Operation

C99IB001EN-B 27

Fig. 6 - 11 Cabling

Cabling Plan CAN-Bus

Fig. 6 - 12 Cabling Plan

6.5 Self diagnosis of the Inline Pump 5

The Inline Pump 5 is equipped with the self diagnosis according to NAMUR NE

107. The pump shuts down by itself automatically, if the microcontroller

recognises an error.

The error messages are listed in Chapter 6.5.1 "Installation with mPDS 5".

The Inline Pump 5 could be installed in two different ways described in chapters

Chapter 6.5.1 "Installation with mPDS 5" and Chapter 6.5.2 "Installation with

mPDS 2000 V3".

6.5.1 Installation with mPDS 5

In case of errors the Inline Pump 5 sends error messages to the mPDS 5. The

pump shuts down by itself. The error message must be reset via the mPDS 5 (see

Fig. 6 - 13)

CAN in CAN out Wire color cable 94268

CAN H 1 4 yellow

CAN L 2 5 green

CAN GND 3 6 brown

6 Installation and Putting into Operation

28 C99IB001EN-B

TIP The communication between mPDS 5 and the Inline Pump 5 (CAN open) is

possible from mPDS 5 software version 3.0.

Fig. 6 - 13 Example: Error message

Error Message Reason / Troubleshooting

Stall Error Blocked impeller or pump motor.

Remove pump adapter and check impeller for

damaging.

Watchdog Error Blocked impeller or pump motor.

Remove pump adapter and check impeller for

damaging.

Motor Current too

low

Required motor current consumption too low.

Check specifications of the power supply (min. 3 A)

Optionally install stronger power supply.

Motor Current too

high

Motor current consumption too high.

Viscosity of liquid could be too high.

Start up the Inline Pump without liquid. If the error

message appears again, send the pump back to your

Anton Paar representative.

6 Installation and Putting into Operation

C99IB001EN-B 29

6.5.2 Installation with mPDS 2000 V3

When using the Inline Pump 5 in combination with the mPDS2000 V3 it is not

possible to view error messages from the pump because there is no CAN

interface on the mPDS 2000 V3.

For diagnosis purposes in this case you can optionally order the error relay

(Mat. No. 94380), see Chapter 6.5.2.1 "Differential relay for Inline Pump 5".

6.5.2.1 Differential relay for Inline Pump 5

The differential relay measures and controls the current of the Inline Pump. In

case of a fault the current of the Inline Pump 5 falls below the adjusted level of

0.5 A and the bottom contact of the relay opens.

Voltage too low Supply voltage too low.

Minimum power supply 20 VDC

Measure the voltage at the pump (min. 20 VDC)

Optionally install a stronger power supply or raise

voltage at an adjustable power supply.

Voltage too high Supply voltage too high.

Maximum voltage: 30 VDC.

Measure the voltage at the Inline Pump 5

(max. 30 VD C).

Motor Temperature

too high

Maximum motor temperature exceeded.

Check liquid temperature:

CIP temp.: +120 C max. 30 min.

Max. liquid temperature: +100C

Power

Consumption too

high

Maximum motor temperature exceeded. Check voltage

and current consumption.

Voltage: max. 30 VDC

Current: max. 3 A

Speed Deviation

too high

Motor cannot hold the set motor speed.

Decrease motor speed with the mPDS 5.

The viscosity of liquid may be too high.

Microchip -

Temperature too

high

Overstepping temperature at the electronic board of

the Inline Pump 5 exceeded. Maximum temperature at

the Microchip: 85C

Check liquid temperature:

CIP temp.: +120 C max. 30 min

Max. liquid temperature: +100C

Error Message Reason / Troubleshooting

6 Installation and Putting into Operation

30 C99IB001EN-B

Fig. 6 - 14 Differential relay

6.6 Installation

Observe the following points before installing Inline Pump 5.

Flow setting:

The Inline Pump 5 is preconfigured at the factory. The set speed and therefore

the flow volume can be only changed with an mPDS 5.

The Inline Pump 5 is safe to run dry. However, to ensure a long working life avoid

running the pump dry if possible.

6.6.1 Checklist for Putting into Operation

1. Install the Inline Pump 5 in the production line (see Chapter 6.3 "Process

Connection of the Inline Pump 5").

2. Check the tightness of the system: After successful installation, make sure that

the connections are secure and leak-tight.

3. For the electrical wiring of the pump (see Chapter 6.4 "Electrical Cabling").

WARNING

Observe the safety instructions given in chapter Chapter 2.1.2 "Installation

and Use of Inline Pump 5".

6 Installation and Putting into Operation

C99IB001EN-B 31

4. Cleaning: Before the pump comes into contact with product, it must be cleaned

with the plant (to remove deposits which collected during installation, see Chapter

7 "Cleaning the Instrument").

5. Start the Inline Pump 5: Make sure that the production line is pressurized and

that there is sample flow.

7 Cleaning the Instrument

32 C99IB001EN-B

7 Cleaning the Instrument

The Inline Pump 5 is suitable for CIP (max. 120C for 30 min) cleaning.

The pump is cleaned during the CIP procedure in the main line.

WARNING

The pump is constructed for a maximum temperature. See Chapter Appendix

A: "Technical Data".

C99IB001EN-B 33

8 Maintenance and Service

If the Inline Pump 5 is correctly operated it is maintenance-free and service-free.

The service work is limited to exchanging the pump impeller (Mat.nr. 82381) and

sealing elements of the connector sets.

Fig. 8 - 1 Changing the pump impeller

Fig. 8 - 2 Installing the new pump impeller

TIP Mount the new pump impeller only with tongs. Strong magnetic attraction! The

impeller and the ceramic bearing of the pump can be destroyed by strong bounce.

34 C99IB001EN-B

Only use original spare parts from Anton Paar GmbH.

Repairs on-site are limited to exchanging the whole Inline Pump 5.

Spare Parts

WARNING

Disconnect all electrical connections before removing the Inline Pump 5.

There is a risk of injury whenever the pump head is open and during

activation of the pump. When working on the open pump head, make sure

the mains supply or the pump control is securely switched off and cannot

be switched on without authorization.

Make sure that the main line is empty and unpressurized before installing

or removing the pump. Residues of corrosive liquids must be completely

removed.

The pipes and the Inline Pump may be very hot. In this case wait for the

entire plant to cool off.

WARNING

Observe the safety instructions in chapter Chapter 2.1.3 "Maintenance and

Service".

Inline Pump 5

82380 Impeller

88375 O-Ring 58x3 EPDM 70 (conform to

FDA)

Connection Kit DPRn 427S/

DSRn 427S

74911 O-Ring 60x3 EPDM 70 (conform to

FDA)

17531 O-Ring 7x1.5 EPDM 70 (conform to

FDA)

17530 O-Ring 7x2.5 EPDM 70 (conform to

FDA)

Connection Kit Tri-Clamp

70769 Washer 25 mm (conform to FDA)

Connection Kit DPRn/DSRn 427

74911 O-Ring 60x3 EPDM 70 (conform to

FDA)

Retrofit Kit Inline Fitting Varivent

with Fitting

C99IB001EN-B 35

8.1 Inline Pump 5 Parameters

The Inline Pump 5 parameters (Target Speed, Operating Time, etc.) can be read

out with the mPDS 5.

To show the pump parameters select " Menu > Service > Diagnosis > Details >

Parameters" Highlight "Inline Pump" and tap <Details>- <Parameters>.

Fig. 8 - 3 Parameter Inline Pump 5

74911 O-Ring 60x3 EPDM 70 (conform to

FDA)

17531 O-Ring 7x1.5 EPDM 70 (conform to

FDA)

17530 O-Ring 7x2.5 EPDM 70 (conform to

FDA)

Retrofit Kit Cobrix3

70769 Washer 25 mm ( conform to FDA)

36 C99IB001EN-B

Fig. 8 - 4 Parameter Inline Pump 5

Fig. 8 - 5 Parameter Inline Pump 5

C99IB001EN-B 37

9 Document Numbers

Document number Date Comment

C99IB02A 24.09.2009 First release

C99IB02B 20.05.2010 Minor changes

C99IB001enA 14.06.2010 Minor changes

C99IB001EN-B 11.11.2010 Minor changes

Appendix A: Technical Data

38 C99IB001EN-B

Appendix A:Technical Data

Appendix A: Technical Data

C99IB001EN-B 39

Appendix A: Technical Data

40 C99IB001EN-B

Appendix A: Technical Data

C99IB001EN-B 41

Appendix A: Technical Data

42 C99IB001EN-B

Appendix A: Technical Data

C99IB001EN-B 43

Appendix B: CE Declaration of Conformity

44 C99IB001EN-B

Appendix B:CE Declaration of

Conformity

Appendix B: CE Declaration of Conformity

C99IB001EN-B 45

Anda mungkin juga menyukai

- P08026 Multisplit C H PDFDokumen3 halamanP08026 Multisplit C H PDFAmry0% (1)

- Grundfos Alignment-White PaperDokumen21 halamanGrundfos Alignment-White PaperDelfinshBelum ada peringkat

- CD150M Technical Specification: Standard Pump Material SpecificationDokumen2 halamanCD150M Technical Specification: Standard Pump Material SpecificationAbcehmu EgiBelum ada peringkat

- 2006 Nissan PathfinderDokumen344 halaman2006 Nissan PathfinderHernold LibonattiBelum ada peringkat

- Capitol 5HD200-service-manual PDFDokumen46 halamanCapitol 5HD200-service-manual PDFlabatea100% (1)

- Two Stage Water Ring Vacuum Pump PDFDokumen24 halamanTwo Stage Water Ring Vacuum Pump PDFvallamreddyBelum ada peringkat

- Manual Motor Siemens 1la8Dokumen174 halamanManual Motor Siemens 1la8Jair ArmandoBelum ada peringkat

- Techniflo Product BrochureDokumen24 halamanTechniflo Product BrochureaasenjoyBelum ada peringkat

- Belt-driven screw compressor operating instructionsDokumen63 halamanBelt-driven screw compressor operating instructionspham quang vinhBelum ada peringkat

- Atlas Copco RH 656 PartsDokumen16 halamanAtlas Copco RH 656 PartsTiago HenriquesBelum ada peringkat

- CLD134 Manual EngDokumen88 halamanCLD134 Manual EngArsenio Dymas100% (1)

- 00 SRM D Design For Automotive - 2008 PDFDokumen315 halaman00 SRM D Design For Automotive - 2008 PDFEduardo BittencourtBelum ada peringkat

- 9161Dokumen5 halaman9161BaytolgaBelum ada peringkat

- Tapflo PT Hose Pumps Operation ManualDokumen44 halamanTapflo PT Hose Pumps Operation ManualBoopyJoe100% (1)

- Omega 600S ManualDokumen36 halamanOmega 600S ManualLeandroBelum ada peringkat

- Ed0053031210 R00 Mo CHD enDokumen108 halamanEd0053031210 R00 Mo CHD eng1763970Belum ada peringkat

- Injection Pump Specification ©Dokumen4 halamanInjection Pump Specification ©Kevin TtitoBelum ada peringkat

- XAS 188-10 PACE S5 APP S/N APP840175 - : Spare Parts List: Mobile Air CompressorsDokumen216 halamanXAS 188-10 PACE S5 APP S/N APP840175 - : Spare Parts List: Mobile Air CompressorsMAQUINOR MAQUINORBelum ada peringkat

- Check Valves Guide: Pilot Operated & Direct Acting ModelsDokumen24 halamanCheck Valves Guide: Pilot Operated & Direct Acting Models2267airportBelum ada peringkat

- Parts List for Fuel Injection Pump AssemblyDokumen5 halamanParts List for Fuel Injection Pump AssemblyEdinson Ariel Chavarro QuinteroBelum ada peringkat

- Fuel System With Bosch Fuel InjDokumen4 halamanFuel System With Bosch Fuel InjreggissBelum ada peringkat

- PM7 Motor Protection ManualDokumen15 halamanPM7 Motor Protection ManualKaiser Iqbal100% (1)

- vp44 Pump Detail Schematic PDF FreeDokumen7 halamanvp44 Pump Detail Schematic PDF Freepablo pérezBelum ada peringkat

- Dokumen - Tips Manual de Compresor Ingersoll Rand SSR Ep50se de Compresor Ingersoll Rand SSR Ep50seDokumen3 halamanDokumen - Tips Manual de Compresor Ingersoll Rand SSR Ep50se de Compresor Ingersoll Rand SSR Ep50seMoisésBelum ada peringkat

- 3042f152 DPA DESPIECEDokumen20 halaman3042f152 DPA DESPIECEEduardo David Castillo QuijandriaBelum ada peringkat

- Preventative Maintenance Price List for Air Compressor Parts and ServicesDokumen28 halamanPreventative Maintenance Price List for Air Compressor Parts and ServicesErica Lindsey100% (1)

- Yamaha F200 Maintenance ScheduleDokumen2 halamanYamaha F200 Maintenance ScheduleGrady SandersBelum ada peringkat

- Hatz Diesel Parts Manual 4L and 4MDokumen46 halamanHatz Diesel Parts Manual 4L and 4MHarry van LeeuwenBelum ada peringkat

- Service Manual: HP 5890 Series Ii Gas ChromatographDokumen170 halamanService Manual: HP 5890 Series Ii Gas ChromatographRuben MartinezBelum ada peringkat

- ECM PerkinsDokumen9 halamanECM PerkinshemenedyBelum ada peringkat

- Delphi DP200 Injection Pump John Deere HousingDokumen3 halamanDelphi DP200 Injection Pump John Deere HousingGeorge ZormpasBelum ada peringkat

- Code 386 RepairDokumen12 halamanCode 386 RepairCarlos A RomeroBelum ada peringkat

- Despiece GeneralDokumen263 halamanDespiece GeneralSebastián LagosBelum ada peringkat

- Product Manual 26098 (Revision NEW) : LCS Series Integrated Speed ControlDokumen20 halamanProduct Manual 26098 (Revision NEW) : LCS Series Integrated Speed ControlmichaeltibocheBelum ada peringkat

- Gates Belt Number and Identification ChartDokumen1 halamanGates Belt Number and Identification ChartalanbrannBelum ada peringkat

- Dhpp10 Powerpack GuideDokumen6 halamanDhpp10 Powerpack Guideapi-3803863100% (1)

- Operator'S Manual Diesel Engine: 2L41C - 2M41 - 2M41ZDokumen110 halamanOperator'S Manual Diesel Engine: 2L41C - 2M41 - 2M41ZMauricio OlayaBelum ada peringkat

- General Manual: Automatic Greasing SystemsDokumen58 halamanGeneral Manual: Automatic Greasing SystemsAhmed LikeBelum ada peringkat

- TEEL BRONZE ROTARY PUMP Manual & Parts ListDokumen8 halamanTEEL BRONZE ROTARY PUMP Manual & Parts ListMoToBunnYBelum ada peringkat

- G1315 DAD Manual PDFDokumen318 halamanG1315 DAD Manual PDFdriveBelum ada peringkat

- M10-BASE SpareDokumen7 halamanM10-BASE SpareAmato GelatoBelum ada peringkat

- Opera Ting Manual: HQ400/3A - HQ400/3B - HQ400/3L Multi - Purpose MachineDokumen34 halamanOpera Ting Manual: HQ400/3A - HQ400/3B - HQ400/3L Multi - Purpose MachinerianrureBelum ada peringkat

- Screw Compressor PDS100S 6B4 PDS130S 6B4 PDS185S 6B4 39600 64220 PDFDokumen65 halamanScrew Compressor PDS100S 6B4 PDS130S 6B4 PDS185S 6B4 39600 64220 PDFKeith McCannBelum ada peringkat

- Spare Parts 56557b92ce830 PDFDokumen160 halamanSpare Parts 56557b92ce830 PDFkiyogx100% (1)

- 0281002238Dokumen3 halaman0281002238Ricardo UrioBelum ada peringkat

- TICS Pump Electrical Part Resistance For HINODokumen35 halamanTICS Pump Electrical Part Resistance For HINOBala Equal BalanceBelum ada peringkat

- PASX710 SP CatalogueDokumen67 halamanPASX710 SP CatalogueLuis Antonio Chiapas GarciaBelum ada peringkat

- Caterpillar Solenoids For Electronic Fuel InjectionDokumen6 halamanCaterpillar Solenoids For Electronic Fuel Injectionsayeed younis sadaatBelum ada peringkat

- Do All 3613 Band SawDokumen164 halamanDo All 3613 Band SawRamon TorresBelum ada peringkat

- Back Leak TestDokumen13 halamanBack Leak Testcartronix20100% (1)

- Oven Lindberg Blue M BF51800pdfDokumen94 halamanOven Lindberg Blue M BF51800pdfAlfonsoBelum ada peringkat

- Ziegler - Fire Pumps - FPN 10-6000-2 HDokumen55 halamanZiegler - Fire Pumps - FPN 10-6000-2 HSecu09Belum ada peringkat

- Operations & Maintenance Manual Infinity PDFDokumen57 halamanOperations & Maintenance Manual Infinity PDFPauloGenettiBelum ada peringkat

- Camshaft Less PumpsDokumen12 halamanCamshaft Less PumpsJosue Nu�Belum ada peringkat

- C99ib002en e Inline Pump 520 ImsiDokumen31 halamanC99ib002en e Inline Pump 520 Imsizitouniianis2Belum ada peringkat

- Fermentation Monitor 5100 - EnglishDokumen33 halamanFermentation Monitor 5100 - EnglishXian KrispBelum ada peringkat

- 3410 ATEX LoresDokumen56 halaman3410 ATEX LoresRaquel RodriguezBelum ada peringkat

- 2a33687 Exl Back Pressure Relief Valve PDFDokumen51 halaman2a33687 Exl Back Pressure Relief Valve PDFEnrique HortaBelum ada peringkat

- Foam Pump Operating and Maintenance ManualDokumen16 halamanFoam Pump Operating and Maintenance ManualsaifBelum ada peringkat

- Operator’S Guide to Rotating Equipment: An Introduction to Rotating Equipment Construction, Operating Principles, Troubleshooting, and Best PracticesDari EverandOperator’S Guide to Rotating Equipment: An Introduction to Rotating Equipment Construction, Operating Principles, Troubleshooting, and Best PracticesPenilaian: 5 dari 5 bintang5/5 (3)

- BA SI 104 10 21 EN BA Sigma 3 HMI C ENDokumen120 halamanBA SI 104 10 21 EN BA Sigma 3 HMI C ENikuzma_1Belum ada peringkat

- Lapp Pro217enDokumen6 halamanLapp Pro217enikuzma_1Belum ada peringkat

- Manual Icy Box IB-3640Dokumen20 halamanManual Icy Box IB-3640ikuzma_1Belum ada peringkat

- Installation Instructions Flat Cable SplitterDokumen4 halamanInstallation Instructions Flat Cable Splitterikuzma_1Belum ada peringkat

- PackoDokumen30 halamanPackoikuzma_1Belum ada peringkat

- Tonsen Brewing CatalogueDokumen25 halamanTonsen Brewing Catalogueikuzma_1Belum ada peringkat

- Installation Instructions Vibration SensorDokumen6 halamanInstallation Instructions Vibration SensorHoang HiepBelum ada peringkat

- Traycontrol 600 C 2Dokumen2 halamanTraycontrol 600 C 2ikuzma_1Belum ada peringkat

- Stainless Steel Mesh Tray for Humid AreasDokumen2 halamanStainless Steel Mesh Tray for Humid Areasikuzma_1Belum ada peringkat

- Tonsen Brewing CatalogueDokumen25 halamanTonsen Brewing Catalogueikuzma_1Belum ada peringkat

- Audi Infotainment Guide PDFDokumen45 halamanAudi Infotainment Guide PDFikuzma_1Belum ada peringkat

- Flender - Motox-NDokumen51 halamanFlender - Motox-Nikuzma_1Belum ada peringkat

- Elektricni PastirDokumen5 halamanElektricni Pastirikuzma_1100% (1)

- Kito - Electric Chain Hoist PDFDokumen89 halamanKito - Electric Chain Hoist PDFikuzma_1Belum ada peringkat

- SeepexDokumen127 halamanSeepexikuzma_1100% (3)

- Flender - Gear MotorDokumen42 halamanFlender - Gear Motorikuzma_10% (1)

- Fläkt Woods - Axial FansDokumen30 halamanFläkt Woods - Axial Fansikuzma_1Belum ada peringkat

- Iwaki - MD-R (OI) - EDokumen28 halamanIwaki - MD-R (OI) - Eikuzma_1Belum ada peringkat

- Flender - Gear MotorDokumen42 halamanFlender - Gear Motorikuzma_10% (1)

- ABB - Induction MotorDokumen12 halamanABB - Induction Motorikuzma_1Belum ada peringkat

- Align and protect ABM motorsDokumen2 halamanAlign and protect ABM motorsikuzma_1Belum ada peringkat

- Top 10 Things To Do in JakartaDokumen3 halamanTop 10 Things To Do in Jakartaikuzma_1Belum ada peringkat

- Atoz of Malaria: - . - and MoreDokumen32 halamanAtoz of Malaria: - . - and Moreikuzma_1Belum ada peringkat

- Molecular Diffusion in Fluids-1Dokumen17 halamanMolecular Diffusion in Fluids-1Er Harin PatoliyaBelum ada peringkat

- Corken ManualDokumen24 halamanCorken Manualطارق سويد100% (1)

- Oil / Chemical Tanker Instruction Manual: Controlled Copy #03Dokumen381 halamanOil / Chemical Tanker Instruction Manual: Controlled Copy #03Nikita GalinBelum ada peringkat

- General Chemistry Module 2Dokumen19 halamanGeneral Chemistry Module 2Arthur TecsonBelum ada peringkat

- Control Valve Technical Specification For Severe Service - CCIDokumen5 halamanControl Valve Technical Specification For Severe Service - CCIVikas SinghBelum ada peringkat

- EU-109H Portable Handle Ultrasonic FlowmeterDokumen3 halamanEU-109H Portable Handle Ultrasonic Flowmetersales1068Belum ada peringkat

- Compressor Api617 LMC BMC 311f Maintenance ManualDokumen6 halamanCompressor Api617 LMC BMC 311f Maintenance ManualAvishek HazraBelum ada peringkat

- Solids and Fluids ChapterDokumen4 halamanSolids and Fluids ChapterKenberly DingleBelum ada peringkat

- Phase Changes WorksheetDokumen3 halamanPhase Changes WorksheetLyn ManzanoBelum ada peringkat

- G10 Chemistry BookletDokumen41 halamanG10 Chemistry BookletMemory SitambuliBelum ada peringkat

- Viking PumpDokumen36 halamanViking PumpSakir Zak100% (2)

- Safeguard and Epg Liquid Level Gauges 05.16Dokumen2 halamanSafeguard and Epg Liquid Level Gauges 05.16Alex Bautista BordaBelum ada peringkat

- Rules of ThumbDokumen105 halamanRules of ThumbEllen DawitriBelum ada peringkat

- Safety Meo Class 4 CocDokumen16 halamanSafety Meo Class 4 CocROSHANBelum ada peringkat

- Hydrogenation Reactor DesignDokumen10 halamanHydrogenation Reactor DesignasdfBelum ada peringkat

- Final Revision 8Dokumen53 halamanFinal Revision 8Trang TrangBelum ada peringkat

- Problem Sets Ce Review 2014Dokumen93 halamanProblem Sets Ce Review 2014RyanCalleja33% (3)

- ASTM D525 - 12 - Standard Test Method For Oxidation Stability of GasolineDokumen8 halamanASTM D525 - 12 - Standard Test Method For Oxidation Stability of Gasolinenam88100% (1)

- Calidades Carbon-Grafito SCHUNKDokumen2 halamanCalidades Carbon-Grafito SCHUNKcpchectorhBelum ada peringkat

- CO2 Safety ManualDokumen51 halamanCO2 Safety ManualKrishna YadavBelum ada peringkat

- Evaporator SDokumen5 halamanEvaporator SBea UyBelum ada peringkat

- Heat and Temperature 2017Dokumen32 halamanHeat and Temperature 2017ALBelum ada peringkat

- Chapter 1 Kinetic Theory and DiffusionDokumen4 halamanChapter 1 Kinetic Theory and DiffusionKhondokar TarakkyBelum ada peringkat

- VLL Separator - Train1Dokumen9 halamanVLL Separator - Train1yamen-691904Belum ada peringkat

- Statistical Mechanics PDFDokumen578 halamanStatistical Mechanics PDFraymon6666100% (6)

- Guide Document GE P312 4.1.2 I General ConsiderationsDokumen31 halamanGuide Document GE P312 4.1.2 I General ConsiderationsDiarista Thoma SaputraBelum ada peringkat

- RSE 110-01 Mechanical Separation Data SheetDokumen6 halamanRSE 110-01 Mechanical Separation Data SheetRaghunath MajeeBelum ada peringkat

- FB Optimix Paddle Mixer en DataDokumen8 halamanFB Optimix Paddle Mixer en DataTan Thinh Nguyen0% (1)

- Instrumentation Design BasicsDokumen28 halamanInstrumentation Design BasicsCharles ChettiarBelum ada peringkat

- Dry Gas Seal System StandarDokumen8 halamanDry Gas Seal System StandarRonny AjaBelum ada peringkat