316 316L

Diunggah oleh

Khin Aung ShweJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

316 316L

Diunggah oleh

Khin Aung ShweHak Cipta:

Format Tersedia

Type 316, Type 316L UNS S31600, UNS S31603

A molybdenum-containing austenitic stainless steel with improved resistance to chlorides relative to Type 304/304L stainless steel.

Description Corrosion Resistance

Type 316/316L is a molybdenum-containing austenitic stainless steel intended to provide improved corrosion resistance relative to Type 304/304L in moderately corrosive process environments, particularly those containing chlorides or other halides. Type 316/316L is non-magnetic in the annealed condition but may become slightly magnetic as a result of welding.

Dual Certification

The addition of molybdenum provides improved resistance to pitting and crevice corrosion in environments containing chlorides and other halides. Type 316/316L has been used in handling many chemicals used by the process industries, including pulp and paper, textile, food, pharmaceutical, medical, and other chemical processing.

Mechanical Properties at Room Temperature

It is common for Type 316L to be dual certified as Type 316 and Type 316L when the material meets both the lower carbon limit of Type 316L and the slightly higher strengths of Type 316. The producer of the steel must certify the material as Type 316 if it is to be used as Type 316 instead of Type 316L.

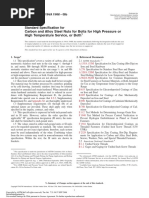

Specifications

Table 1

ASTM Typical* Type 316 Type 316L

Ultimate Tensile Strength, ksi 0.2% Offset Yield Strength, ksi Elongation in 2 inches, % Reduction in Area, % Hardness, Rockwell B *0.375 inch plate 85 44 56 69 81 75 min 30 min 40 min 95 max 70 min 25 min 40 min 95 max

Type 316/316L can be supplied to meet AMS, ASTM, ASME, QQS, and MIL-S specifications.

Product Forms Available

Chemical Composition, wt. pct.

Carbon Manganese Phosphorus Sulfur Silicon Chromium Nickel Molybdenum Nitrogen* *flat-rolled products only

Table 2 Type 316L

0.030 max 2.00 max 0.045 max 0.030 max 0.75 max 16.0-18.0 10.0-14.0 2.00-3.00 0.10 max

Plate Sheet Tubular Products Bar Angle Wire Rod Billet Fittings

Type 316

0.08 max 2.00 max 0.045 max 0.03 max 0.75 max 16.0-18.0 10.0-14.0 2.00-3.00 0.10 max

www.outokumpu.com/stainless/na

Type 316, Type 316L

Heat Treatment Annealing

Workability Cold Working

Type 316/316L should be heated to 1900F and water quenched or rapidly cooled by other means.

Hardening

Type 316/316L cannot be hardened by heat treatment. However, Type 316 can be hardened by cold working.

Physical Properties

Density, lb/in3 Modulus of Elasticity, psi Coefficient of Thermal Expansion, 68-212F, /F Thermal Conductivity, Btu/ft hrF Heat Capacity, Btu/lbF Electrical Resistivity, -inch

Type 316/316L is readily formed and fabricated through a full range of cold working operations. It can be used in heading, drawing, bending, and upsetting. Any cold working operations will increase the strength and hardness of the material.

Hot Working

Table 3

0.285 29 x 106 8.9 x 10-6 8.7 0.12 29.5 x 10-6

Type 316/316L can be forged in the 1700-2200F range. For maximum corrosion resistance, forgings should be annealed at 1900F minimum and water quenched or rapidly cooled by other means after hot working operations.

Lowest Temperature (F) at Which the Corrosion Rate Exceeds 5 mpy

Corrosion Environment 654 SMO

Table 4

254 Type 316L Type Outokumpu 2205 Code Outokumpu SMO 904L (2.7 Mo) 304 2507 Plus Two 2304

>Boiling 158 140 104 68 230 >Boiling 212 >Boiling 212 239 194 140 >Boiling 203ps 104 140 176 140 >Boiling >Boiling >Boiling >Boiling 122 86 86p >Boiling 140 122 167 185 <54 <57 95 113 86 248 203 176 203 >Boiling >Boiling >Boiling >Boiling 212 212 212 230 >Boiling >Boiling 212p >Boiling 212p 104 50 194 Boiling 194 185 230 248 149 113 140 >140 >140 >140 >140 >Boiling 248 >Boiling 230 140ps 77p 68p 203ps 131 77 122 122 <<59p 104 122 50 <<50 203 95 50 <<50 167 >Boiling 185 140 <59 77 194 >Boiling 221 >Boiling 194 194 122 >140 212 113ps 95 <59 113 140 >Boiling 131 149 <<55 59 203 >Boiling 203 >Boiling 59 203 95 >140 194 68p <55 <<50 86 95

0.2% Hydrochloric Acid >Boiling 1% Hydrochloric Acid 203 10% Sulfuric Acid 158 60% Sulfuric Acid 104 96% Sulfuric Acid 86 85% Phosphoric Acid 194 10% Nitric Acid >Boiling 65% Nitric Acid 221 80% Acetic Acid >Boiling 50% Formic Acid 158 50% Sodium Hydroxide 275 83% Phosphoric Acid + 2% Hydrofluoric Acid 185 60% Nitric Acid + 2% Hydrochloric Acid >140 50% Acetic Acid + 50% Acetic Anhydride >Boiling 1% Hydrochloric Acid + 0.3% Ferric Chloride >Boiling, p 10% Sulfuric Acid + 2000ppm Cl- + N2 149 10% Sulfuric Acid + 2000ppm Cl + SO2 167 WPA1, High Cl- Content 203 WPA2, High F- Content 176 ps = pitting can occur ps = pitting/crevice corrosion can occur

WPA

1 2

P2O5

54 54

Cl-

0.20 0.02

F-

0.50 2.0

H2SO4

4.0 4.0

Fe2O3

0.30 0.30

Al2O3

0.20 0.20

SiO2

0.10 0.10

CaO

0.20 0.20

MgO

0.70 0.70

Type 316, Type 316L 3

Corrosion Performance of Stainless Steels

Table 4 compares several Outokumpu stainless steels in a variety of common corrosive environments. The lowest temperature at which the corrosion rate exceeds 5 mpy was determined. All testing was done in accordance with the requirements of the Materials Technology Institute of the Chemical Process Industries (MTI).

Welding

results are achieved with slower speeds, heavier feeds, excellent lubrication, sharp tooling, and powerful, rigid equipment.

Technical Support

Type 316/316L is readily welded by a full range of conventional welding procedures (except oxyacetylene). AWS E316L/ER316L and other filler metals with molybdenum content higher than that of the base metal should be used with Type 316/316L stainless steel.

Machinability

Type 316/316L is a tough austenitic stainless steel subject to work hardening during deformation and, unless modified for improved machining response, is resistant to chip breaking. The best machining

Outokumpu assists users and fabricators in the selection, qualification, installation, operation, and maintenance of Type 316/316L stainless steel. Technical personnel, supported by the research laboratory of Outokumpu, can draw on years of field experience with Type 316/316L to help you make the technically and economically correct materials decision. Outokumpu is prepared to discuss individual applications and to provide data and experience as a basis for selection and application of Type 316/316L. Outokumpu works closely with its distributors to ensure timely availability of Type 316/316L in the forms, sizes, and quantities required by the user. For assistance with technical questions and to obtain top quality Type 316/316L, call Outokumpu at 1-800-833-8703.

Type 316, Type 316L

1087EN, Schaumburg, USA. December 2008.

2205 Code Plus Two is a trademark of Outokumpu Stainless, Inc. 254 SMO and 654 SMO are trademarks of Outokumpu Stainless.

Information given in this brochure may be subject to alterations without notice. Care has been taken to ensure that the contents of this publication are accurate but Outokumpu and its affiliated companies do not accept responsibility for errors or for information that is found to be misleading. Suggestions for or descriptions of the end use or application of products or methods of working are for information only and Outokumpu and its affiliated companies accept no liability in respect thereof. Before using products supplied or manufactured by the company the customer should satisfy himself of their suitability. Outokumpu is a global leader in stainless steel. Our vision is to be the undisputed number one in stainless, with success based on operational excellence. Customers in a wide range of industries use our stainless steel and services worldwide. Being fully recyclable, maintenance-free, as well as very strong and durable material, stainless steel is one of the key building blocks for sustainable future. What makes Outokumpu special is total customer focus all the way, from R&D to delivery. You have the idea. We offer world-class stainless steel, technical know-how and support. We activate your ideas.

Outokumpu 425 North Martingale Road, Suite 1600, Schaumburg, IL 60173-2218 USA Tel. 1-800-833-8703 Fax 1-800-545-8617

www.outokumpu.com/stainless/na

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Microscopy With Light and ElectronsDokumen36 halamanMicroscopy With Light and ElectronsCORE Materials100% (1)

- Effect of Heat Input To Weld Residual StressDokumen4 halamanEffect of Heat Input To Weld Residual StressSurya DharmaBelum ada peringkat

- Focus On Proper Weld Size When Developing WPS Parameter Ranges - Fabricating and MetalworkingDokumen4 halamanFocus On Proper Weld Size When Developing WPS Parameter Ranges - Fabricating and MetalworkingKhin Aung ShweBelum ada peringkat

- Experimental Investigation On Weld Ability of Cast IronDokumen5 halamanExperimental Investigation On Weld Ability of Cast IronKhin Aung ShweBelum ada peringkat

- Austenitic Ductile Iron For Low Temperature ApplicationDokumen6 halamanAustenitic Ductile Iron For Low Temperature ApplicationKhin Aung ShweBelum ada peringkat

- Manual de Servicio Olympus SZ-IIIDokumen18 halamanManual de Servicio Olympus SZ-IIIcarlosibaBelum ada peringkat

- ERNI-1 Cast Iron ElectrodeDokumen1 halamanERNI-1 Cast Iron ElectrodeKhin Aung ShweBelum ada peringkat

- Fracture and Crack Propagation in WeldmentsDokumen66 halamanFracture and Crack Propagation in WeldmentsKhin Aung ShweBelum ada peringkat

- Theweldignofaluminiumcastingsoctober2011 111210001526 Phpapp02Dokumen68 halamanTheweldignofaluminiumcastingsoctober2011 111210001526 Phpapp02Khin Aung ShweBelum ada peringkat

- Lab Exericise 3 For MicroscopeDokumen9 halamanLab Exericise 3 For MicroscopeKhin Aung ShweBelum ada peringkat

- JK Stereo1Dokumen26 halamanJK Stereo1Yongliang LiuBelum ada peringkat

- Mo SteelDokumen0 halamanMo SteelSamsi B HanifBelum ada peringkat

- Investigation of The Cause of Reinforcing Steel Fracture Induced by Alkali-Silica Reaction and Study On MaintenanceDokumen10 halamanInvestigation of The Cause of Reinforcing Steel Fracture Induced by Alkali-Silica Reaction and Study On MaintenanceKhin Aung ShweBelum ada peringkat

- အမ်ားသံုး ျမန္မာ-အဂၤလိပ္-ပါဠိ အဘိဓါန္ PDFDokumen1.080 halamanအမ်ားသံုး ျမန္မာ-အဂၤလိပ္-ပါဠိ အဘိဓါန္ PDFKo Lin96% (45)

- Brazil: "PLANTAR" Project: Sustainable Fuelwood and Charcoal Production and Substitution of Coke in Pig Iron ProductionDokumen33 halamanBrazil: "PLANTAR" Project: Sustainable Fuelwood and Charcoal Production and Substitution of Coke in Pig Iron ProductionKhin Aung ShweBelum ada peringkat

- DryerDokumen80 halamanDryerAaron Paulo Bernardo100% (2)

- Safety of Machinery - Principles of Risk AssessmentDokumen27 halamanSafety of Machinery - Principles of Risk AssessmentKhin Aung ShweBelum ada peringkat

- Lampiran PQR 003Dokumen3 halamanLampiran PQR 003Khin Aung ShweBelum ada peringkat

- Braze Cast Iron - Videos, Tips and ProceduresDokumen5 halamanBraze Cast Iron - Videos, Tips and ProceduresKhin Aung ShweBelum ada peringkat

- Cast Iron Welding AlloysDokumen4 halamanCast Iron Welding AlloysKhin Aung ShweBelum ada peringkat

- Welding of Nonferrous Metal and Their AlloysDokumen62 halamanWelding of Nonferrous Metal and Their AlloysKhin Aung ShweBelum ada peringkat

- The Crucible PowerpointDokumen11 halamanThe Crucible PowerpointKhin Aung Shwe100% (1)

- Fundamentals of Metal CastingDokumen14 halamanFundamentals of Metal CastingKhin Aung ShweBelum ada peringkat

- Material Grade Comparison Chart PDFDokumen1 halamanMaterial Grade Comparison Chart PDFHelen Kate Saccuan100% (1)

- Casting Material WCBDokumen8 halamanCasting Material WCBYusri WyeuserieyBelum ada peringkat

- Boiler Furnace TheoryDokumen8 halamanBoiler Furnace TheoryArun YogaBelum ada peringkat

- Effect of Pouring Temperature and Stirring Speed OnDokumen6 halamanEffect of Pouring Temperature and Stirring Speed OnInternational Journal of Research in Engineering and TechnologyBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Astm F 19 - 64 R00 - Rje5Dokumen4 halamanAstm F 19 - 64 R00 - Rje5phaindika100% (1)

- Abrasive Jet Machine - AbstractDokumen6 halamanAbrasive Jet Machine - AbstractManju KbBelum ada peringkat

- Uncoated SteelDokumen2 halamanUncoated SteelBui Chi TamBelum ada peringkat

- 05 Catpg 016Dokumen1 halaman05 Catpg 016naseema1100% (1)

- Mousom Thesis1Dokumen95 halamanMousom Thesis1Arnab AcharyaBelum ada peringkat

- Corrosion Science Volume 32 Issue 7 1991 (Doi 10.1016/0010-938x (91) 90082-z) E. Otero A. Pardo J. Hernáez F.J. Pérez - The Hot Corrosion of In-657 Superalloy in Na2SO4-V2O5 Melt EutecticDokumen7 halamanCorrosion Science Volume 32 Issue 7 1991 (Doi 10.1016/0010-938x (91) 90082-z) E. Otero A. Pardo J. Hernáez F.J. Pérez - The Hot Corrosion of In-657 Superalloy in Na2SO4-V2O5 Melt EutecticLina CardonaBelum ada peringkat

- GPM RevDokumen138 halamanGPM RevJuan Cortes TorizBelum ada peringkat

- Erifon HD603HP Series MacDermid OffshoreDokumen2 halamanErifon HD603HP Series MacDermid OffshoreVictor RomeroBelum ada peringkat

- CH 15Dokumen6 halamanCH 15onlydlonly100% (4)

- High Strength Low Alloy (HSLA) : Prof. Dr.-Ing. Bambang SuharnoDokumen28 halamanHigh Strength Low Alloy (HSLA) : Prof. Dr.-Ing. Bambang SuharnoLuan carlosBelum ada peringkat

- RPT Instruction PlanDokumen5 halamanRPT Instruction PlanSaurabh AnandBelum ada peringkat

- Oxy Acetylene WeldingDokumen3 halamanOxy Acetylene WeldingMonika100% (1)

- SAIL Refractory Company LimitedDokumen3 halamanSAIL Refractory Company LimitedSanthosh 8055Belum ada peringkat

- Periodic TableDokumen2 halamanPeriodic TableSithanandan GanapathyBelum ada peringkat

- Grinding Final NotesDokumen21 halamanGrinding Final NotesGaikwad Aniket100% (1)

- 0620 w15 QP 63Dokumen12 halaman0620 w15 QP 63Tran UkinBelum ada peringkat

- Lista e UriDokumen25 halamanLista e UriGgy VictorBelum ada peringkat

- Astm 193Dokumen2 halamanAstm 193Nilesh TadhaBelum ada peringkat

- Code C On Extec Jaw CrusherDokumen6 halamanCode C On Extec Jaw CrusherAdal Vera100% (1)

- Rocas EjerciciosDokumen2 halamanRocas EjerciciosStiwarth Cuba Asillo0% (1)

- Chemistry P Block ElementsDokumen14 halamanChemistry P Block ElementsSurendra Tyagi0% (1)

- Batteries PresentationDokumen21 halamanBatteries PresentationS ABelum ada peringkat

- Norma Astm A194Dokumen11 halamanNorma Astm A194EstefaníaBelum ada peringkat

- Cathodic Protection - WikipediaDokumen12 halamanCathodic Protection - WikipediaSanthosh Reddy BBelum ada peringkat

- Suck My D: Cambridge O LevelDokumen20 halamanSuck My D: Cambridge O LevelBasratul RafidBelum ada peringkat

- RacerX SunlitNightsDokumen2 halamanRacerX SunlitNightsLeo Hurtado0% (1)

- Nickel and Other Super Alloys: TSUF 06 Materiales AeronauticosDokumen28 halamanNickel and Other Super Alloys: TSUF 06 Materiales AeronauticosFam HandmBelum ada peringkat

- Ergil CatalogueDokumen166 halamanErgil Catalogueevrim77Belum ada peringkat

- Magnesium Alloys in Ingot Form For Sand Castings, Permanent Mold Castings, and Die CastingsDokumen4 halamanMagnesium Alloys in Ingot Form For Sand Castings, Permanent Mold Castings, and Die CastingsDhavalBelum ada peringkat

- Comminution CostsDokumen15 halamanComminution CostsAlvaroFloresBelum ada peringkat